Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Improve initial discharge capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen-sulfur-carbon nanocomposites and their application as cathode materials in lithium-sulfur batteries

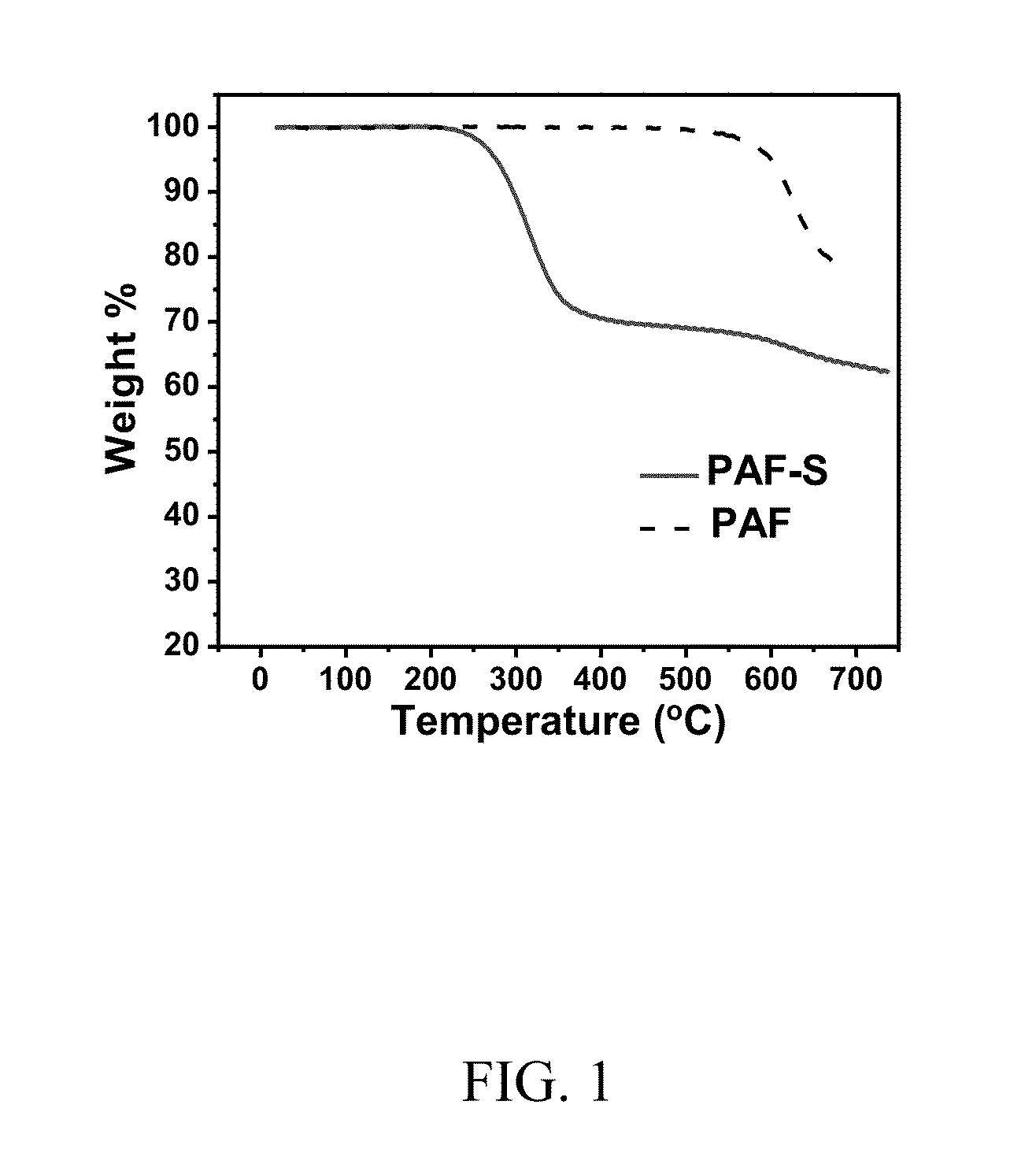

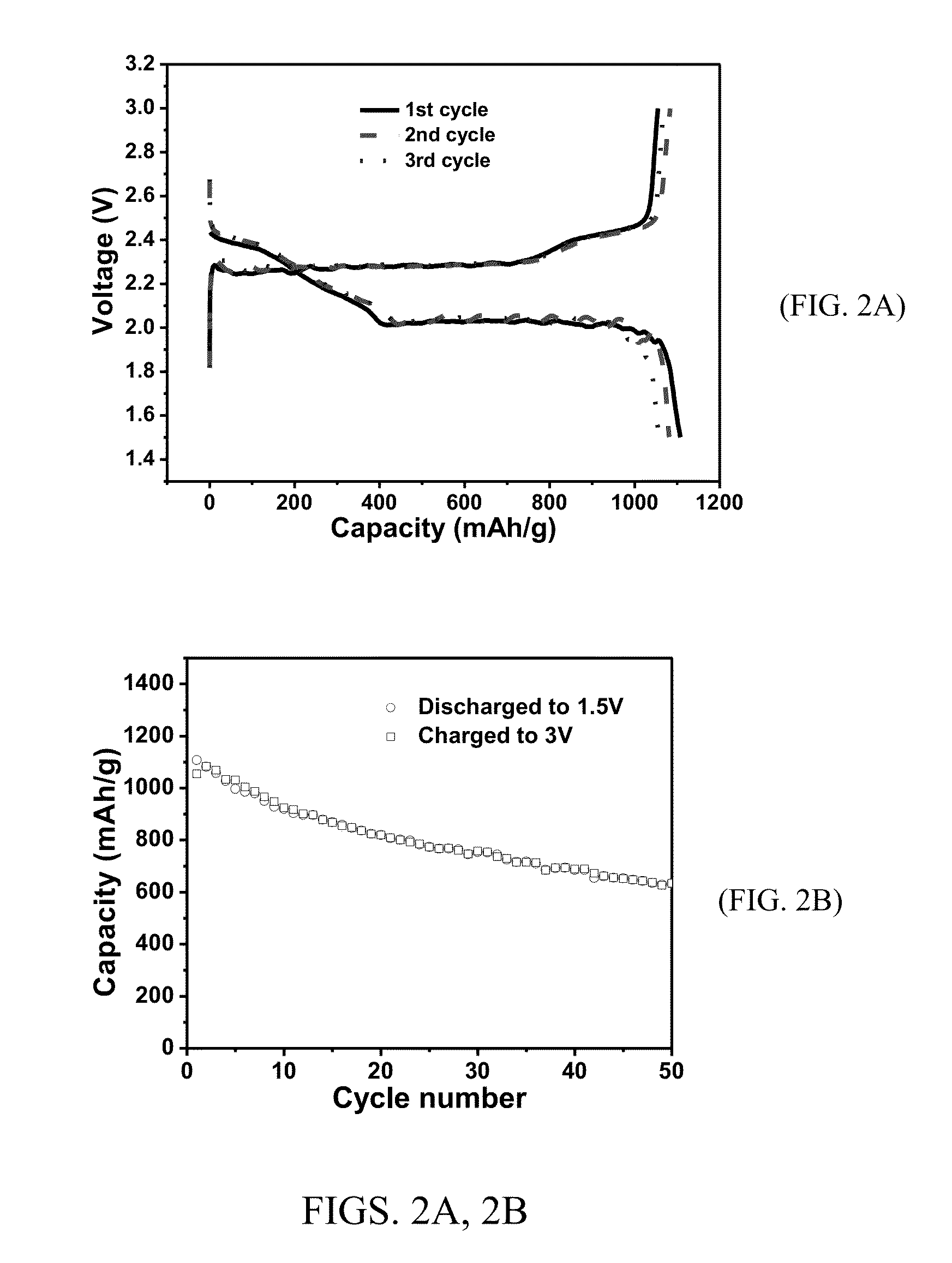

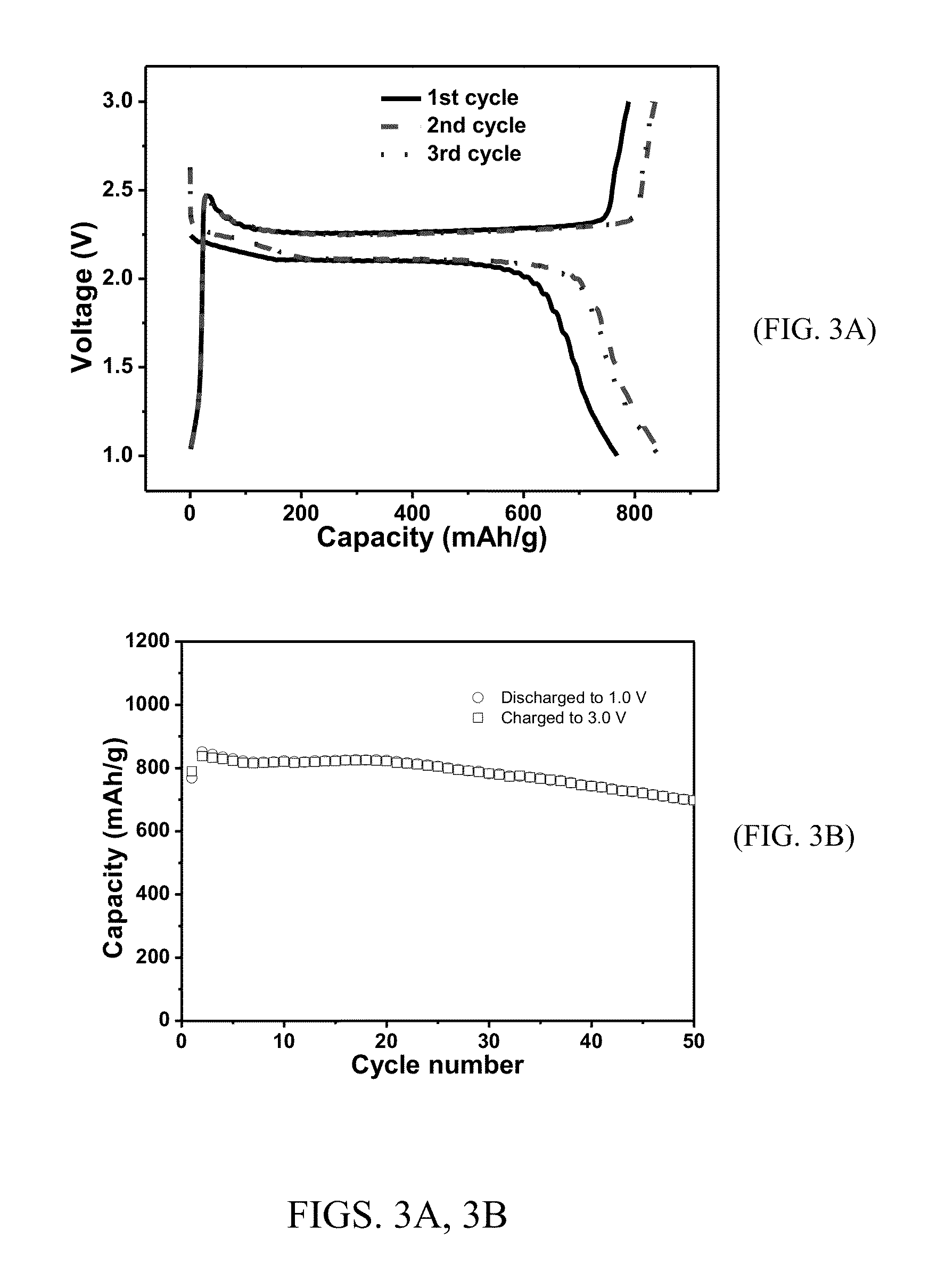

ActiveUS20140141328A1Minimize formationImprove initial discharge capacityMaterial nanotechnologySecondary cellsLithium–sulfur batterySulfur

The invention is directed in a first aspect to electron-conducting porous compositions comprising an organic polymer matrix doped with nitrogen atoms and having elemental sulfur dispersed therein, particularly such compositions having an ordered framework structure. The invention is also directed to composites of such S / N-doped electron-conducting porous aromatic framework (PAF) compositions, or composites of an S / N-doped mesoporous carbon composition, which includes the S / N-doped composition in admixture with a binder, and optionally, conductive carbon. The invention is further directed to cathodes for a lithium-sulfur battery in which such composites are incorporated.

Owner:UT BATTELLE LLC

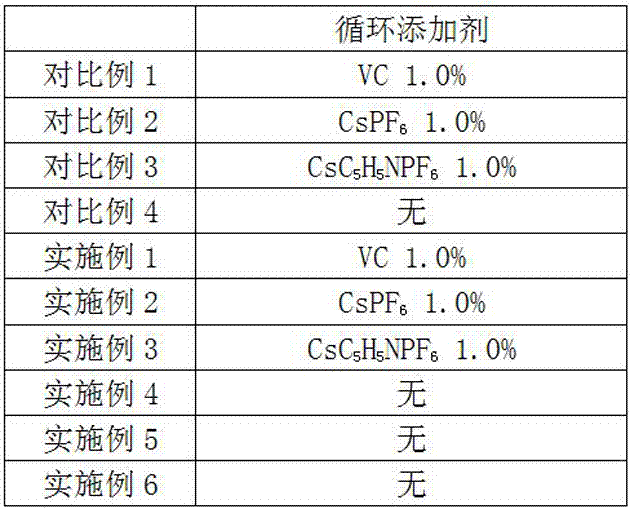

Electrolyte taking propylene carbonate as main solvent and secondarily liquid injected lithium ion battery

InactiveCN105449281AImprove compatibilitySuppress co-embeddingFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentElectrical battery

The invention aims at providing electrolyte containing functional additives and taking propylene carbonate as the main solvent, and a secondarily liquid injected lithium ion battery comprising the electrolyte taking propylene carbonate as the main solvent. In the invention, the electrolyte comprises nonaqueous organic solvent, electrolyte salt and additives; the nonaqueous organic solvent comprises a main component propylene carbonate, wherein the propylene carbonate is 50%-10% of the total mass of the electrolyte; the electrolyte salt is lithium salt; the concentration of the lithium salt is 2.5-4.0 mol / L; the additives comprise general film-forming additives; the secondarily liquid injected lithium ion battery comprises cathode, anode, diaphragm and the electrolyte taking the propylene carbonate as the main solvent. Through using the secondary liquid injection method, the PC solvent is prevented from co-intercalation, therefore the primary efficiency of the battery is clearly promoted, and the normal temperature cycle performance and the low temperature discharging performance of the battery are improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Method for producing positive electrode active material for lithium ion battery, positive electrode active material for lithium ion battery, electrode for lithium ion battery, and lithium ion battery

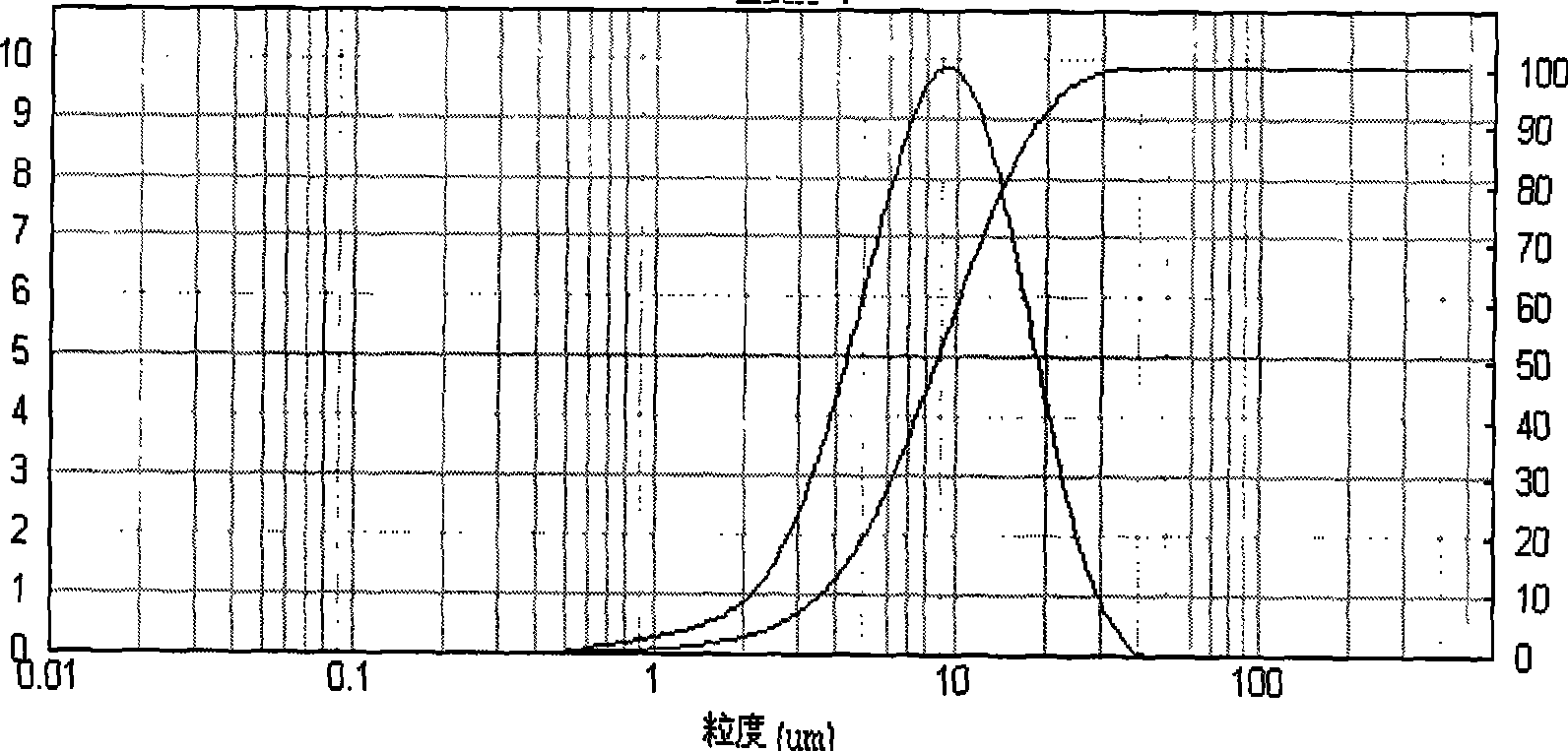

InactiveCN102356488AGenerate efficientlyNarrow particle size distributionCell electrodesLi-accumulatorsPhosphoric acidSodium-ion battery

Owner:SUMITOMO OSAKA CEMENT CO LTD

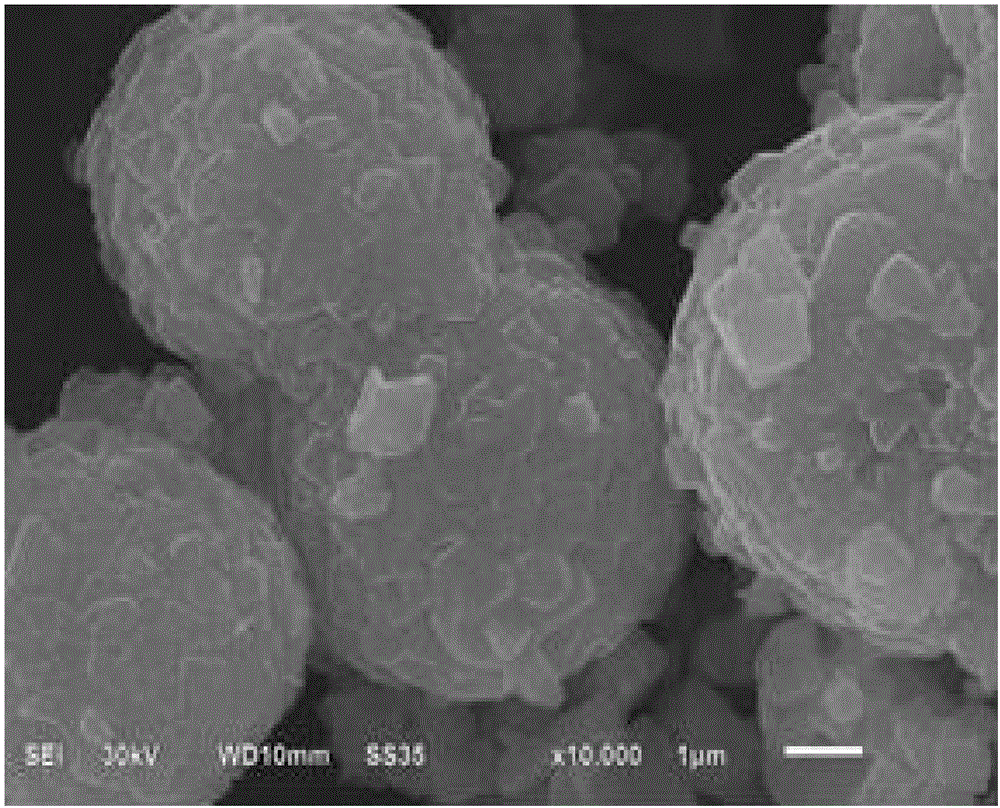

Preparation method of spinel-type spherical high-entropy oxide material for lithium ion battery anode material

ActiveCN108933248AImprove efficiencySimple processCell electrodesSecondary cellsMolecular levelCobalt

The invention discloses a preparation method of a spinel-type spherical high-entropy oxide material for a lithium ion battery anode material and belongs to the field of lithium ion battery anode materials. The preparation method integrates chemical reduction and low temperature thermal treatment and particularly includes: with chlorides, sulfates, nitrates, carbonates, acetates and oxalates of cobalt, chromium, copper, iron and nickel being metal sources and sodium borohydride and sodium hydrosulfite being reducing agents, calcining the products, subjected to a redox reaction, in a device at 300-500 DEG C to obtain the target product. Through liquid-phase burdening, it is guaranteed that the raw materials are blended at molecular level, thus achieving stoichiometric ratio of the product; meanwhile, the method is simple in process, is gentle in reactions, is short in time and high in efficiency, and has no special demands on calcining equipment. The high-entropy oxide powder is high inpurity, is small in particle size and has high initial discharge capacity and great cycle performance.

