Sponge foaming equipment and working method thereof

A foaming equipment and sponge technology, applied in metal processing and other directions, can solve problems such as affecting the production efficiency of sponges, unable to continuously complete sponge foaming, conveying, cutting, unloading, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

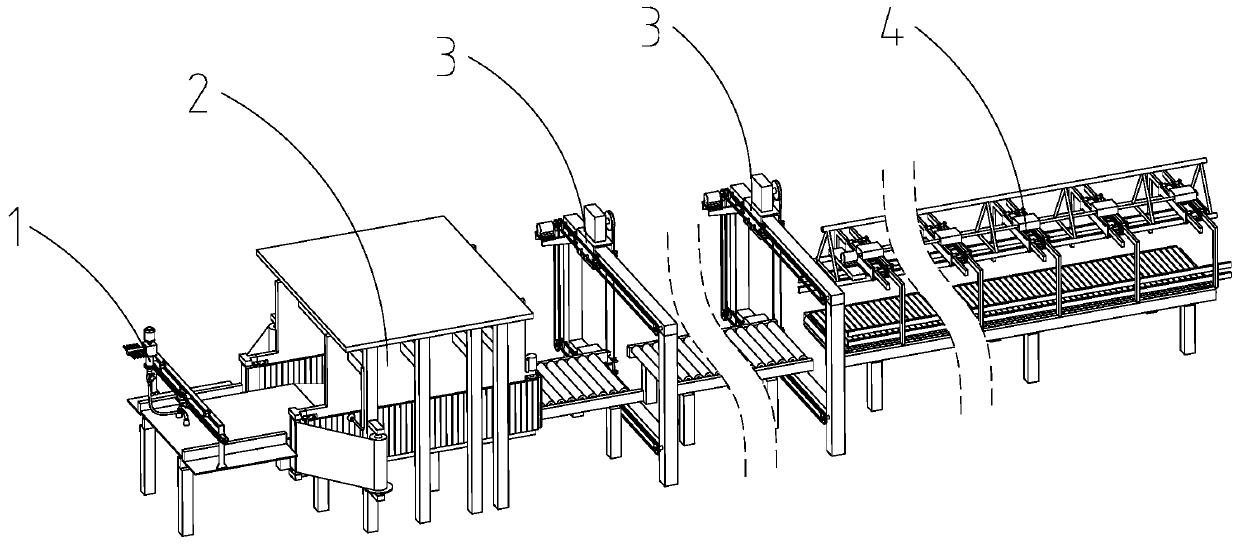

[0054] figure 1 It is a schematic structural diagram of the sponge foaming device of the present invention;

[0055] like figure 1 As shown, a sponge foaming equipment includes a frame, a feeding device 1, a foaming conveying device 2, a heating device, a cutting device 3 and an unloading device 4, wherein,

[0056] The frame is provided with a foaming sponge conveying channel;

[0057] The feeding device 1, the foaming conveying device 2, the cutting device 3 and the unloading device 4 are sequentially arranged along the advancing direction of the foamed sponge in the foamed sponge conveying channel;

