Surface active agent composition for improving foaming property of detergent and preparation method and application thereof

A surfactant and detergent technology, applied in the field of daily chemicals, can solve the problems of reduced product stability, increased skin irritation, strong skin irritation, etc., to improve foam performance, less irritation, and good foam stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

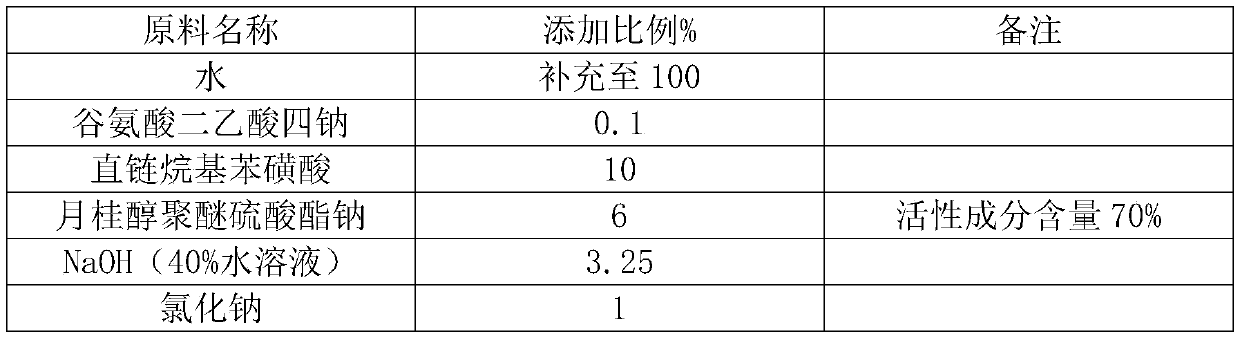

[0030] A dish soap:

[0031] formula:

[0032] raw material name Add ratio% Remark water replenish to 100 Tetrasodium glutamate diacetate 0.1 linear alkylbenzene sulfonic acid 10 Sodium Laureth Sulfate 6 Active ingredient content 70% Surfactant composition 4 NaOH (40% aqueous solution) 3.25 Sodium chloride 1 preservative 0.1 essence Appropriate amount

[0033]Wherein, the surfactant composition is made of the following components by weight: 1 part of cationic surfactant, 10 parts of nonionic surfactant, 1 part of polymer surfactant and 10 parts of plant saponin extract ; Wherein, the cationic surfactant is linoleamidopropyl PG-dimethylammonium chloride phosphate and cocoamidopropyl PG-dimethylammonium chloride phosphate sodium to form a composite, the composite The ratio of linoleamidopropyl PG-dimethylammonium chloride phosphate and sodium cocoamidopropyl PG-dimethylammonium chloride p...

Embodiment 2

[0040] A dish soap:

[0041] formula:

[0042] raw material name Add ratio% Remark water replenish to 100 Tetrasodium glutamate diacetate 0.1 linear alkylbenzene sulfonic acid 10 Sodium Laureth Sulfate 6 Active ingredient content 70% Surfactant composition 4 NaOH (40% aqueous solution) 3.25 Sodium chloride 1 preservative 0.1 essence Appropriate amount

[0043] Wherein, the surfactant composition is made of the following components by weight: 4 parts of cationic surfactant, 20 parts of nonionic surfactant, 4 parts of polymer surfactant and 20 parts of plant saponin extract Parts; wherein, the cationic surfactant is linoleamidopropyl PG-dimethylammonium chloride phosphate and cocoamidopropyl PG-dimethylammonium chloride phosphate sodium to form a complex, the The ratio by weight of linoleamidopropyl PG-dimethylammonium chloride phosphate and cocoamidopropyl PG-dimethylammonium chloride ph...

Embodiment 3

[0046] A dish soap:

[0047] formula:

[0048] raw material name Add ratio% Remark water replenish to 100 Tetrasodium glutamate diacetate 0.1 linear alkylbenzene sulfonic acid 10 Sodium Laureth Sulfate 6 Active ingredient content 70% Surfactant composition 4 NaOH (40% aqueous solution) 3.25 Sodium chloride 1 preservative 0.1 essence Appropriate amount

[0049] Wherein, the surfactant composition is made of the following components by weight: 2 parts of cationic surfactant, 16 parts of nonionic surfactant, 2 parts of polymer surfactant and 16 parts of plant saponin extract ; Wherein, the cationic surfactant is linoleamidopropyl PG-dimethylammonium chloride phosphate and cocoamidopropyl PG-dimethylammonium chloride phosphate sodium to form a composite, the composite The ratio of linoleamidopropyl PG-dimethylammonium chloride phosphate and sodium cocoamidopropyl PG-dimethylammonium chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com