Owner:衢州市衢发瑞新能源材料有限公司

Method for preparing nickle lithium manganate material for lithium ion power battery anode

InactiveCN101465420AImprove electrochemical performanceGood sphericityElectrode manufacturing processesPower batteryManganate

The invention discloses a preparation method of nickel lithium manganate anode material LiNixMn2-xO4(x is more than 0 and is less than 1) and belongs to the preparing field of secondary battery materials. The preparing steps are that: nickel-source containing compound and manganese-source containing compound are firstly mixed according to chemometry, and then de-ionized water is added in the raw material mixture, and the solution is spray-dried for preparing the mixed powder; the mixed powder is mixed and sintered with the nickel-source containing compound, thus preparing the lithium ion battery anode material LiNixMn2-xO4(x is more than 0 and is less than 1). The method has simple and convenient process, short preparing time and low producing cost; the prepared product has stable structure, high specific capacity and good electrochemical performance; the method is suitable for large-scale industrial production of the lithium ion battery active material. The mean grain size of the product is 10mum and the initial discharge capacity thereof is 138mAh / g; after 200 times of 1.5C charge-discharge circulation, the capacity attenuation is less than 8 percent.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Preparation method for coated silicon/carbon/graphite composite negative electrode material

ActiveCN106025222AIncrease incidenceReduce the first charge and discharge efficiencyCell electrodesSecondary cellsNitrogenSlurry

Disclosed is a preparation method for a coated silicon / carbon / graphite composite negative electrode material. The preparation method comprises the steps of adding silicon powder and a dispersing agent into deionized water, wherein the D50 of the silicon powder is 1.2-1.5[mu]m; performing ball milling for 2-10h, and screening 100-mesh slurry; adding graphite, an organic carbon source and a binder into the deionized water, stirring and mixing uniformly, and enabling the obtained mixture to be mixed with the slurry, and continuously to stir the mixture uniformly; performing spray drying to obtain a silicon / carbon / graphite precursor; performing thermolysis on the silicon / carbon / graphite precursor under the protection of nitrogen or argon; and after screening, mixing the precursor with a coating agent, and performing ball milling for 1-3h, and carrying out heat treatment at a temperature of 400-600 DEG C under the protection of nitrogen or argon for 2-6h to obtain the coated silicon / carbon / graphite composite negative electrode material. According to the preparation method for the coated silicon / carbon / graphite composite negative electrode material provided by the invention, the initial charge-discharge efficiency of the material can be improved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

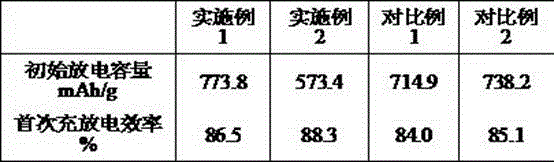

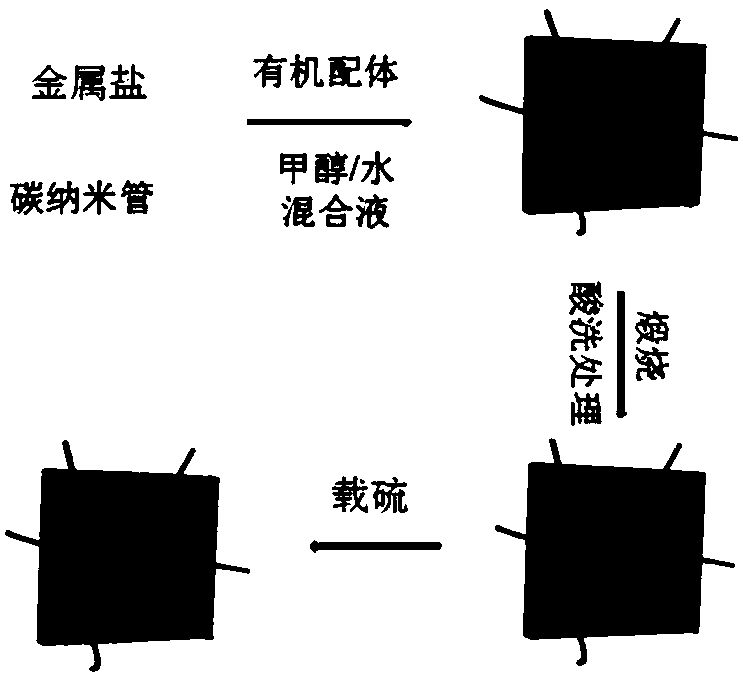

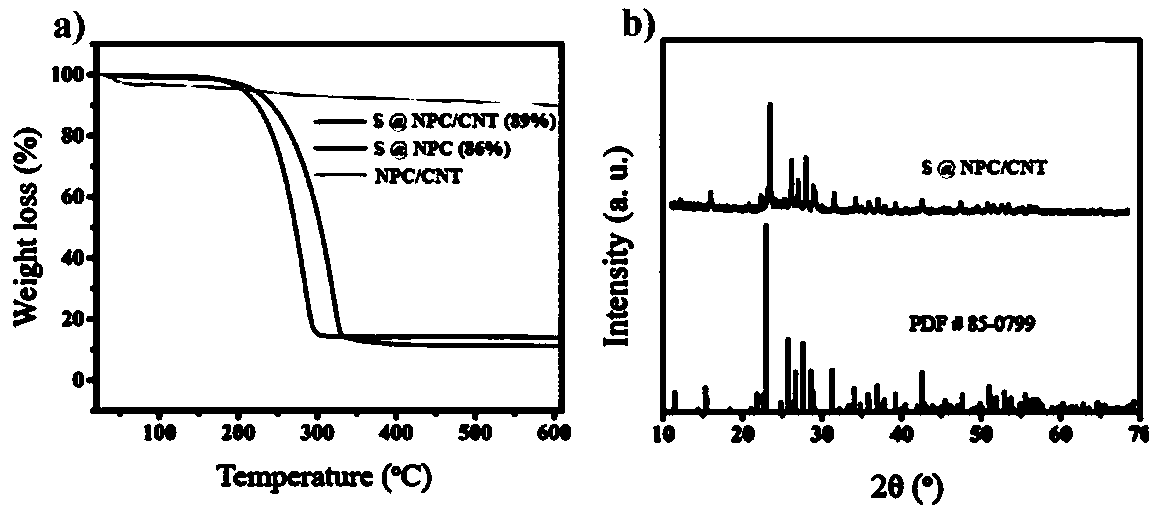

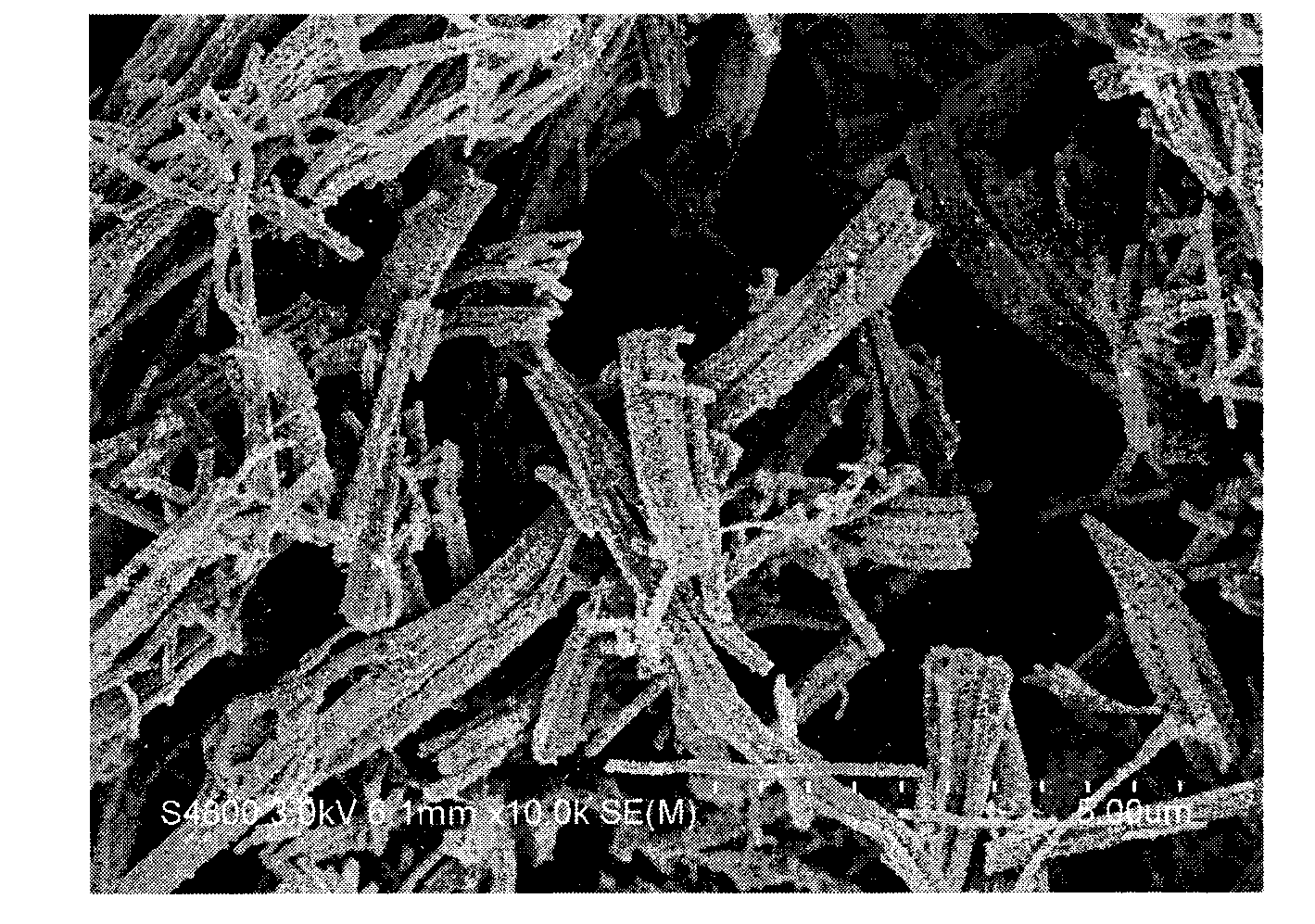

S@NPC/CNT composite material and preparation method and application thereof

InactiveCN109686951AInhibition of dissolutionStop the spreadCell electrodesDiffusion methodsPorous carbon

The invention discloses an S@NPC / CNT composite material and a preparation method and application thereof. The S@NPC / CNT composite material is obtained from an NPC / CNT composite material by sulfur loading. The NPC / CNT composite material is composed of nitrogen doped porous carbon and carbon nanotubes in the interweaving mode. The nitrogen doped porous carbon is a carbon material derived from a Zn / Co-bimetallic organic framework. The nitrogen doped carbon material is obtained by stirring, drying, calcining and acid treatment of a methyl alcohol and water mixed solution containing zinc and / or cobalt transition metal salt, organic ligand and a carbon material, and finally the high sulfur loaded S@NPC / CNT composite material is prepared by a melt diffusion method. The material exhibits extremelyhigh sulfur content. In addition, the invention also discloses the application of the high sulfur loaded nitrogen doped carbon material prepared by the method in a lithium sulfur battery. The composite material is used for an anode material of the lithium sulfur battery. The obtained battery has high area capacity and good electrochemical performance. The efficient method for preparing the nitrogen doped carbon material with high performance and high sulfur content is provided.

Owner:CENT SOUTH UNIV

Preparation method of zinc oxide nanometer fiber cathode material for lithium ion battery

A zinc oxide nanometer fiber cathode material for lithium ion battery and a preparation method thereof belong to the technical fields of high polymer material and chemical power source. The zinc oxide nanometer fiber material for lithium ion battery provided by the invention has large specific surface area. The method first prepares composite nanometer fiber by electrospinning, and then the nanometer fiber is subjected to high-temperature calcination to obtain the zinc oxide nanometer fiber. The preparation process provided by the invention is simple and easy to control, and has low production cost. The cathode electrode material for lithium ion battery provided by the invention overcomes the disadvantages of zinc oxide nanorod prepared by other methods as cathode material for lithium ion battery, such as low first cycling efficiency, weak cycle stability and high-rate discharge ability. The invention provides a zinc oxide nanometer fiber cathode material for lithium ion battery and the preparation method thereof. The material has high initial discharge capacity and cycling stability, improves high power characteristic and high-rate discharge capacity of cathode material, and is suitable for development requirements of lithium ion power battery for electric vehicles.

