Preparation method of zinc oxide nanosheet for negative electrode of lithium-ion battery

A zinc oxide nanometer, lithium-ion battery technology, applied in nanotechnology for materials and surface science, battery electrodes, zinc oxide/zinc hydroxide, etc. The effect of improving initial discharge capacity and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

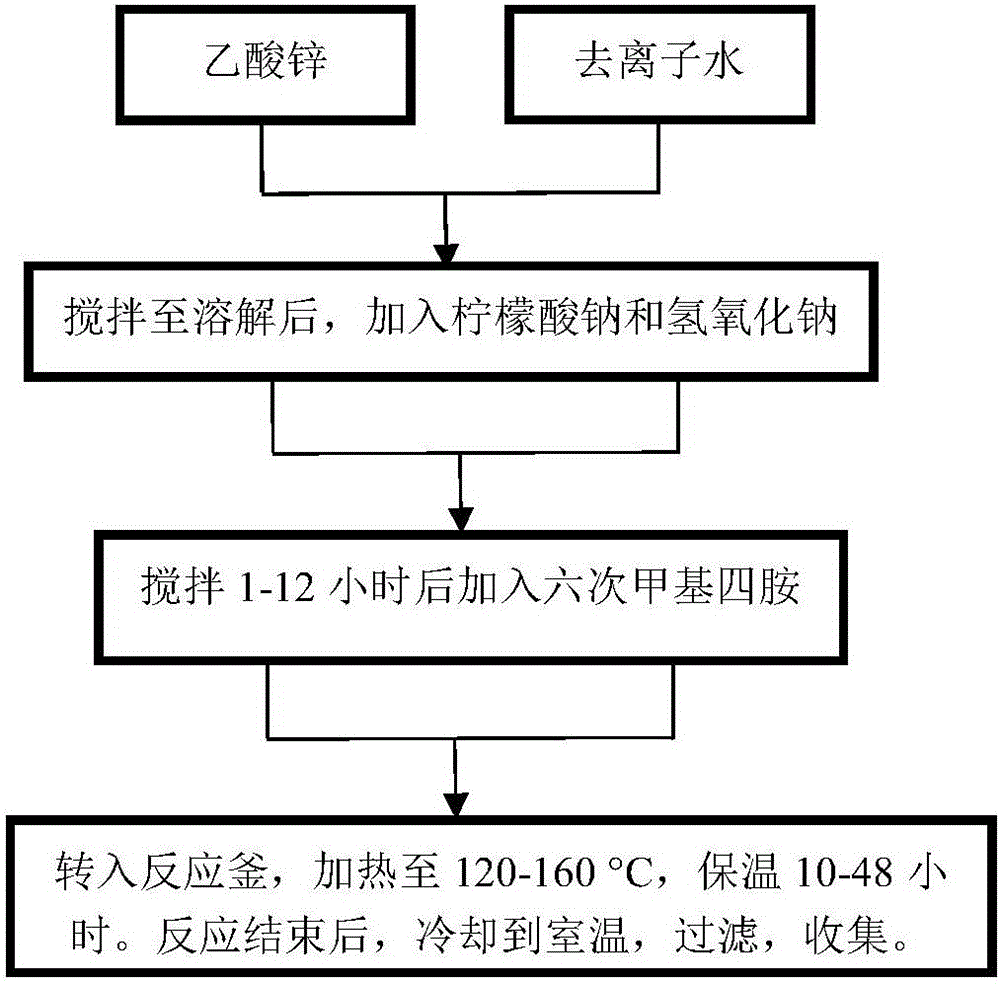

[0026] 1) Place 5 mmol of zinc acetate in 70 mL of deionized water and dissolve under magnetic stirring;

[0027] 2) When the zinc acetate is completely dissolved, add 10 mmol sodium citrate and 10 mmol sodium hydroxide, and stir for 1 hour;

[0028] 3) 5 mmol of hexamethylenetetramine is added to the solution in step 2, and stirred until dissolved;

[0029] 4) Transfer to a 100ml reaction kettle, heat to 120°C, and keep warm for 12 hours;

[0030] 5) After the reaction is finished, cool to room temperature, filter, and collect to obtain the zinc oxide nanosheet material;

[0031] 6) Put the prepared zinc oxide nanosheet material, conductive agent acetylene black, and binder polyvinylidene fluoride in a mortar in a mass ratio of 7:2:1, grind and mix evenly, and drop in nitrogen methyl Grind the pyrrolidone solvent into a slurry, scrape the slurry evenly on the copper foil, dry it at 60°C for 12 hours, and press it into a thin sheet with a tablet press under a pressure of 5 M...

Embodiment 2

[0036] 1) Place 6 mmol of zinc acetate in 70 mL of deionized water and dissolve under magnetic stirring;

[0037] 2) When the zinc acetate is completely dissolved, add 10.8mmol sodium citrate and 10.8mmol sodium hydroxide, and stir for 4 hours;

[0038] 3) Add 6 mmol of hexamethylenetetramine to the solution in step 2, and stir until dissolved;

[0039] 4) Transfer to a 100ml reaction kettle, heat to 150°C, and keep warm for 12 hours;

[0040] 5) After the reaction is finished, cool to room temperature, filter, and collect to obtain the zinc oxide nanosheet material;

[0041] 6) Put the prepared zinc oxide nanosheet material, conductive agent acetylene black, and binder polyvinylidene fluoride in a mortar in a mass ratio of 7:2:1, grind and mix evenly, and drop in nitrogen methyl Grind the pyrrolidone solvent into a slurry, scrape the slurry evenly on the copper foil, dry it at 60°C for 12 hours, and press it into a thin sheet with a tablet press under a pressure of 5 MPa to o...

Embodiment 3

[0044] 1) Place 7mmol of zinc acetate in 70mL of deionized water and dissolve under magnetic stirring;

[0045] 2) When the zinc acetate is completely dissolved, add 14.7mmol sodium citrate and 14.7mmol sodium hydroxide, and stir for 2 hours;

[0046] 3) Add 7 mmol of hexamethylenetetramine to the solution in step 2, and stir until dissolved;

[0047] 4) Transfer to a 100ml reaction kettle, heat to 160°C, and keep warm for 15 hours;

[0048] 5) After the reaction is finished, cool to room temperature, filter, and collect to obtain the zinc oxide nanosheet material;

[0049] 6) Put the prepared zinc oxide nanosheet material, conductive agent acetylene black, and binder polyvinylidene fluoride in a mortar in a mass ratio of 7:2:1, grind and mix evenly, and drop in nitrogen methyl Grind the pyrrolidone solvent into a slurry, scrape the slurry evenly on the copper foil, dry it at 60°C for 12 hours, and press it into a thin sheet with a tablet press under a pressure of 5 MPa to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com