Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Meet the needs of lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

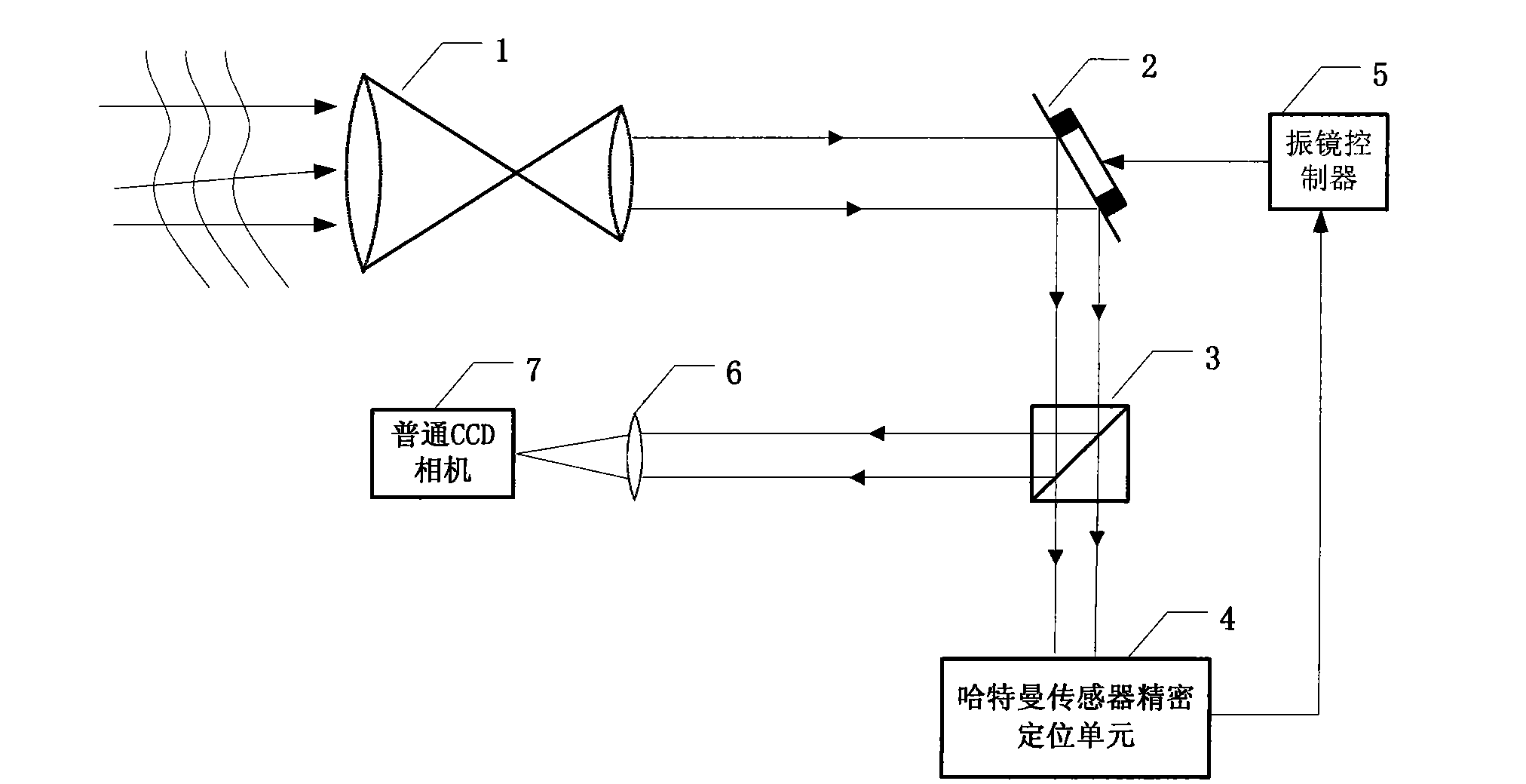

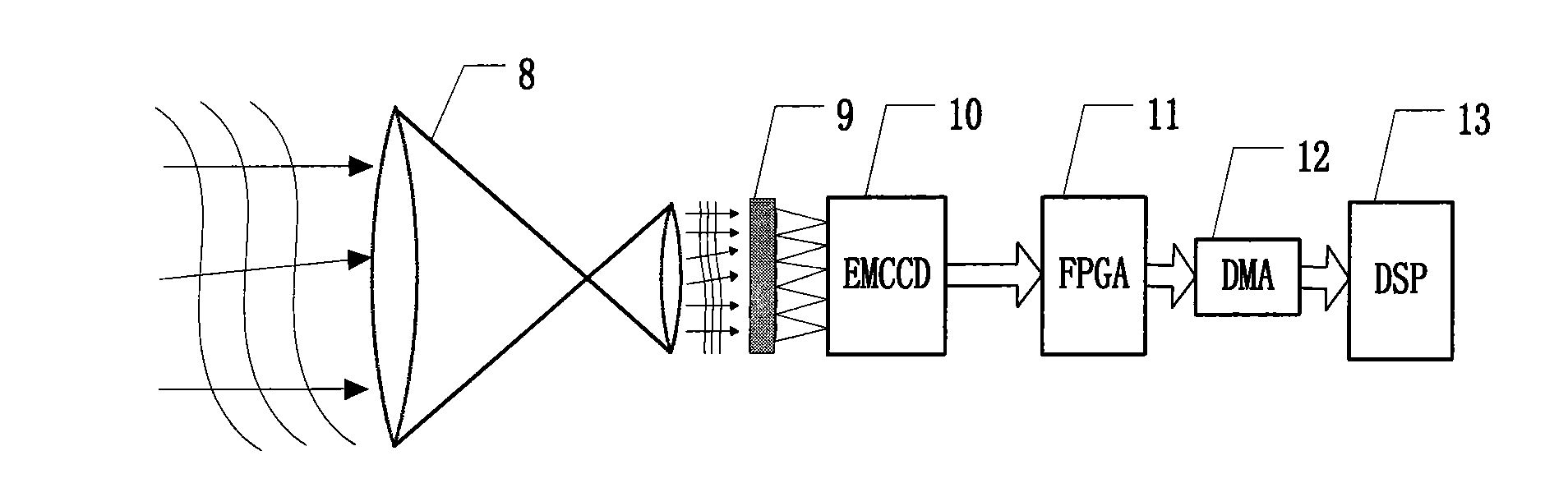

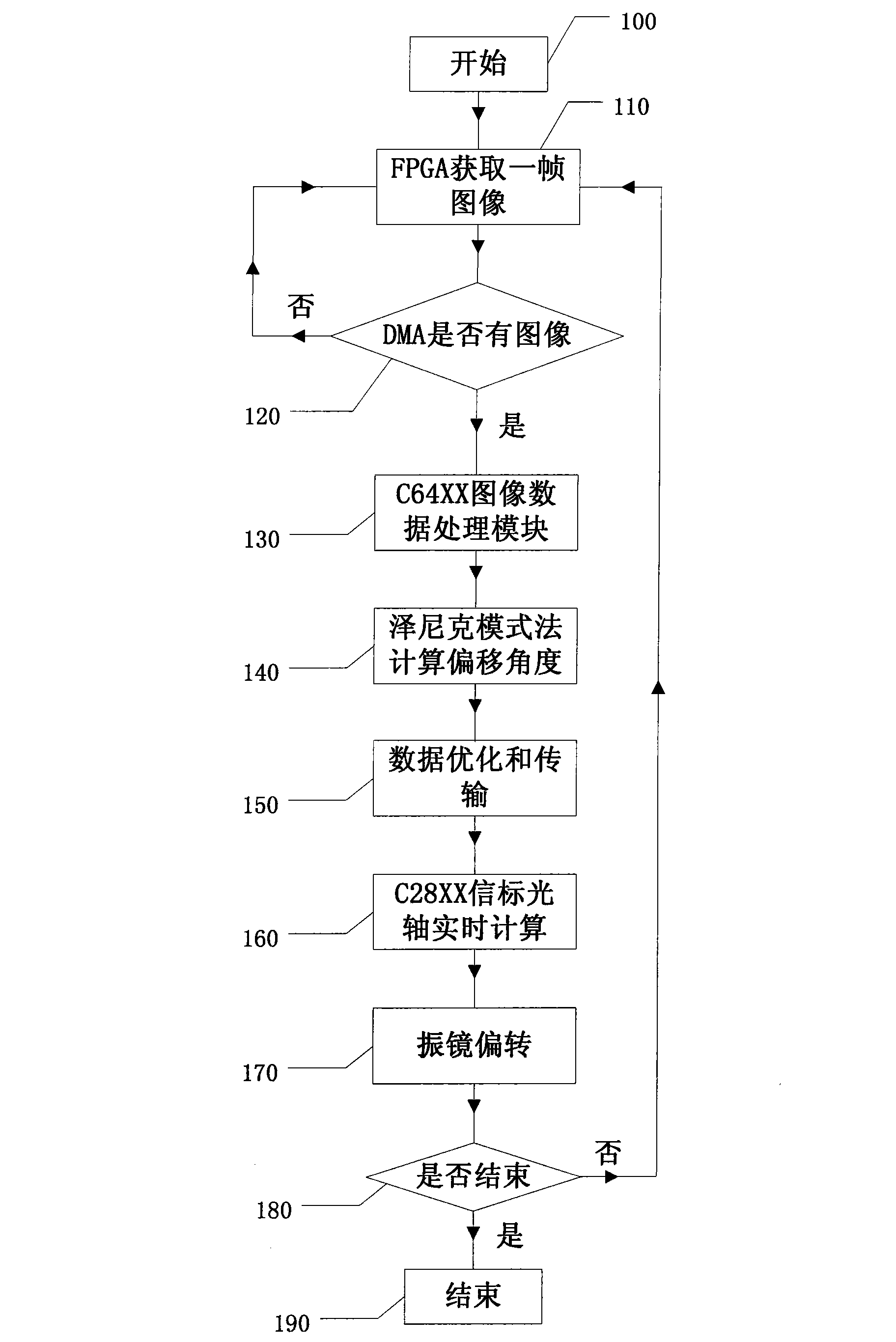

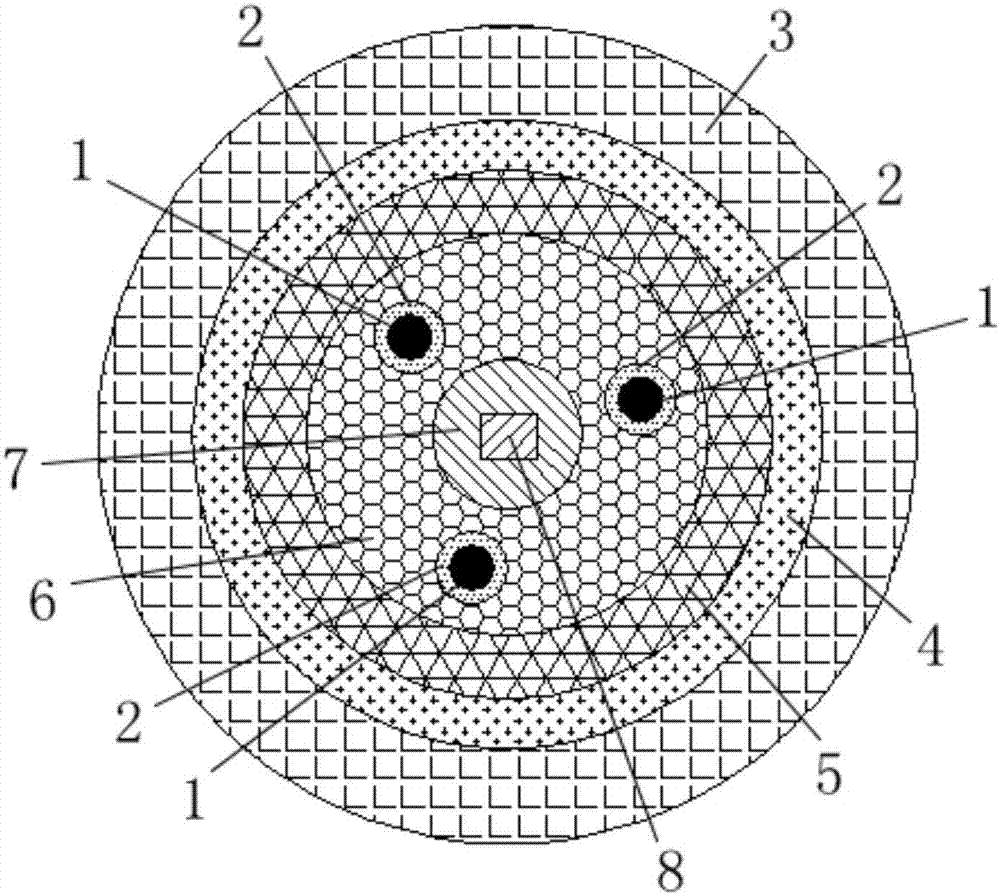

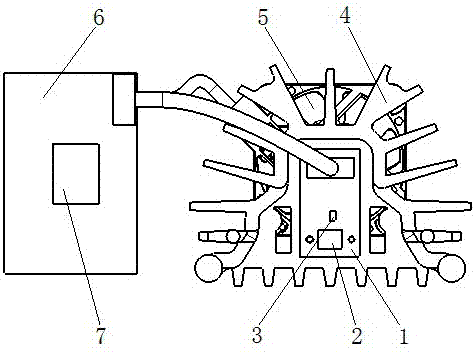

Beacon optical axis precision positioning system in atmosphere laser communication system

