Low-specific-weight heat-conducting silica-gel gasket for new-energy vehicle and preparation method thereof

A technology of new energy vehicles and heat-conducting silica gel, applied in chemical instruments and methods, materials for heat exchange, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

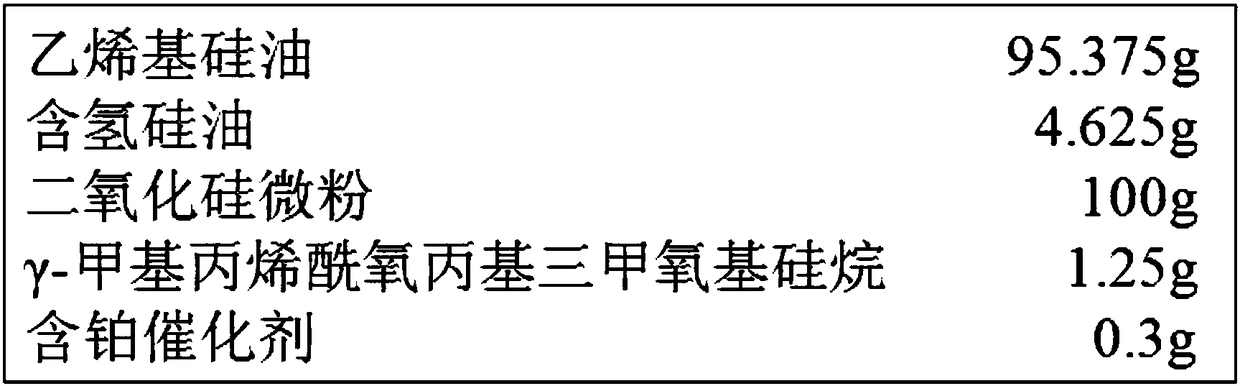

Embodiment 1

[0059] 1) Weigh 95.375g of vinyl silicone oil, 4.625g of hydrogen-containing silicone oil, 100g of silica micropowder, 1.25g of γ-methacryloxypropyltrimethoxysilane, and 0.3g of platinum-containing catalyst;

[0060] 2) Put vinyl silicone oil, hydrogen-containing silicone oil, silicon dioxide micropowder, and γ-methacryloxypropyltrimethoxysilane in a double planetary mixer, and stir for 180min at 40RPM under a vacuum of <-0.9MPA to ensure that all The material is mixed evenly;

[0061] 3) Add a platinum-containing catalyst, and stir all materials at 40RPM for 30min under a vacuum of <-0.9MPA;

[0062] 4) Place the mixed material in a double-roll calender and press it into a 2MM thick sheet;

[0063] 5) Place the pressed product at 130 degrees and mold it for 30 minutes to obtain the test product.

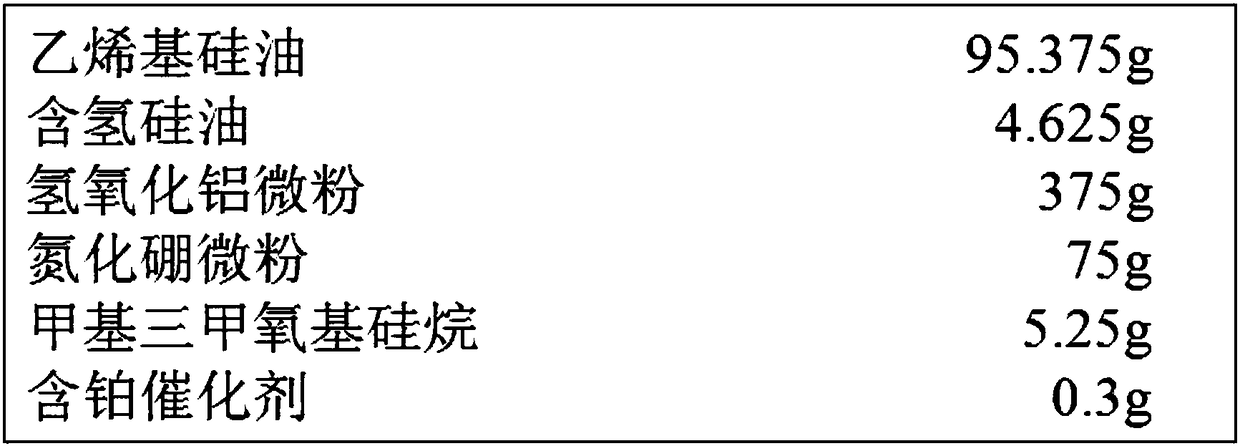

Embodiment 2

[0065] 1) Weigh 95.375g of vinyl silicone oil, 4.625g of hydrogen-containing silicone oil, 375g of aluminum hydroxide micropowder, 75g of boron nitride micropowder, 5.25g of methyltrimethoxysilane, and 0.3g of platinum-containing catalyst;