Owner:JIANGNAN UNIV

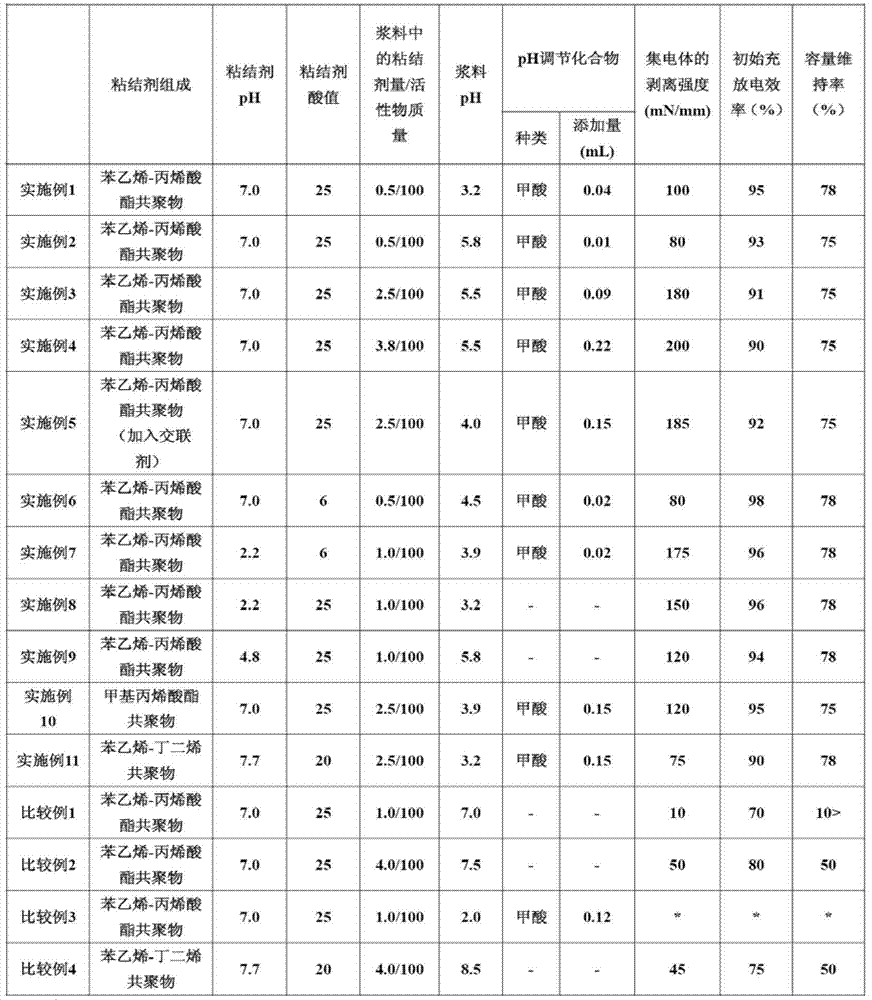

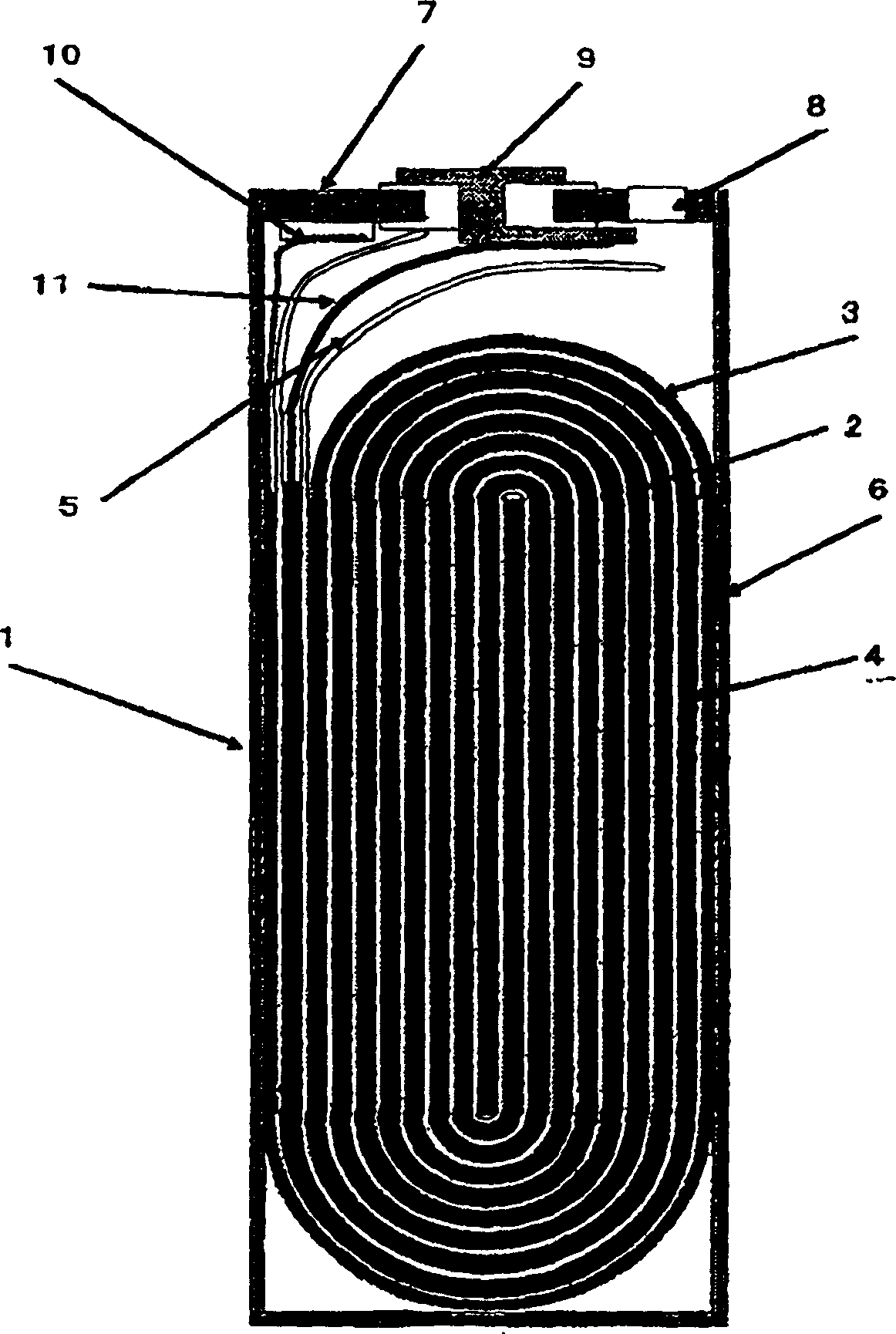

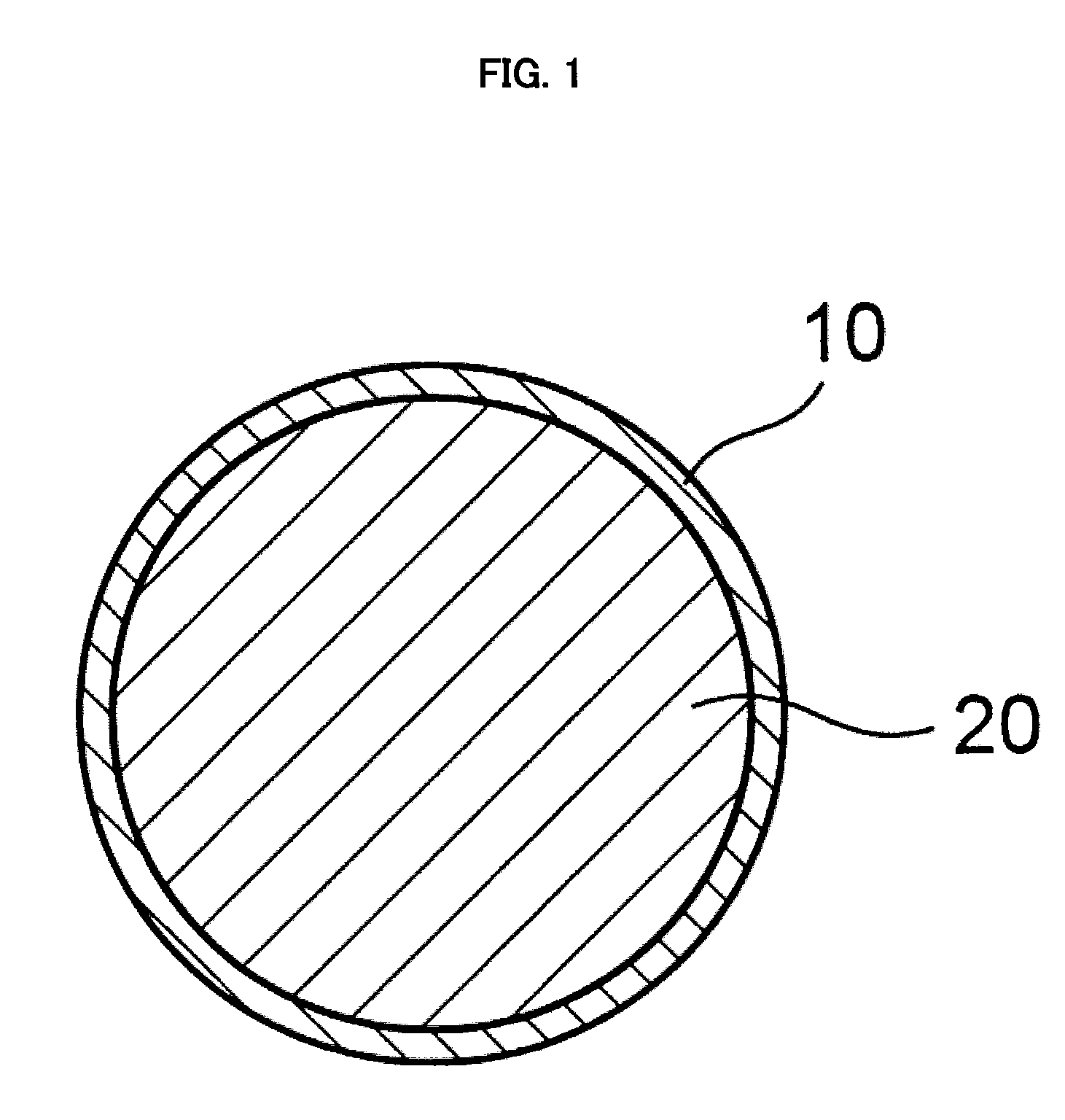

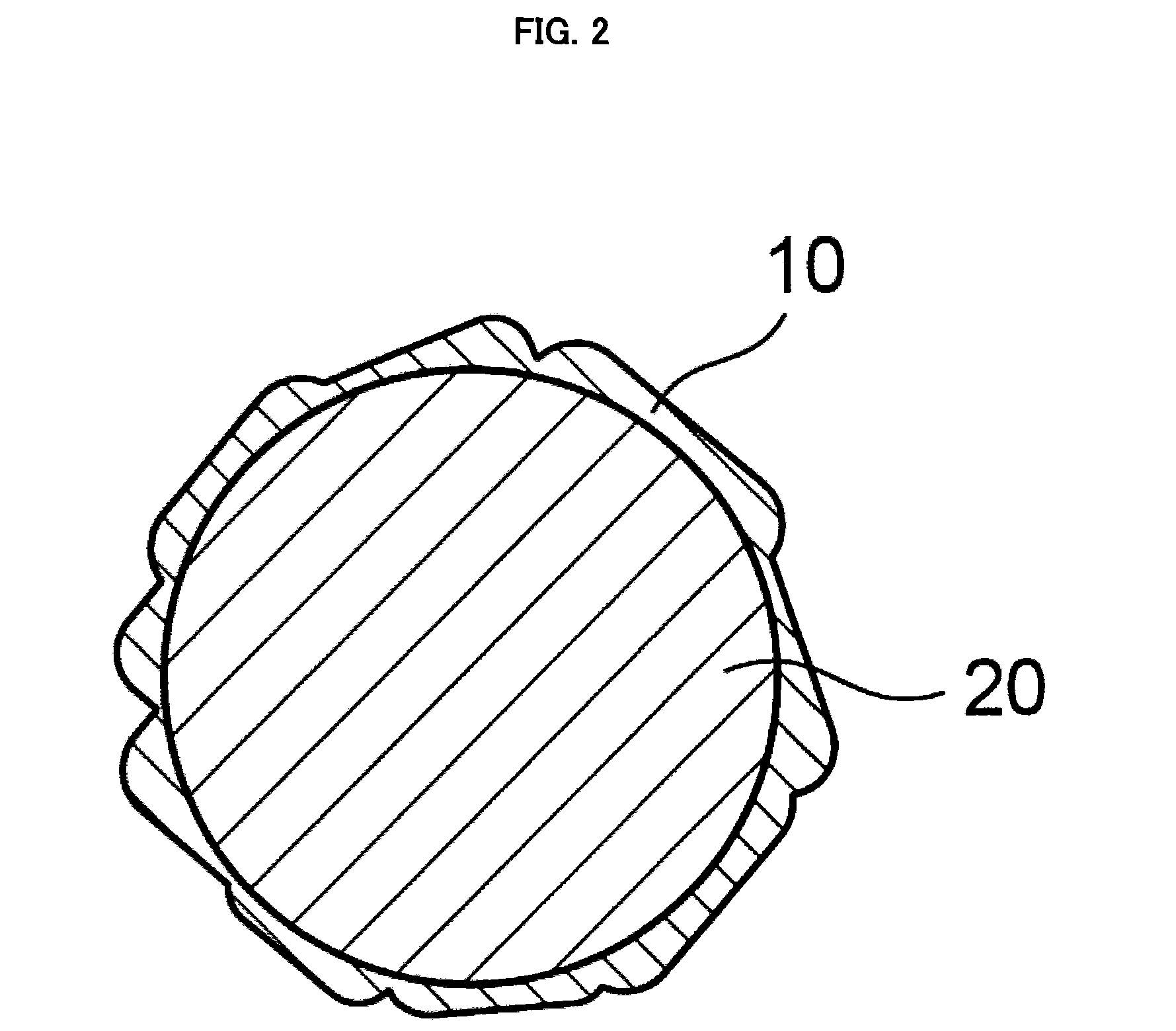

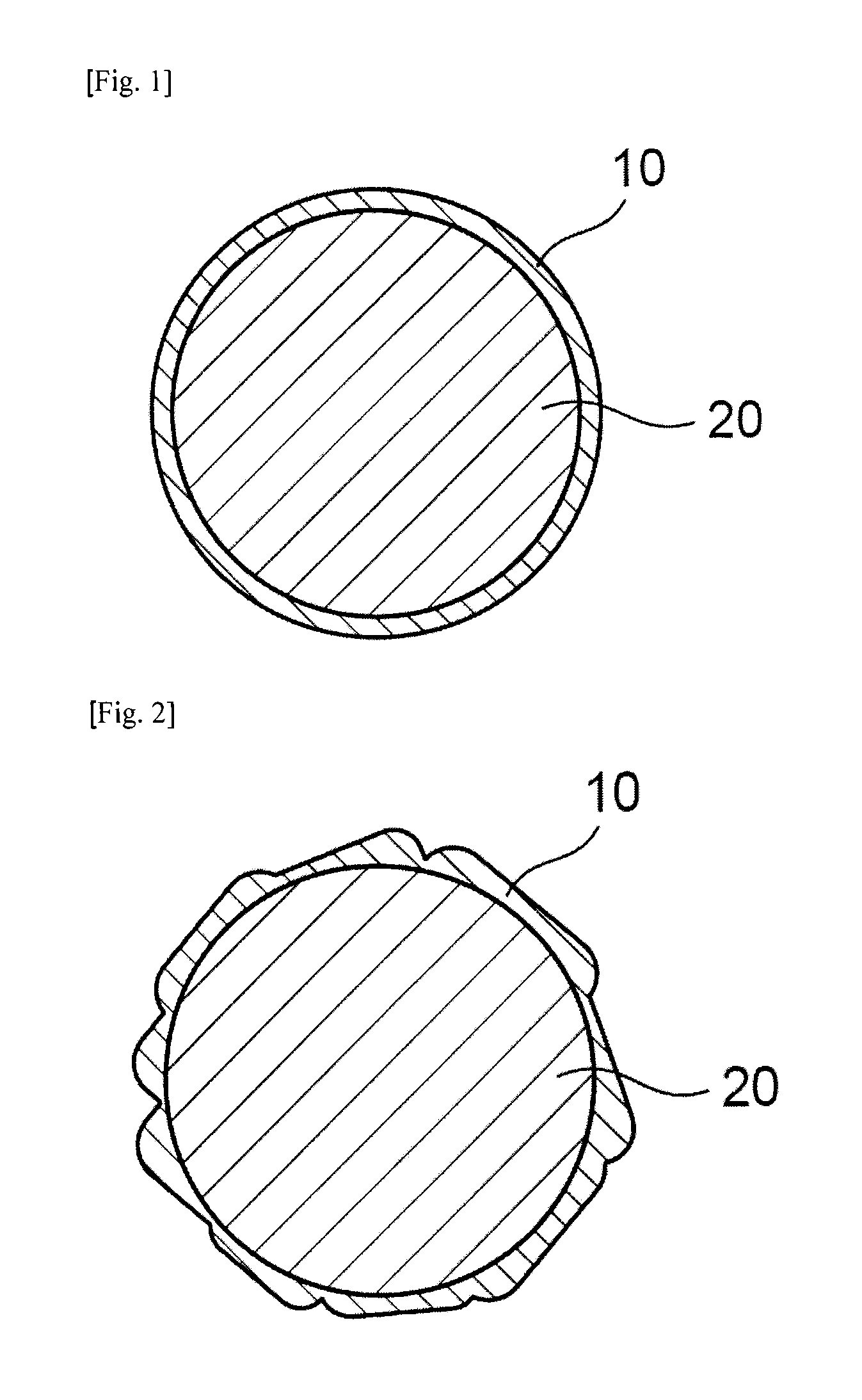

Slurries obtained using binder for cell electrodes, electrodes obtained using slurries, and lithium-ion secondary cell obtained using electrodes

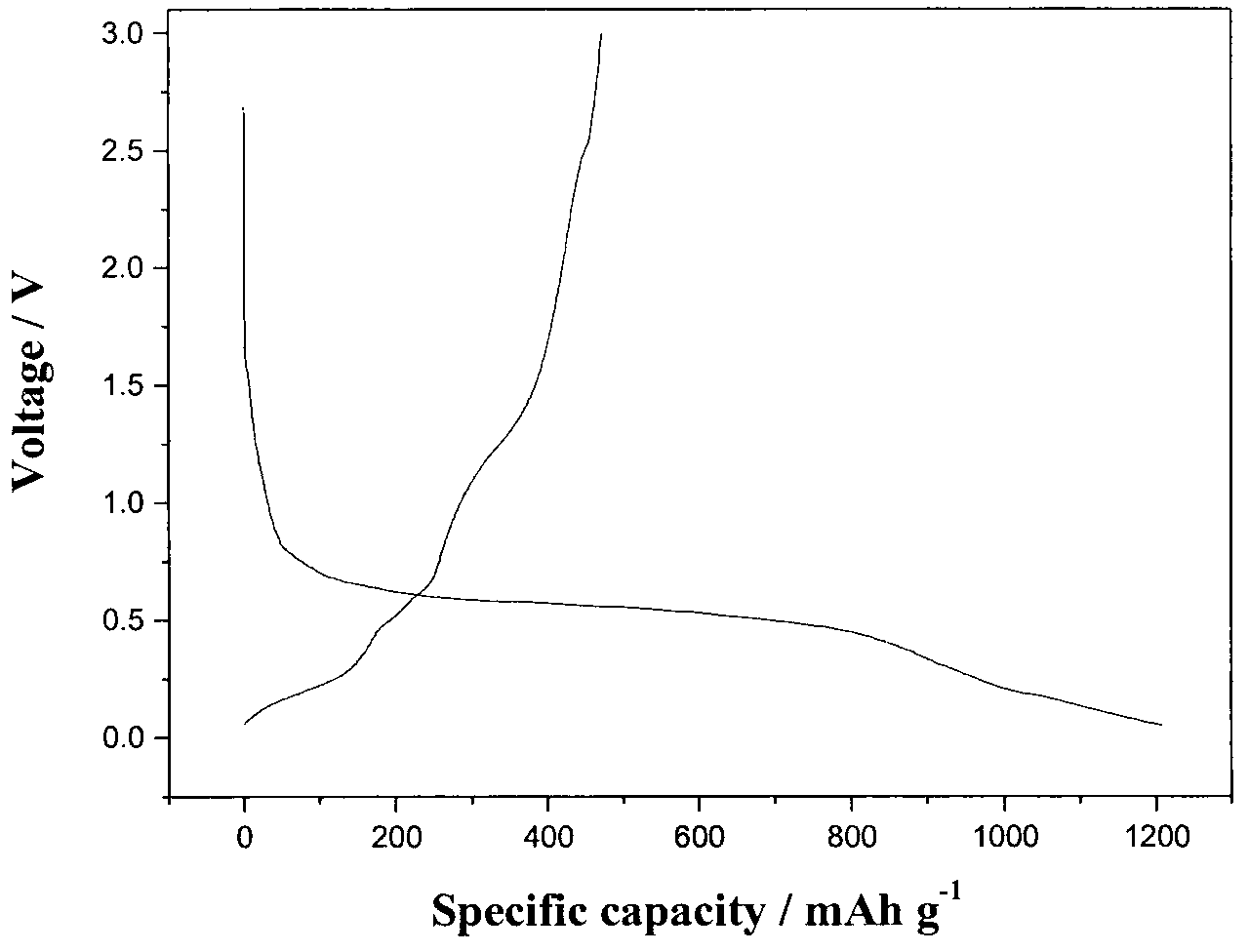

InactiveCN103370816AAdhesiveImprove initial discharge capacitySecondary cellsNon-aqueous electrolyte accumulator electrodesLithiumElectrical battery

Provided are: slurries for a lithium-ion secondary cell electrode having an excellent binding performance between active materials and between the active materials and a current collector; electrodes in which the slurries are used; and a lithium-ion secondary cell in which the electrodes are used, the lithium-ion secondary cell having both a high initial discharge capacity and superior charge-discharge cycle characteristics at high temperatures. The present invention relates to slurries for a lithium-ion secondary cell electrode, the slurries being obtained using a binder for a cell electrode and an active material and having a pH of 3.0-6.0. Preferably, the binder for a cell electrode is contained at 0.2-4.0 mass% in relation to the active material.

Owner:SHOWA DENKO KK

Secondary cell with nonaqueous electrolyte

InactiveCN1417881ADecreased initial discharge capacityImprove high temperature storage performanceOrganic electrolyte cellsLi-accumulatorsSulfateLithium-ion battery