InactiveCN101651496AIncrease frame rateMeet the needs of lightweightUsing optical meansFree-space transmissionOptoelectronicsPrism

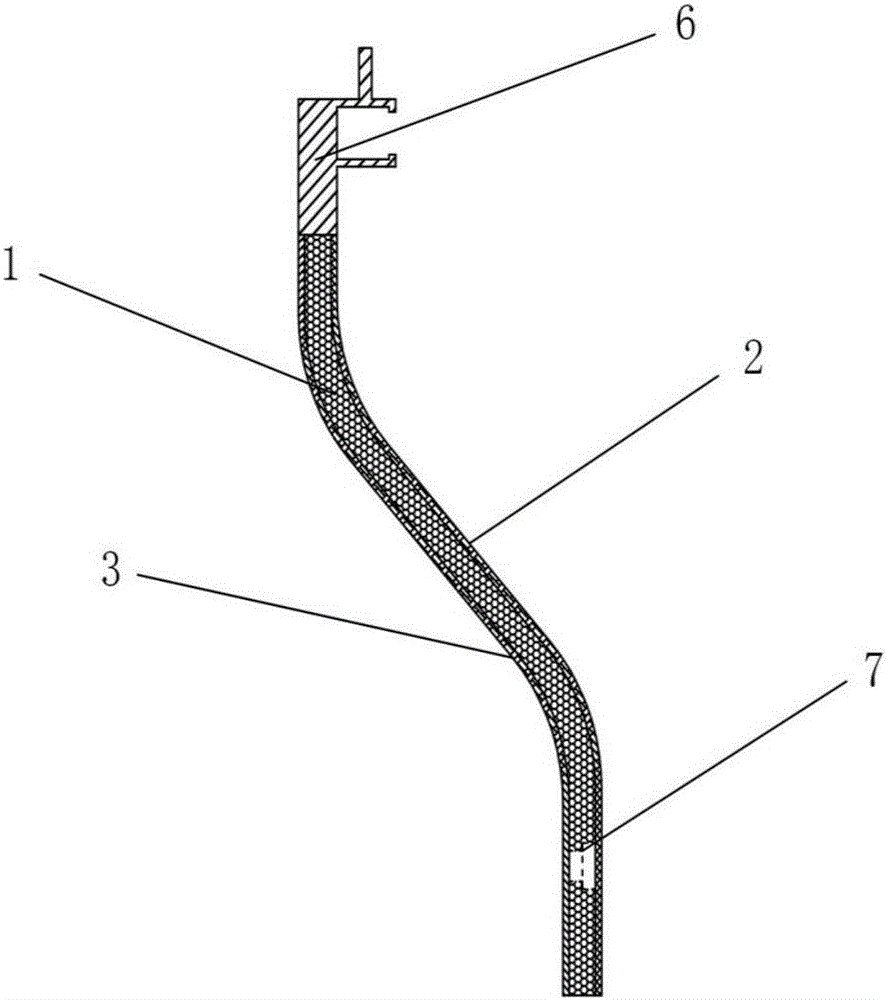

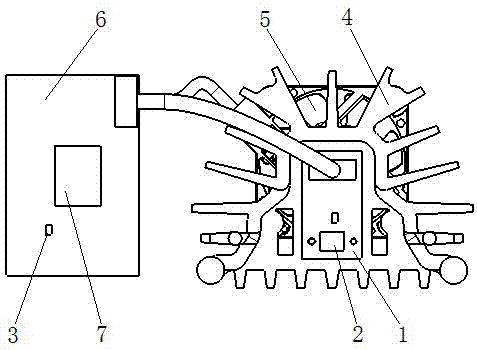

The invention relates to a beacon optical axis precision positioning system in an atmosphere laser communication system, which is characterized by comprising an optical receiving antenna (1), a vibrating mirror (2), a dispersion prism (3), a Hartmann sensor optical axis precision positioning unit (4), a vibrating mirror controller (5), a lens (6) and a common CCD camera (7). To realize the real-time correction of the pointing direction of a beacon optical axis, the beacon optical axis precision positioning system detects a beacon light beam by a Schack Hartmann sensor with microlenses array and reconstructs a real-time wavefront image by a Zernike Polynomial mode method, thereby resolving the real pointing direction of the beacon optical axis of the atmosphere laser communication system and achieving final optical axis positioning precision exceeding 2 mu rad. If a common CCD positioned at a receiving end needs to obtain same resolution ratio and measuring precision, an optical systemof the common CCD has large volume and heavier weight; in addition, compared with the traditional platform, the invention has obviously reduced volume and weight, thereby effectively meeting the requirement of future space laser communication for the light type of an onboard platform.

Owner:CHANGCHUN UNIV OF SCI & TECH

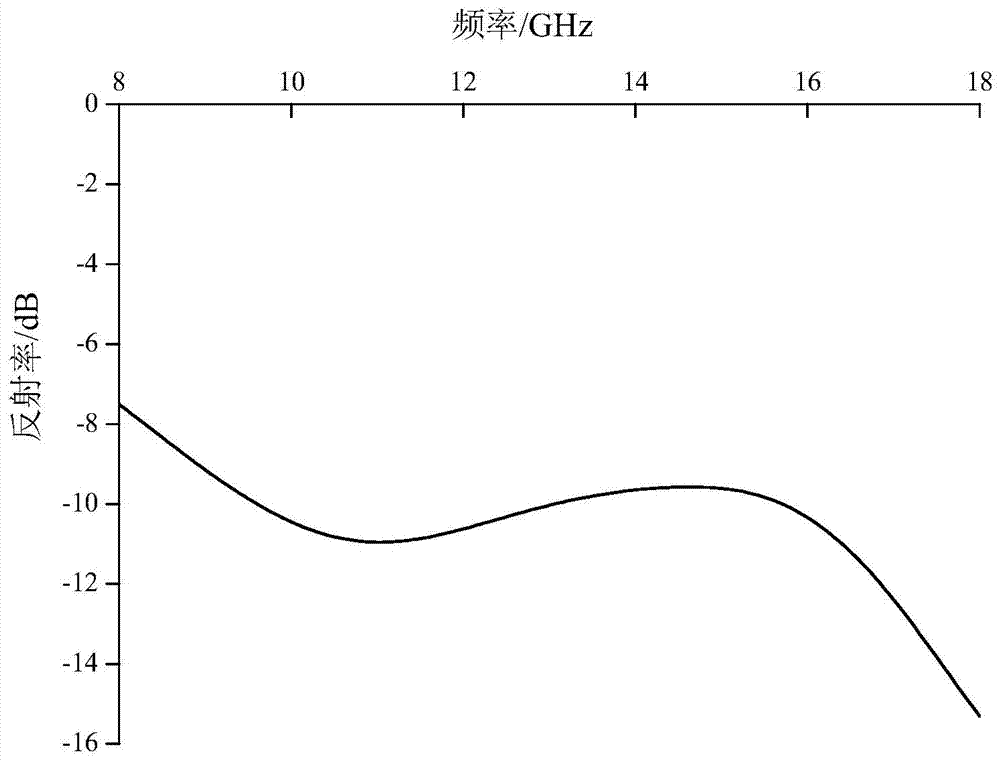

Silicon carbide fibre-reinforced silicon carbide composite microwave-absorbing ceramic and preparation method thereof

ActiveCN103922776AIncreased interlaminar shear strengthImprove mechanical propertiesCarbon fibersMicrowave

The invention discloses a silicon carbide fibre-reinforced silicon carbide composite microwave-absorbing ceramic. The microwave-absorbing ceramic consists of continuous silicon carbide fibre-reinforced silicon carbide composite material; wherein silicon carbide fibre cloth overlaid layer by layer is used as reinforcement; the silicon carbide fibre cloth is connected into a whole in a way of sewing with carbon fibres in Z direction; the band width, of which the reflectivity is lower than -8dB in frequency band of 8GHz to 18GHz, is 6.5 GHz to 10 GHz at normal temperature; and the density is lower than 2.1 / cm <3>. The method for preparing the microwave-absorbing ceramic comprises the following steps: weaving the continuous silicon carbide fibres into silicon carbide fibre plain cloth; sewing the plain cloth into a whole body in a Z direction by carbon fibres to prepare a preformed body; dipping, pyrolyzing and densifying the preformed body repeatedly by using precursor dipping and pyrolysis technology, thus obtaining the microwave-absorbing ceramic. The product provided by the invention has advantages of simple structure, wide absorbing frequency band, light weight, thin thickness, good mechanical property, etc.

