Preparation method of spinel-type spherical high-entropy oxide material for lithium ion battery anode material

A technology for lithium-ion batteries and negative electrode materials, applied in the field of 3O4 high-entropy oxide materials and their preparation, to achieve the effects of high efficiency, mild reaction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

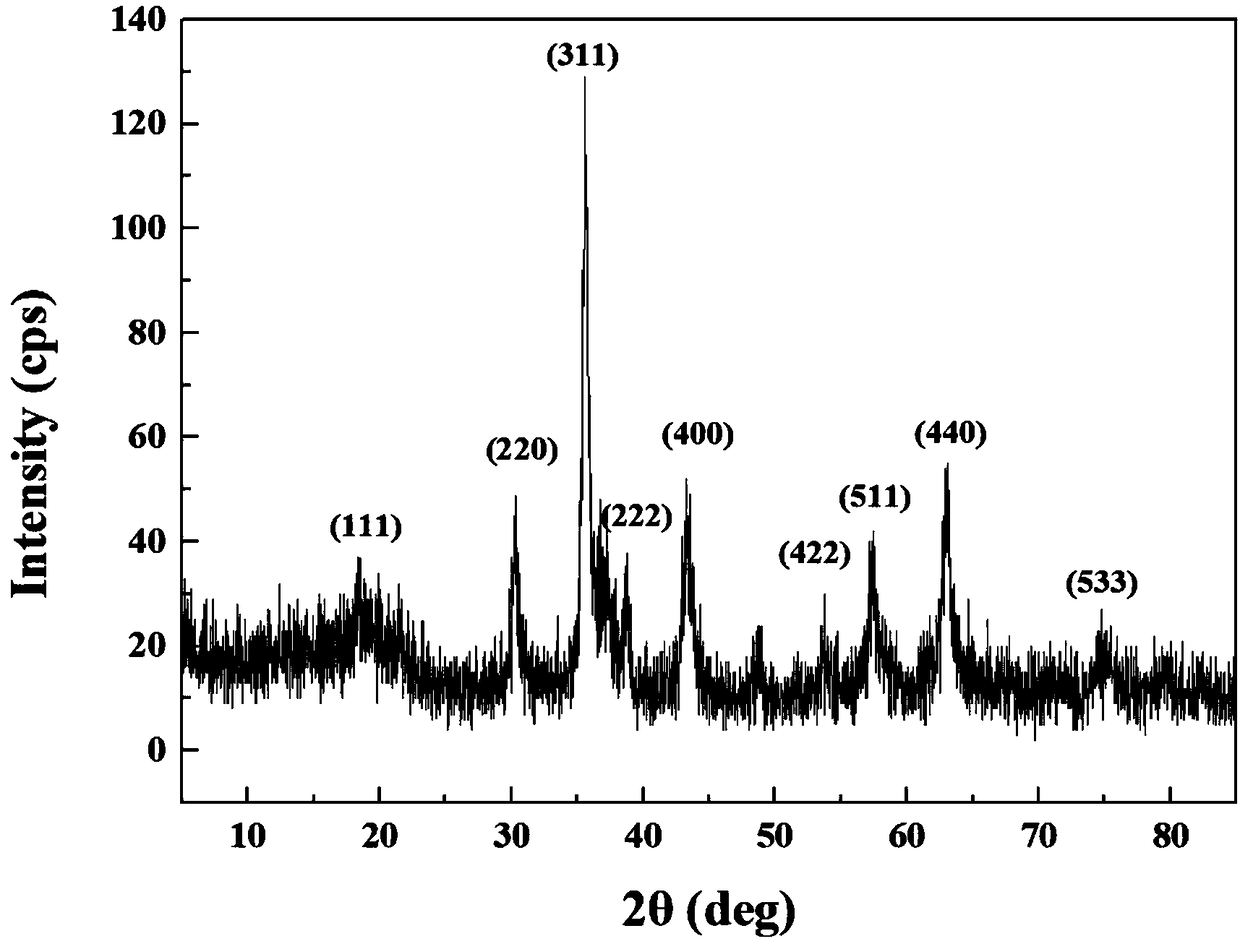

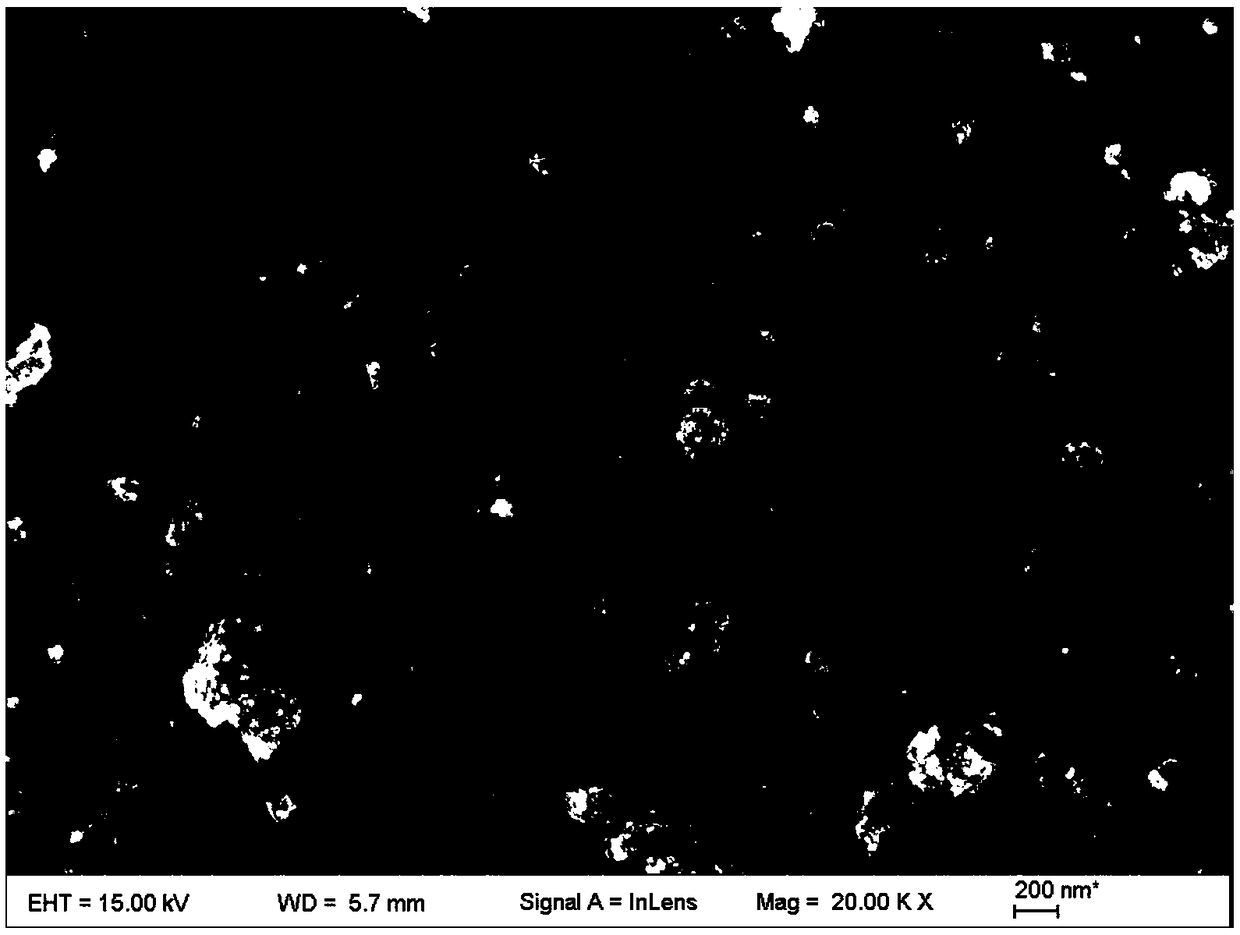

[0021] Weigh an equimolar amount of 11.90g of CoCl 2 ·6H 2 O, 13.32g of CrCl 3 ·6H 2 O, 7.95g of CuCl 2 2H 2 O, 13.52 g of FeCl 3 ·6H 2 O and 11.89 g of NiCl 2 ·6H 2 O five kinds of metal salts, dissolve them in 250mL distilled water, mix well and use as oxidation solution; weigh 20.4g of NaOH and dissolve in 1700mLH 2 After adding 26.35g of sodium thiosulfate and 0.14g of surfactant polyvinylpyrrolidone in O, mix well and use it as a reducing solution; drop the above oxidation solution into the reducing solution at a speed of 15mL / min, and Magnetic stirring at a reaction temperature of ℃, continued stirring for 30 minutes after the dropwise addition, aging for 30 minutes, centrifuged and calcined in a muffle furnace at 300 ℃ to obtain the final product. XRD spectrum ( figure 1 ) shows that the prepared (CoCrCuFeNi) 3 o 4 The high-entropy oxide material is a spinel structure, and the SEM picture ( figure 2 ) shows that the prepared (CoCrCuFeNi) 3 o 4 The averag...

Embodiment 2

