Magnetorheological fluid settleability testing device and testing method

A magnetorheological fluid and testing device technology, applied in the direction of material resistance, etc., can solve the problems of time-consuming measurement, cumbersome operation experiments, large errors, etc., and achieve the effects of improving the accuracy of test data, simple experimental operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the features and advantages of this patent more obvious and easy to understand, the following specific examples are given together with the accompanying drawings and described in detail as follows:

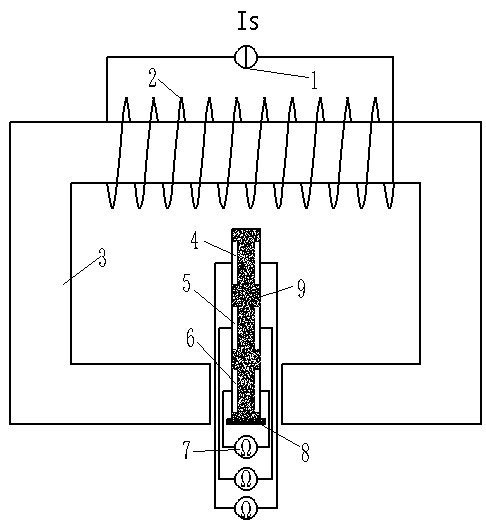

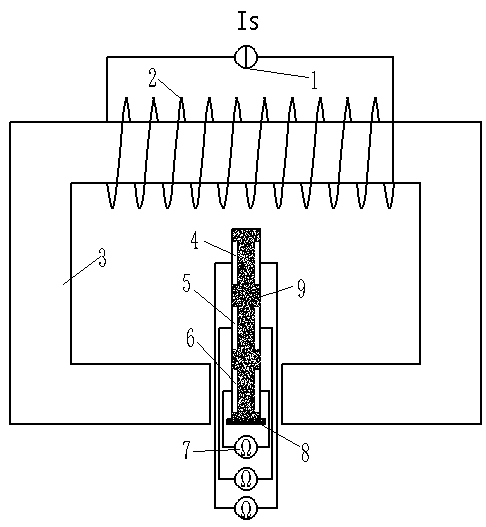

[0026] Such as figure 1 As shown, the device of this embodiment includes: a C-shaped magnetizer 3 and an excitation coil 2 wound on the magnetizer 3, both ends of the excitation coil 2 are connected to a DC current source 1, and a magnetorheological fluid is provided at the opening of the magnetizer 3 The container 9 and the bracket 8 for fixing the magnetorheological fluid container 9 are placed in the magnetorheological fluid container 9. The upper conductive sheet 4, the middle conductive sheet 5, and the lower conductive sheet 6 are placed in pairs, all of which are made of metal, and each pair of conductive sheets The sheets are preferably equal in height, equidistant and parallel to each other, and an ohmmeter 7 for measuring the resistance between ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com