Owner:GS YUASA INT LTD

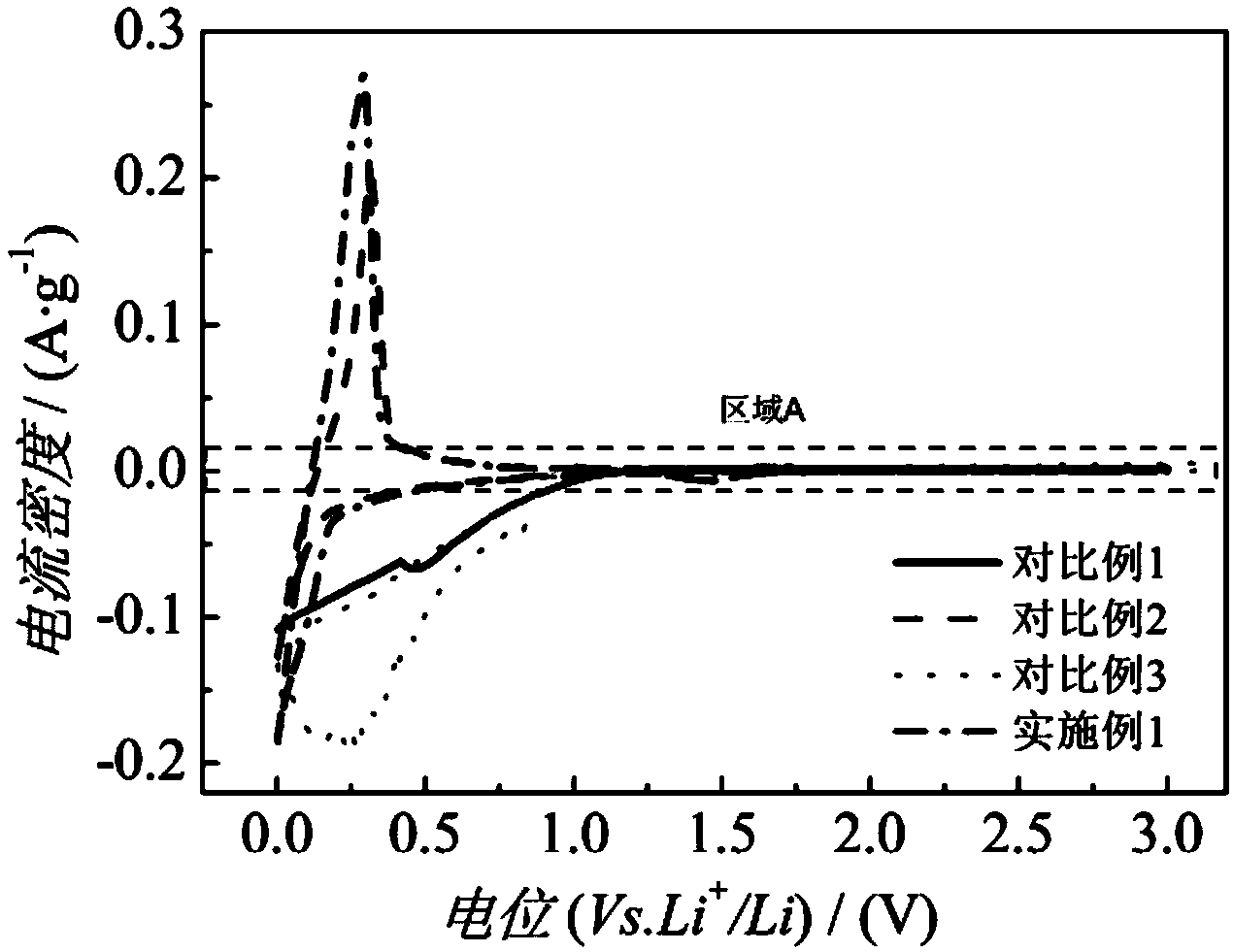

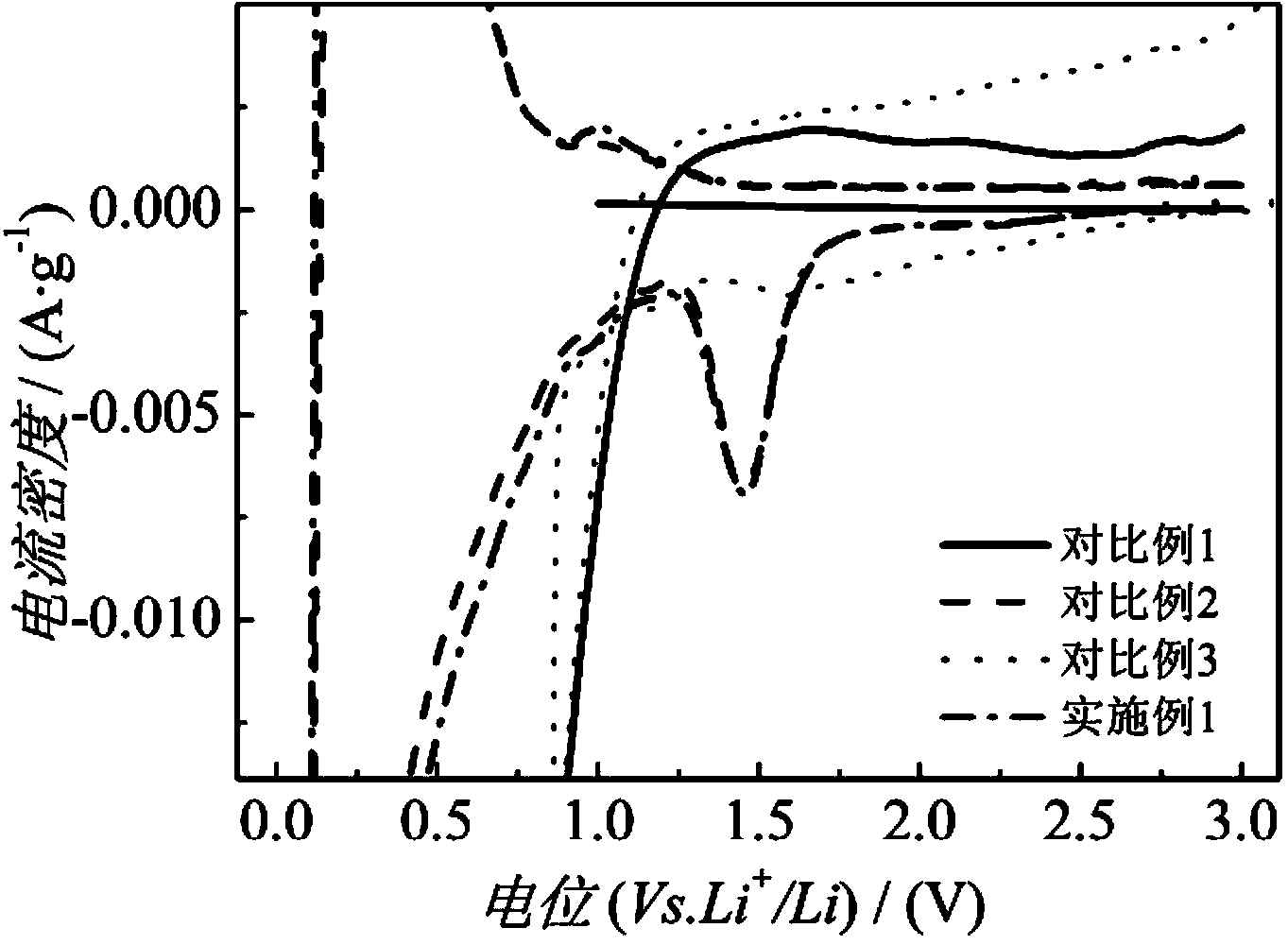

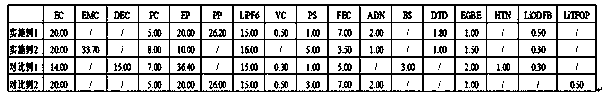

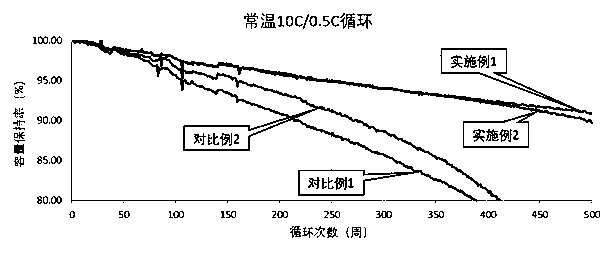

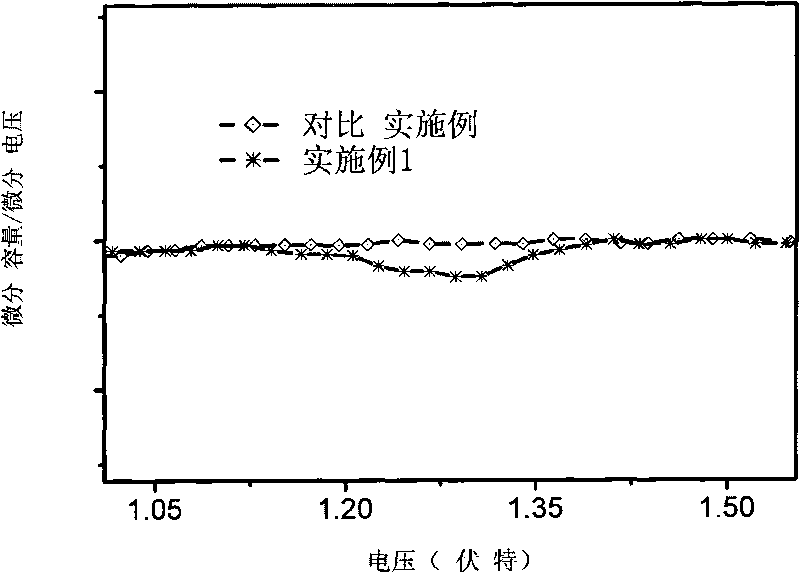

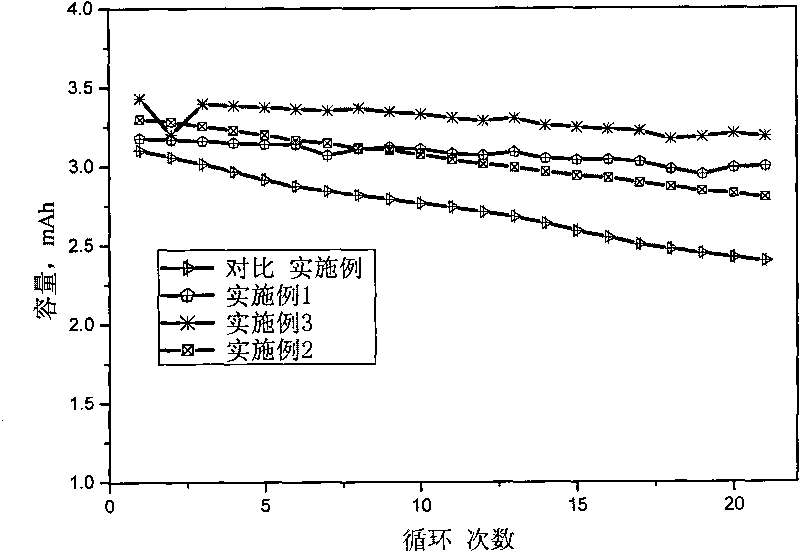

Electrolyte employing propylene carbonate as main solvent and lithium-ion battery

InactiveCN105186034AImprove cycle performanceImprove low temperature discharge performanceSecondary cellsElectrolytesElectrolytic agentElectrical battery

The invention discloses an electrolyte employing propylene carbonate as a main solvent and a lithium-ion battery. The electrolyte is prepared from a lithium salt, an organic solvent and an additive, wherein the organic solvent comprises the propylene carbonate and other non-aqueous solvents; the propylene carbonate is 10%-60% of total mass of the electrolyte; the additive comprises a conventional film-forming additive and a novel functional additive AB or AXB; the content of the conventional film-forming additive in the electrolyte is 0.1%-10%; and the molar concentration of the functional additive is 0.001mol / L to 0.1mol / L, preferably 0.03mol / L to 0.06mol / L. According to the functional additive of the electrolyte, an electrolyte system can be prompted to form stable interfacial films on the surfaces of a cathode and an anode; a propylene carbonate solvent is effectively restrained from being embedded into a graphite layer along with lithium ions; and the initial efficiency, the cycle performance and the low-temperature discharge property of the battery are effectively improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

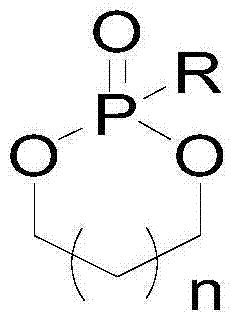

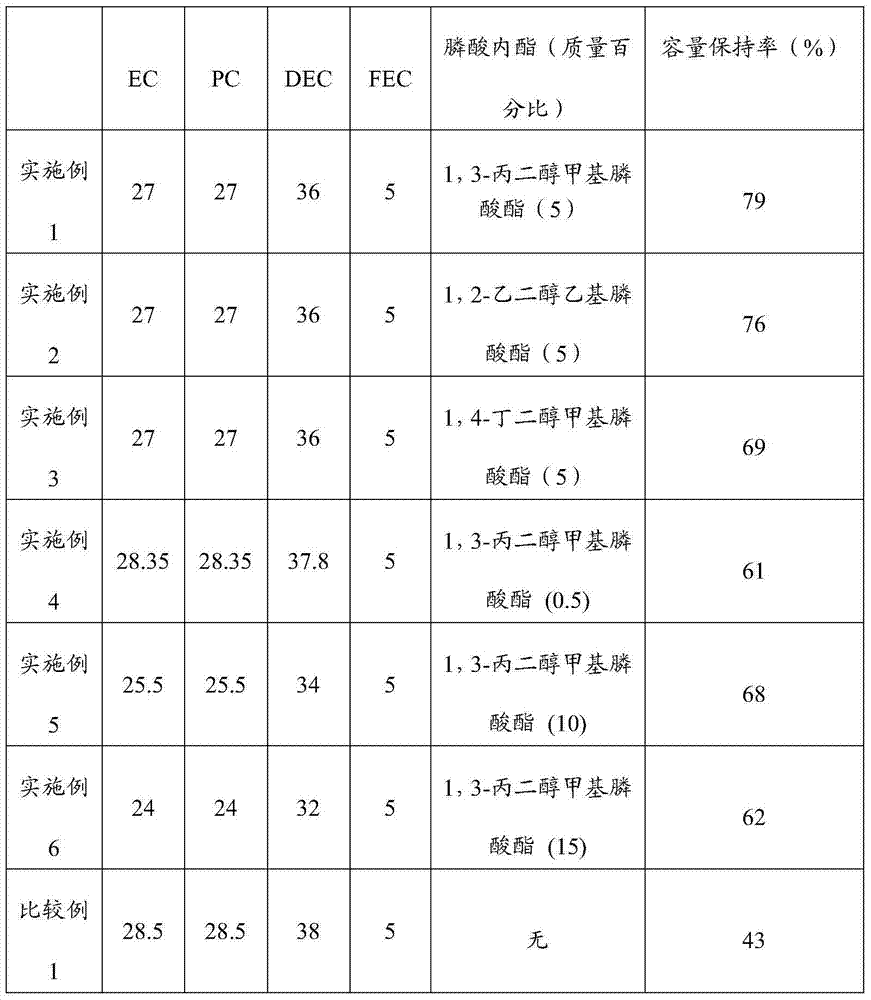

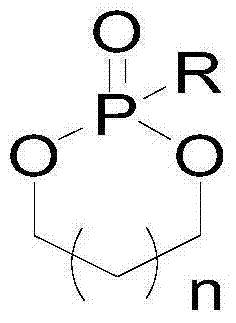

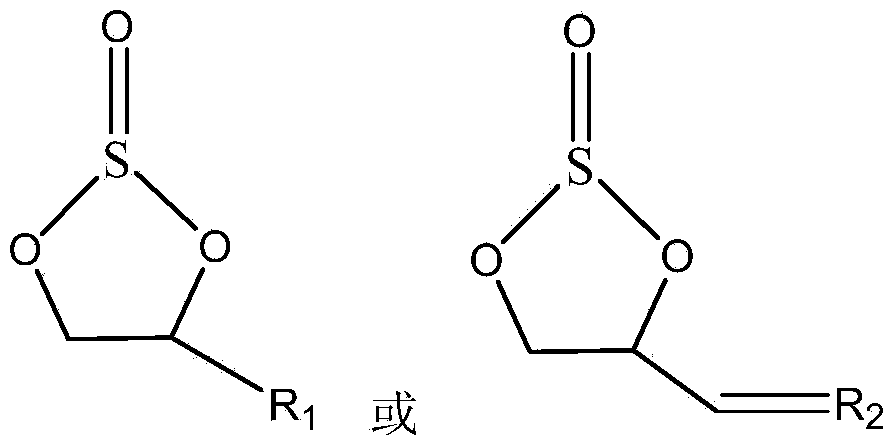

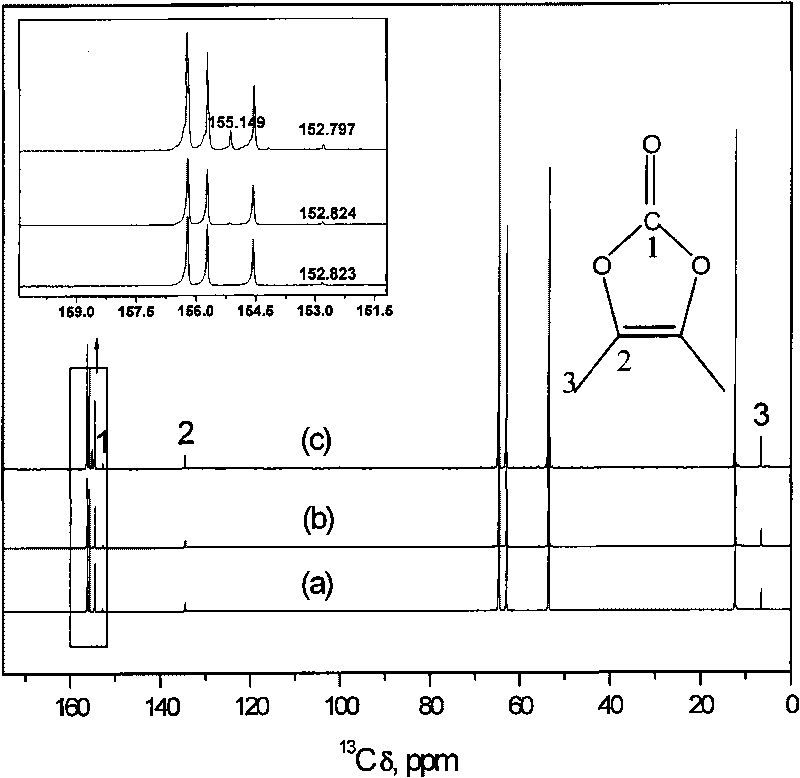

Lithium ion secondary battery electrolyte

InactiveCN103887563AImprove initial discharge capacityImprove cycle lifeSecondary cellsOrganic electrolytesPhosphoric Acid EstersSolid state electrolyte

The invention discloses lithium ion secondary battery electrolyte comprising a non-aqueous solvent and lithium salt dissolved into the non-aqueous solvent, wherein non-aqueous solvent contains cyclic phosphoric ester accounting for 0.5-15% of the total mass of non-aqueous solvent. Cyclic phosphoric ester has the structural formula as the specification, wherein n is an integer ranging from 0 to 2, and R is a straight-chain or branched-chain alkyl from C1 to C4. A functional additive used by the lithium ion secondary battery electrolyte has a relatively high reduction potential and can be used for forming a layer of compact and stable solid electrolyte passive film (SEI) in the first charging process, so that the co-intercalation of propylene carbonate (PC) to graphite can be effectively inhibited, the initial discharging capacity of a battery can be effectively increased, the cycle life of the battery can be effectively prolonged, and the high-and-low temperature performance of the battery can be effectively improved.