[0066] 2) Put vinyl silicone oil, hydrogen-containing silicone oil, aluminum hydroxide micropowder, boron nitride micropowder, and methyltrimethoxysilane in a double planetary mixer, and stir for 180min at 40RPM under vacuum <-0.9MPA to ensure that all materials are mixed uniform;

[0067] 3) Add a platinum-containing catalyst, and stir all materials at 40RPM for 30min under a vacuum of <-0.9MPA;

[0068] 4) Place the mixed material in a double-roll calender and press it into a 2MM thick sheet;

[0069] 5) Place the pressed product at 130 degrees and mold it for 30 minutes to obtain the test product.

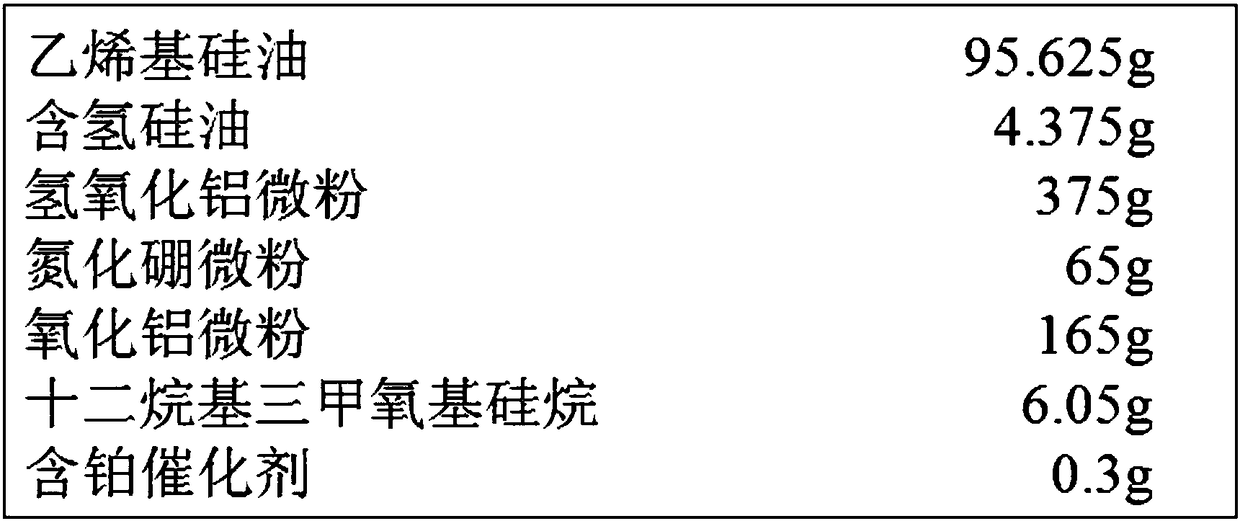

Embodiment 3

[0071] 1) Weigh 95.625g of vinyl silicone oil, 4.375g of hydrogen-containing silicone oil, 375g of aluminum hydroxide micropowder, 65g of boron nitride micropowder, 165g of alumina micropowder, 6.05g of dodecyltrimethoxysilane, and 0.3g of platinum-containing catalyst;

[0072] 2) Put vinyl silicone oil, hydrogen-containing silicone oil, aluminum hydroxide micropowder, boron nitride micropowder, alumina micropowder, and dodecyltrimethoxysilane in a double planetary mixer, and stir at 40RPM under a vacuum of <-0.9MPA 180MIN, to ensure that all materials are mixed evenly;

[0073] 3) Add a platinum-containing catalyst, and stir all materials at 40RPM for 30min under a vacuum of <-0.9MPA;

[0074] 4) Place the mixed material in a double-roll calender and press it into a 2MM thick sheet;

[0075] 5) Place the pressed product at 130 degrees and mold it for 30 minutes to obtain the test product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com