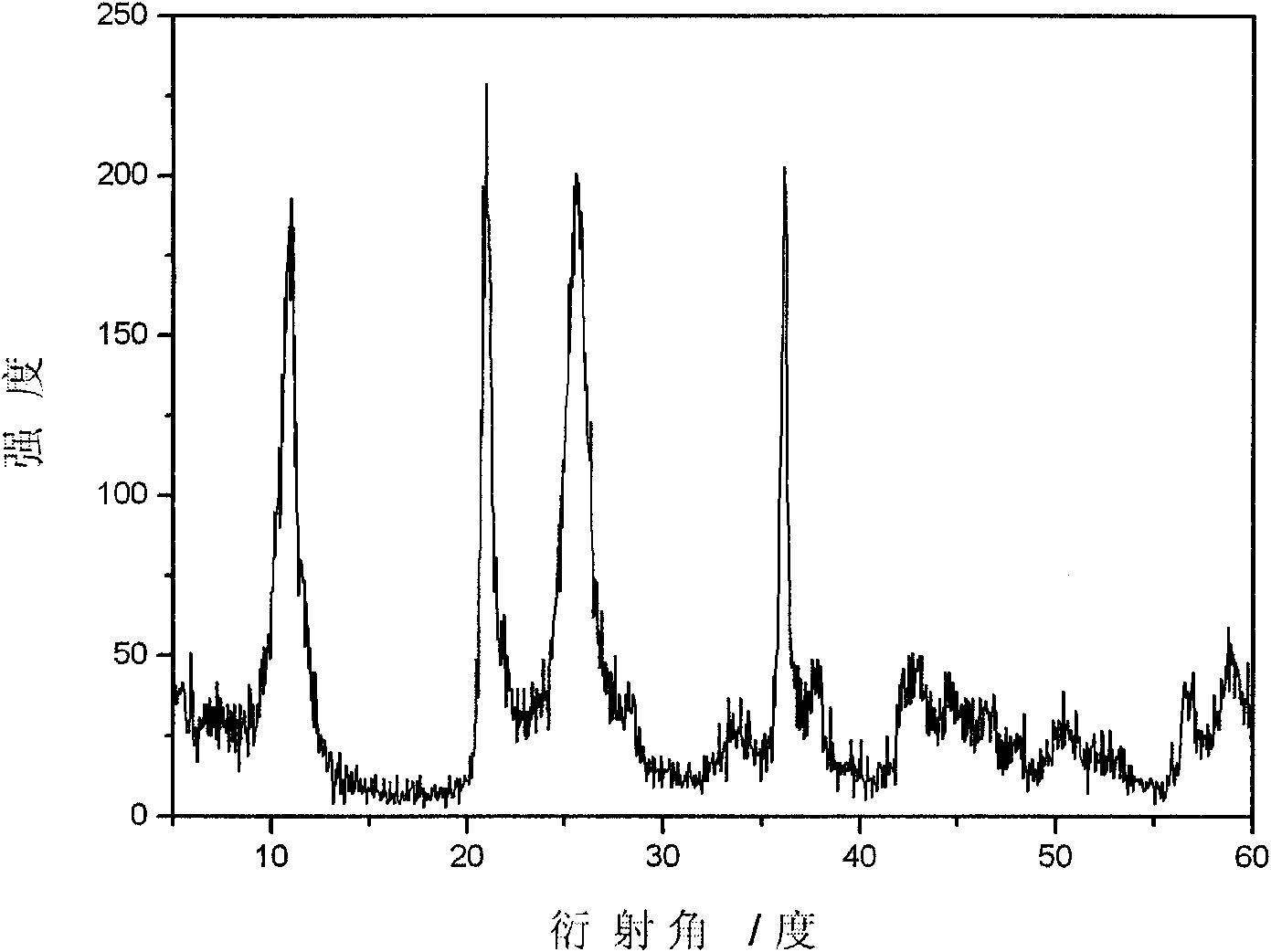

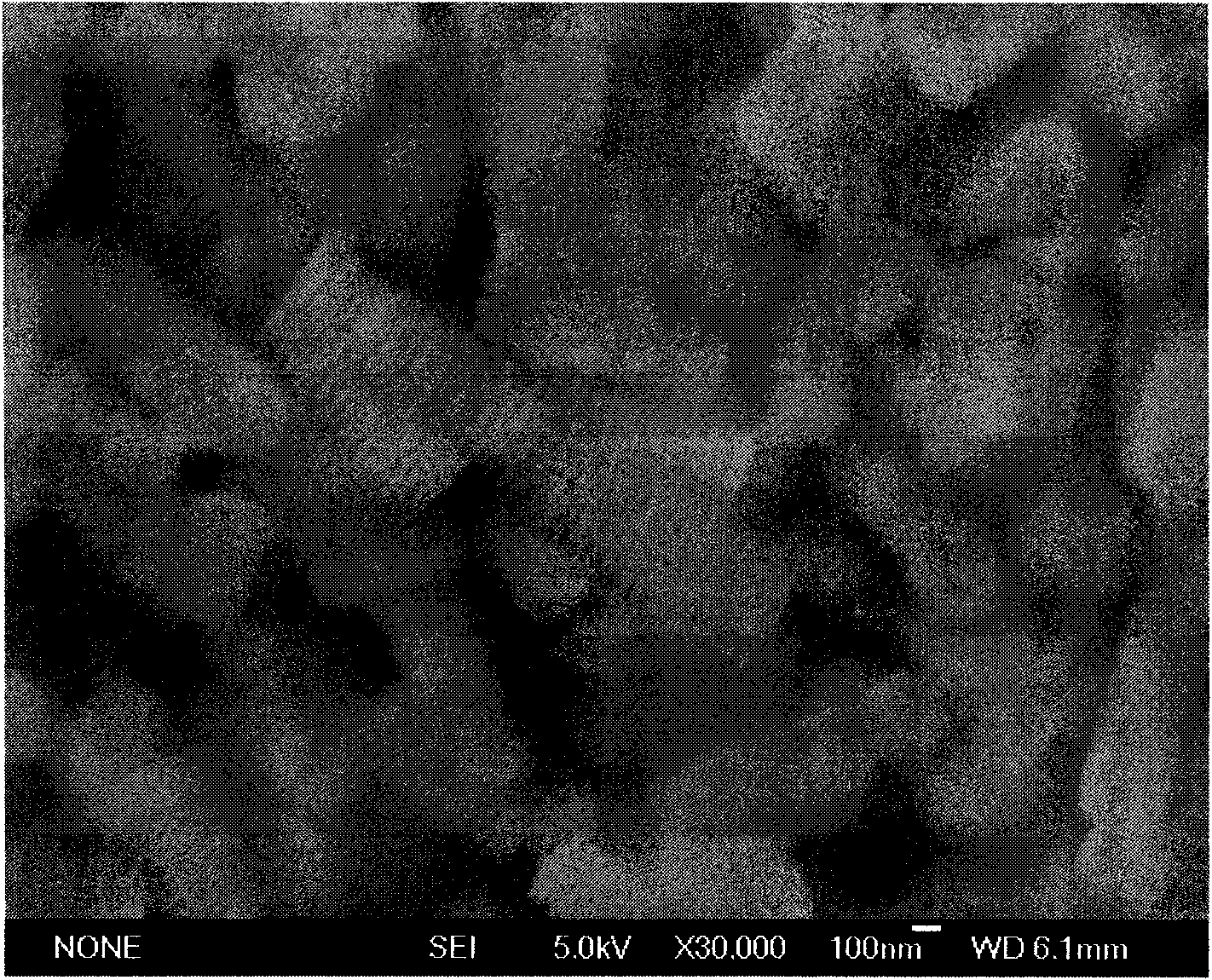

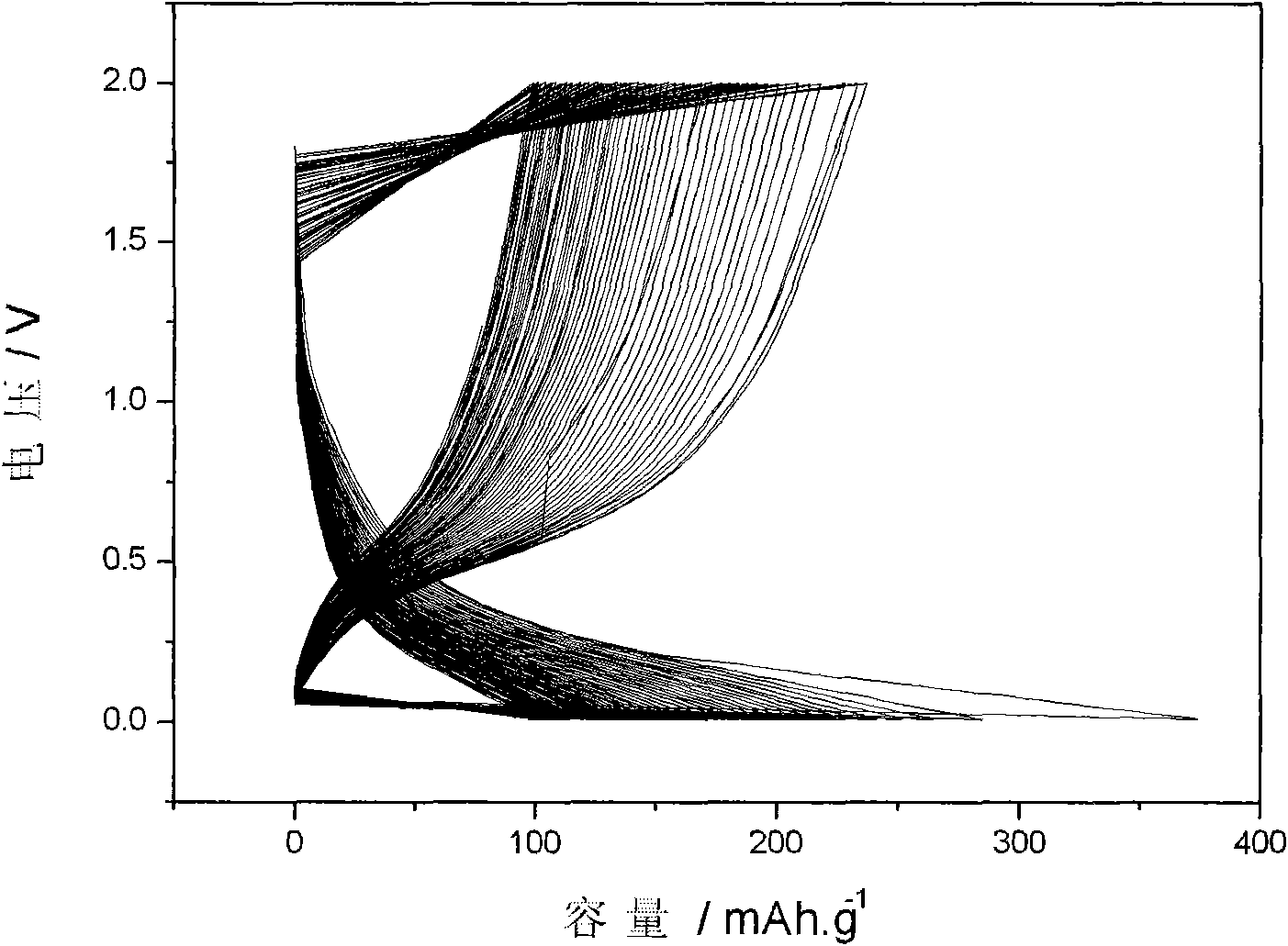

Solvent-thermal method for preparing spring-shaped superstructural Sn(HPO4)2.H2O nanodisk

A solvothermal and superstructure technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as no nanodisk negative electrode material, and achieve easy control of process parameters, simple preparation equipment and process, and production. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1, take by weighing tin chloride, it is dissolved in dehydrated alcohol, is made into 160 milliliters of tin ion concentration and is 0.2mol / L solution;

[0020] Step 2, dropwise adding 85wt% concentrated phosphoric acid to adjust the pH value of the solution to 5;

[0021] Step 3, placing the solution obtained in step 2 in a 200 ml reactor, and performing a solvothermal reaction at 180° C. for 24 hours;