Owner:XIAMEN SHOUNENG TECH

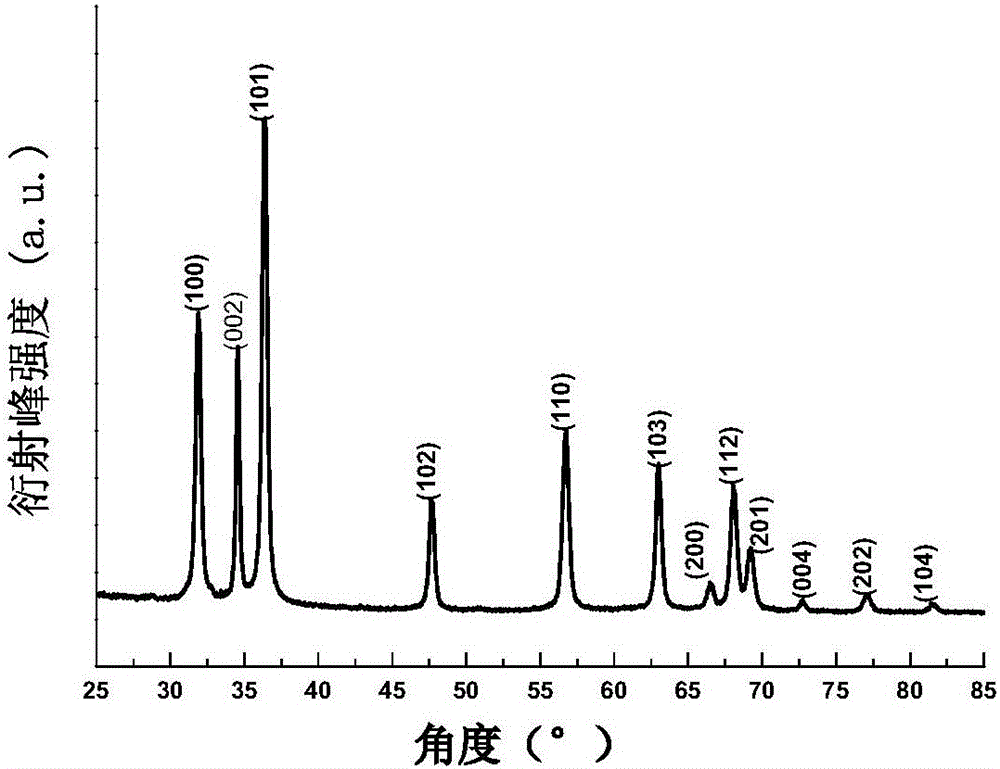

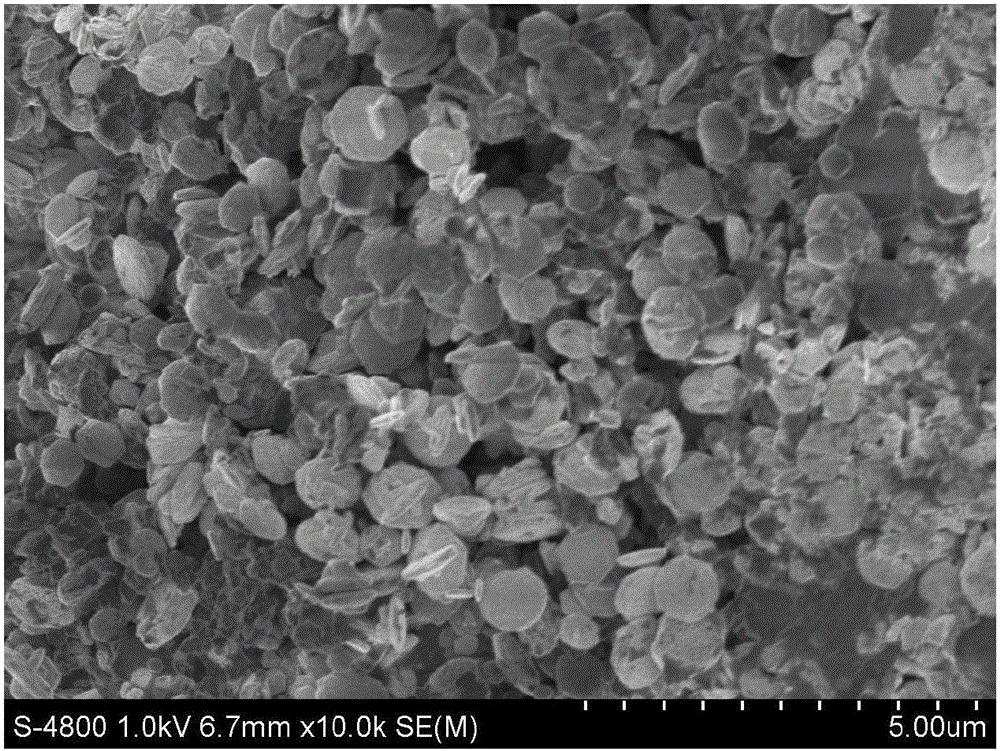

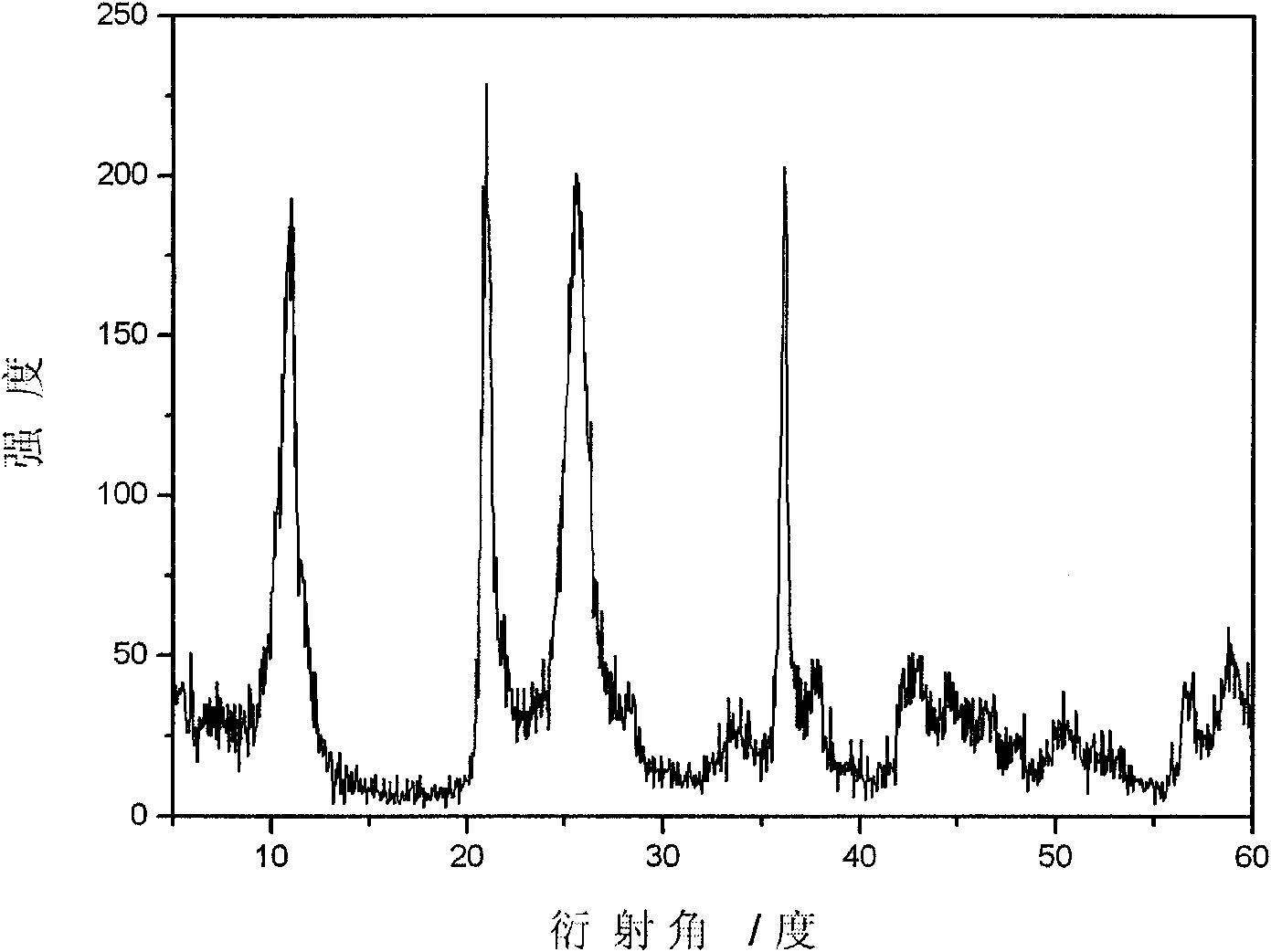

Lithium titanate particles and process for producing the lithium titante particles, MG-Containing lithium titanate particles and process for producing the MG-Containing lithium particles, negative electrode active substance particles for non-aqueous electrolyte secondary batteries, and non-aqeous electrolyte secondary battery

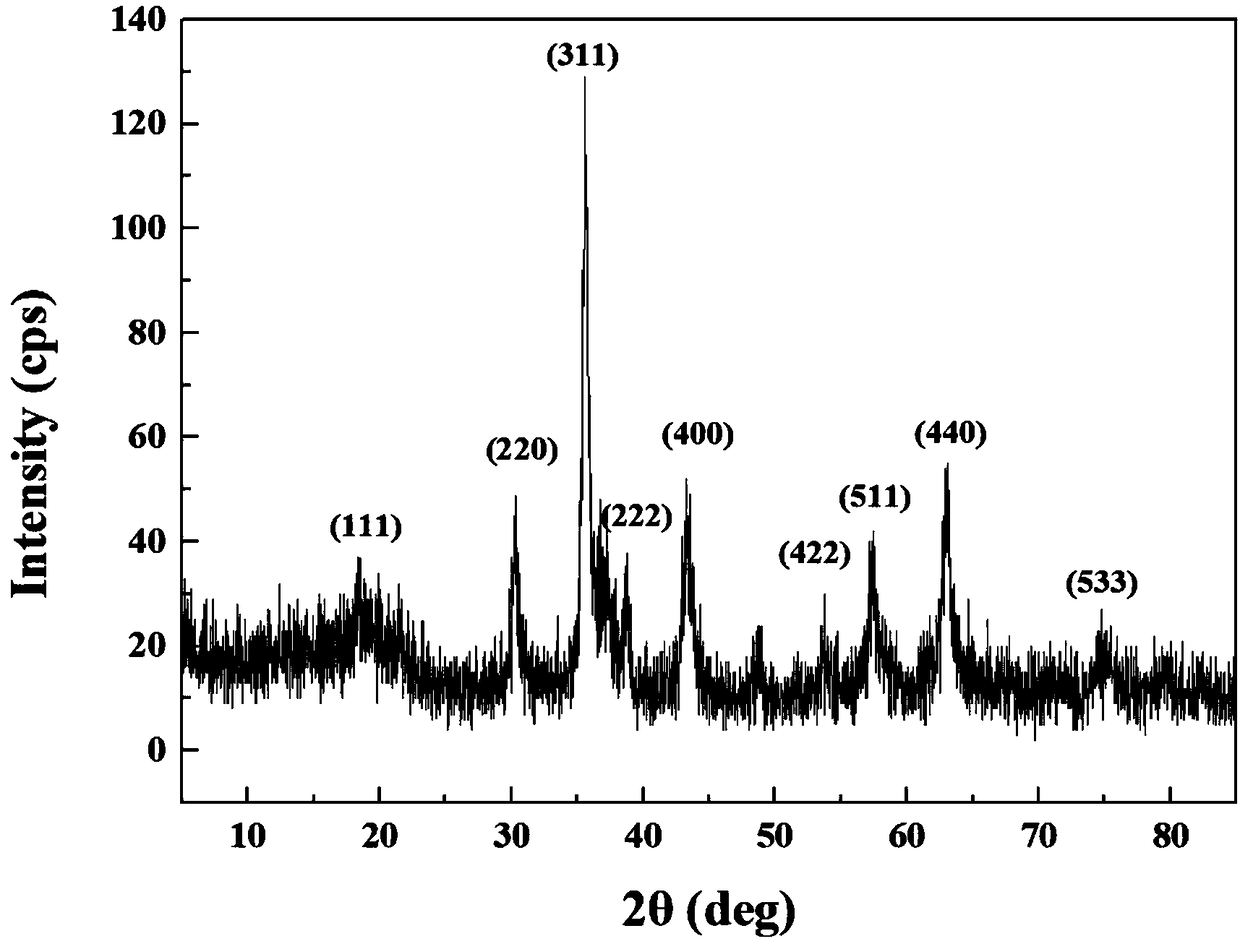

ActiveUS20130244114A1Well-balanced battery characteristicImprove output characteristicsAlkaline earth titanatesAlkali titanatesFiltrationLattice constant

According to the present invention, there are provided lithium titanate particles which exhibit an excellent initial discharge capacity and an enhanced high-efficiency discharge capacity retention rate as an active substance for non-aqueous electrolyte secondary batteries and a process for producing the lithium titanate particles, and Mg-containing lithium titanate particles. The present invention relates to lithium titanate particles with a spinel structure comprising TiO2 in an amount of not more than 1.5%, Li2TiO3 in an amount of not less than 1% and not more than 6%, and Li4Ti5O12 in an amount of not less than 94% and not more than 99% as determined according to Rietveld analysis when indexed with Fd-3m by XRD, and having a specific surface area of 7 to 15 m2 / g as measured by BET method, a process for producing lithium titanate particles comprising the steps of adding and mixing a water-soluble lithium solution into a water suspension of an oxide of titanium having a BET specific surface area of 40 to 400 m2 / g and a primary particle diameter of 5 to 50 nm and subjecting the resulting mixed suspension to aging reaction at a temperature of 50 to 100° C.; subjecting the resulting reaction product to filtration, drying and pulverization; and subjecting the obtained dry particles to heat-calcination treatment at a temperature of 550 to 800° C., and Mg-containing lithium titanate particles having a composition represented by the formula: LixMgyTizO4 wherein x, z>0; 0.01≦y≦0.20; 0.01≦y / z≦0.10; and 0.5≦(x+y) / z≦1.0, the Mg-containing lithium titanate particles having a BET specific surface area of 5 to 50 m2 / g, a spinel single phase as a crystal structure, and a lattice constant (a) represented by a value of 0.050y+8.3595<a≦0.080y+8.3595 (Å).

Owner:TODA IND

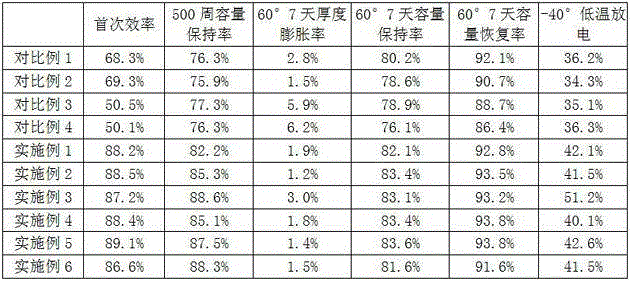

Slurry obtained using binder for battery electrodes, electrode obtained using the slurry, and lithium ion secondary battery obtained using the electrode

InactiveUS20140054496A1High initial discharge capacityExcellent characteristicSecondary cellsNon-aqueous electrolyte accumulator electrodesBinding propertiesEngineering

Provided is a slurry for lithium ion secondary battery electrodes, which has proper binding properties between active materials and between an active material and a current collector, an electrode using the slurry, and a lithium ion secondary battery using the electrode and having both a high initial discharge capacity and an excellent charge-discharge high-temperature cycle characteristic. The present invention relates to a slurry for lithium ion secondary battery electrodes, which is obtained using a binder for battery electrodes and an active material and has a pH of 3.0 to 6.0. Preferably, the slurry contains a binder for battery electrodes in an amount of 0.2 to 4.0% by mass based on the active material.

Owner:SHOWA DENKO KK

Ethylene sulfate preparation method

InactiveCN110818674AHigh purityChange cycle performanceOrganic chemistrySecondary cellsElectrolytic agentSulfate

The invention relates to an ethylene sulfate preparation method, which comprises: dissolving ethylene glycol in an aprotic organic solvent, adding an aprotic organic alkali, introducing sulfuryl fluoride, stirring while reacting, filtering after the reaction is completed, and carrying out evaporating concentrating and drying on the filtrate to obtain ethylene sulfate. According to the invention, the ethylene sulfate prepared by the method has extremely high purity of more than 99.9%, low moisture content of less than or equal to 20 ppm and low acid value of less than or equal to 10 ppm, and effectively changes the influence of the moisture and the acid value in an electrolytic solution on the cycle performance and the storage stability of a battery.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

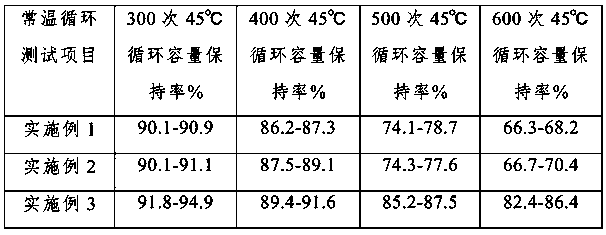

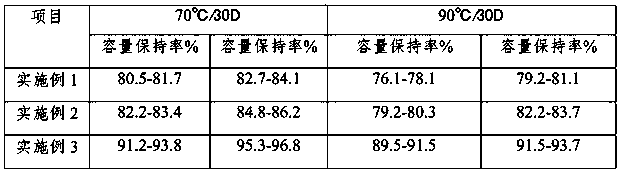

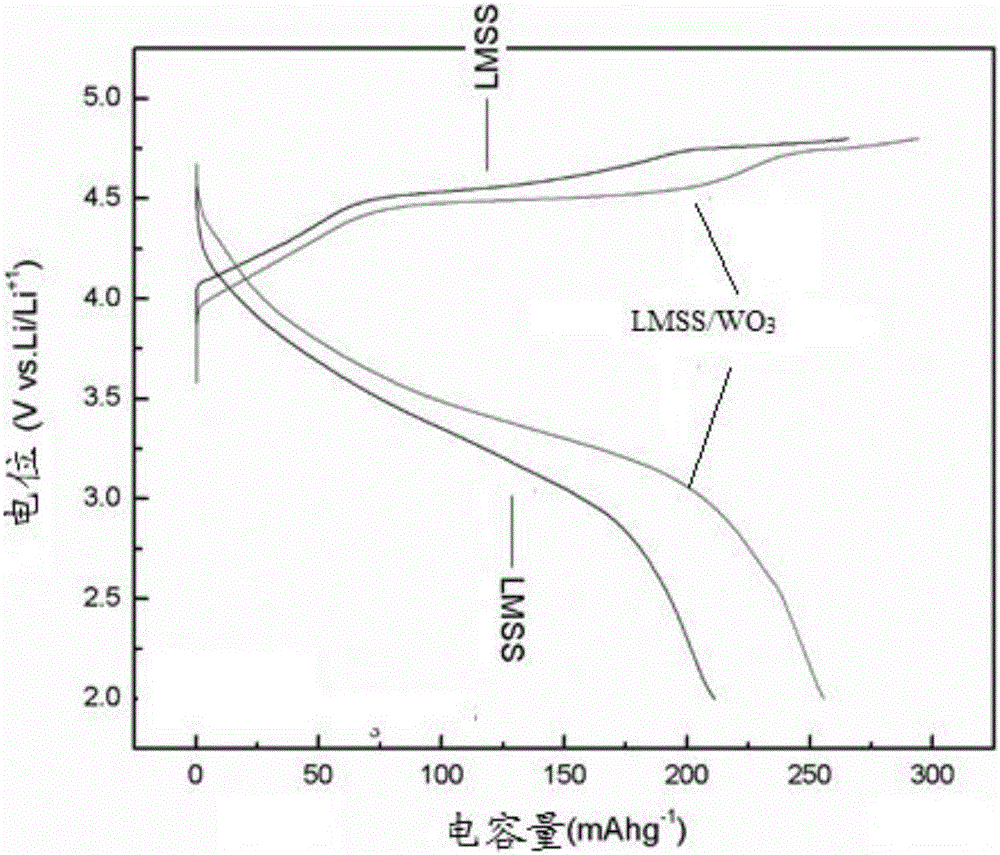

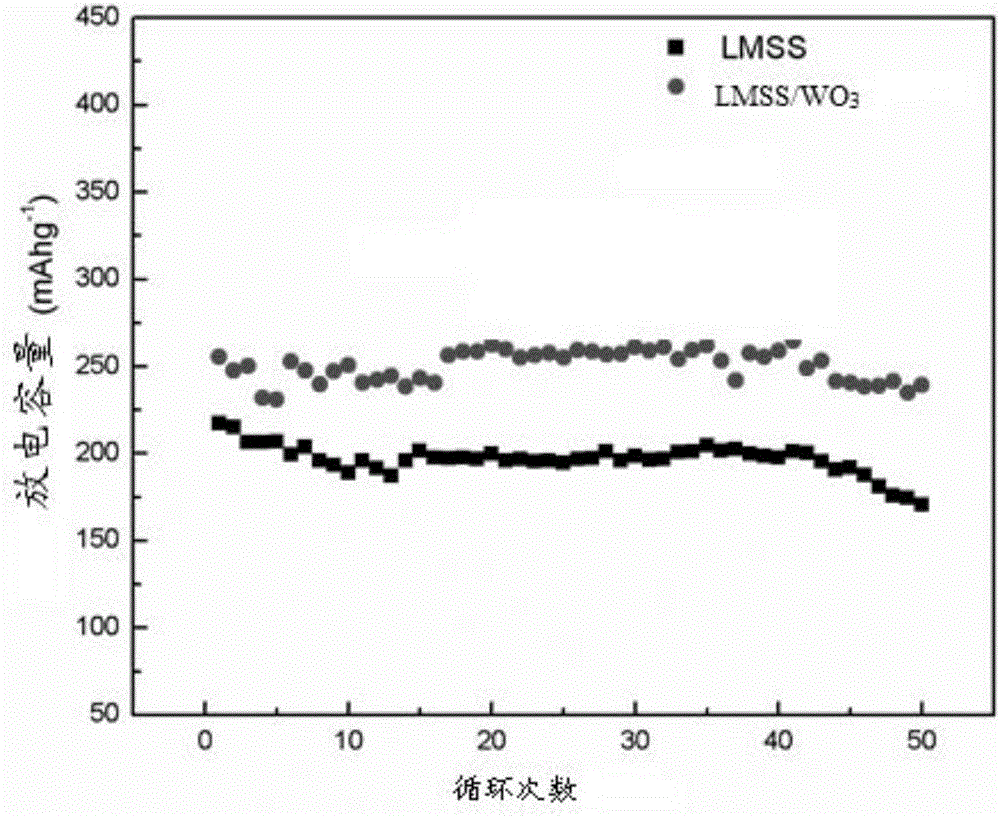

Lithium secondary battery lithium-rich cathode composite and preparation method thereof

InactiveCN105870438AImprove initial discharge capacityImprove cycle performanceCell electrodesNickel saltCobalt salt

The invention provides a preparation method of a lithium secondary battery lithium-rich cathode composite, comprising the following steps: subjecting a reaction solution containing nickel salts, cobalt salts, manganese salts, sodium carbonate and a chelating agent to precipitation to obtain a precursor; pre-calcining the precursor to obtain a pre-calcined precursor; subjecting a mixture containing the pre-calcined precursor and lithium salts to first calcining to obtain a base material; subjecting a mixture of the base material with tungsten salts to second calcining to obtain WO3-coated lithium-rich cathode composite (LMSS / WO3). Detection results according to embodiments show that the LMSS / WO3 obtained herein is up to 255 mAh / g in initial discharge specific capacity that is 239 mAh / g after 50 cycles, with capacity holding rate being 93%.

