Abrasive band magnetorheological double curvature controllable composite finishing tool

A magneto-rheological and variable-curvature technology, applied in the direction of manufacturing tools, abrasive belt grinders, metal processing equipment, etc., can solve the problems of difficult processing in local areas and difficult matching of contact wheels, and achieve the effect of improving processing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

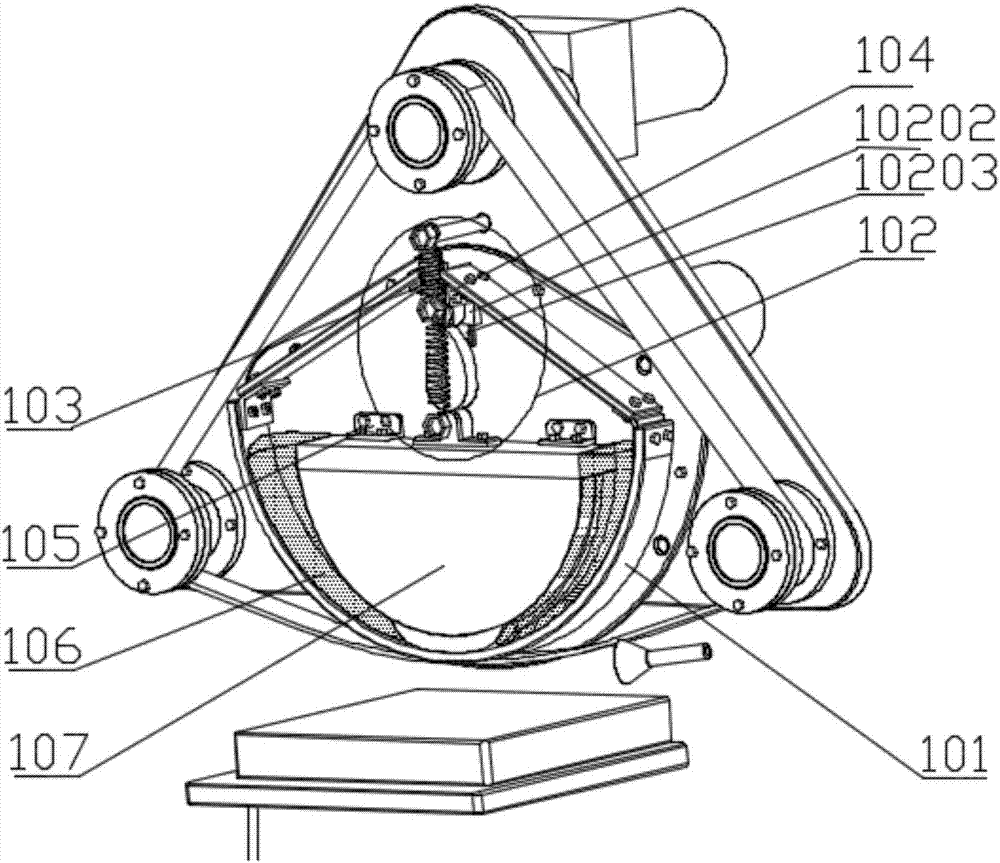

[0027] The macro-curvature adjustment mechanism 1, the motor 6, the driving wheel 3 and the tensioning wheel 4 are all fixed on the frame 7, wherein the output shaft of the motor 6 is connected with the driving wheel 3, and the abrasive belt 2 is wound around the driving wheel 3, the tensioning wheel 4 and the On the macro-curvature adjustment mechanism 1 , a magnetorheological fluid supply and recovery system 5 is arranged below the abrasive belt 2 .

[0028] The structure of the magnetorheological fluid supply and recovery system 5 of the present invention is: the nozzle 504 is connected to the magnetorheological fluid supply pipe 501, and the magnetorheological fluid supply pipe 501 is connected to the pump 502 and the magnetorheological fluid tank 503 in turn, and the magnetorheological fluid The magnetorheological fluid is stored in the liquid tank 503 , and the recovery pipe 506 is connected to the bottom of the workbench 505 , and the recovery tube 506 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com