A kind of road concrete and preparation method thereof

A concrete and road technology, applied in the field of concrete materials, can solve problems such as solid waste discharge and environmental pollution, and achieve the effects of increasing compactness, reducing production costs, and avoiding performance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

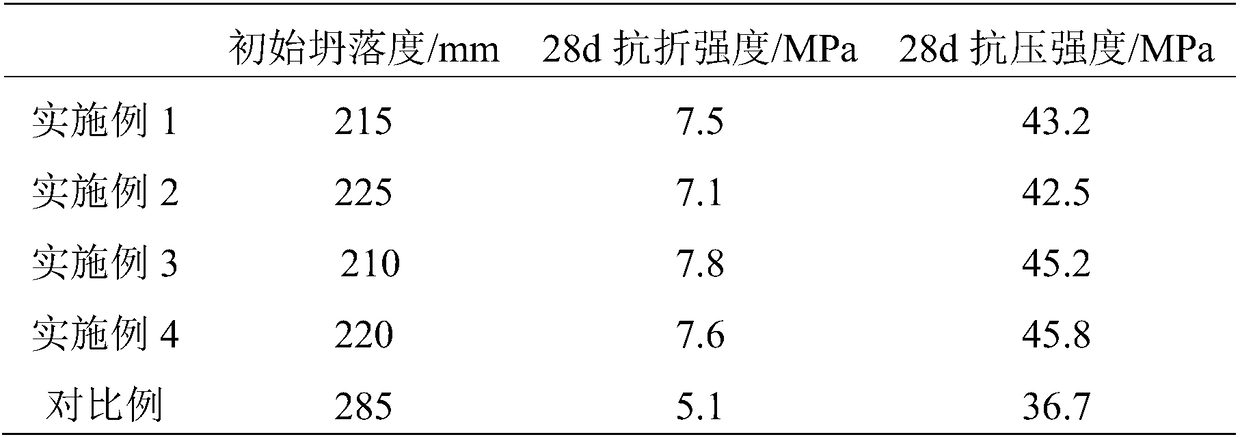

Examples

Embodiment 1

[0026] The invention provides a kind of road concrete, each component of this concrete is: portland cement 7.5kg, ferronickel slag micropowder 2.1kg, slag powder 1.5kg, fly ash 0.6kg, steel slag micropowder 0.5kg, fine aggregate 24.9kg, coarse aggregate 30.6kg, admixture 120g, activator 150g, water 5.1kg; the Portland cement is P.O 42.5 grade, specific surface area is 350-600m 2 / kg; the specific surface area of ferronickel slag powder is 400-550m 2 / kg; the specific surface area of slag powder is 380-500m 2 / kg; the specific surface area of fly ash is 450-580m 2 / kg; the specific surface area of steel slag powder is 430-550m 2 / kg; the admixture is polycarboxylate high-efficiency water reducer; the activator includes 80g of sodium cocoyl sulfate and 70g of polyacrylamide; the fine aggregate is continuously graded, and the particle size of the fine aggregate is controlled at 0.15-4.75mm. The fineness modulus is 3.2, and the coarse aggregate particle size is controll...

Embodiment 2

[0031] The invention provides a kind of road concrete, each component of this concrete is: portland cement 6.0kg, ferronickel slag micropowder 2.7kg, slag powder 2.5kg, fly ash 0.5kg, steel slag micropowder 0.8g, fine aggregate 4.3kg, coarse aggregate 30.9kg, admixture 126g, activator 95g, water 4.8kg; the Portland cement is P.O 42.5 grade, specific surface area is 350-600m 2 / kg; the specific surface area of ferronickel slag powder is 400-550m 2 / kg; the specific surface area of slag powder is 380-500m 2 / kg; the specific surface area of fly ash is 450-580m 2 / kg; the specific surface area of steel slag powder is 430-550m 2 / kg; the admixture is polycarboxylate high-efficiency water reducer; the activator includes 45g of water glass and 50g of diethanol monoisopropanolamine; the fine aggregate adopts continuous gradation, and the particle size of the fine aggregate is controlled at 0.15-4.75mm. The fineness modulus is 3.2, and the coarse aggregate particle size is ...

Embodiment 3

[0036] The invention provides a kind of road concrete, each component of this concrete is: portland cement 8.0kg, ferronickel slag micropowder 2.5kg, slag powder 1.1kg, fly ash 0.8kg, steel slag micropowder 0.7kg, fine aggregate 23.8kg, coarse aggregate 29.3kg, admixture 124g, activator 200g, water 5.4kg; the Portland cement is P.O 42.5 grade, specific surface area is 350-600m 2 / kg; the specific surface area of ferronickel slag powder is 400-550m 2 / kg; the specific surface area of slag powder is 380-500m 2 / kg; the specific surface area of fly ash is 450-580m 2 / kg; the specific surface area of steel slag powder is 430-550m 2 / kg; the admixture is polycarboxylate high-efficiency water reducer; the activator is sodium cocoyl sulfate 200g; the fine aggregate adopts continuous gradation, the particle size of fine aggregate is controlled at 0.15-4.75mm, and the fineness modulus is 3.2 , the coarse aggregate particle size is controlled at 4.75-26.5mm.

[0037] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com