Owner:XIANGTAN UNIV

Electrolyte adopting propylene carbonate as main solvent

InactiveCN103985905AImprove initial discharge capacityImprove cycle lifeSecondary cellsOrganic solventDecomposition

The invention relates to an electrolyte adopting propylene carbonate as a main solvent, which relates to the electrolyte of a lithium ion battery. The electrolyte contains lithium salt, organic solvent and additive; the organic solvent contains propylene carbonate and chain-type carbonic ester; the additive contains a film-forming additive A and an additive B for inhibiting the embedding of the propylene carbonate; the electrolyte contains the following components by mass percent: 10 to 18 percent of lithium salt, 25 to 60 percent of propylene carbonate, 15 to 60 percent of chain-type carbonic ester, 0.5 to 5 percent of additive A and 0.1 to 10 percent of the additive B. Sulfite is used as the additive of the lithium ion battery electrolyte; since the sulfite is high in reduction potential which is higher than the decomposition potential of the propylene carbonate, the sulfite forms a layer of stable and compact SEI film on the surface of graphite before the decomposition of the propylene carbonate, the propylene carbonate solvent can be effectively prevented from being collectively embedded into the graphite layer along with the lithium ion, the initial discharging capacity of the battery is improved, and the cycle life of the battery is prolonged.

Owner:XIAMEN UNIV +1

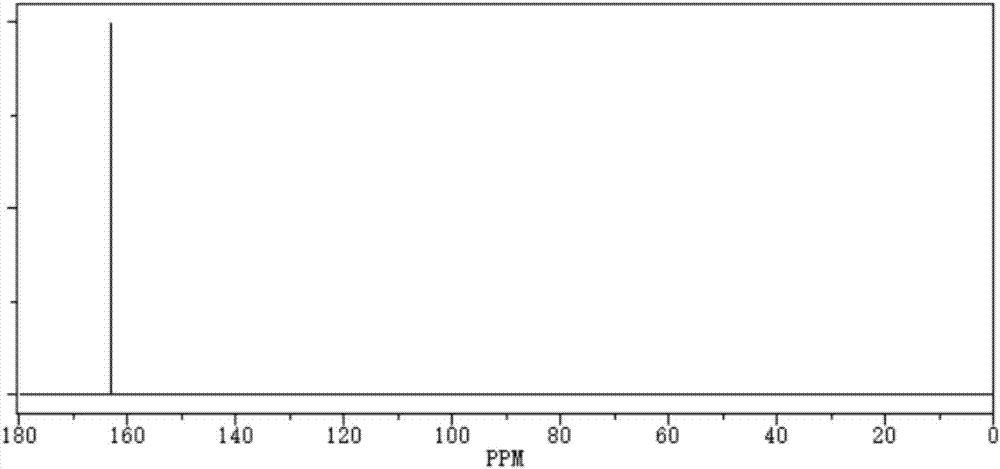

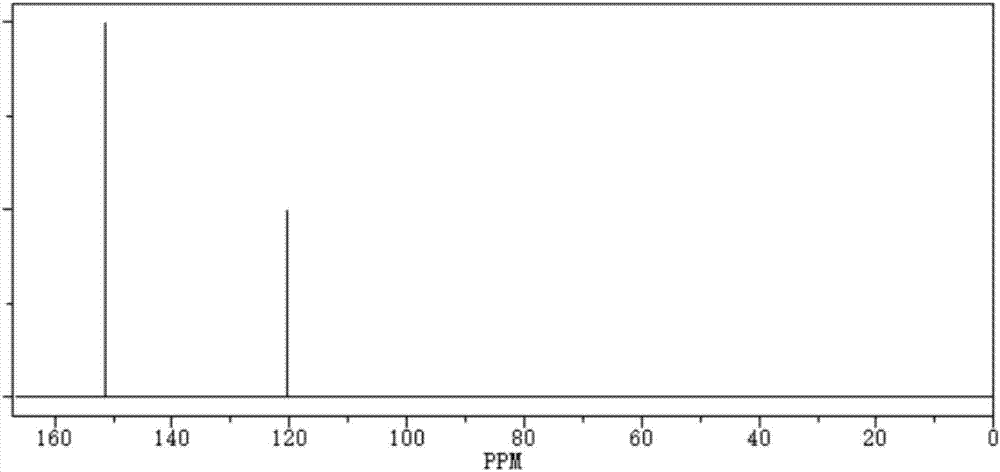

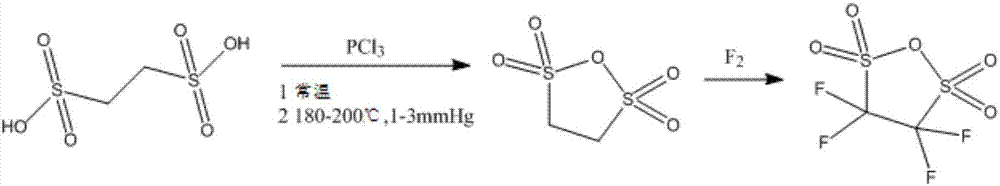

Preparation method for perfluoro-substituted disulfonic anhydride

InactiveCN107973773AEasy to prepareLess investmentOrganic chemistrySecondary cellsMolecular sievePhosphorus trichloride

The invention provides a preparation method for perfluoro-substituted disulfonic anhydride, belonging to the technical field of battery electrolyte additives. The preparation method comprises the following steps: A, with ethanedisulfonic acid or propanedisulfonic acid as a raw material, adding a molecular sieve into the ethanedisulfonic acid or the propanedisulfonic acid, allowing an obtained mixture to react with phosphorus trichloride at a normal temperature for 5 h, then carrying out heating to 180 to 200 DEG C, continuing a reaction at a vacuum degree of 1 to 3 mmHg for 2 to 5 h, then carrying out extraction through dichloromethane, and carrying out crystallization so as to obtain ethanedisulfonic anhydride or propanedisulfonic anhydride; and B, introducing fluorine gas into the ethanedisulfonic anhydride or the propanedisulfonic anhydride obtained in the step A, and controlling a mol ratio of the ethanedisulfonic anhydride / the propanedisulfonic anhydride to the fluorine gas to be1: (4-10) so as to prepare the perfluoro-substituted disulfonic anhydride. The preparation method provided by the invention is simple; and the perfluoro-substituted disulfonic anhydride prepared by using the preparation method provided by the invention has high yield and high purity, and has good effects when applied to battery electrolytes.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Method for improving capacitance of lithium secondary battery

InactiveCN101136497AIncrease capacityGood dispersionElectrode manufacturing processesFinal product manufactureCapacitanceLithium

This invention discloses a method for increasing capacity of Li-secondary batteries including: mixing a solvent, adhesive, a positive active material and a conductive agent to prepare positive slurry in the following three steps: 1, putting part of the solvent into the adhesive and mixing them fully to dissolve them completely and then adding the conductive agent and mixing them fully, 2, putting the rest solvent into a positive active material to mix them fully and the positive active material is wet uniformly, 3, fully mixing the products got from step 1 and 2 fully, which increases dispersion degree of the conductive agent in the positive active material.

Owner:湖北盐光能源科技有限公司

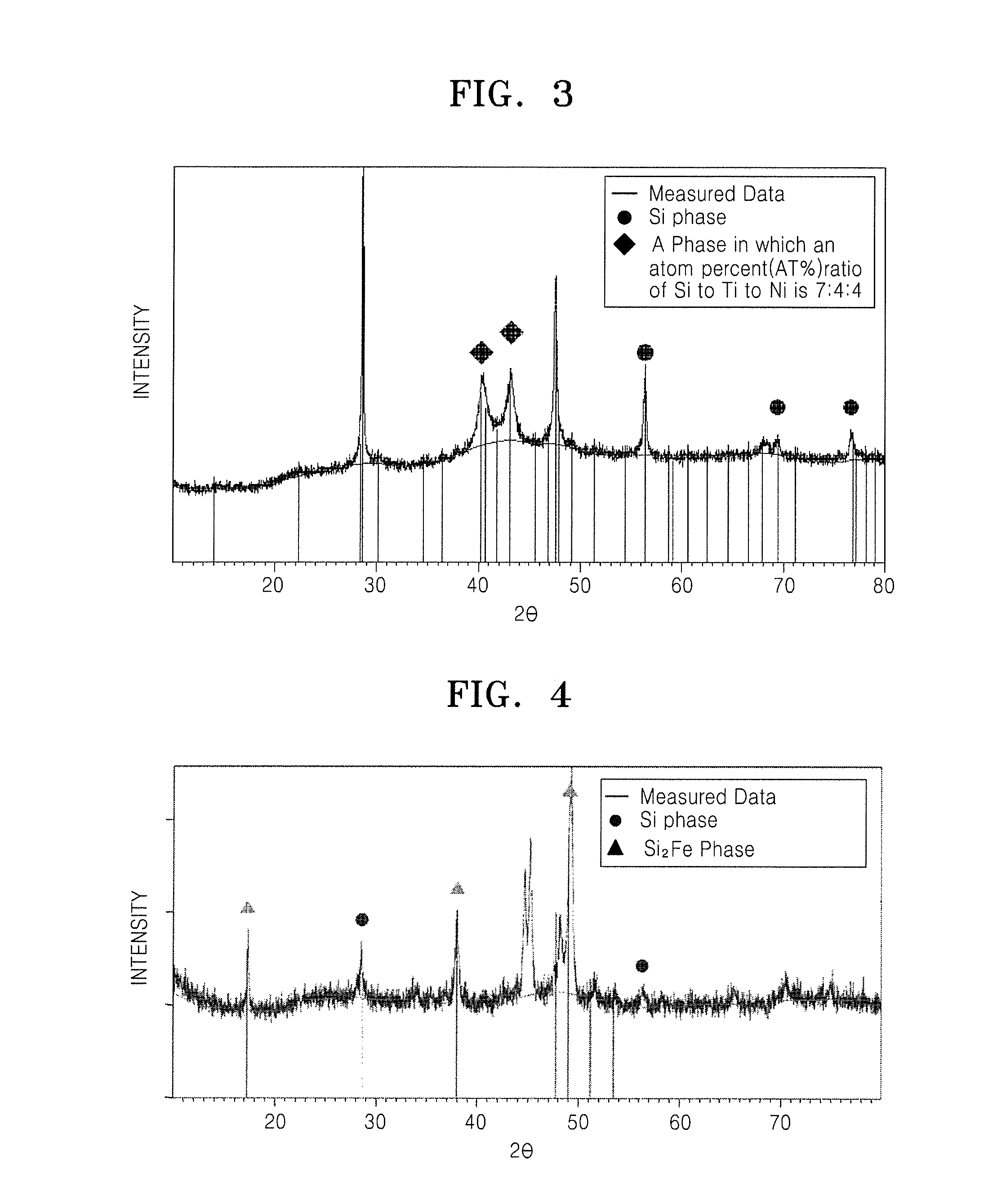

Negative electrode material for lithium ion secondary battery, negative electrode for lithium ion secondary battery, and lithium ion secondary battery

ActiveUS20150270540A1Improve discharge efficiencyEasy dischargeSilicaElectrode carriers/collectorsLithiumX-ray

A negative electrode material for a lithium ion secondary battery includes a silicon oxide and having a diffraction peak attributable to Si (111) in an X-ray diffraction spectrum, in which a size of a silicon crystallite calculated from the diffraction peak is from 2.0 nm to 8.0 nm.

Owner:RESONAC CORP

Electrolyte of high-voltage fast-charging lithium ion battery and lithium ion battery

InactiveCN111193071ALow viscosityImprove wettabilityFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentLithium-ion battery

The invention discloses an electrolyte of a high-voltage fast-charging lithium ion battery and the lithium battery. The electrolyte comprises a non-aqueous organic solvent, an electrolyte salt and anadditive, and the mass percentages of the non-aqueous organic solvent, the electrolyte salt and the additive in the electrolyte are 65%-90%, 10%-20% and 0-15% respectively. The electrolyte can improvethe normal-temperature quick charge cycle performance, the high-temperature storage performance and the low-temperature discharge performance of the high-voltage battery at the same time. The lithiumion battery prepared by adopting the electrolyte has lower surface density, is beneficial to reducing the impedance of the lithium ion battery, is smoother in lithium ion migration, can effectively improve the rate charge-discharge performance, and obviously improves the low-temperature discharge performance at the same time; the electrolyte of the high-voltage fast-charging lithium ion battery has the relatively high charging cut-off voltage, the capacity of the lithium ion battery can be improved by about 15%, and energy density reduction caused by surface density reduction is made up; andcompared with a conventional battery, the lithium ion battery has wider tabs, so that the ohmic impedance of the lithium ion battery is effectively reduced to facilitate electron transmission.

