Preparation method for coated silicon/carbon/graphite composite negative electrode material

A technology of negative electrode material and graphite, applied in the field of preparation of silicon/carbon/graphite composite negative electrode material, achieves the effects of high initial charge and discharge efficiency, high initial discharge capacity and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

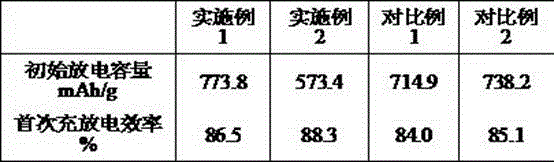

Examples

Embodiment 1

[0018] Will D 50 Micron-sized silicon powder of 1.5 µm and citric acid of 1% by mass of the silicon powder are mixed, added to deionized water, and ball-milled in a high-energy ball mill for 4 hours to obtain a uniformly dispersed slurry; the mass ratio of silicon powder, artificial graphite and glucose is 1 :3:1, resin arabic accounted for 4% of the mass of the mixture, the D 50 Mix 8µm artificial graphite, glucose and Arabic resin, add it into deionized water, stir well, then mix with the aforementioned silicon slurry, continue stirring evenly; at the inlet air temperature of 350°C, the outlet air temperature of 150°C, the speed of the feed pump 25rpm, spray pressure 0.25MPa, spray dry the above mixed slurry to obtain the silicon / carbon / graphite precursor; place the silicon / carbon / graphite precursor in a tube furnace, under the protection of nitrogen, at a rate of 5°C / min Raise the temperature to 600°C, keep it warm for 6 hours, cool down to 300°C at a rate of 5°C / min, and ...

Embodiment 2

[0021] Will D 50 The micron silicon powder of 80nm and the citric acid of silicon powder quality 1% are mixed, add deionized water, ball mill 4h in the high-energy ball mill, obtain the evenly dispersed slurry; According to silicon powder, artificial graphite and glucose mass ratio is 1: 3:0.8, resin arabic accounted for 4% of the mass of the mixture, the D 50 Mix 8µm artificial graphite, glucose and Arabic resin, add it into deionized water, stir well, then mix with the aforementioned silicon slurry, continue stirring evenly; at the inlet air temperature of 350°C, the outlet air temperature of 150°C, the speed of the feed pump 25rpm, spray pressure 0.25MPa, spray dry the above mixed slurry to obtain the silicon / carbon / graphite precursor; place the silicon / carbon / graphite precursor in a tube furnace, under the protection of nitrogen, at a rate of 5°C / min Heat up to 1100°C, hold for 3 hours, cool down to 300°C at a rate of 5°C / min, and cool to room temperature with the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com