Owner:NAT UNIV OF DEFENSE TECH

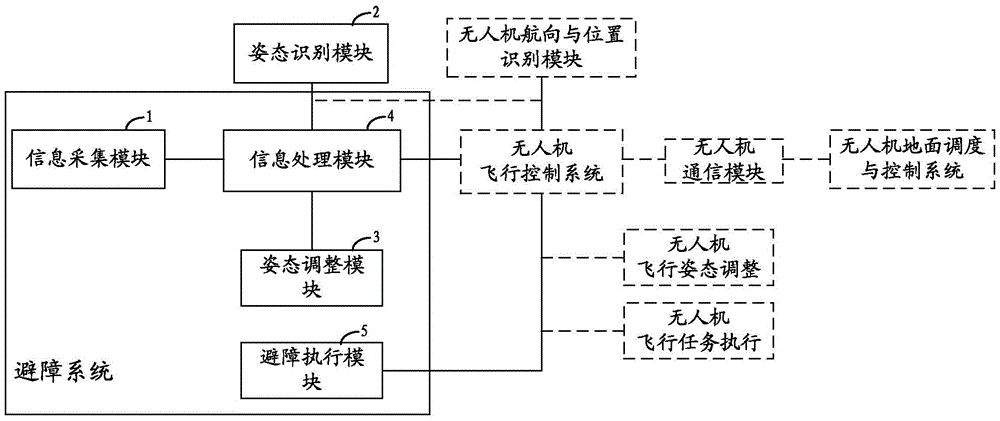

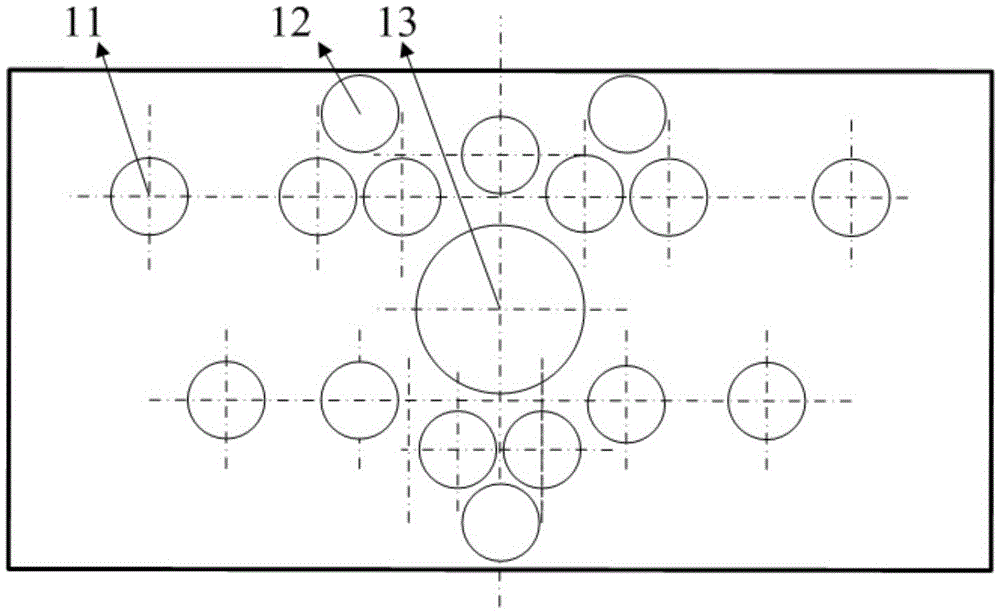

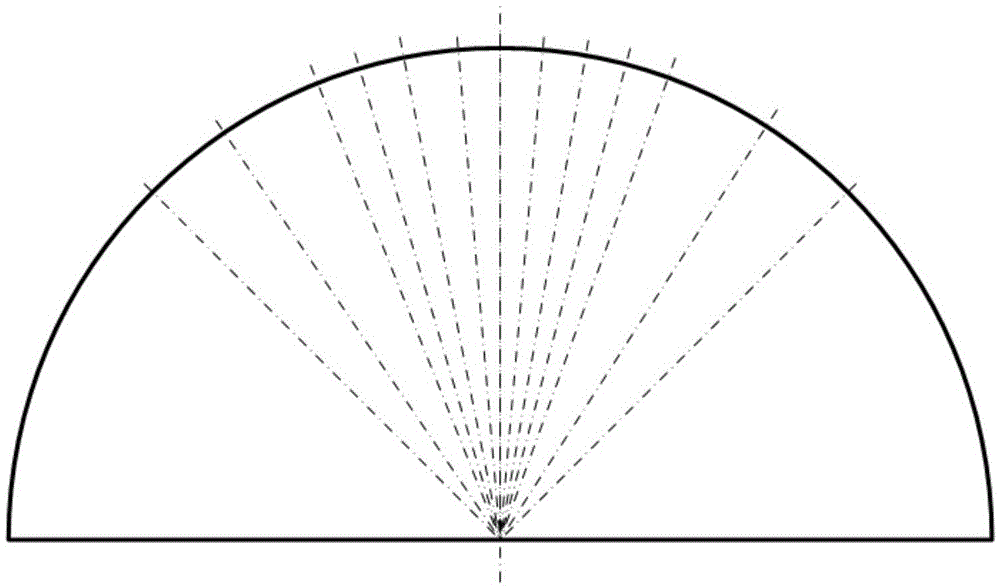

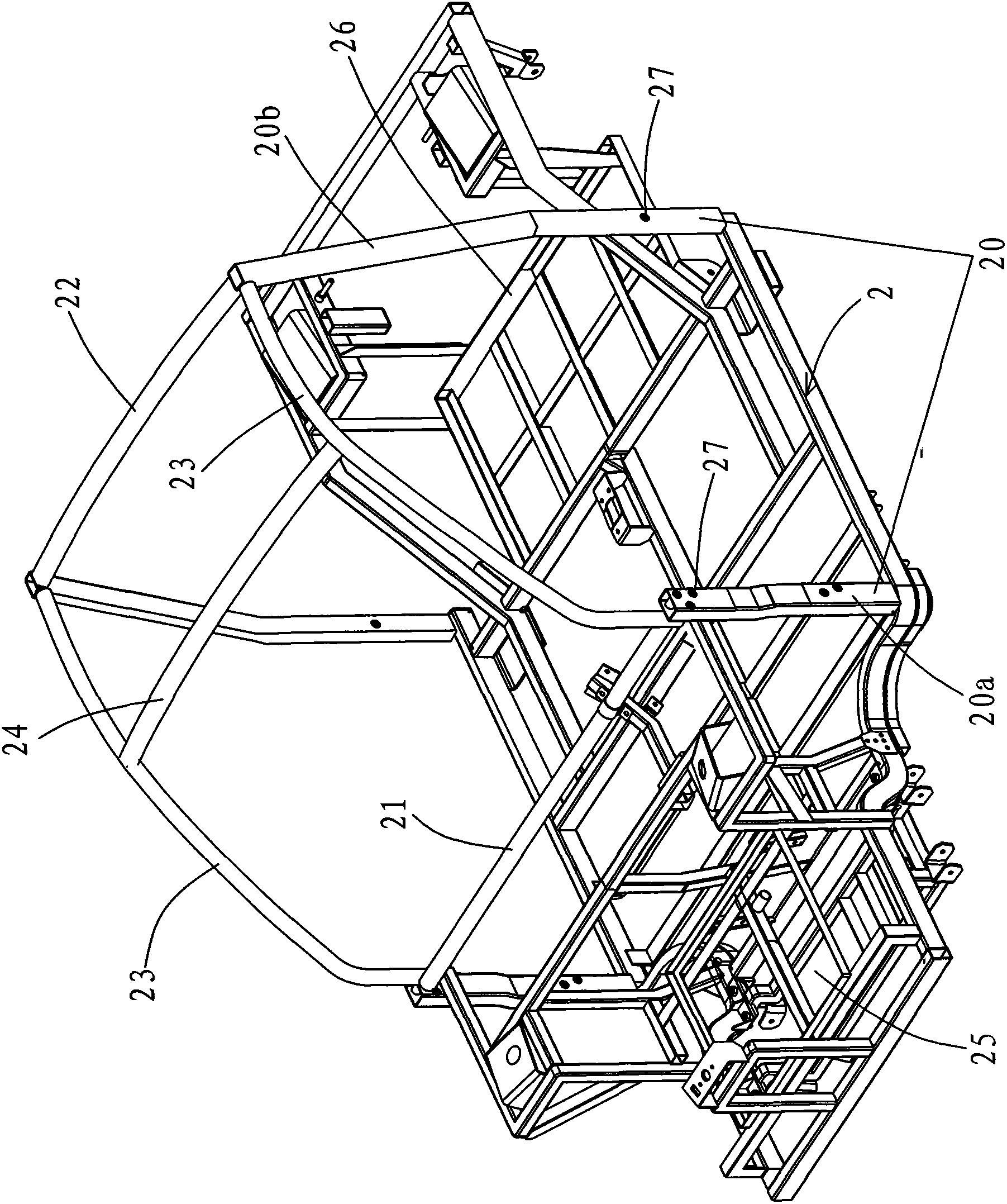

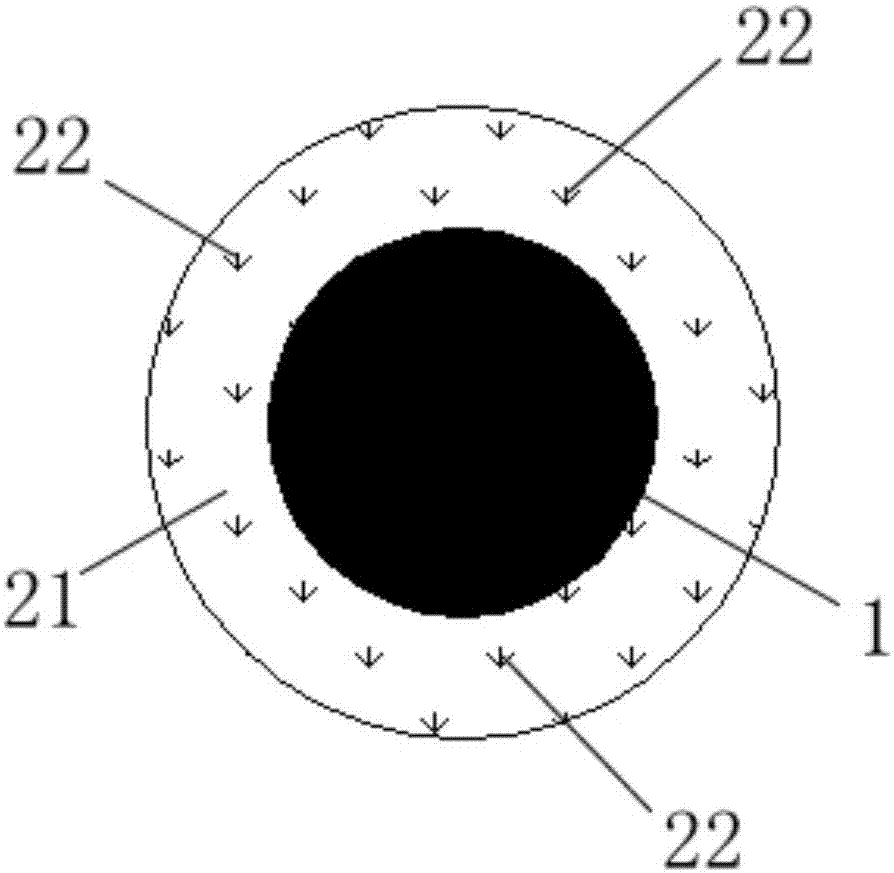

Multi-shaft unmanned aerial vehicle barrier avoiding system based on laser array, and barrier avoiding method thereof

ActiveCN105549616AEffectively detect and avoidMeet the needs of lightweightPosition/course control in three dimensionsLaser rangingInformation processing

The invention is applied to the technical field of aviation science, and provides a multi-shaft unmanned aerial vehicle barrier avoiding system based on a laser array, and a barrier avoiding method thereof. The system comprises five modules, i.e., an information acquisition module, a posture identification module, a posture adjustment module, an information processing module and a barrier avoiding execution module. The method comprises information acquisition of a stereo scene in front of an unmanned aerial vehicle, posture identification of the unmanned aerial vehicle, posture adjustment of the barrier avoiding system and information processing so as to realize effective barrier avoidance. The system is mainly characterized in that a laser distance-measuring array comprises a receiving head in the middle and multiple laser emission heads, and each laser emission head is provided with a cylindrical lens for emitting linear light spots. According to the invention, through special arrangement of a laser emission head array, the emitted linear light spots can be effectively superposed at a sector area in a certain horizontal included angle, a front sector area can be scanned, whether there are barriers and the size and orientations of the barriers can be detected, through combination with a current posture of the unmanned aerial vehicle, accurate alarm is realized, a path is replanned, and effective detection and avoidance of the barriers in a three-dimensional environment can be realized.