Owner:CHONGQING VDL ELECTRONICS

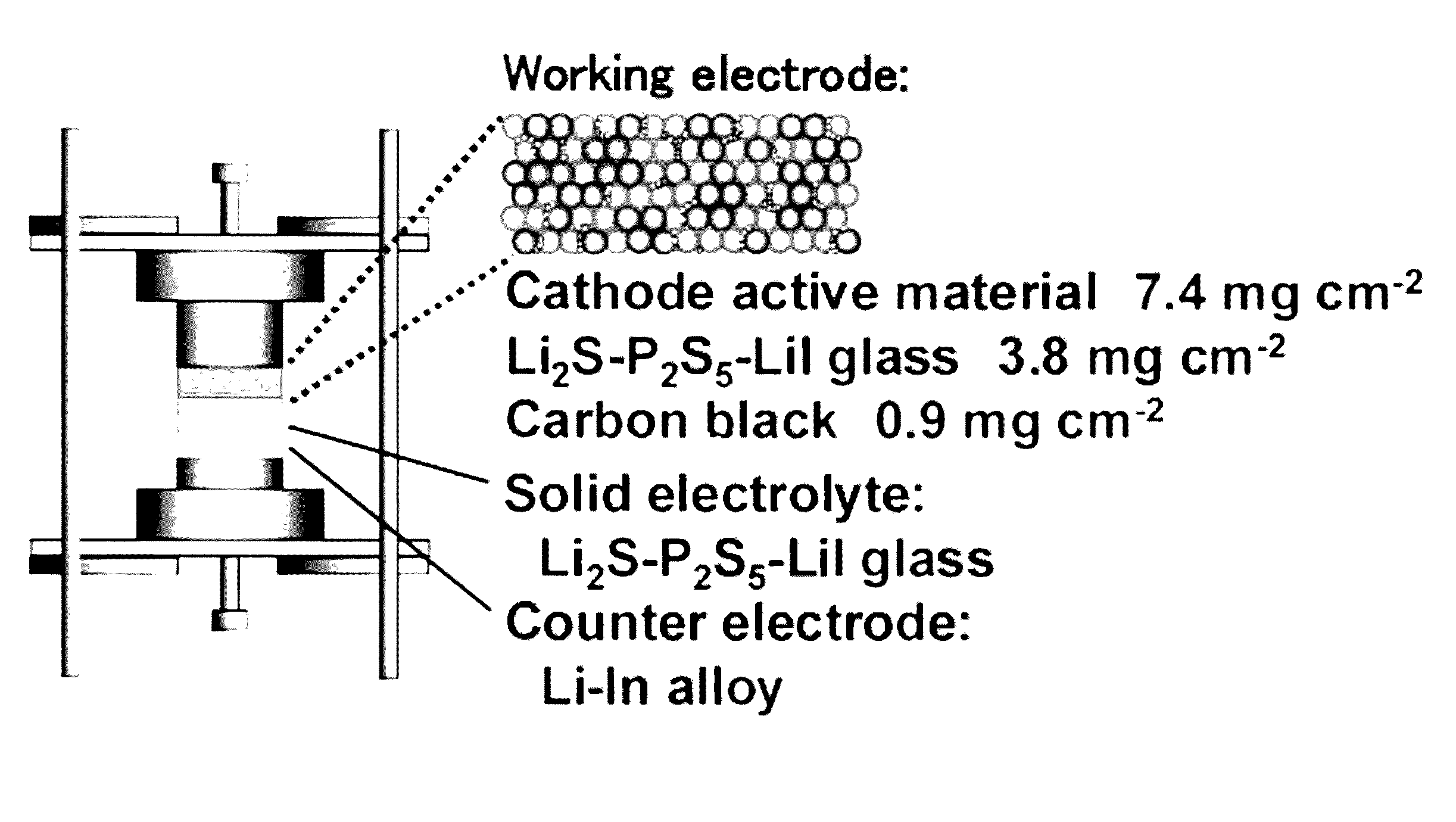

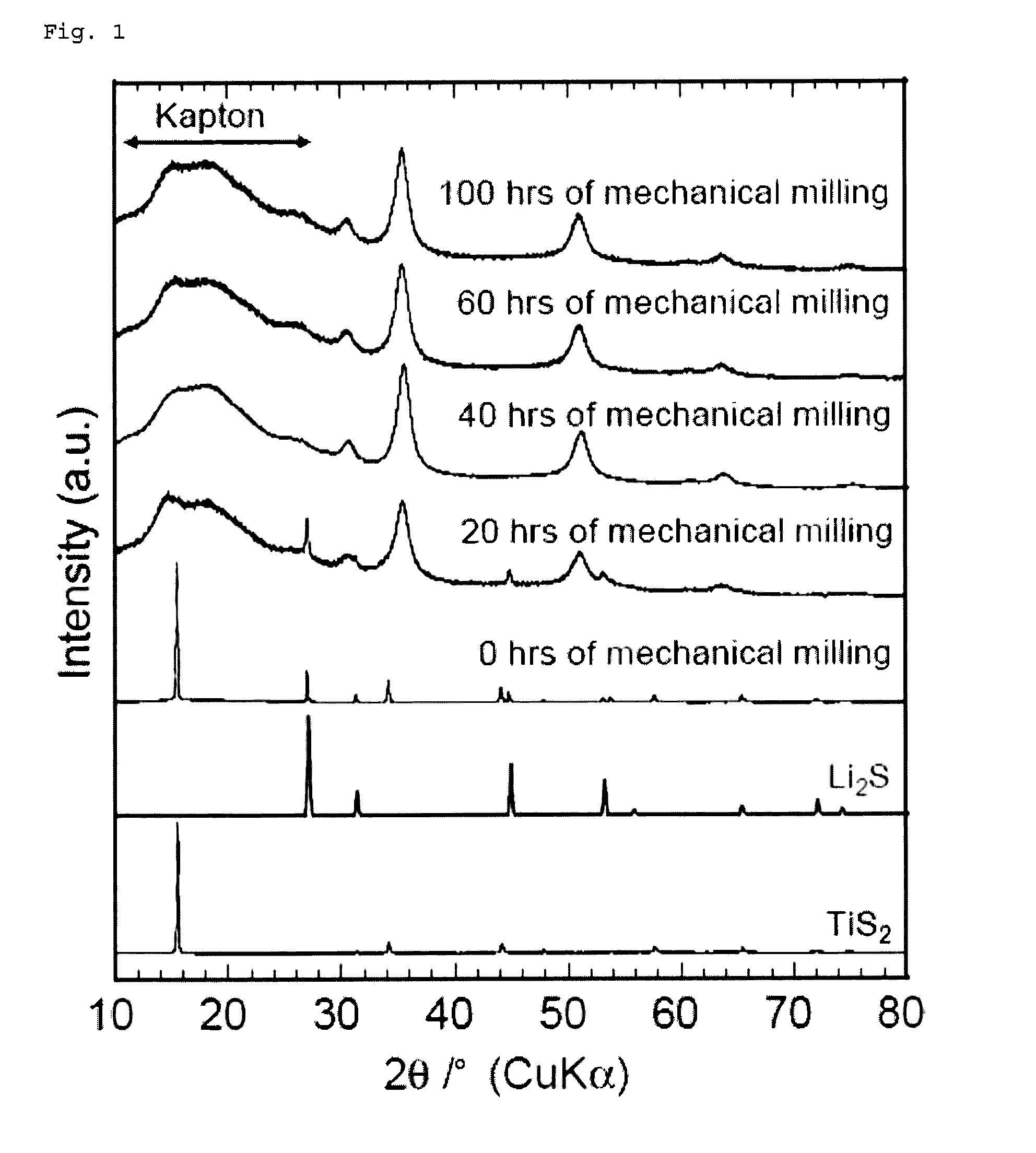

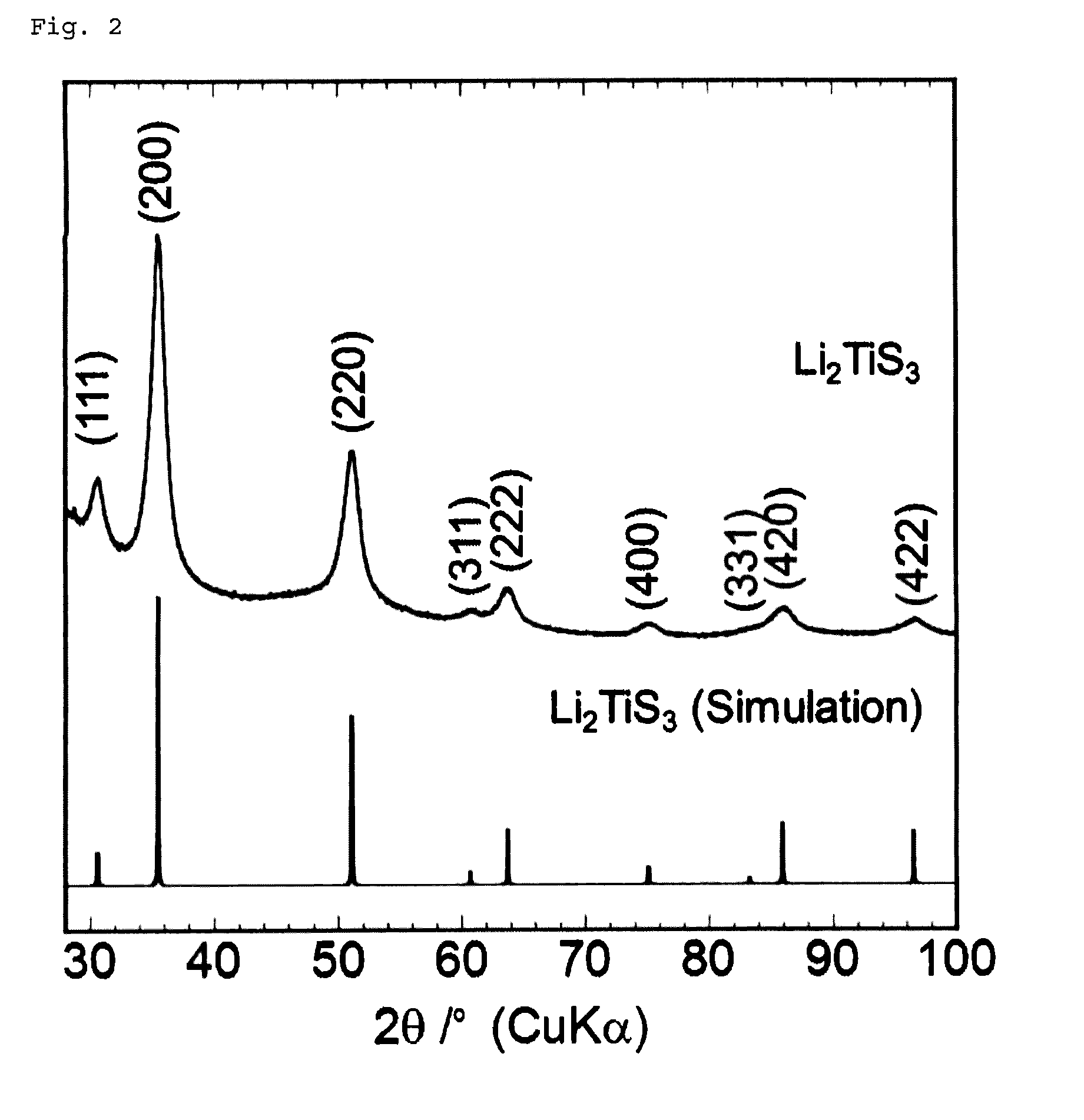

Lithium titanium sulfide, lithium niobium sulfide, and lithium titanium niobium sulfide

ActiveUS20160285097A1High charge and discharge capacityStable structurePositive electrodesTitanium compoundsNiobiumSulfur

The present invention provides a novel lithium titanium sulfide, lithium niobium sulfide, or lithium titanium niobium sulfide that contains a sulfide containing lithium, titanium and / or niobium, and sulfur as constituent elements, and that has excellent charge-discharge performance (especially excellent charge-discharge capacity and charge-discharge potential) useful as a cathode active material or the like for lithium batteries, such as metal lithium secondary batteries or lithium-ion secondary batteries. Particularly preferred are, for example, (1) lithium titanium sulfide containing lithium, titanium, and sulfur as constituent elements and having a cubic rock salt crystal structure, (2) lithium niobium sulfide containing lithium, niobium, and sulfur as constituent elements and having a diffraction peak at a specific position in an X-ray diffractogram, and (3) lithium titanium niobium sulfide containing lithium, titanium, niobium, and sulfur as constituent elements and having a diffraction peak at a specific position in an X-ray diffractogram.

Owner:NAT INST OF ADVANCED IND SCI & TECH

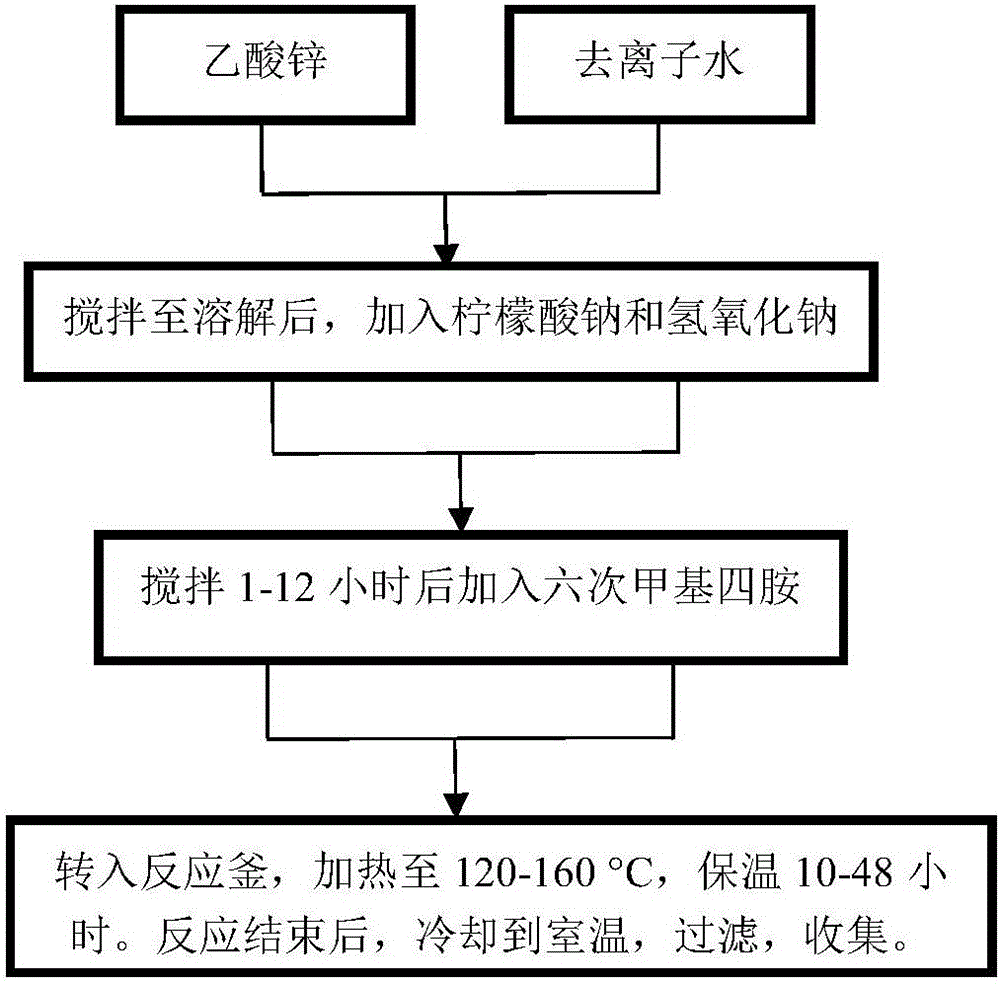

Preparation method of zinc oxide nanosheet for negative electrode of lithium-ion battery

InactiveCN105789602ASimple contact areaIncrease contact areaMaterial nanotechnologyZinc oxides/hydroxidesHexamethylenetetramineElectrochemistry

The invention provides a preparation method of a zinc oxide nanosheet for a negative electrode of a lithium-ion battery. The method comprises the following steps: (1) dissolving zinc acetate into deionized water as a precursor at a room temperature; (2) sequentially adding sodium citrate and sodium hydroxide to the solution prepared in the step (1) for stirring for 1-12 hours; (3) adding hexamethylenetetramine to the solution obtained in the step (2) and stirring and dissolving the hexamethylenetetramine, wherein the molar ratio of the zinc acetate to the sodium citrate to the sodium hydroxide to the hexamethylenetetramine is 1 to (1.8-2.1) to (1.8-2.1) to 1; and (4) transferring the solution into a reaction kettle, heating the solution to 120-160 DEG C, carrying out heat preservation for 10-48 hours, cooling the solution to a room temperature after reaction is ended, and filtering and collecting the solution to obtain a target material. The preparation method is simple to operate and low in cost; the zinc oxide nanosheet can be obtained through a one-step hydrothermal synthesis method; the contact area of the obtained zinc oxide nanosheet and an electrolyte is large; and the lithium-ion battery has relatively good electrochemical properties.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

Valve controlled lead acid cell with composite oxides additive contained in positive electrode

ActiveCN1595690AImprove initial discharge capacityExtend discharge timeLead-acid accumulatorsLead-acid accumulator electrodesEnergy technologyElectrical battery

The invention belongs to electrochemiscal energy technical field ,which concretely relates to a valve controlled lead acid battery whose positive electrode contains composite oxides, the composite oxides is formed by rare earth oxide with a certain chemical ratio and oxide of V group metal elements, the rare earth oxide is one of lanthanum department whose mass percentage is 3~9% in composite oxides and that of V group metal elements is 97~91%. Add the composite oxides into lead powder 1according the mass percentage of lead powder powder which is (0.03~1.0)%, then valve controlled lead acid battery can be manufactured. The accumulator has notably increased discharge capacity by adding the composite oxides in positive electrode, prolong its service life, and has important practical use in development of motor bicycle power source and extension of lead accumulator into other fields.

Owner:ANHUI LEOCH POWER SUPPLY

Negative electrode material for lithium ion secondary battery, negative electrode for lithium ion secondary battery, and lithium ion secondary battery

ActiveUS20150263339A1Improve initial discharge capacitySuperior in initial initial chargeSecondary cellsNegative electrodesLithiumSilicon

Owner:RESONAC CORP

Non-water electrolyte for lithium ion battery as well as preparation and application thereof

InactiveCN101702446AImprove initial discharge capacityImprove cycle performanceFinal product manufactureElectrolyte accumulators manufactureDecompositionCarbonate ester

The invention discloses a non-water electrolyte for a lithium ion battery as well as a preparation method and application thereof. In the invention, cyclic carbonate ester and chain carbonate ester are mixed; and then lithium salts and film forming additive are added in sequence to obtain the non-water electrolyte for the lithium ion battery. The non-water electrolyte is prepared by adding dimethyl vinylene carbonate, furanone or Alpha-angelica lactone in the traditional non-water electrolyte for the lithium ion battery, wherein the dimethyl vinylene carbonate, the furanone and the Alpha-angelica lactone can restrict the decomposition of the electrolyte and participate in the formation of a positive SEI film and a negative SEI film, therefore, the decomposition of the electrolyte under the high temperature can be effectively restricted, the initial discharge capacity and the circulation property of the lithium ion battery can be enhanced, and the capacity storage characteristic of the battery under the high temperature can be improved. Besides, the introduction of the dimethyl vinylene carbonate, the furanone or the Alpha-angelica lactone can also improve the thermal stability of the electrolyte. The prepared non-water electrolyte for the lithium ion battery has low cost and better application prospect.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Solvent-thermal method for preparing spring-shaped superstructural Sn(HPO4)2.H2O nanodisk

InactiveCN101559933AMild preparation conditionsSimple preparation equipmentNanostructure manufacturePhosphatesMaterials preparationPhosphoric acid

The invention provides a solvent-thermal method for preparing a spring-shaped superstructural Sn(HPO4)2.H2O nanodisk, which belongs to the category of nanometer material preparation by a wet chemical method. The method is characterized in that the method comprises the following steps of: adopting stannic salt as a raw material, and dissolving the stannic salt into anhydrous ethanol to obtain a tin salt solution; then dripping 85 weight percent strong phosphoric acid into the solution; and obtaining a spring-shaped superstructural Sn(HPO4).2H2O nanodisk powder material through the solvent-thermal treatment at a temperature of between 140 and 200 DEG C, the centrifugal washing and the drying. The method has the advantages that the method has mild preparation conditions, can obtain the spring-shaped superstructural Sn(HPO4)2.H2O nanodisk without high-temperature roasting, can control the size of the material by changing the preparation conditions, has simple equipment and process, and is easy to realize mass industrialized production.

Owner:HUAZHONG NORMAL UNIV

Negative active material, method of preparing the same, negative electrode for lithium secondary battery including negative active material, and lithium secondary battery including negative electrode

