Water pump automatic circulation assembly line

An assembly line and transfer line technology, applied in pump testing, assembly machines, machines/engines, etc., can solve problems such as low production efficiency, low work efficiency, and high labor intensity, and achieve simple structure, reduce labor intensity, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

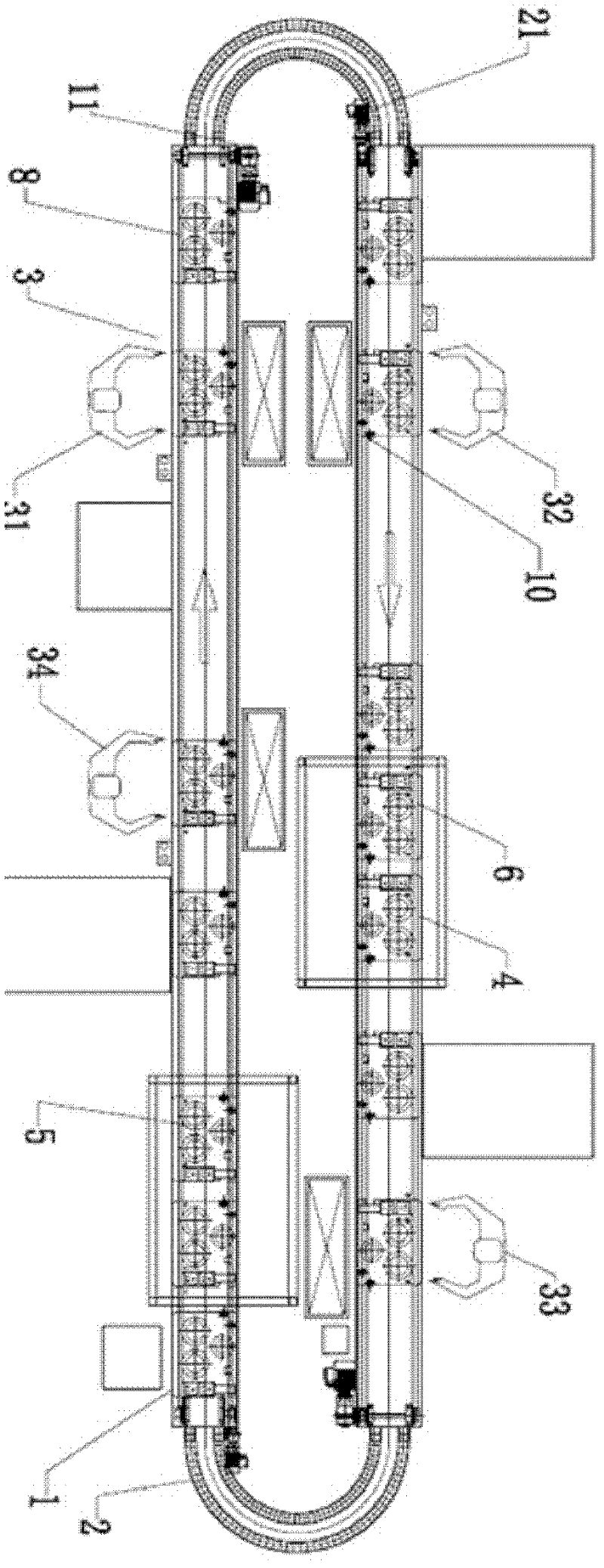

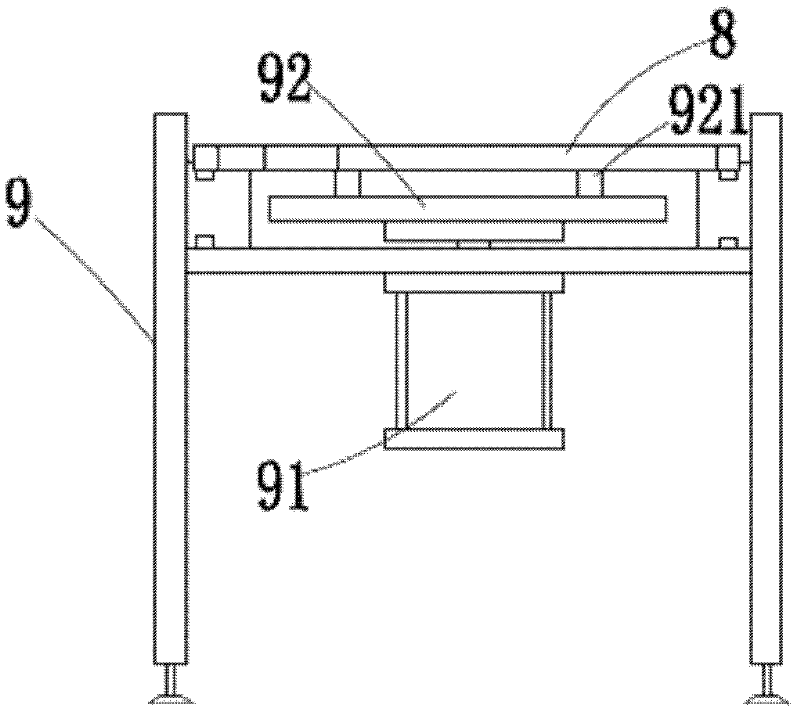

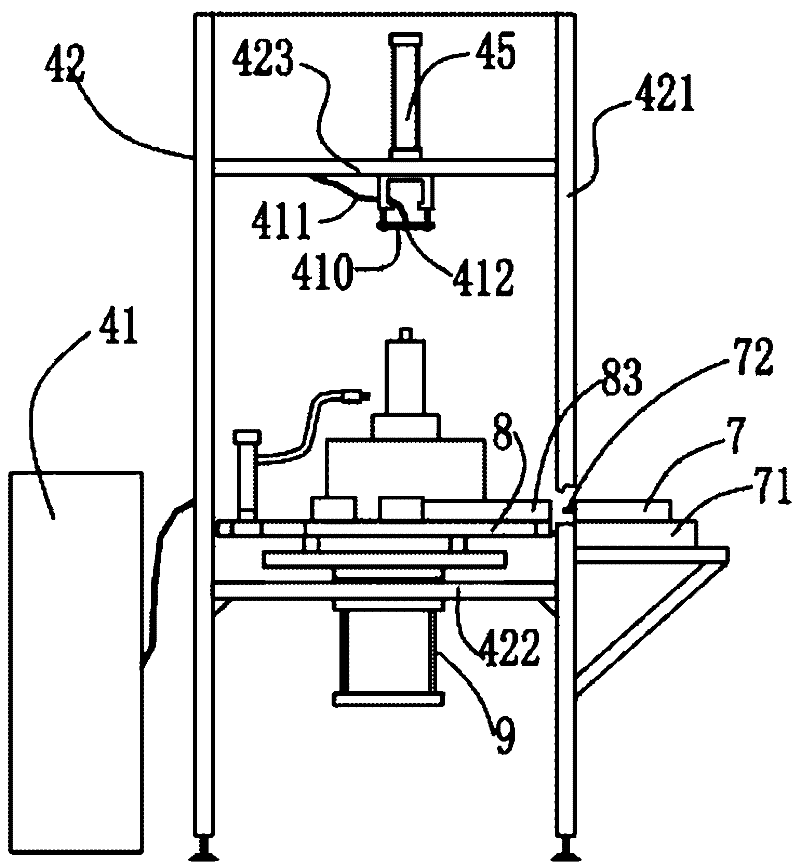

[0024] Such as figure 1 As shown, the water pump automatic circulation assembly line provided by this embodiment includes a circulation circulation line composed of a differential speed chain line 1 and an arc flat top chain line 2, and is characterized in that the circulation circulation line is provided with more than two artificial The assembly station 3 is also equipped with a tooling board 8 that is circulated on the circulation line, and a tooling board jacking device 9 and a seat stopper 10 are provided on the manual assembly station 3 .

[0025] During implementation, the manual assembly station can set the wiring station 31, the cable discharge machine station 32, whether the parameters of the checkpoints are qualified, the main pump casing, the impeller and other stations 33, and check the qualification of the airtight test according to the needs of the circulation. Will assemble the water pump off-line station 34. Displays can be installed next to the stations wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com