Owner:云瓣科技有限公司

Automobile with one-time formed plastic shell

InactiveCN102328702ASimple manufacturing processIncrease productivitySuperstructure subunitsSuperstructure connectionsEngineeringBody weight

The invention relates to an automobile with a one-time formed plastic shell. The automobile comprises an automobile body and a chassis, wherein the automobile body is a hollow double-layer plastic shell which is integrally formed at one time by a rotational molding process and is provided with an automobile door installation hole and an automobile window installation hole in advance; a plurality of contact reinforcing ribs are formed between an inner-layer wall body and an outer-layer wall body of the hollow double-layer plastic shell; a plurality of convex reinforcing ribs are formed on the external surface of the outer-layer wall body or the inner-layer wall body of the hollow double-layer plastic shell; a chassis embedding groove is formed at the lower end of the external surface of the inner-layer wall body of the hollow double-layer plastic shell; a plurality of threaded sleeves are embedded into the chassis embedding groove; the chassis is embedded into and in threaded connection with the chassis embedding groove; the external surface of the inner-layer wall body of the hollow double-layer plastic shell is provided with door post embedding grooves on two sides of the automobile door installation hole; and the upper end of the chassis is fixedly provided with door posts inserted into the door post embedding grooves. The automobile has the advantages of high strength and surface performance, light body weight, low cost and the like, and is easy to manufacture and convenient to assemble.

Owner:应革

A liquid-cooled plate for power battery of electric vehicle

A liquid-cooled plate for a power battery of an electric vehicle belongs to the technical field of electric vehicles, the liquid-cooled plate for a power battery of an electric vehicle comprises an integrally formed liquid-cooled plate body, both ends of the liquid-cooled plate body are provided with openings and a flow channel structure is arranged inside the liquid-cooled plate body, the two ends of the liquid-cooled plate body are connected with a first hollow end plate and a second hollow end plate communicating with the liquid-cooled plate body in a sealing manner, a water inlet joint isarranged on the first hollow end plate, a water outlet joint is arranged on the second hollow end plate, the invention has the beneficial effect that, the electric vehicle power battery liquid-cooledplate has the advantages of simple and stable overall structure, low manufacturing cost, increases heat exchange contact area and contact time with the power battery module, improved heat exchange efficiency, improved cooling effect of the power battery module, and light overall weight, which meets the lightweight requirements of the whole vehicle.

Owner:奇瑞新能源汽车股份有限公司

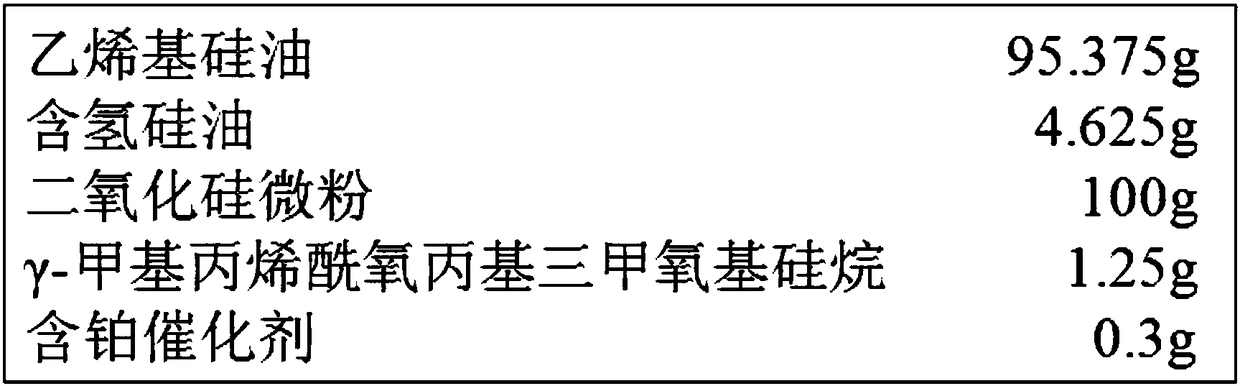

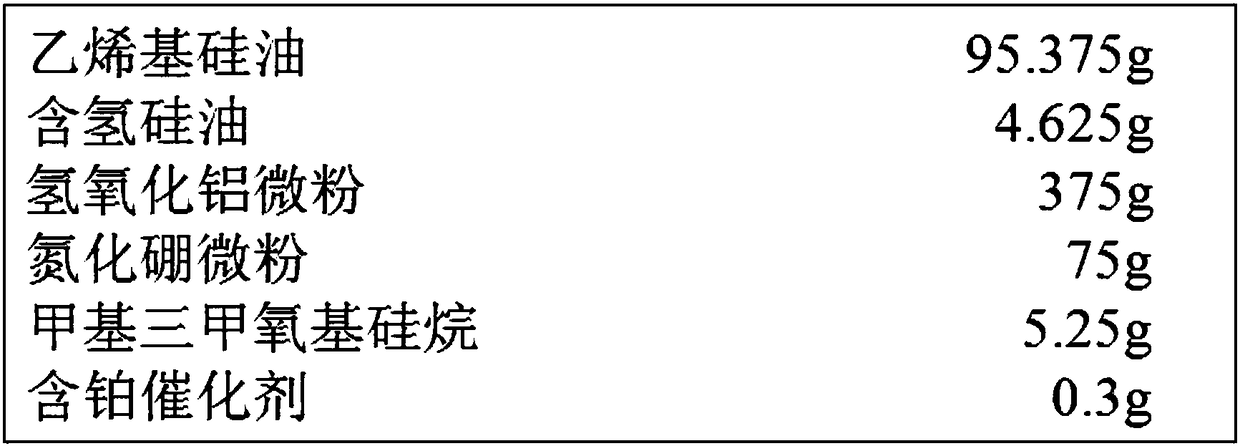

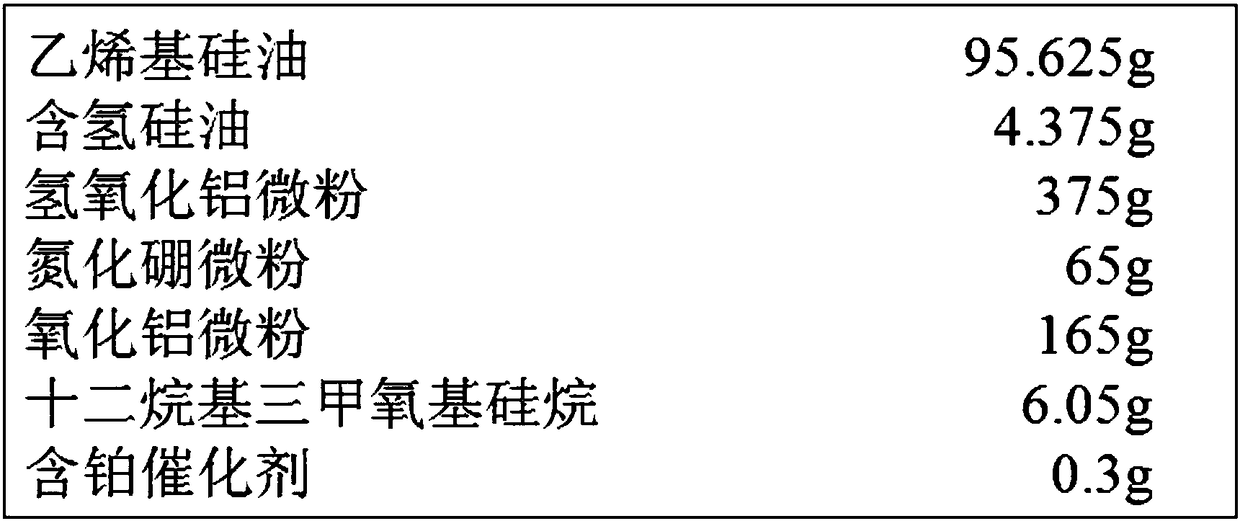

Low-specific-weight heat-conducting silica-gel gasket for new-energy vehicle and preparation method thereof

InactiveCN108440971ARegular Performance GuaranteedGuaranteed thermal conductivityHeat-exchange elementsAluminium hydroxideHeat conducting

The invention discloses a low-specific-weight heat-conducting silica-gel gasket for a new-energy vehicle. The low-specific-weight heat-conducting silica-gel gasket is prepared from the following components in parts by weight: 100 parts of organopolysiloxane, 200-2000 parts of high-heat-conductivity inorganic filler, 0-50 parts of lightweight filler, 0.05-0.5 part of catalyst and pigment, wherein the organopolysiloxane is a composition of vinyl polysiloxane and hydrogen-containing polysiloxane; the high-heat-conductivity inorganic filler is prepared from one or more of silicon dioxide, aluminium oxide, zinc oxide, magnesium oxide, aluminium hydroxide, aluminium nitride, silicon nitride, boron nitride and silicon carbonate; the particle size of the high-heat-conductivity inorganic filler is0.1-100mu m. The low-specific-weight heat-conducting silica-gel gasket disclosed by the invention has the beneficial effects that the conventional performances of the heat-conducting silica-gel gasketcan be ensured, meanwhile the low specific weight of the heat-conducting silica-gel gasket is realized, the weight of the low-specific-weight heat-conducting silica-gel gasket under the equal heat-conductivity coefficient is 40%-70% of that of the conventional heat-conducting gasket in the prior art, and the lightweight requirement for the new-energy vehicle is met.

