Manufacturing method for composite particle for magnetorheological finishing

A magnetorheological polishing and composite particle technology, applied in the field of polishing, can solve the problems of ferromagnetic particles being easily worn or corroded, shortening the service life of magnetorheological polishing fluid, limiting polishing objects, and polishing efficiency, so as to improve the polishing effect , Improve the scope of action, increase the effect of polishing objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

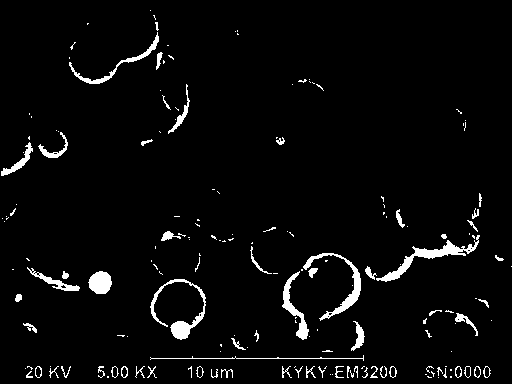

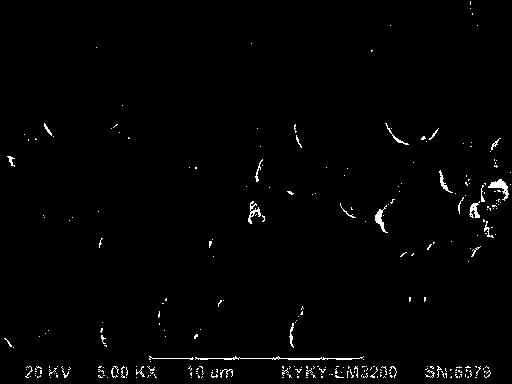

Image

Examples

Embodiment 1

[0027] Example 1 Abrasive particles are coated on the surface of ferromagnetic carbonyl iron powder by hot-melt method. Put 0.1%-10% nano-silica with carbonyl iron powder mass ratio, preferably 1%-5%, after mechanical dispersion, put 10-25 kg of methanol or ethanol and 50-500 g of silane coupling agent In the diluted liquid, stir evenly, add 200 kg of carbonyl iron powder, ball mill for 2 hours, evaporate ethanol until the powder is dry. After drying, the carbonyl iron powder coated with nano-silica and silane coupling agent is thermally fused under the protection of nitrogen above 400°C, and after cooling, composite particles composed of ferromagnetic particles and abrasive nano-silica are obtained.

Embodiment 2

[0028] Example 2 As described in Example 1, the heat fusion process is omitted to obtain composite particles composed of ferromagnetic particles and abrasive nano-silica.

Embodiment 3

[0029] Example 3 Dissolve carbonyl iron powder mass ratio 0.5%-10% epoxy resin in acetone with carbonyl iron powder mass ratio 5%-12%, add carbonyl iron powder and carbonyl iron powder mass ratio 5% diamond powder, After kneading and evaporating acetone, granulate, solidify at 110-200°C (specifically set according to the resin requirements), and obtain composite particles composed of ferromagnetic particles and abrasive diamond after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com