Low-pressure diffusion technology for solar cells

A solar cell, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low cost, difference in square resistance, and high conversion efficiency, achieve high conversion efficiency, and reduce the cost of chemical and special gas losses , the effect of increasing the amount of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

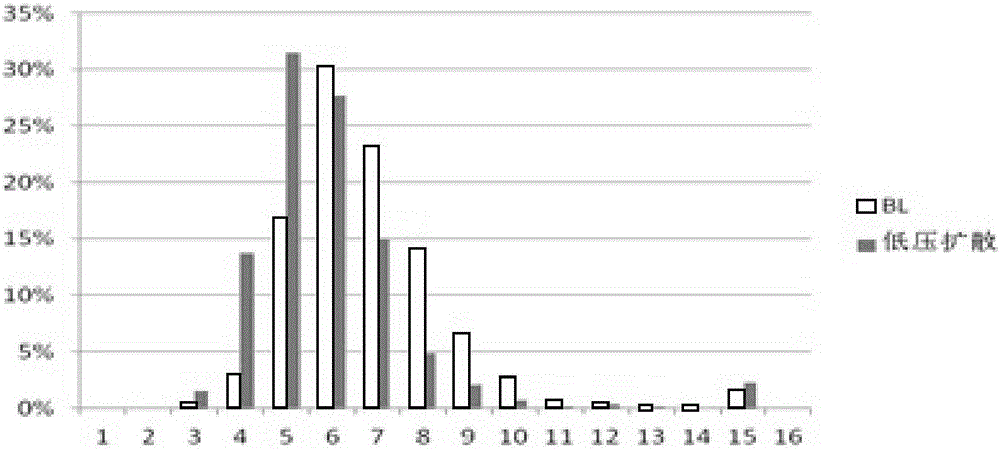

Image

Examples

Embodiment 1

[0038] The diffusion furnace used has five heating zones, and the specific process flow is as follows:

[0039] Into the furnace: place the cleaned and textured crystalline silicon wafers on the quartz boat in sequence, place the quartz boat full of crystalline silicon wafers on the quartz boat support, and then move them from the horizontal diffusion furnace at a speed of 200mm / min by SiC paddles The furnace mouth is pushed into the furnace at a constant speed, and large nitrogen is introduced into the furnace at the same time during the pushing process. The initial temperature in the furnace is 750 ° C, the maximum nitrogen flow rate is 3L / min, and the pressure is 91mbar;

[0040] Vacuuming: After the quartz boat is pushed to the specified position in the furnace, the SiC paddle returns to the initial position outside the furnace at a speed of 300mm / min, the furnace door is closed, the temperature rises to 760°C, and the maximum nitrogen flow rate is reduced to 2.7L / min. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com