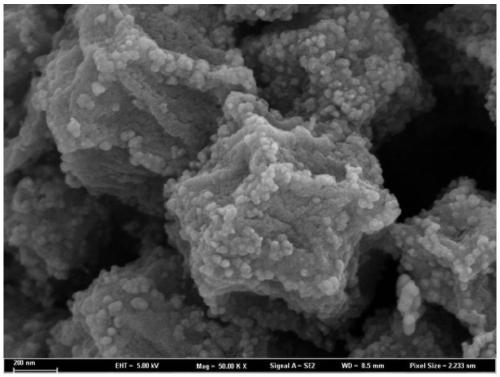

Preparation method of cobalt and oxide embedded porous carbon absorbing material

A wave-absorbing material and oxide technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as high risk factor, increase in dielectric loss and magnetic loss, general wave-absorbing performance, etc., and achieve particle size distribution Uniformity, mild reaction conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of the reaction solution:

[0035] 1) Preparation of ZIF-67 precursor reaction solution:

[0036] with V 甲醇 :V 去离子水 Prepare a solution in the following proportions for 7:1 as solvent.

[0037] CoCl 2 ·6H 2 O-------------------0.04mol / L

[0038] PVP K30------------------------0.8g / L

[0039] (metal salt solution)

[0040] 2-Methylimidazole ------------------0.6mol / L

[0041] (organic ligand solution)

[0042] Temperature ----------------------------- 25℃

[0043] Stirring time ------------------------20min

[0044] 2. Co / Co 3 o 4 Preparation of embedded nanoporous carbon composites:

[0045] 1) Put the solution prepared by the above method at 25°C for 24 hours, and a purple precipitate appears at the bottom of the beaker;

[0046] 2) Centrifuge the solution, wash the ZIF-67 powder 3 times with ethanol, dry it in a vacuum oven at 60°C for 12 hours, and collect it;

[0047] 3) Disperse the purple powder in a magnetic boat for calcination. The ...

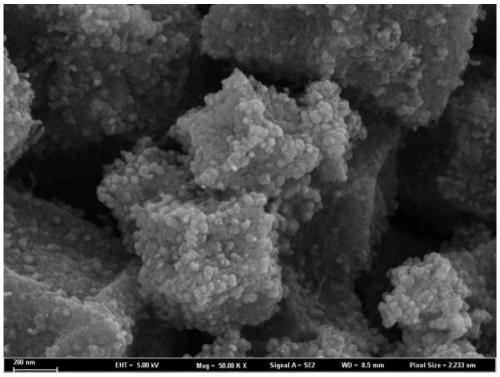

Embodiment 2

[0051] 1. Preparation of the reaction solution:

[0052] 1) Preparation of ZIF-67 precursor reaction solution:

[0053] with V 甲醇 :V 去离子水 Prepare a solution in the following proportions for 7:1 as solvent.

[0054] CoCl 2 ·6H 2 O-------------------0.12mol / L

[0055] PVP K30------------------------12g / L

[0056] 2-Methylimidazole------------------1.2mol / L

[0057] Temperature ----------------------------- 25℃

[0058] Stirring time ------------------------20min

[0059] 2. Co / Co 3 o 4 Preparation of embedded nanoporous carbon composites:

[0060] 1) Put the solution prepared by the above method at 25°C for 24 hours, and a purple precipitate appears at the bottom of the beaker;

[0061] 2) Centrifuge the solution, wash the ZIF-67 powder 3 times with ethanol, dry it in a vacuum oven at 60°C for 18 hours, and collect it;

[0062] 3) Disperse the purple powder in a magnetic boat for calcination. The magnetic boat is placed in an argon-protected tube furnace with a heat...

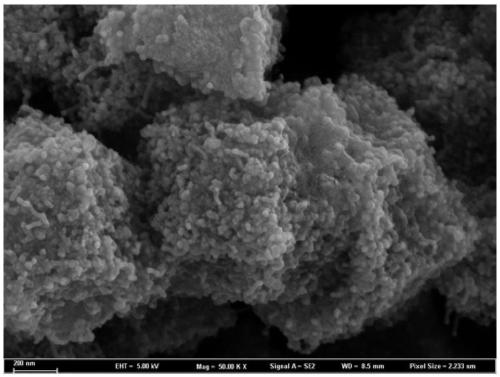

Embodiment 3

[0066] 1. Preparation of the reaction solution:

[0067] 1) Preparation of ZIF-67 precursor reaction solution:

[0068] with V 甲醇 :V 去离子水 Prepare a solution in the following proportions for 7:1 as solvent.

[0069] CoCl 2 ·6H 2 O-------------------0.40mol / L

[0070] PVP K15------------------------40g / L

[0071] 2-Methylimidazole------------------1.8mol / L

[0072] Temperature ----------------------------- 25℃

[0073] Stirring time ------------------------20min

[0074] 2. Co / Co 3 o 4 Preparation of embedded nanoporous carbon composites:

[0075] 1) Put the solution prepared by the above method at 25°C for 24 hours, and a purple precipitate appears at the bottom of the beaker;

[0076] 2) Centrifuge the solution, wash the ZIF-67 powder 3 times with ethanol, dry in a vacuum oven at 60°C for 24 hours, and then collect;

[0077] 3) Disperse the purple powder in a magnetic boat, place the magnetic boat in an argon-protected tube furnace, heat up at a rate of 5°C / min, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com