Ceramic-based composite material as well as preparation method and application thereof

A composite material and ceramic-based technology, applied in the field of low residual Si composite material and its preparation, can solve the problems of limitation, poor interface bonding performance, low connection strength, etc., and achieve improved reaction activity, uniform spatial distribution, and carbon-silicon reaction. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

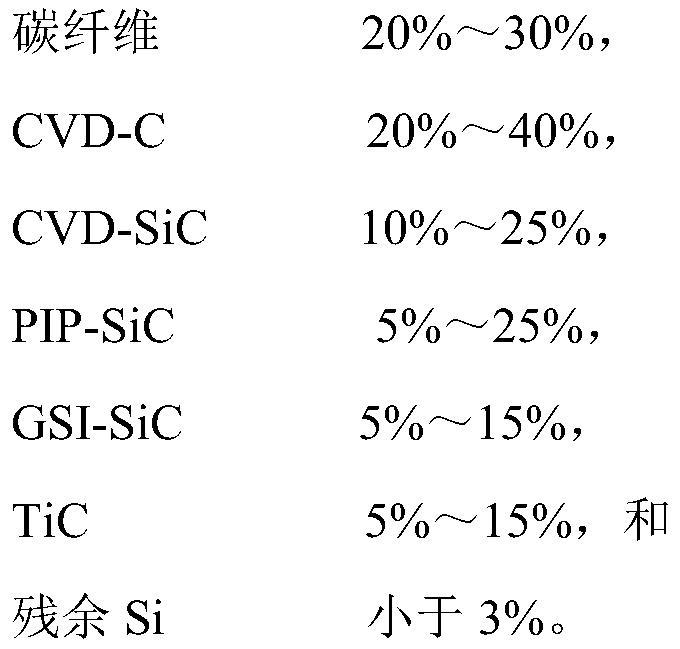

[0038] A ceramic matrix composite material of the present invention, comprising the following components in mass fraction:

[0039] Carbon Fiber: 22.7%,

[0040] CVD-C: 28.8%,

[0041] CVD-SiC: 13.0%,

[0042] PIP-SiC: 17.8%,

[0043] GSI-SiC: 7.9%,

[0044] TiC: 7.4%, and

[0045] Residual Si: 2.4%.

[0046] A preparation method of the ceramic matrix composite material of this embodiment, comprising the following steps:

[0047] (1) Deposit C layer: use carbon fiber to make a single layer of 0° non-weft cloth, 90° non-weft cloth and tire net, in order of 0° no weft cloth-tire net-90° no weft cloth-tire net Circular superimposition for laying, and then stitching by needle punching, introducing carbon fiber bundles perpendicular to the laying direction to obtain a three-dimensional needle punched carbon fiber preform with a density of 0.53g / cm 3 . The three-dimensional needle-punched carbon fiber preform was deposited and densified by chemical vapor deposition. The carb...

Embodiment 2

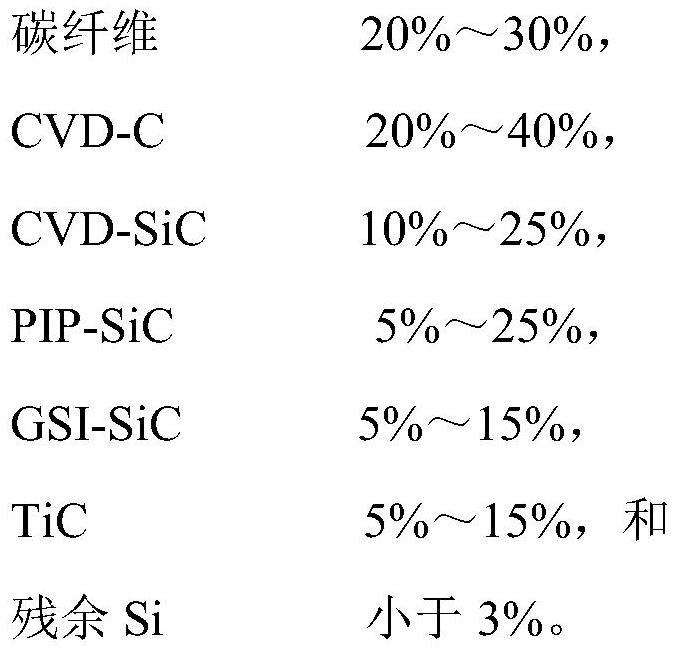

[0059] A kind of ceramic matrix composite material of the present invention, the mass percent of material constituent is as follows:

[0060] Carbon Fiber: 22.5%,

[0061] CVD-C: 27.4%,

[0062] CVD-SiC: 19.1%,

[0063] PIP-SiC: 10.4%,

[0064] GSI-SiC: 8.9%,

[0065] TiC: 9.2%, and

[0066] Residual Si: 2.5%.

[0067] A preparation method of the ceramic matrix composite material of this embodiment, comprising the following steps:

[0068] (1) Deposit C layer: use carbon fiber to make a single layer of 0° non-weft cloth, 90° non-weft cloth and tire net, in order of 0° no weft cloth-tire net-90° no weft cloth-tire net Circularly superimposed for laying, and then stitched by needle punching, introducing carbon fiber bundles perpendicular to the laying direction to obtain a three-dimensional needle-punched carbon fiber prefabricated body of 0.53g / cm 3 . The three-dimensional needle-punched carbon fiber preform was deposited and densified by chemical vapor deposition. The ...

Embodiment 3

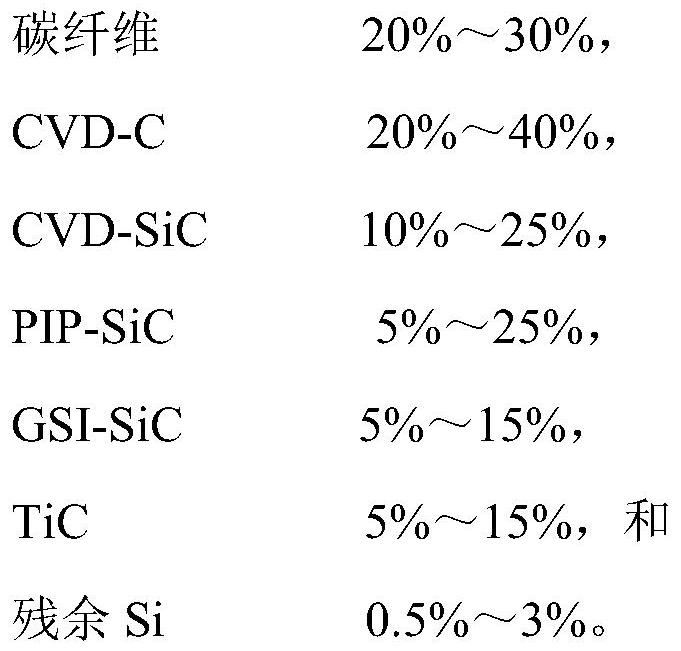

[0078] A kind of carbon ceramic material of the present invention, the mass percent of material constituent is as follows:

[0079] Carbon Fiber: 22.5%,

[0080] CVD-C: 24.0%,

[0081] CVD-SiC: 10.1%,

[0082] PIP-SiC: 24.8%,

[0083] GSI-SiC: 7.8%,

[0084] TiC: 8.3%, and

[0085] Residual Si: 2.5%.

[0086] A preparation method of the ceramic matrix composite material of this embodiment, comprising the following steps:

[0087] (1) Deposit C layer: use carbon fiber to make a single layer of 0° non-weft cloth, 90° non-weft cloth and tire net, in order of 0° no weft cloth-tire net-90° no weft cloth-tire net Circularly superimposed for laying, and then stitched by needle punching, introducing carbon fiber bundles perpendicular to the laying direction to obtain a three-dimensional needle-punched carbon fiber prefabricated body of 0.53g / cm 3 . The three-dimensional needle-punched carbon fiber preform was deposited and densified by chemical vapor deposition. The carbon sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com