Defoaming method of unsaturated polyester transparent undercoat

A transparent primer, unsaturated technology, used in polyester coatings, foam dispersion/prevention, coatings, etc., can solve the problems of not completely eliminating bubbles, affecting product quality, increasing product costs, etc., to eliminate small bubbles, eliminate Air bubbles, the effect of eliminating foaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

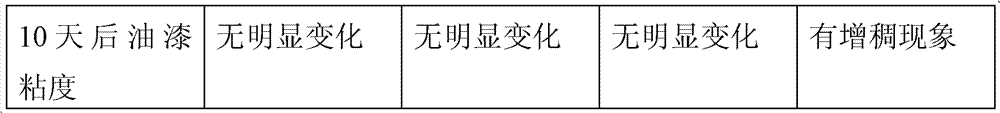

Examples

Embodiment 1

[0033] A kind of defoaming method of unsaturated polyester transparent primer, comprises the steps:

[0034] (1) Manufacture of unsaturated polyester transparent primer: produce transparent primer of unsaturated polyester; put quantitative unsaturated polyester resin in dispersion tank according to formula, then add quantitative styrene, speed of 500 rpm Stir, slowly add dispersant and defoamer under stirring, disperse at a high speed of 1200-1500 rpm for 5 minutes, reduce the speed to 500 rpm, slowly add zinc stearate and filler according to the formula amount, 1000- Disperse at a high speed of 1500 rpm for 15 minutes until the fineness is acceptable, then add color paste, anti-sedimentation agent and styrene, and stir at a speed of 800 rpm for 10 minutes.

[0035] (2) Suction filtration by suction filter: The unsaturated polyester transparent primer that has been produced is suction filtered by a suction filter; the KL series of Jiangsu Hongliu Chemical Machinery Co., Ltd. (...

Embodiment 2

[0039] A kind of defoaming method of unsaturated polyester transparent primer, comprises the steps:

[0040] (1) Manufacture of unsaturated polyester transparent primer: produce transparent primer of unsaturated polyester; put quantitative unsaturated polyester resin in dispersion tank according to formula, then add quantitative styrene, speed of 500 rpm Stir, slowly add dispersant and defoamer under stirring, disperse at a high speed of 1200-1500 rpm for 5 minutes, reduce the speed to 500 rpm, slowly add zinc stearate and filler according to the formula amount, 1000- Disperse at a high speed of 1500 rpm for 15 minutes until the fineness is acceptable, then add color paste, anti-sedimentation agent and styrene, and stir at a speed of 800 rpm for 10 minutes.

[0041] (2) suction filter suction filtration: the produced unsaturated polyester transparent primer adopts suction filter suction filtration; adopts KL series suction filter suction filtration of Jiangsu Hongliu Chemical ...

Embodiment 3

[0044] A kind of defoaming method of unsaturated polyester transparent primer, comprises the steps:

[0045] (1) Manufacture of unsaturated polyester transparent primer: produce transparent primer of unsaturated polyester; put quantitative unsaturated polyester resin in dispersion tank according to formula, then add quantitative styrene, speed of 500 rpm Stir, slowly add dispersant and defoamer under stirring, disperse at a high speed of 1200-1500 rpm for 5 minutes, reduce the speed to 500 rpm, slowly add zinc stearate and filler according to the formula amount, 1000- Disperse at a high speed of 1500 rpm for 15 minutes until the fineness is acceptable, then add color paste, anti-sedimentation agent and styrene, and stir at a speed of 800 rpm for 10 minutes.

[0046] (2) suction filter suction filtration: the produced unsaturated polyester transparent primer adopts suction filter suction filtration; adopts KL series suction filter suction filtration of Jiangsu Hongliu Chemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com