Device for automatic calibration of thickness of magnetorheological finishing ribbon

A technology of magnetorheological polishing and automatic calibration, which is applied in the direction of instruments, computer control, simulators, etc., to achieve high-safety automatic measurement and calibration, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

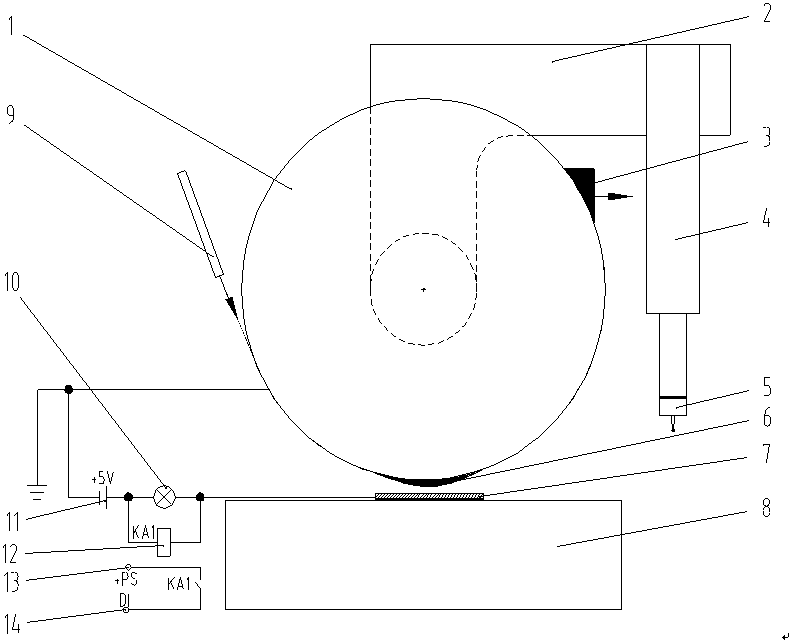

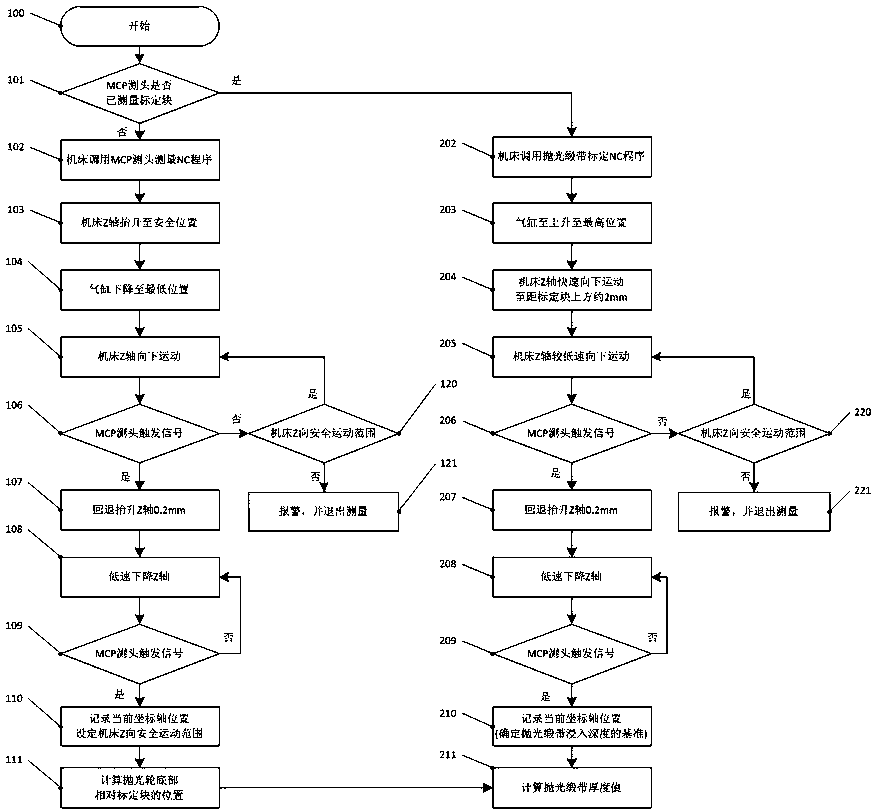

[0017] Such as figure 1 As shown, the present invention is a device for automatically calibrating a magneto-rheological polishing ribbon, including a cylinder 4, an MCP measuring head 5, a calibrating block 7, a 5V DC power supply 11, an indicator light 10, a relay 12, a switching power supply 13 and signal terminals 14. The connection relationship is that the calibration block 7 has electrical conductivity and is placed on the workpiece 1. The polishing liquid in the nozzle 9 acts on the polishing wheel 1 to form a polishing ribbon 6, and the polishing ribbon 6 is in contact with the calibration block 7. , the calibration block 7 is electrically connected to the polishing wheel 1, and when the polishing ribbon 6 is not in contact with the calibration block 7, the calibration block 7 and the polishing wheel 1 are not electrically connected. The cylinder 4 is installed and fixed on the polishing wheel mounting bracket 2, and the piston rod of the cylinder 4 rises and falls unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com