Owner:苏州佰旻电子材料科技有限公司

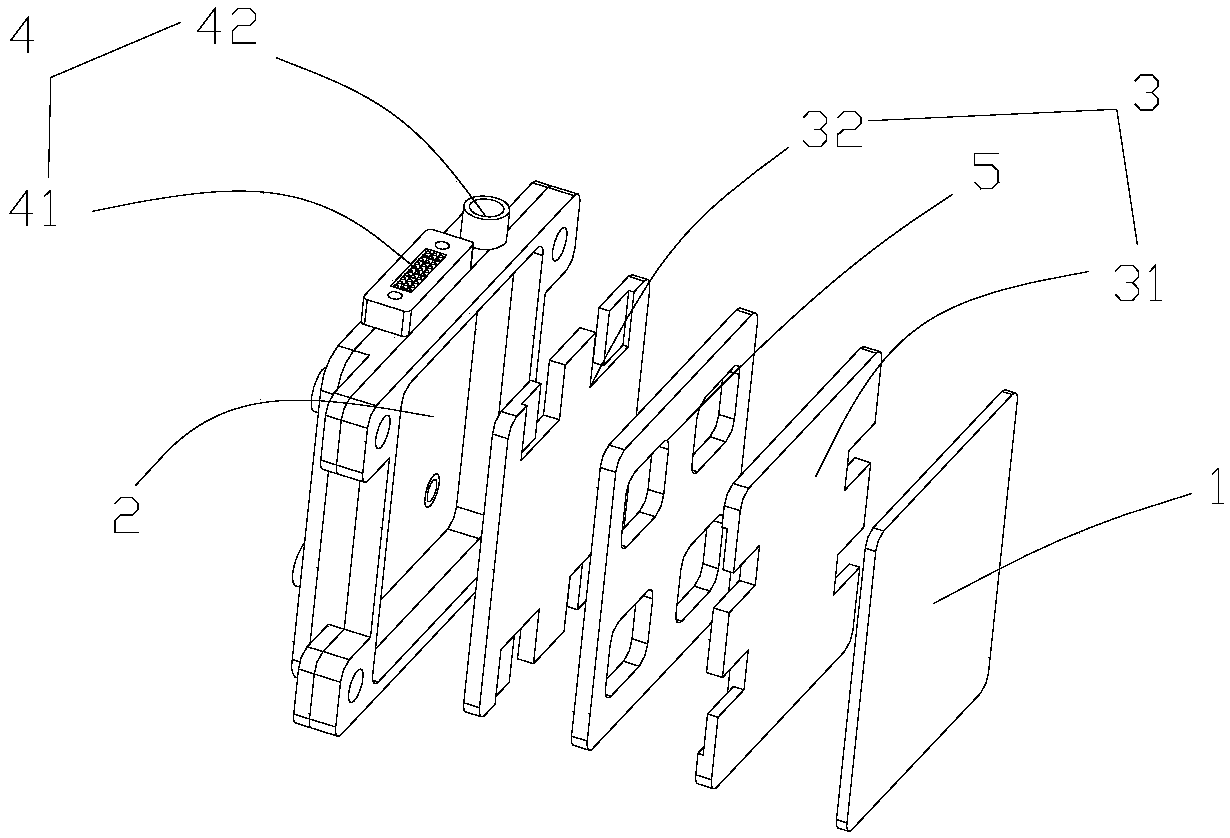

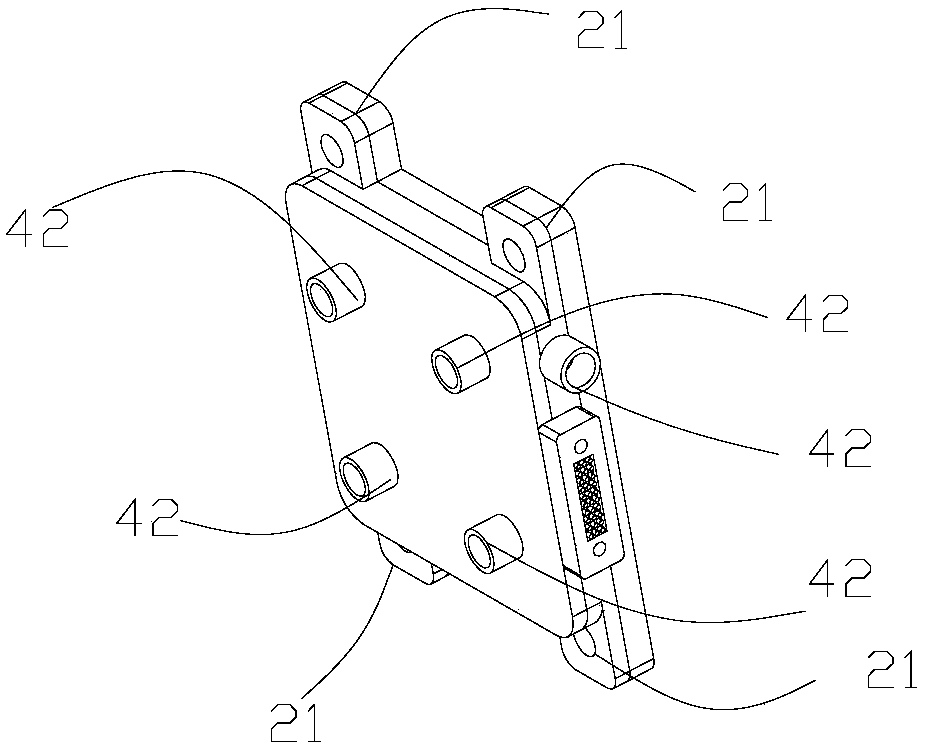

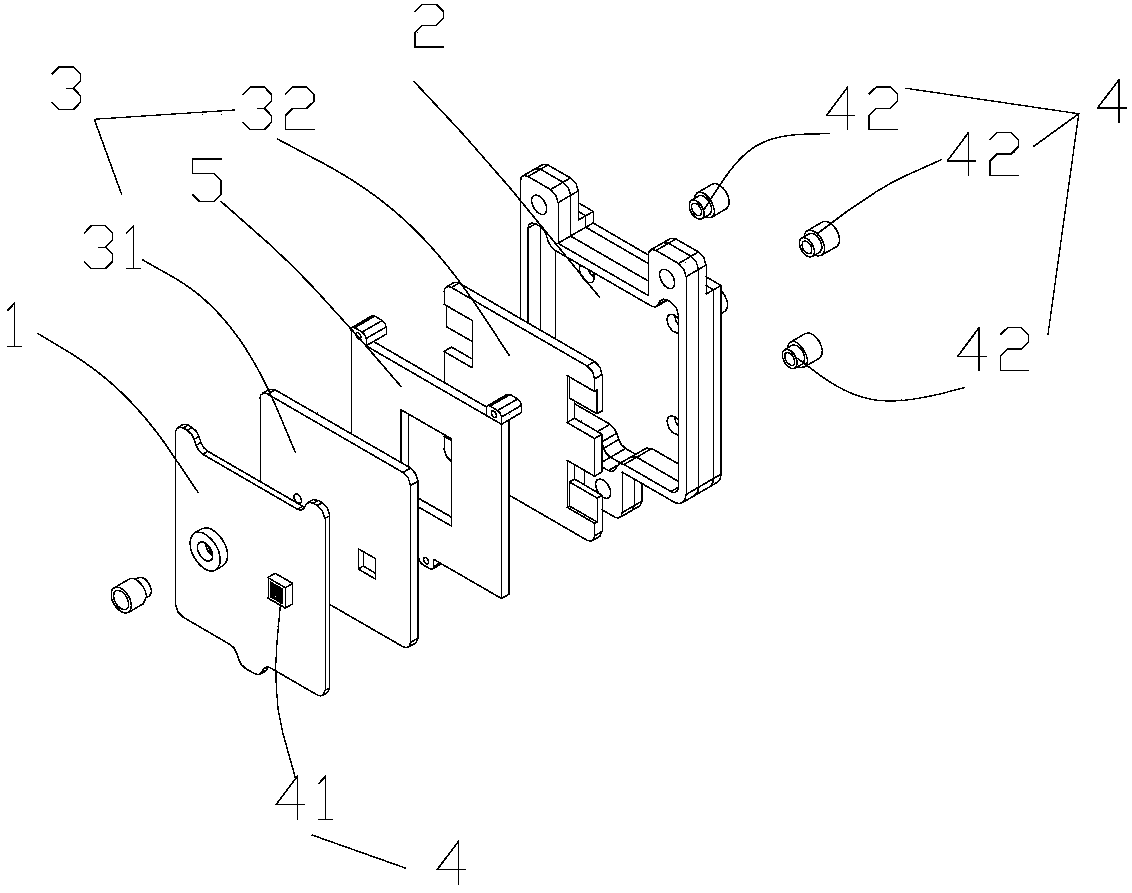

Silicon-aluminum-alloy-case-based three-dimensional assembling and packaging structure of microwave module

ActiveCN108305853ASolve technical problems with high integration requirementsRealize three-dimensional assemblySemiconductor/solid-state device detailsSolid-state devicesMicrowaveComputer module

The invention discloses a silicon-aluminum-alloy-case-based three-dimensional assembling and packaging structure of a microwave module. The assembling and packaging structure comprises a split type case body and one or more functional units. The case body includes an inner cavity type shell and one and more flat type cover plates; the shell includes one or more inner cavities. In packaging, the inner cavity is in sealed connection by the cover plate; the function units are assembled to the bottom of the inner cavity and the inner side of the cover plate; and the case body is formed by stackingof at least three different silicon-aluminum alloy material with different components. The assembling and packaging structure has the following beneficial effects: three-dimensional assembling and packaging inside the microwave module are realized; compared with the traditional microwave module only assembling components at the bottom of the inner cavity of the shell, the assembling and packagingstructure enables the integration rate to be improved by two for four times; and with the silicon aluminum alloy, the size and the mass are reduced, the thermal stress reliability is improved, and the heat dissipation performance is enhanced.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

1000 MPa-grade hot-rolled automotive frame steel and manufacturing method thereof

ActiveCN109023111AReduce manufacturing costSimple and feasible hot rolling process controlSteel platesSheet steel

The invention discloses 1000 MPa-grade hot-rolled automotive frame steel and a producing method thereof. The raw materials of the steel comprise the chemical components including, by mass, 0,10-0.20%of C, not greater than 0.10% of Si, 1.5-1.7% of Mn, not greater than 0.005% of S, not greater than 0.015% of P, 0.045-0.055% of Nb, 0.08-0.10% of Ti, not greater than 40 ppm of N, 0.025-0.060% of Als,not greater than 0.002% of H and the balance Fe. According to a hot-rolled steel plate produced through the method, the yield strength is greater than or equal to 750 MPa, the tensile strength is greater than or equal to 1000 MPa, the elongation is greater than or equal to 10%, and cold bend positions are free of cracks and a good cold bend effect is achieved under the conditions that the wide cold bend is 180 degrees and the cold bend flexual center diameter D is equal to 4t (thickness). The technological flow adopted by the method is simple, no equipment needs to be additionally arranged, and the steel has the advantages of being capable of being produced on a large scale, economical, feasible and stable in performance.