[0023] Weigh 43.66g of Co(NO 3 ) 2 ·6H 2 O, 60.18g of Cr(NO 3 ) 3 9H 2 O, 36.24g of Cu(NO 3 ) 2 ·3H 2 O, 60.6g of Fe(NO 3 ) 3 9H 2 O and 43.62g of Ni(NO 3 ) 2 ·6H 2 O five kinds of metal salts, dissolve them in 250mL distilled water, mix well and use as oxidation solution; weigh 75g of NaOH and dissolve in 2500mLH 2 After adding 28.37g of sodium borohydride and 1.78g of surfactant polyethylene glycol, mix well and use it as a reducing solution; drop the above oxidation solution into the reducing solution at a speed of 30mL / min, and in 20 Magnetic stirring at the reaction temperature of ℃, continue to stir for 40 minutes after the dropwise addition and age for 60 minutes, and then calcined in a muffle furnace at 500 ℃ after centrifugation to obtain a spherical (CoCrCuFeNi) with a spinel structure and an average particle size of 110 nm. 3 o 4 High entropy oxide materials.

Embodiment 3

[0025] Weigh an equimolar amount of 11.24g of CoSO 4 ·7H 2 O, 6.60g of Cr(OH)SO 4 , 9.99g of CuSO 4 ·5H 2 O, 11.12g of FeSO 4 ·7H 2 O and 10.51 g NiSO 4 ·6H 2O five kinds of metal salts, dissolve them in 200mL distilled water, mix well and use as oxidation solution; weigh 16g of NaOH and dissolve in 320mLH 2 After adding 6.05g of sodium borohydride and 1.03g of surfactant sorbitol, mix well and use it as a reducing solution; add the above-mentioned oxidizing solution to the reducing solution dropwise at a speed of 10mL / min, and heat Stir magnetically at the reaction temperature, continue to stir for 60 minutes after the dropwise addition, and age for 40 minutes. After centrifugation, it is calcined in a muffle furnace at 400 ° C to obtain a spherical (CoCrCuFeNi) with a spinel structure and an average particle size of 75 nm. 3 o 4 High entropy oxide materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com