High-remanence low-coercivity samarium cobalt permanent magnetic material and preparation method

A permanent magnet material, low coercivity technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of difficult magnetization to saturation, restrict the application field of samarium cobalt magnets, etc., achieve easier saturation magnetization, overcome the The effect of magnetization unsaturated, high surface magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

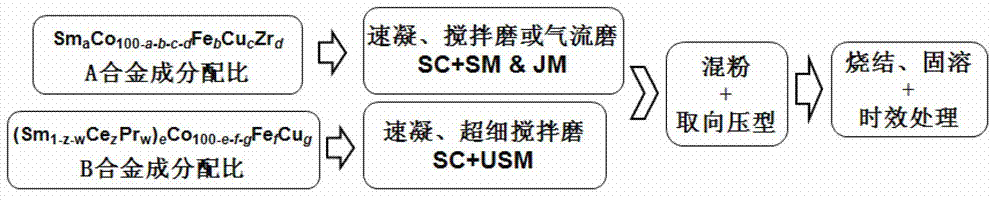

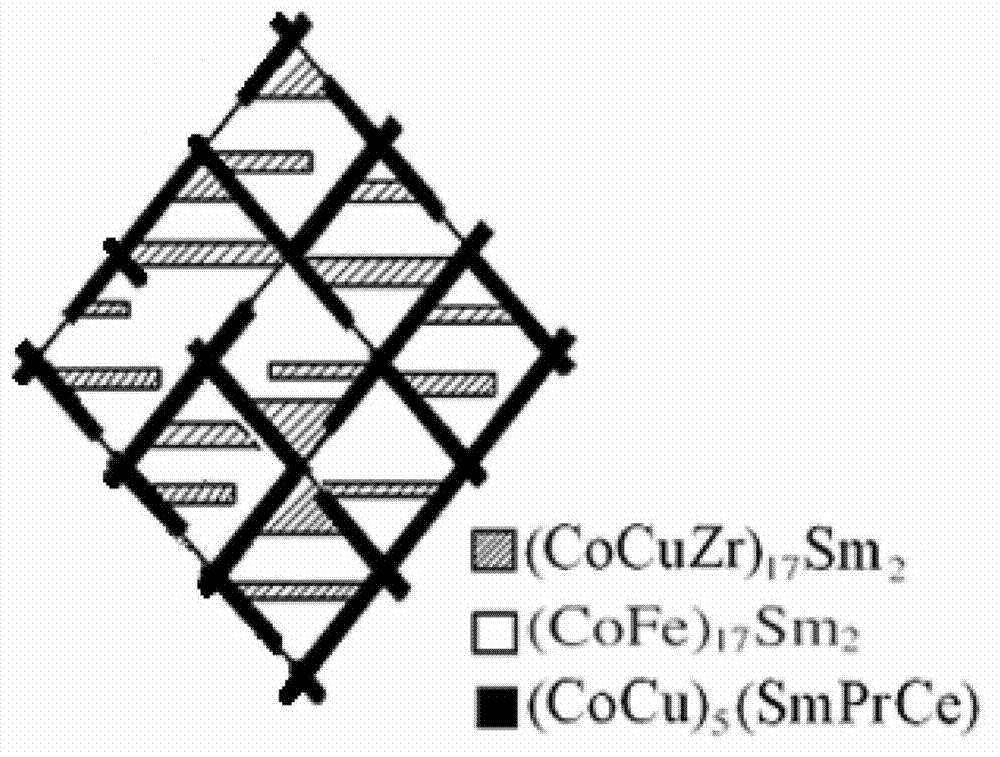

Method used

Image

Examples

Embodiment 1

[0039] The following steps are used to prepare the samarium cobalt permanent magnet material containing the composition of 1# in Table 1.

[0040] 1) Prepare alloy castings with the composition of 1# shown in Table 1 (without considering burning loss), in which, the chemical composition of Alloy A is: Sm~25%, Co~49.2%, Fe~18% , Cu~5%, Zr~2.8%; the chemical composition of B alloy is: Sm~10%, Pr~5%, Ce~20%, Co~47%, Fe~8%, Cu~10% . Smelt the prepared two raw materials separately to make alloy cast or quick-setting flakes. The average thickness of the quick-setting flakes ranges from 0.15-0.5mm;

[0041] 2) The alloy casting sheet or quick-setting thin sheet in 1) is mechanically crushed into particles with a size of 0.5-1.0 mm;

[0042] 3) Use the ball milling method to crush the A alloy particles in 2) into a powder of about 3 microns; use a high-energy ball mill to further grind the powder of the B component to 100 nanometers; mix A and B powders, of which A powder is 95%, B ...

Embodiment 2

[0048] The following steps are used to prepare the samarium cobalt permanent magnet material containing the composition of 2# in Table 1.

[0049] 1) Prepare alloy castings with the composition of 2# shown in Table 1 (without considering burning loss), in which, the chemical composition of Alloy A is: Sm~25%, Co~49.2%, Fe~20% , Cu~3%, Zr~2.8%; the chemical composition of B alloy is: Sm~10%, Pr~5%, Ce~20%, Co~47%, Fe~8%, Cu~10% .

[0050] 2) The alloy casting sheet or quick-setting thin sheet in 1) is mechanically crushed into particles with a size of 0.5-1.0 mm;

[0051] 3) Under protective gas, mix the particles in 2) with the anti-oxidation lubricant at a ratio of 3ml / kg, and use dry method (jet milling) to crush it into a powder of about 2 microns; wherein, the anti-oxidation lubricant Alcohol and gasoline account for 96%, and base synthetic oil accounts for 4%; the base synthetic oil is polya-olefin, and the viscosity index is greater than 90; the alcohol is ethanol.

...

Embodiment 3

[0058] The following steps are used to prepare the samarium cobalt permanent magnet material containing the composition of 3# in Table 1.

[0059] 1) Prepare alloy castings with the composition of 3# (without considering burning loss) shown in Table 1, wherein the chemical composition of Alloy A is: Sm~24.5%, Co~49.5%, Fe~18% by mass percentage , Cu~5%, Zr~3%; the chemical composition of B alloy is: Sm~10%, Pr~5%, Ce~20%, Co~47%, Fe~8%, Cu~10% by mass percentage .

[0060] 2) The alloy casting sheet or quick-setting thin sheet in 1) is mechanically crushed into particles with a size of 0.5-1.0 mm;

[0061] 3) Under protective gas, mix the particles in 2) with the anti-oxidation lubricant at a ratio of 7ml / kg, and use dry method (jet milling) to crush it into a powder of about 1.5 microns; wherein, the anti-oxidation lubricant Alcohol and gasoline account for 85%, and base synthetic oil accounts for 15%; the base synthetic oil is ester oil with a viscosity index greater than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com