[0022] After step 4 and step 3 are finished, the solid product is centrifuged and washed 3 times with distilled water and absolute ethanol respectively;

[0023] Step 5. Place the product obtained in step 4 in a constant temperature drying oven at 60°C for 12 hours to obtain a spring-like superstructure Sn(HPO 4 ) 2 ·H 2 O nanodisks.

Embodiment 2

[0025] Step 1, take by weighing tin chloride, be dissolved in dehydrated alcohol, be made into the concentration of 160 milliliters of tin ions and be 1mol / L solution;

[0026] Step 2, dropwise adding 85wt% concentrated phosphoric acid to adjust the pH value of the solution to 5;

[0027] Step 3, placing the solution obtained in step 2 in a 200 ml reactor, and performing a solvothermal reaction at 180° C. for 24 hours;

[0028] After step 4 and step 3 are finished, the solid product is centrifuged and washed 4 times with distilled water and absolute ethanol respectively;

[0029] Step 5. Place the product obtained in step 4 in a constant temperature drying oven at 60°C for 12 hours to obtain a spring-like superstructure Sn(HPO 4 ) 2 ·H 2 O nanodisks.

Embodiment 3

[0031] Step 1, take by weighing tin chloride, be dissolved in dehydrated alcohol, be made into the concentration of tin ion in 160 milliliters of solutions and be 0.2mol / L;

[0032] Step 2, dropwise adding 85wt% concentrated phosphoric acid to adjust the pH value of the solution to 5;

[0033] Step 3, placing the solution obtained in step 2 in a 200 ml reactor, and performing a solvothermal reaction at 180° C. for 48 hours;

[0034] After step 4 and step 3 are finished, the solid product is centrifuged and washed 3 times with distilled water and absolute ethanol respectively;

[0035] Step 5. Place the product obtained in step 4 in a constant temperature drying oven at 60°C for 12 hours to obtain a spring-like superstructure Sn(HPO 4 ) 2 ·H 2 O nanodisks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com