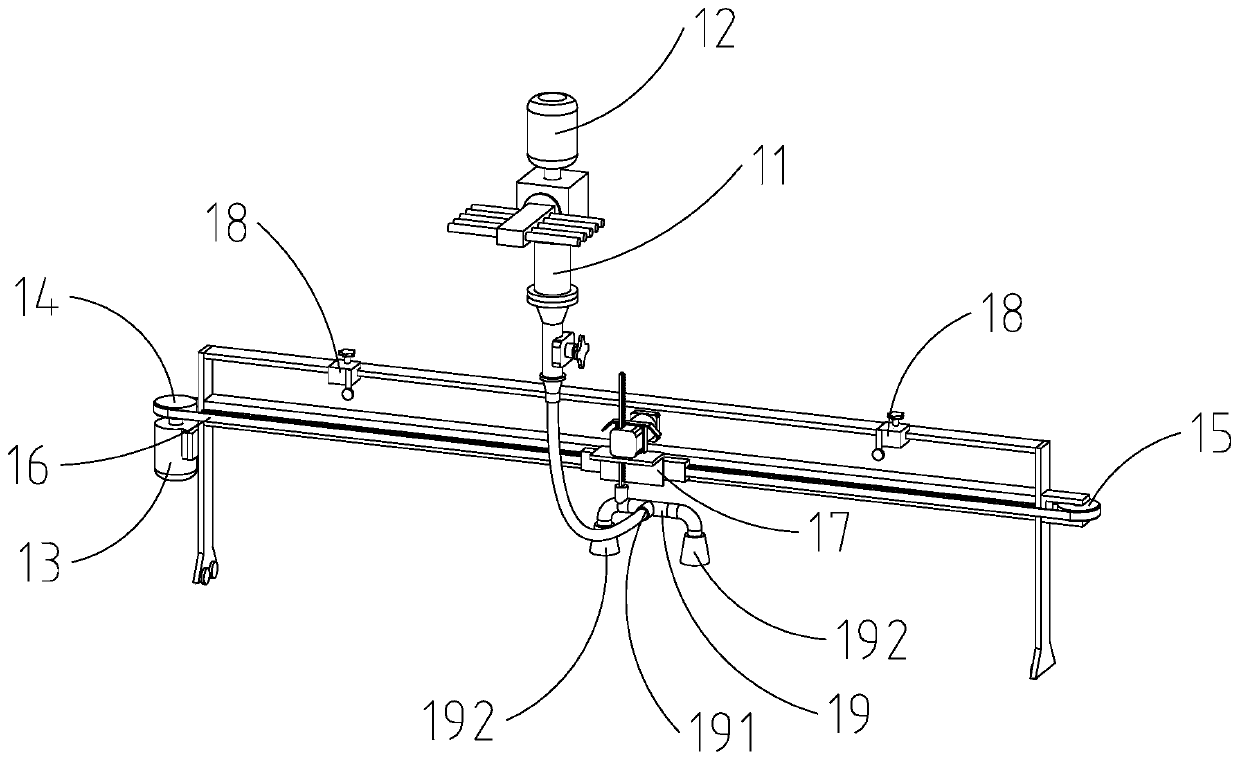

[0058] The feeding device 1 is arranged on the frame, and the feeding device 1 is used for inserting raw materials and stirring the raw materials evenly and then discharging them into the foaming sponge conveying channel, and the raw materials are discharged to the foaming sponge. Foaming begins after the sponge is transported in the channel.

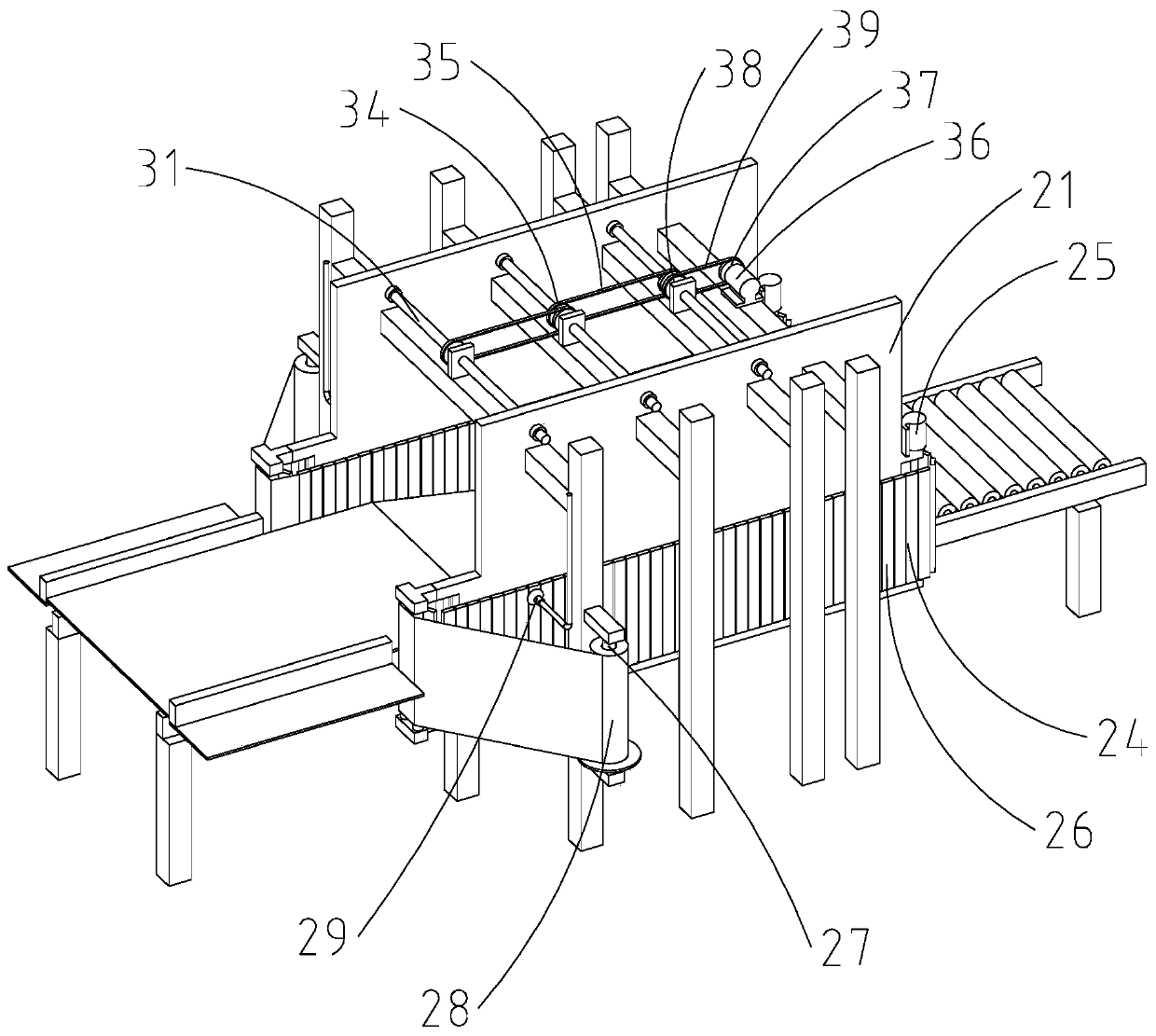

[0059] The foaming conveying ...

Embodiment 2

[0098] A working method of the sponge foaming device as described in Embodiment 1, comprising in the steps of the method:

[0099] The feeding device 1 is connected to the raw material, and the raw material is stirred evenly and then discharged into the foaming sponge conveying channel;

[0100] The raw material is foamed in the foaming sponge conveying channel, and the foaming conveying device 2 clamps and conveys the foaming foam in the foaming sponge conveying channel forward, and the heating device simultaneously treats the foaming foam. The foam sponge is heated to speed up the foaming;

[0101] The cutting device 3 cuts the foamed foam that has been foamed and formed to be conveyed to the cutting device 3 along a direction perpendicular to the advancing direction of the foamed sponge;

[0102] The unloading device 4 is actuated to remove the cut foamed sponge.

[0103] The working principle of the present invention is as follows:

[0104] The feeding device 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com