Owner:武汉钢铁有限公司

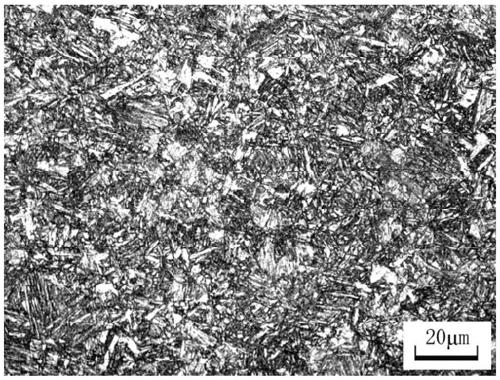

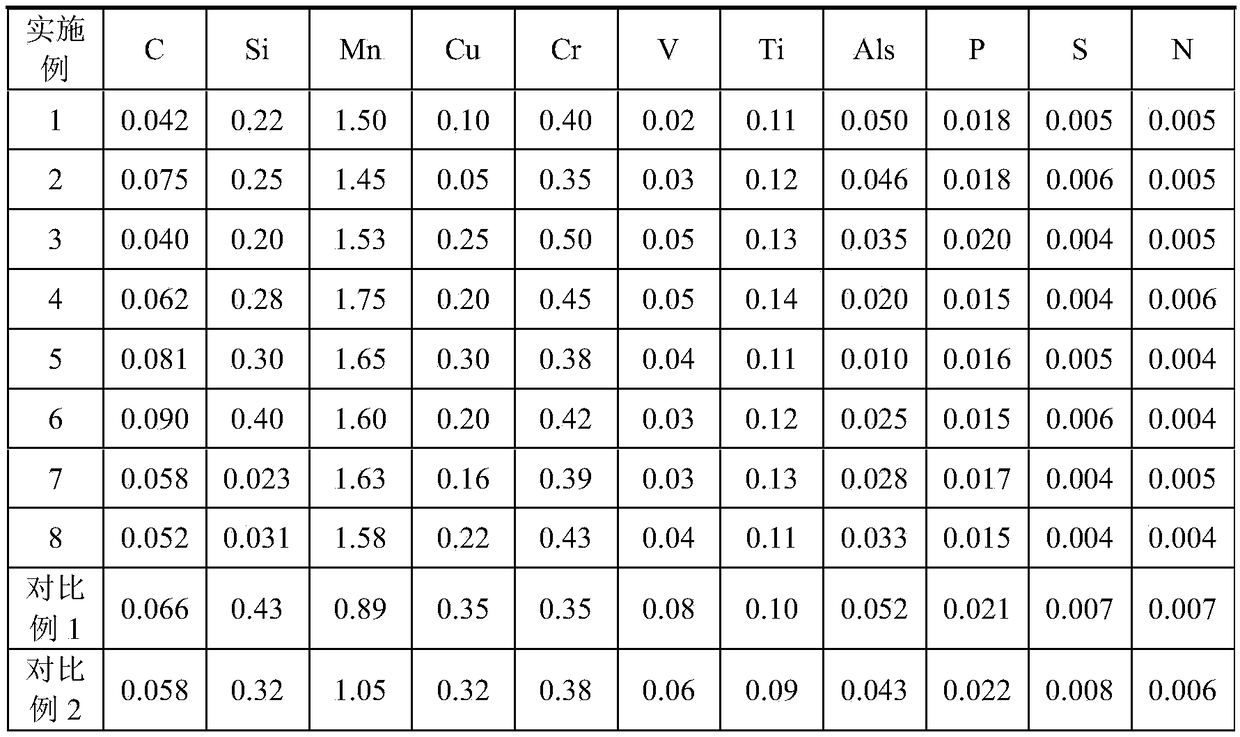

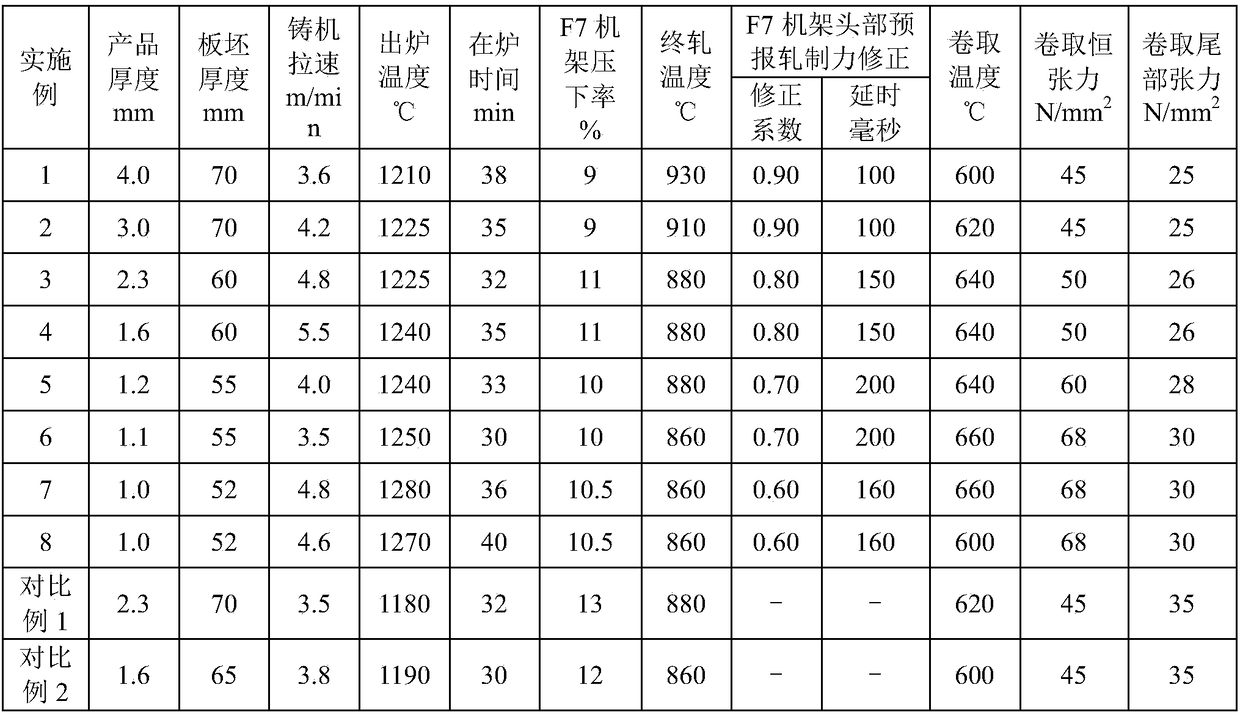

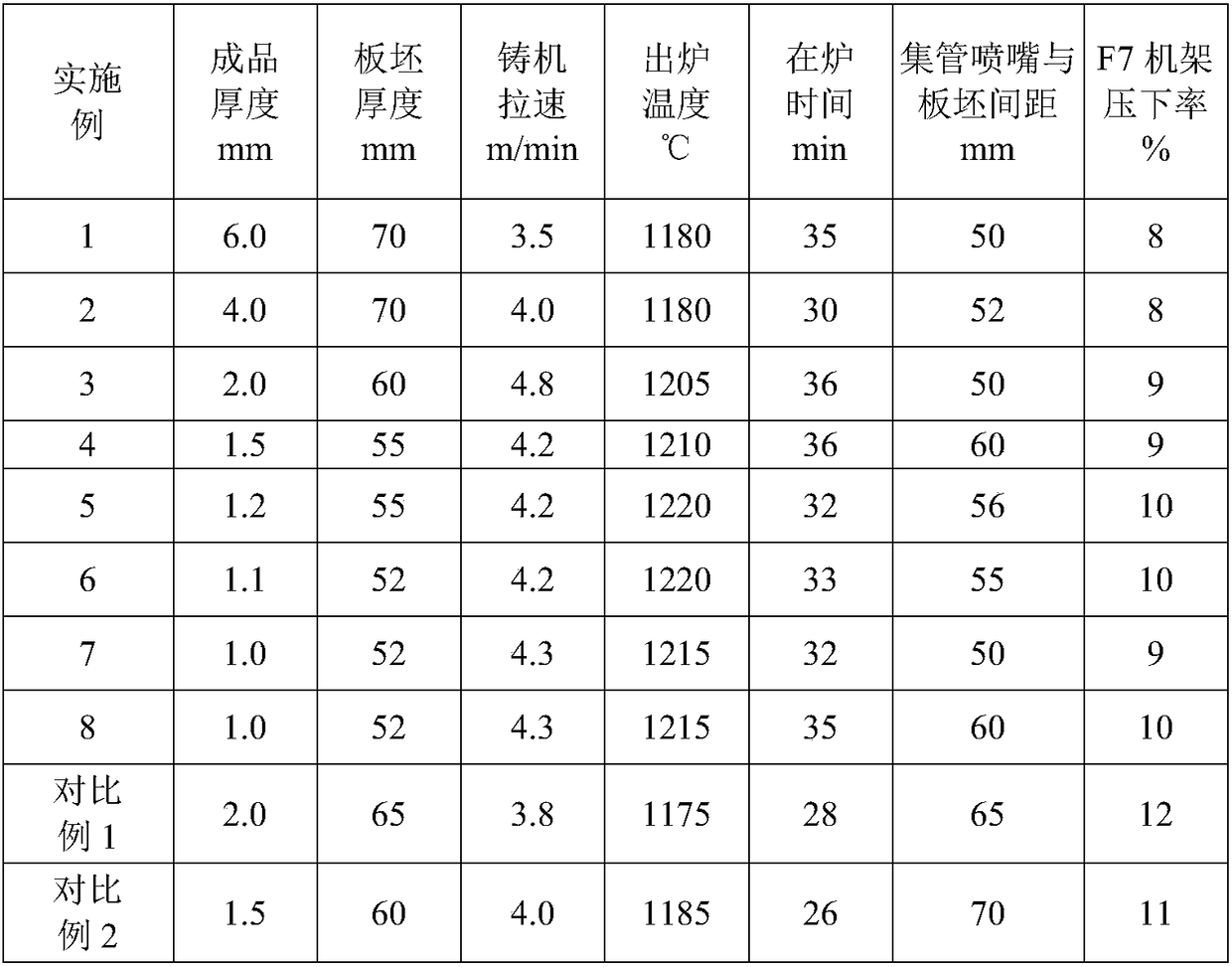

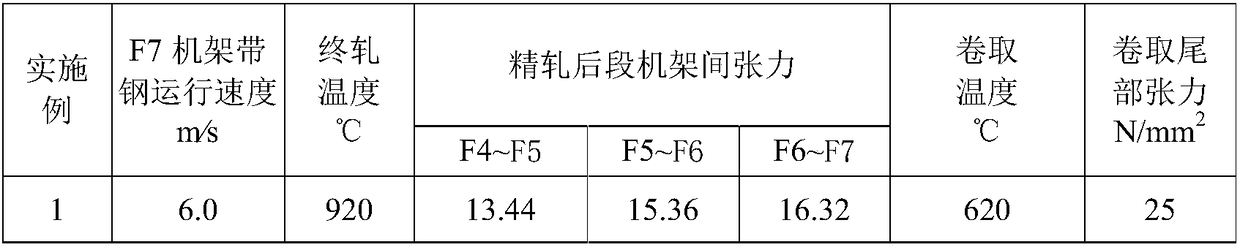

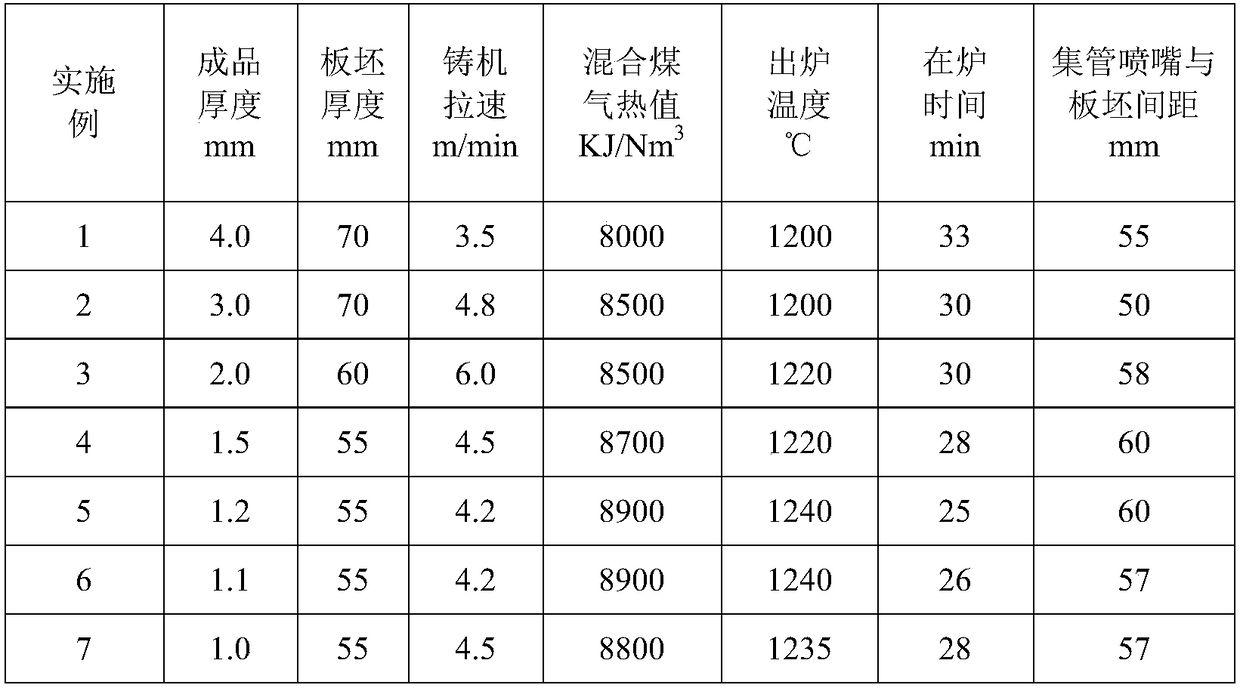

Thin weathering steel with tensile strength of not less than 800 MPa produced by short process, and method

The invention discloses a thin weathering steel with tensile strength of not less than 800 MPa produced by a short process. The thin weathering steel is prepared from the following components in percentage by weight: 0.04 to 0.09 percent of C, 0.20 to 0.40 percent of Si, 1.45 to 1.75 percent of Mn, 0.05 to 0.30 percent of Cu, 0.35 to 0.50 percent of Cr, 0.02 to 0.05 percent of V, 0.11 to 0.14 percent of Ti, 0.010 to 0.050 percent of Als, not more than 0.020 percent of P, not more than 0.006 percent of S, and not more than 0.006 percent of N. A production method comprises: performing continuouscasting into a thin slab after conventional smelting; soaking the thin slab; performing scale removal for two times; performing finishing rolling for seven times; performing laminar cooling to a coiling temperature; coiling; leveling. According to the invention, the full-length thickness of strip steel is uniform, the plate shape and the roll shape are excellent, the rolling process is stable, the finished product rate of an original variety is increased to 92 percent or more, the purpose of replacing a cold-rolled product in batches is achieved, and the demand for the light weight of a container is met.

