S@NPC/CNT composite material and preparation method and application thereof

A composite material and carbon material technology, applied in the field of S@NPC/CNT composite material and its preparation, can solve the problems of loss, low sulfur content, polysulfide dissolution capacity, etc., to improve electrical conductivity, enhance electrical conductivity, reduce The effect of the small shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

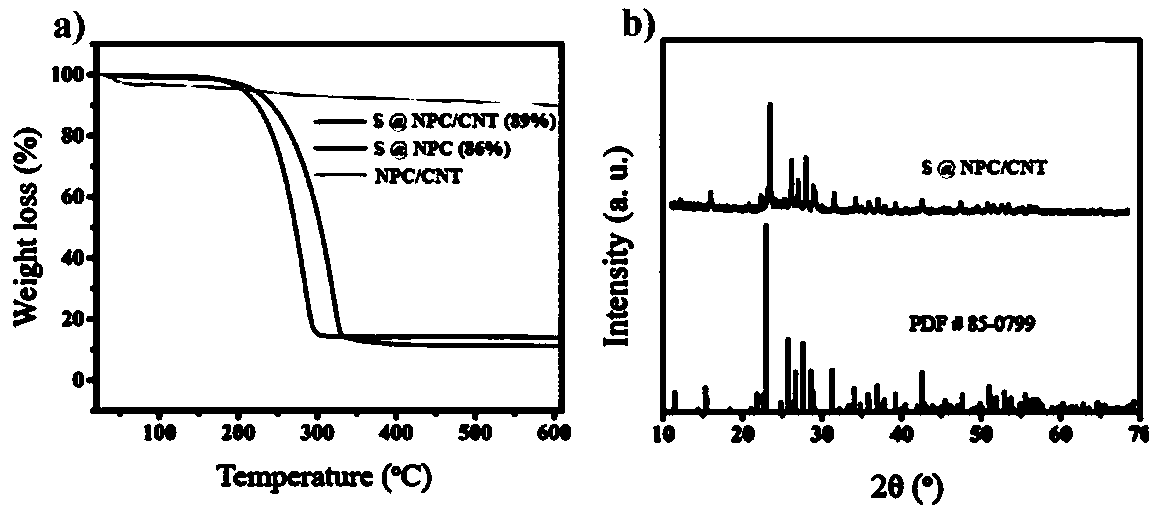

[0066] Preparation of S@NPC / CNT composite material and performance test of its assembled lithium-sulfur battery

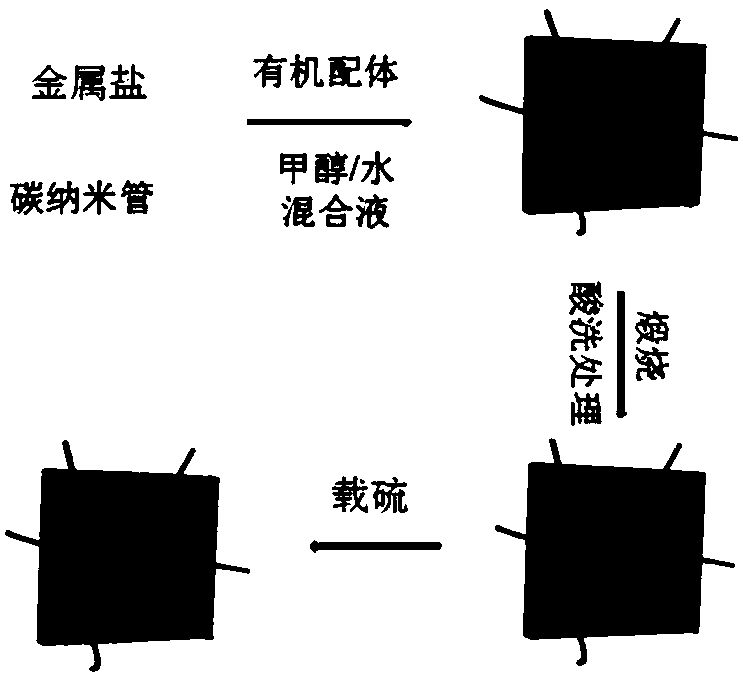

[0067] Step (1): Preparation of Zn / Co-bimetallic ZIFs / / CNT composites

[0068] Put 1.68mmol of zinc nitrate and 1.71mmol of cobalt nitrate into a mixed solution of methanol and water with a volume ratio of 3:1, put them on a magnetic stirrer and dissolve them by stirring to form a uniform pink solution. Then add 6.09mmol of 2-methylimidazole and 50mg of carbon nanotubes (particle size is 20-40nm) to the above solution, after stirring for 6h, the solution is filtered, washed with methanol, and finally placed in a drying oven at 70°C After drying overnight, the ZnCo-ZIFs / CNTs material was obtained.

[0069] Step (2): Preparation of NPC / CNT material

[0070] After fully grinding the ZnCo-ZIFs / CNTs composite material prepared in step (1), put it into a porcelain boat, and keep it at 900°C for 3h at a heating rate of 5°C / min in a nitrogen atmosphere. After naturally ...

Embodiment 2

[0079] Preparation of S@NPC / CNT composite material and performance test of its assembled lithium-sulfur battery

[0080] Step (1): Preparation of Zn / Co-bimetallic ZIFs / / CNT composites

[0081] Put 1.68mmol of zinc nitrate and 1.71mmol of cobalt nitrate into a mixed solution of methanol and water with a volume ratio of 3:1, put them on a magnetic stirrer and dissolve them by stirring to form a uniform pink solution. Then, 5.08 mmol of 2-methylimidazole and 40 mg of carbon nanotubes were added to the above solution, and after stirring for 6 hours, the solution was filtered, washed with methanol, and finally placed in a drying oven at 70°C to dry overnight to obtain ZnCo-ZIFs / CNTs Material.

[0082] Step (2): Preparation of NPC / CNT material

[0083] After fully grinding the ZnCo-ZIFs / CNTs composite material prepared in step (1), put it into a porcelain boat, and keep it at 900°C for 3h in a nitrogen atmosphere at a heating rate of 5°C / min. After naturally cooling to room tempe...

Embodiment 3

[0091] Preparation of S@NPC / CNT composite material and performance test of its assembled lithium-sulfur battery

[0092] Step (1): Preparation of Zn / Co-bimetallic ZIFs / / CNT composites

[0093] Put 1.68mmol of zinc nitrate and 1.71mmol of cobalt nitrate into a mixed solution of methanol and water with a volume ratio of 3:1, put them on a magnetic stirrer and dissolve them by stirring to form a uniform pink solution. Then, 7.24 mmol of 2-methylimidazole and 60 mg of carbon nanotubes were added to the above solution, and after stirring for 6 hours, the solution was filtered, washed with methanol, and finally dried overnight at 70°C in a drying oven to obtain ZnCo-ZIFs / CNT Material.

[0094] Step (2): Preparation of NPC / CNT material

[0095] After fully grinding the ZnCo-ZIFs / CNT composite material prepared in step (1), put it into a porcelain boat, and keep it at 900°C for 3h in a nitrogen atmosphere at a heating rate of 5°C / min. After naturally cooling to room temperature, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com