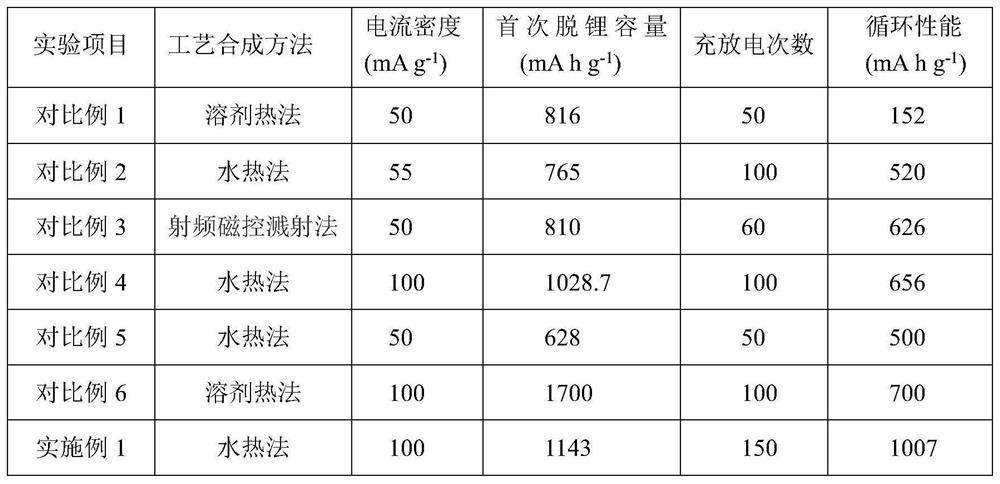

Preparation and application of two-dimensional-structure tungsten trioxide coated graphene negative electrode material

A technology of tungsten trioxide and two-dimensional structure, which is applied in the direction of tungsten oxide/tungsten hydroxide, negative electrode, structural parts, etc. It can solve the problems of low conductivity, strong polarizability, poor recyclability, and reduced battery performance. To achieve the effect of improving the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