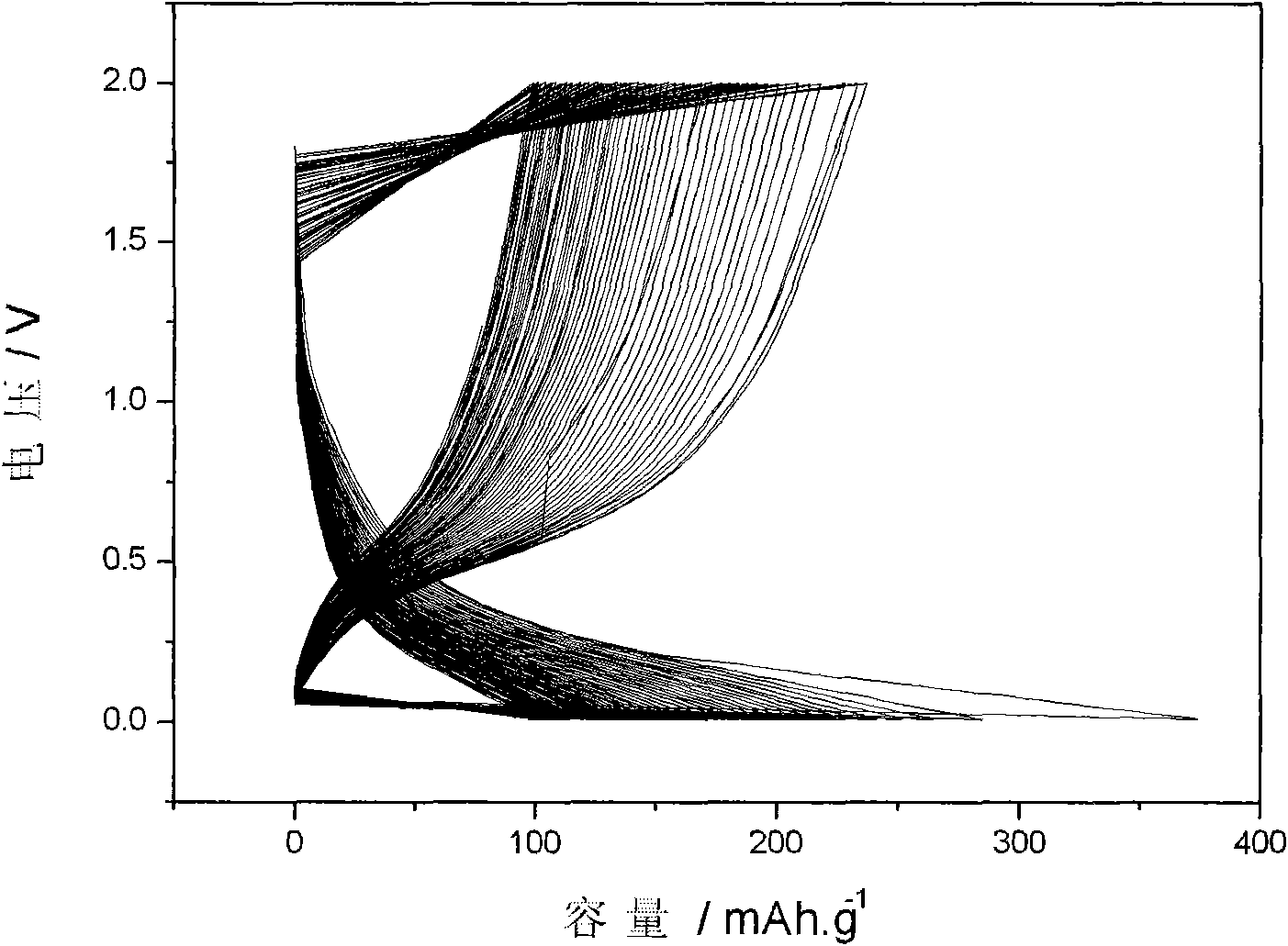

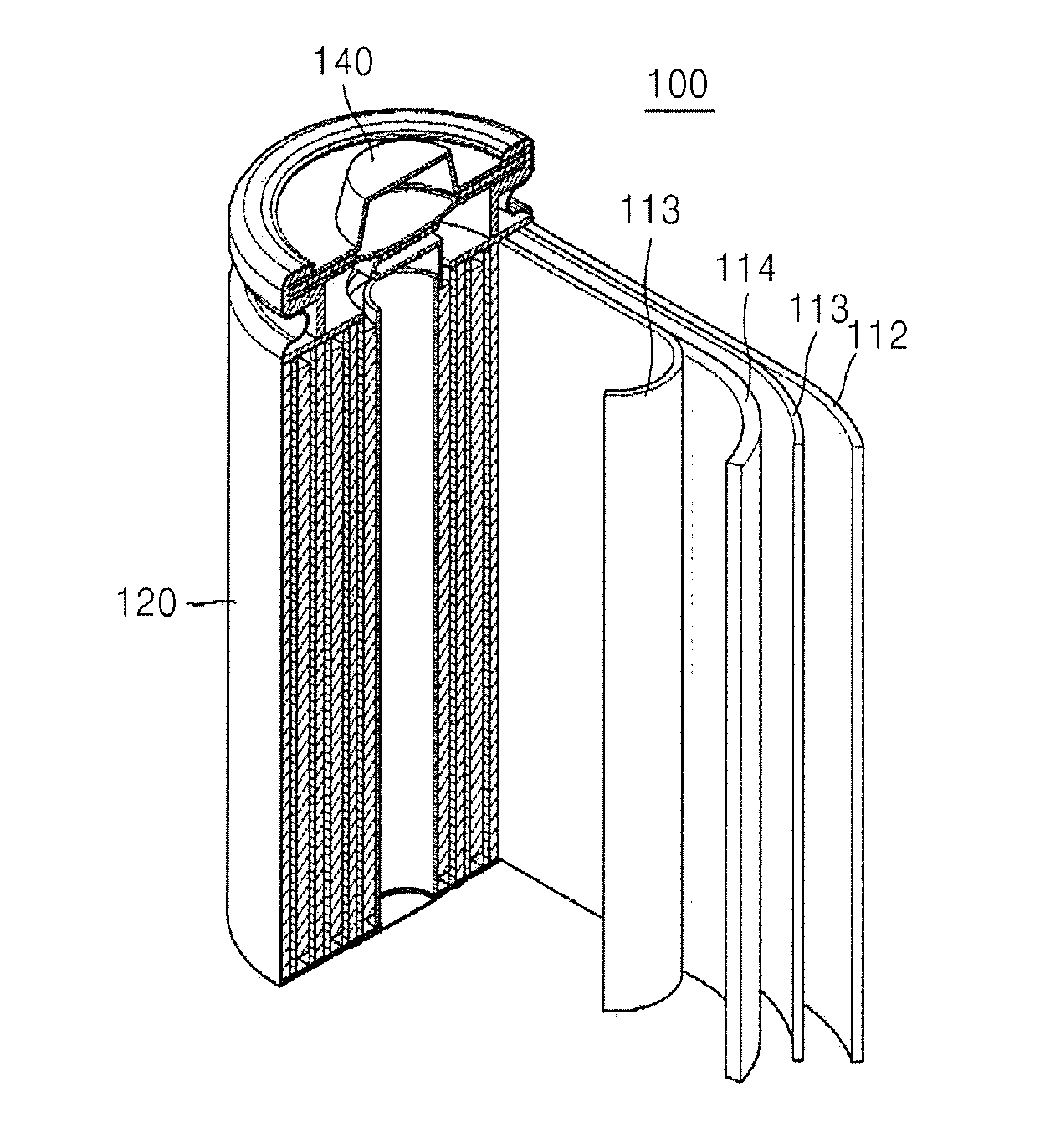

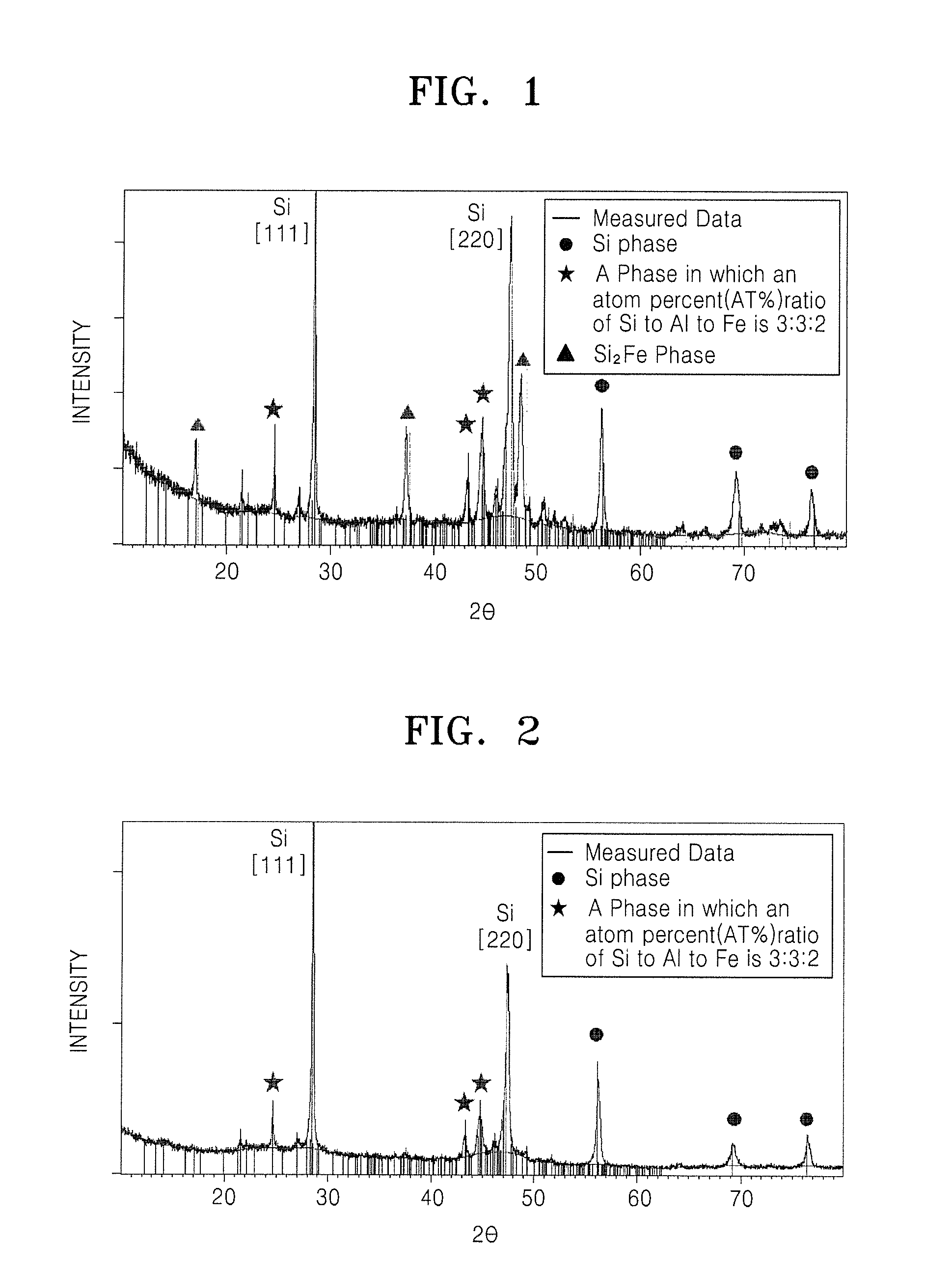

ActiveUS20130196233A1Improve initial discharge capacityExcellent cycle characteristicsMaterial nanotechnologyElectrode manufacturing processesAlloyLithium battery

A negative active material for a rechargeable lithium battery includes a Si—Al—Fe alloy represented by Formula 1. The Si—Al—Fe alloy includes a Si phase and an alloy phase, and the alloy phase includes Si, Al, and Fe in a ratio of atomic percentages of about 3:3:2:xSi-yAl-zFe Formula 1wherein 50 at %≦x≦90 at %, 5 at %≦y≦30 at %, 5 at %≦z≦30 at %, and x+y+z=100 at %.

Owner:SAMSUNG SDI CO LTD

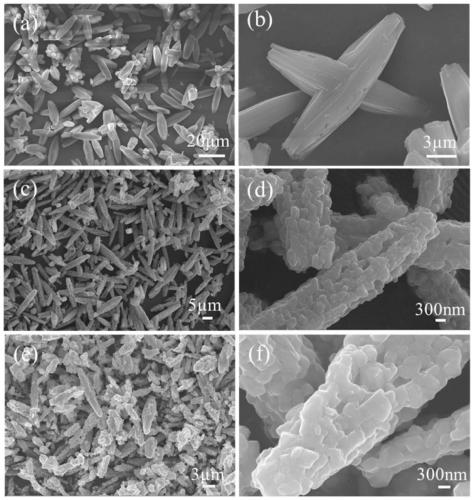

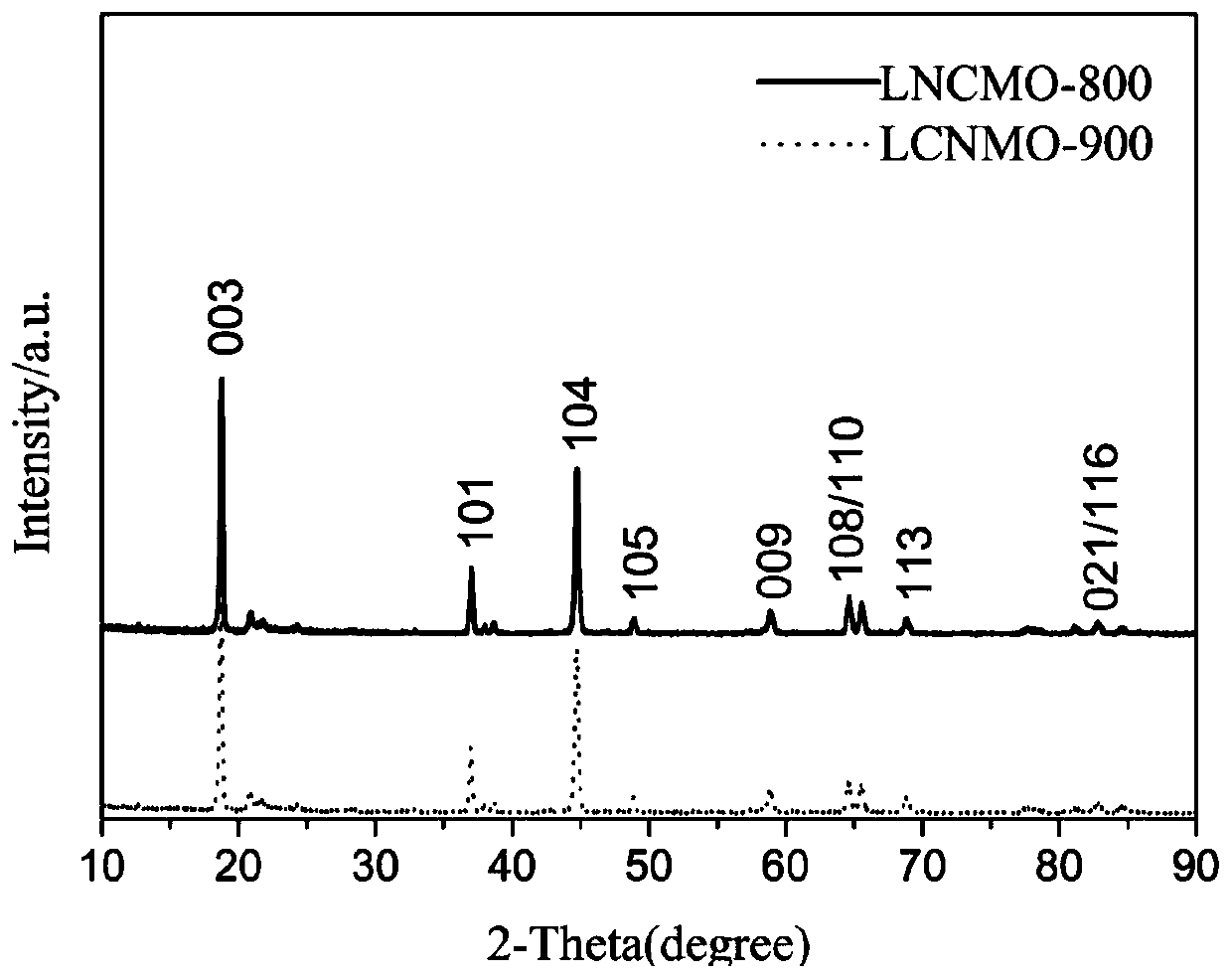

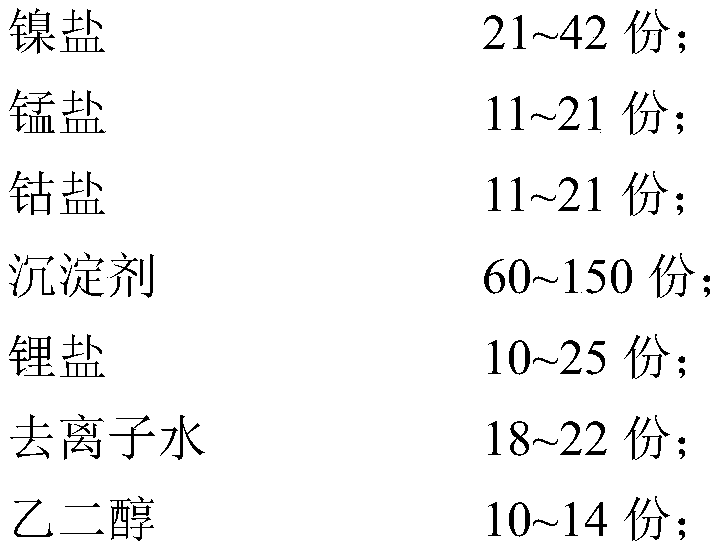

Ternary cathode material of lithium ion battery and preparation method of ternary cathode material

InactiveCN110342588AIncrease collisionSave energySecondary cellsPositive electrodesNickel saltElectrical battery

The invention provides a preparation method of a ternary cathode material of a lithium ion battery. The ternary cathode material is characterized by comprising the following preparation raw materials:21-42 parts of a nickel salt, 11-21 parts of a manganese salt, 11-21 parts of a cobalt salt, 60-150 parts of a precipitant, 10-25 parts of a lithium salt, 20 parts of deionized water and 12 parts ofethylene glycol. The preparation method comprises the following steps: step 1, adding the nickel salt, the manganese salt and the cobalt salt into the deionized water, performing stirring to form a salt solution, mixing the precipitant and the ethylene glycol, performing stirring to form a precipitant solution, mixing the salt solution and the precipitant solution, performing stirring, performinga microwave hydrothermal reaction at 160-200 DEG C for 30 min, and after the reaction product is cooled, taking out the reaction product to obtain a spindle-shaped precursor; and step 2, mixing the spindle-shaped precursor obtained in the step 1 and the lithium salt, putting the mixture into a muffle furnace, performing heat preservation at 800-900 DEG C for 12-24 h, and performing cooling to obtain the ternary cathode material of the lithium ion battery. The ternary cathode material provided by the invention has uniform morphology, a smaller particle size, a high energy density, excellent cycle performance and short consumed time.

Owner:SHANGHAI INST OF TECH

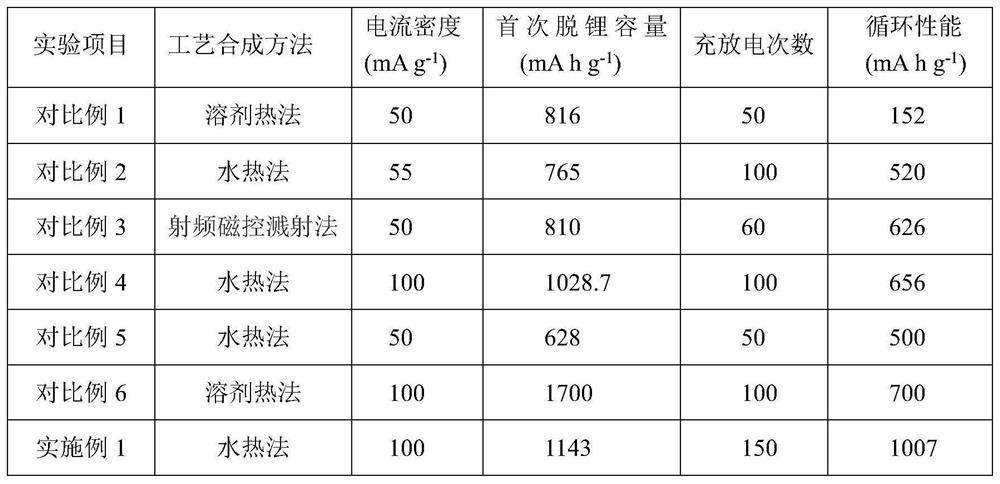

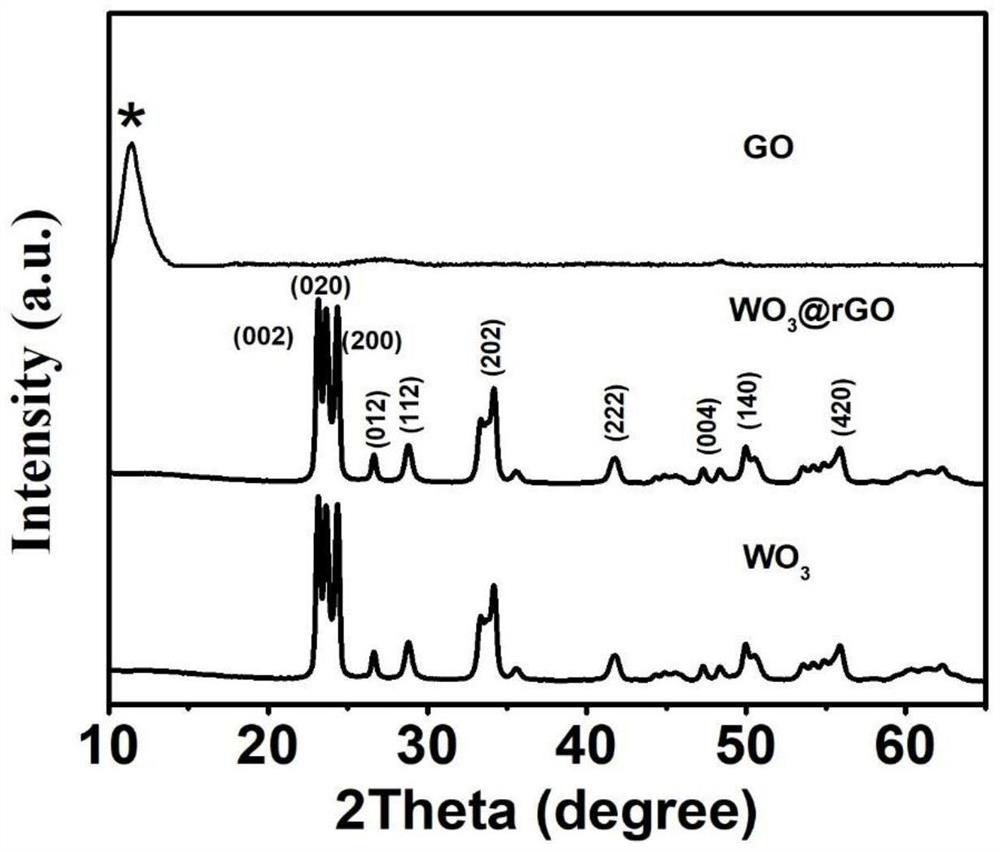

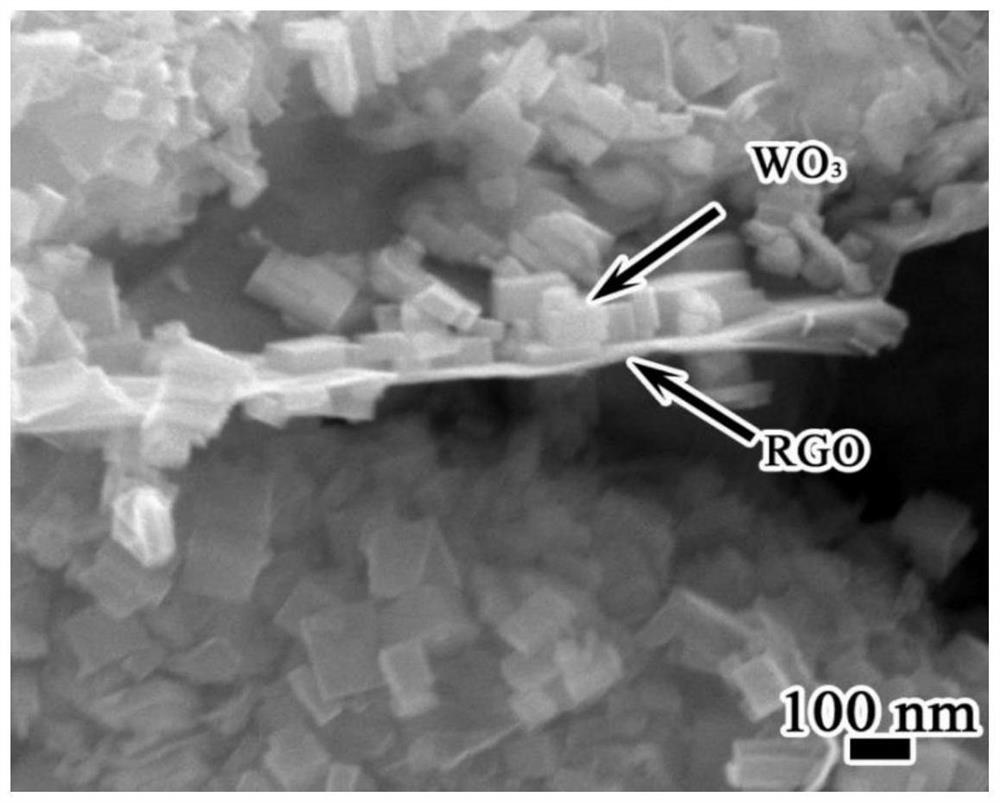

Preparation and application of two-dimensional-structure tungsten trioxide coated graphene negative electrode material

PendingCN112938952AImprove initial discharge capacityImprove electrochemical performanceCarbon compoundsTungsten oxides/hydroxidesElectrical batteryNitrogen gas

The invention discloses a preparation method and application of a graphene-coated tungsten trioxide negative electrode material with a two-dimensional sheet structure. The chemical general formula of the composite material is WO3@rGO. The preparation method comprises the following steps: (1) preparing a graphene dispersion liquid; (2) regulating and controlling the pH value of a mixed solution of a sodium tungstate metal source liquid and the graphene dispersion liquid; (3) synthesizing a WO3@rGO composite material precursor in one step by a hydrothermal synthesis method; and (4) carrying out heat treatment on the powder material in a nitrogen atmosphere to obtain a final product WO3@rGO. The three problems of poor cycling stability, low reversible cycling specific capacity and unstable structure of the material in the charging and discharging process of the transition metal oxide trioxide negative electrode material can be effectively solved. The result shows that the lithium ion deintercalation / intercalation capacity and the cycling stability of the tungsten trioxide single electrode serving as the negative electrode of a lithium ion battery are effectively improved by compounding the tungsten trioxide with the two-dimensional sheet structure and the graphene.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com