Owner:武汉钢铁有限公司

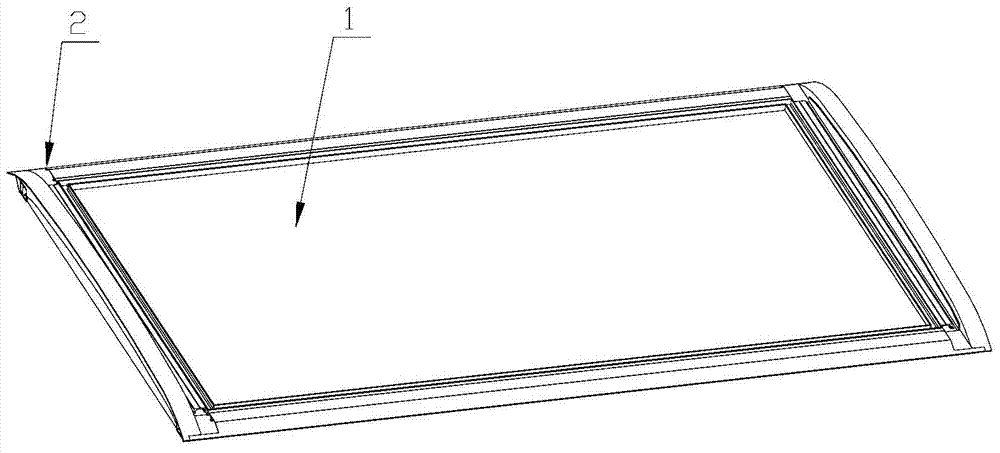

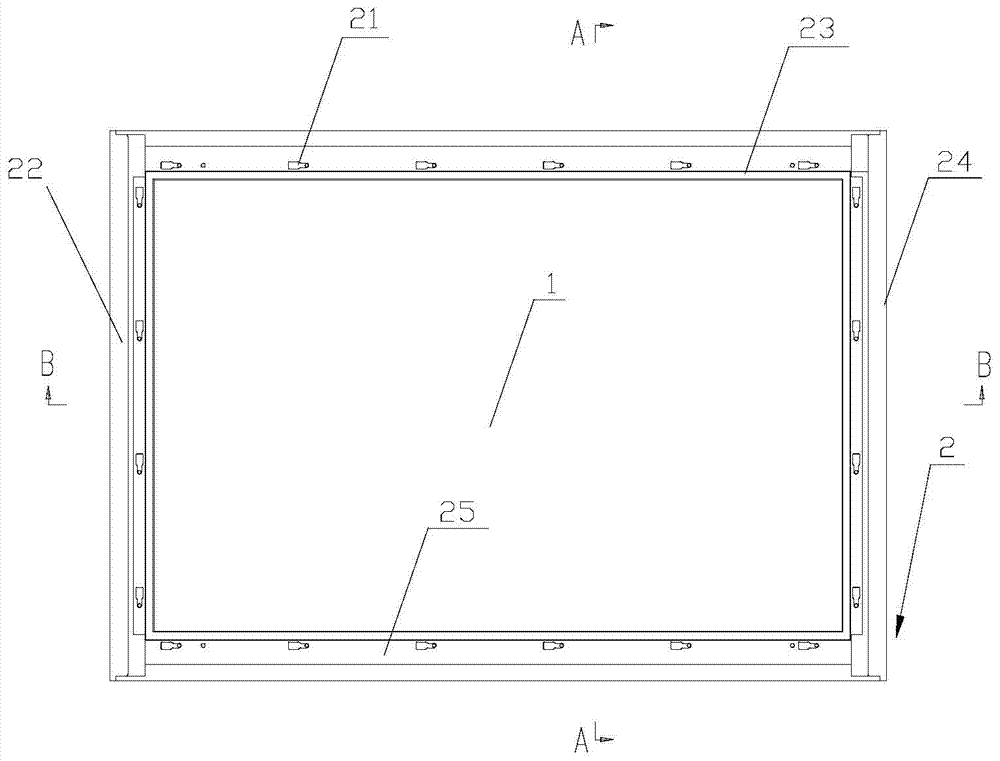

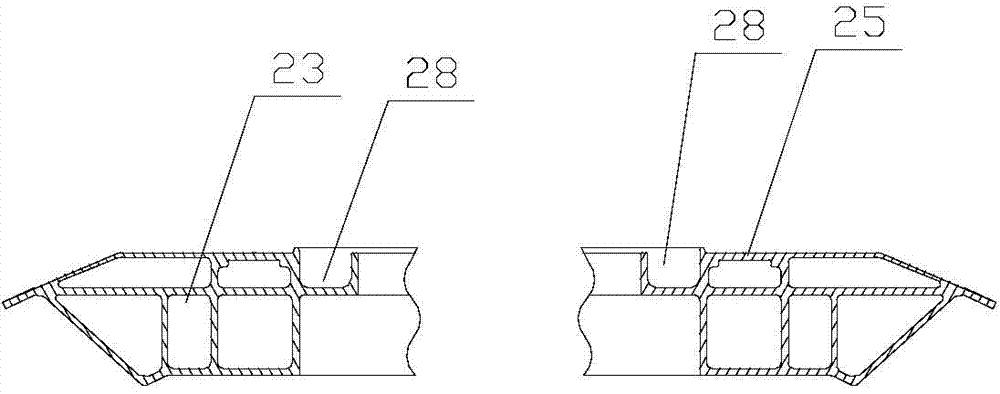

Roof and air conditioner installation seat of railway vehicle

ActiveCN104709303ARealize "sinking" installationDoes not affect the outer contourRailway heating/coolingAxle-box lubricationAerospace engineering

The invention provides a roof and an air conditioner installation seat of a railway vehicle. Sunken installation of an air conditioner can be achieved, the influences on a roof streamline structure are reduced, air resistance and aerodynamic noise are lowered, and the aerodynamic performance of a train is improved. The air conditioner installation seat is arranged on the roof of the railway vehicle and is of a square frame structure, a middle cavity of the square frame structure is used for containing the air conditioner, the four sides of the square frame structure are edge beams made of hollow sectional materials, the inner sides of the edge beams are provided with air conditioner installation positions, the outer sides of the edge beams can be welded to the hollow sectional materials of the roof in an inserted mode, and the top faces of the side beams are each of an arc shape matched with the roof. The middle cavity of the square frame structure is used for containing the air conditioner, the whole air conditioner is conveniently arranged on the roof and cannot protrude out of the roof, sunken installation of the air conditioner is achieved, the influences of air conditioner installation on the roof streamline structure are effectively reduced, air resistance and aerodynamic noise are lowered, and the aerodynamic performance of the train is improved.

Owner:CRRC QINGDAO SIFANG CO LTD +1

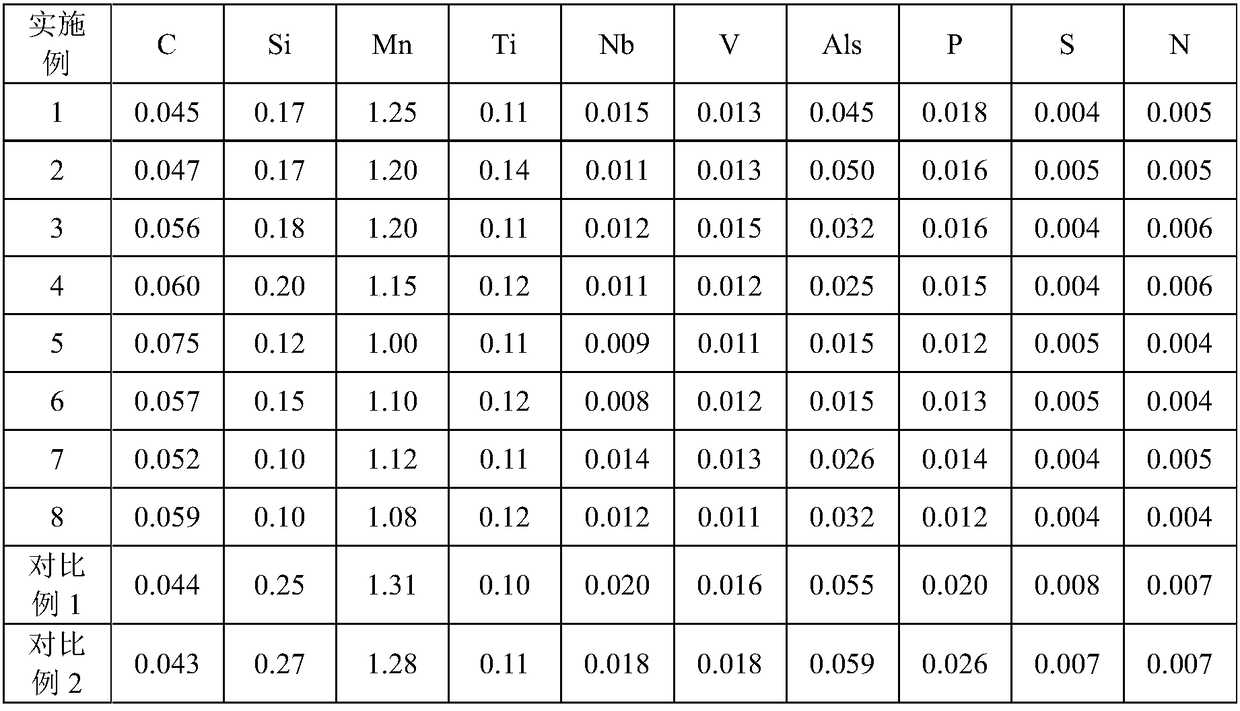

600MPa-grade thin hot-rolled automobile structural steel produced by short process, and method

The invention discloses a 600MPa-grade thin hot-rolled automobile structural steel produced by a short process. The steel is prepared from the following components in percentage by weight: 0.045 to 0.075 percent of C, not more than 0.20 percent of Si, 1.00 to 1.25 percent of Mn, 0.11 to 0.14 percent of Ti, not more than 0.015 percent of Nb, not more than 0.015 percent of V, 0.015 to 0.050 percentof Als, not more than 0.018 percent of P, not more than 0.005 percent of S, and not more than 0.006 percent of N. A production method comprises: performing continuous casting into a thin slab after conventional smelting; soaking the thin slab; performing scale removal for two times; performing finishing rolling for seven times; performing laminar cooling to a coiling temperature; coiling; leveling. According to the invention, the shortcomings of poor plate shape and roll shape, unstable rolling process and the like in the process of rolling the 600MPa-grade thin hot-rolled automobile structural steel by a short process are solved, the high-stability and large-scale production of the 600MPa-grade thin hot-rolled automobile structural steel produced by the short process is realized, the plate shape and the roll shape are excellent, the rolling process is stable, the finished product rate of an original variety is increased to 93 percent or more, and the purpose of replacing a cold-rolledproduct is achieved.

Owner:武汉钢铁有限公司

High-toughness non-heat treatment strengthened die-casting aluminum alloy and preparation method thereof

The invention discloses a high-toughness non-heat treatment strengthened die-casting aluminum alloy and a preparation method thereof. The aluminum alloy comprises, by weight: RE: 7-10%, Mg: 0.05-0.5%,Ti: 0.05-0.1%, inevitable impurity elements: less than or equal to 0.1%, and the balance Al. The component of RE is one or any combination of Ce and La. A pure aluminum ingot, a pure magnesium ingot,Al-Ti master alloy, Al-Ce master alloy and Al-La master alloy are used as raw materials, the preparation process of the aluminum alloy is pressure casting, and the alloy does not need to be subjectedto subsequent heat treatment; the yield strength is more than 150 MPa, the tensile strength is more than 200 MPa and the elongation rate is more than 10% in an as-cast state; and the high-toughness non-heat treatment strengthened die-casting aluminum alloy can be used for structural members with high requirements on mechanical properties in the industries of automobiles and the like, steel structural members are replaced, and the light weight development requirements of automobiles are met.