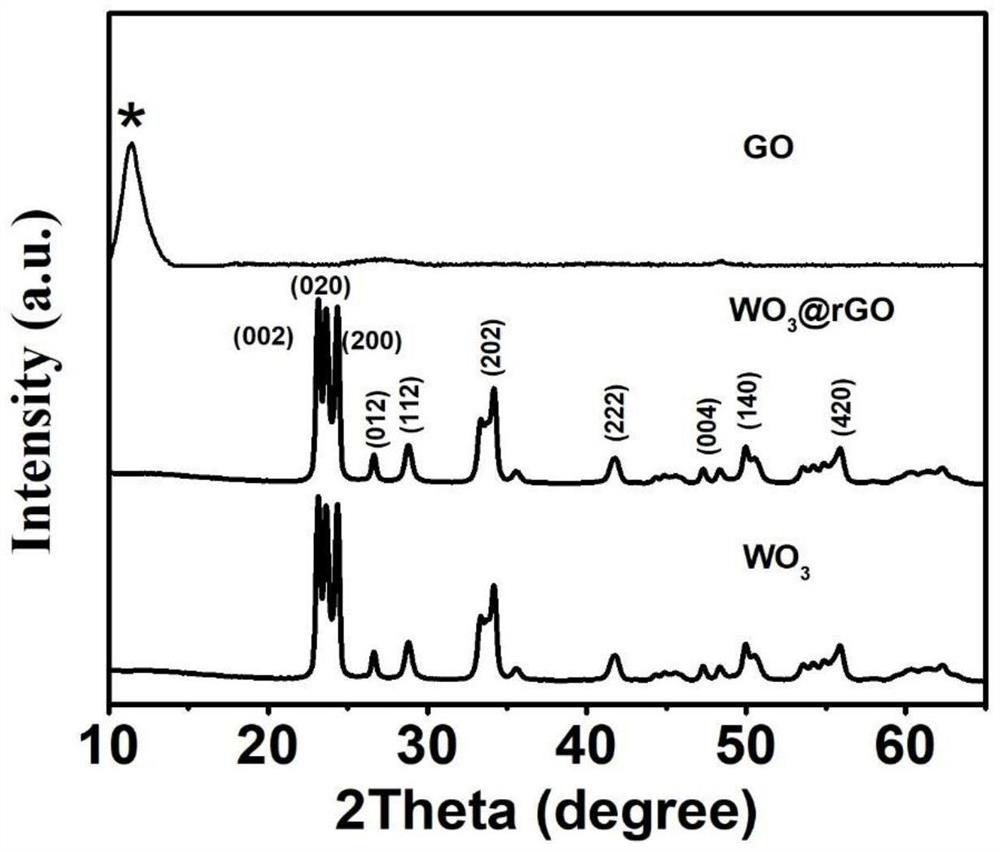

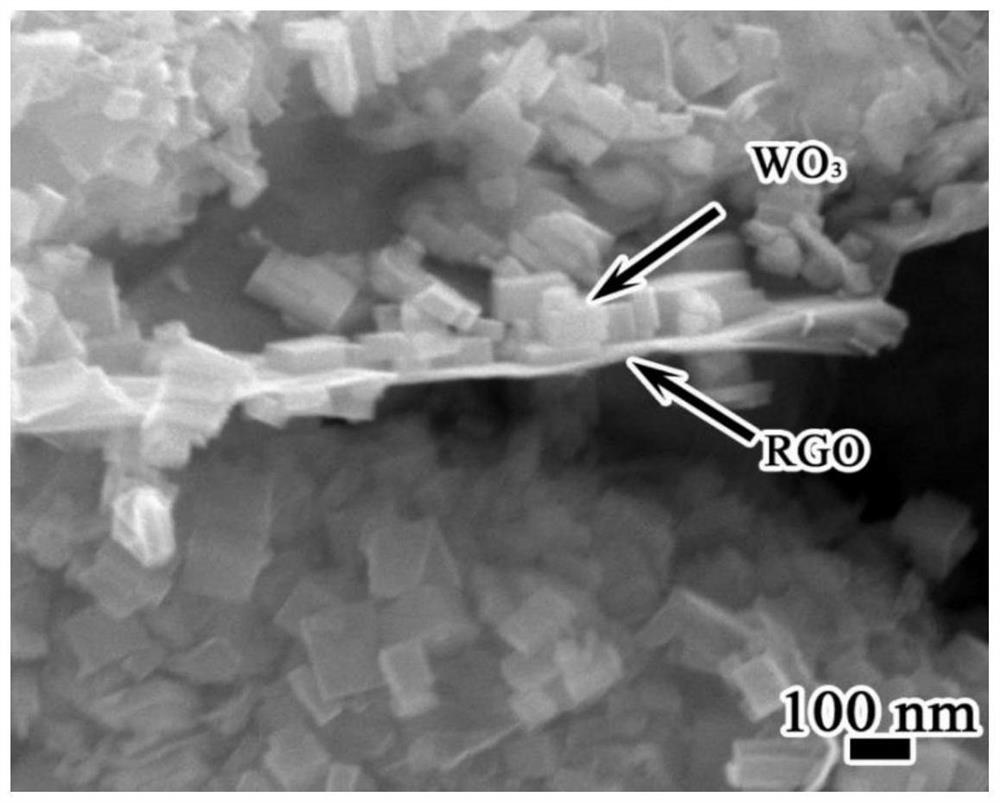

[0035] Embodiment 1: the preparation of the negative electrode material of two-dimensional structure tungsten trioxide coating graphene, comprises the following steps:

[0036] (1) Preparation of two-dimensional nanosheet structure tungsten trioxide as base material: Weigh 11.41g NaWO 4 2H 2O was dissolved in 20mL deionized water and stirred for 1h. During continuous stirring, 5-6mL concentrated hydrochloric acid was slowly added dropwise to adjust the pH of the solution to 2.0. After stirring again at room temperature 25°C for 1h, transfer to an oven at 200°C for 24h. After the reaction, cool to room temperature, wash with deionized water and suction filter, and dry in an oven at 80°C to obtain the desired two-dimensional nanosheet structure tungsten trioxide.

[0037] (2) Preparation of two-dimensional tungsten trioxide nanosheet-coated graphene composite negative electrode material: Weigh 10 mg of graphene and disperse it in 30 mL of deionized water, sonicate for 2 hours a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com