Owner:江苏双梦源精密成型科技有限公司

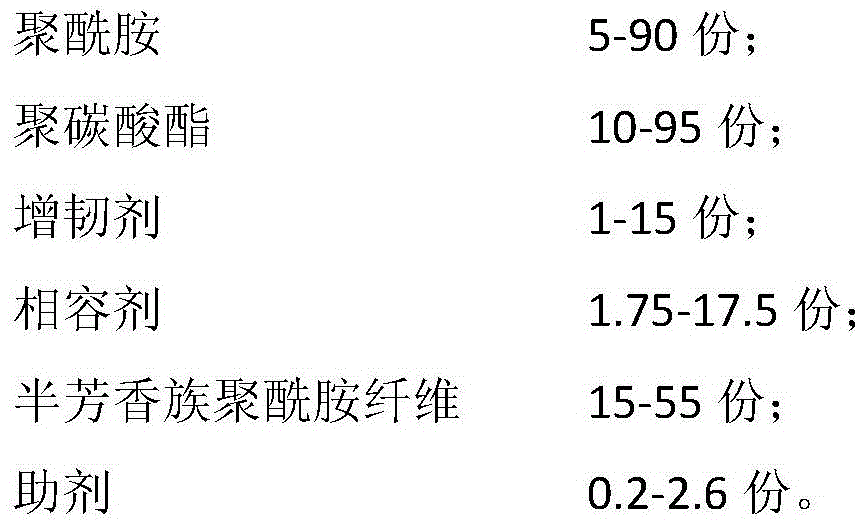

Polyamide polycarbonate alloy material and preparation method and applications thereof

The invention provides a polyamide polycarbonate alloy material and a preparation method and applications thereof. The polyamide polycarbonate alloy material comprises the following components in parts by weight: 5 to 90 parts of polyamide, 10 to 95 parts of polycarbonate, 1 to 15 parts of toughening agent, 1.75 to 17.5 parts of compatilizer, 15 to 55 parts of semi-aromatic polyamide fibers, and 0.2 to 2.6 parts of auxiliary agent. The preparation method comprises the following steps: evenly mixing polyamide, polycarbonate, a toughening agent, a compatibilizer, and an auxiliary agent, adding the mixture into the main feed hopper of a double-screw extruder; adding the semi-aromatic polyamide fibers into the lateral feed hopper of the double-screw extruder, and carrying out extruding, pulling, and cutting to obtain the polyamide polycarbonate alloy material. The provided polyamide polycarbonate alloy material has the advantages of good interfacial compatibility, good particle dispersing property, and high strength, can be used to prepare parts of electronic and electrical products, and has a wide application range.

Owner:上海昶勤实业有限公司

Rail-bound vehicle aramid-fiber honeycomb side ceiling and preparation method therefor

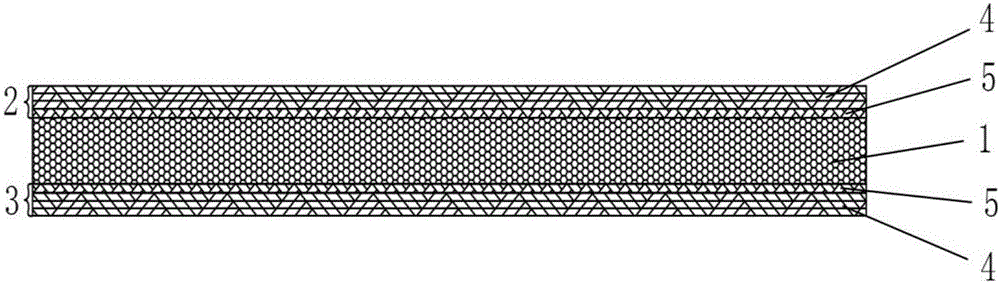

InactiveCN106476330AMeet the needs of lightweightObvious weight loss effectSynthetic resin layered productsLaminationEpoxyHoneycomb

The invention discloses a rail-bound vehicle aramid-fiber honeycomb side ceiling and a preparation method therefor. The aramid-fiber honeycomb side ceiling comprises an aramid-fiber honeycomb core, an upper panel laminated to the upper surface of the aramid-fiber honeycomb core and a lower panel laminated to the lower surface of the aramid-fiber honeycomb core, wherein each of the upper and lower panels comprises a flame-retardant epoxy resin composite fiber fabric layer and a flame-retardant epoxy resin composite chopped fiber mat layer, the chopped fiber mat layer in the upper panel is laminated to the upper surface of the aramid-fiber honeycomb core, the chopped fiber mat layer in the lower panel is laminated to the lower surface of the aramid-fiber honeycomb core, a U-shaped connecting member which is used for being connected with a crossbeam of a rail-bound vehicle is mounted at the upper end of the rail-bound vehicle aramid-fiber honeycomb side ceiling, and lock-hole inserted parts are embedded at the lower part of the rail-bound vehicle aramid-fiber honeycomb side ceiling. The rail-bound vehicle aramid-fiber honeycomb side ceiling is light in weight and high in strength and can reach the flame-retardant standard; and the preparation method for the rail-bound vehicle aramid-fiber honeycomb side ceiling is low in production cost and is applicable to the small-scale development of rail-bound vehicle side ceilings.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

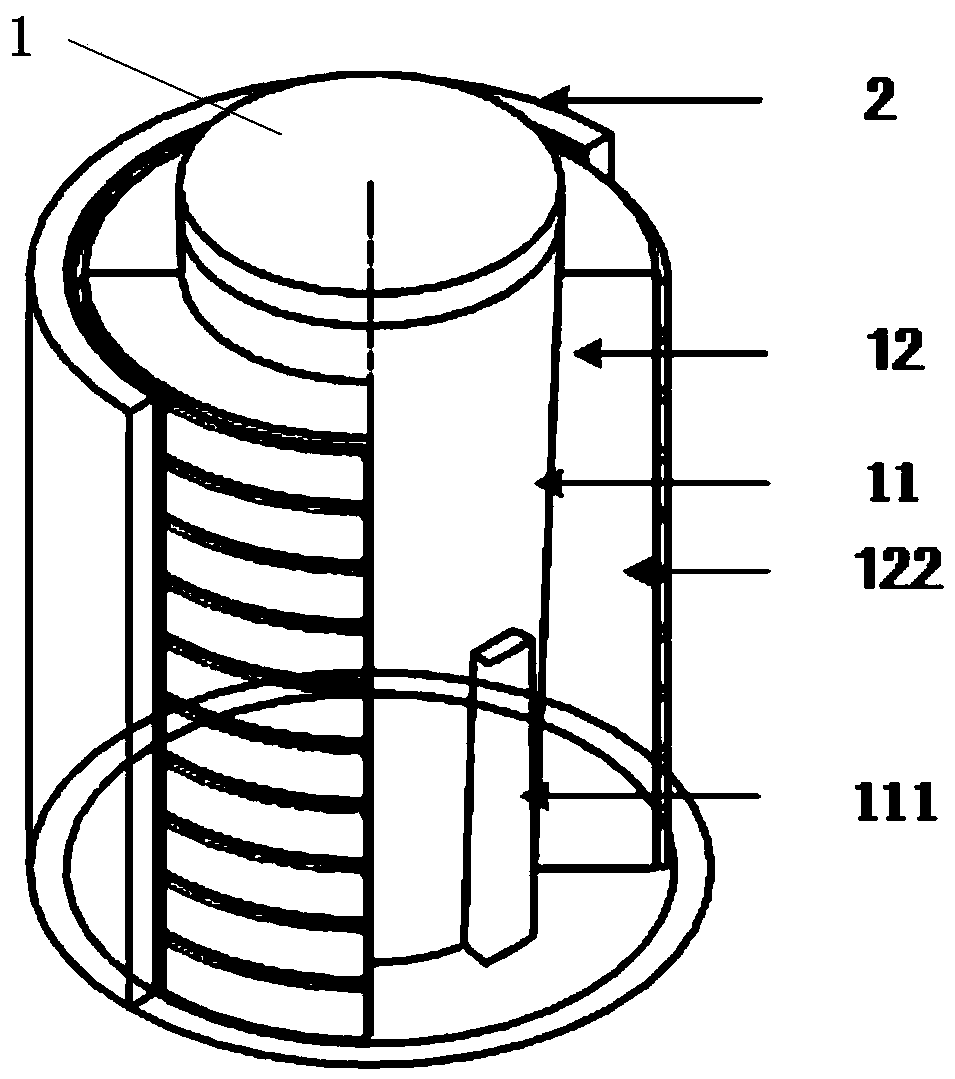

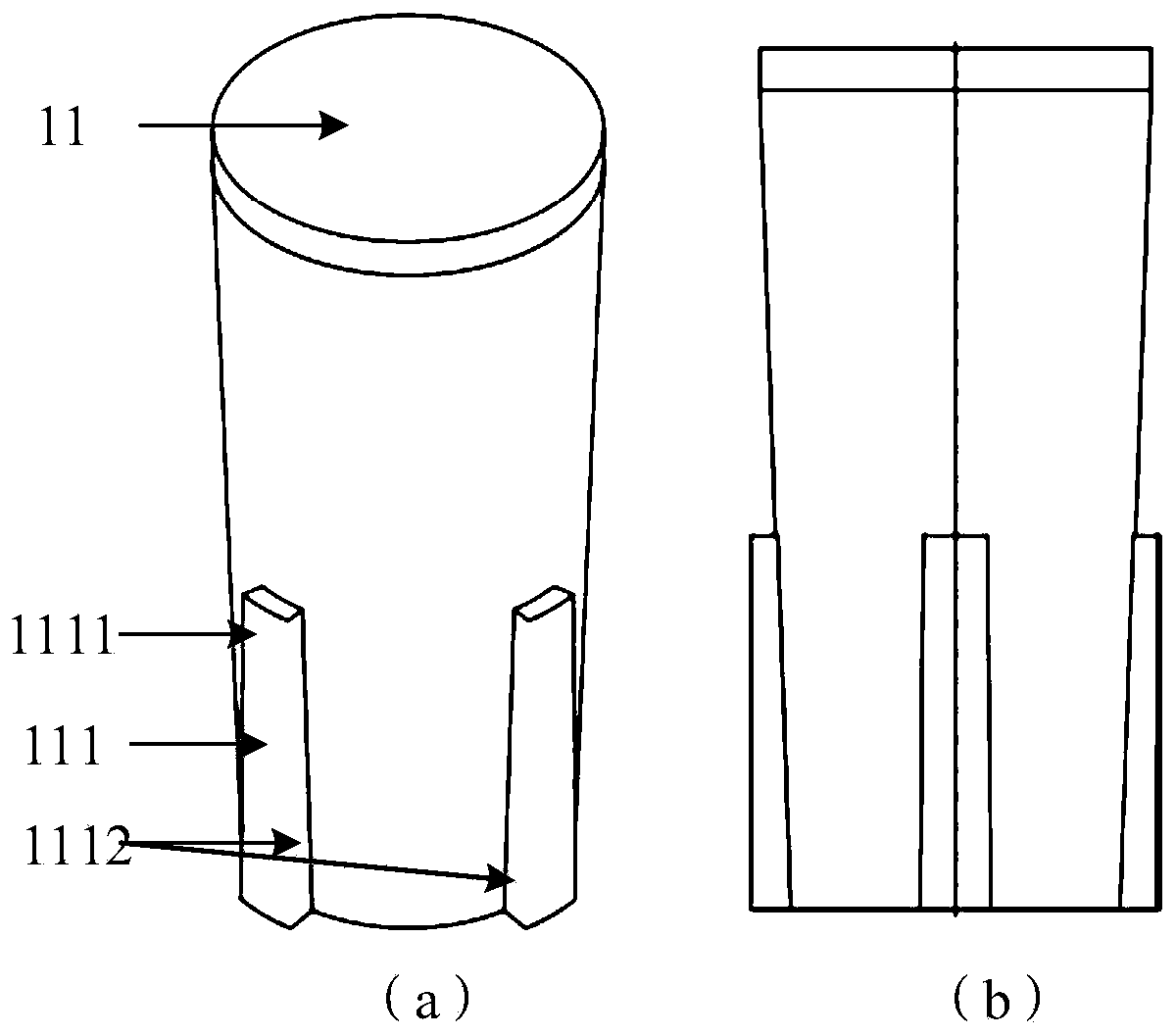

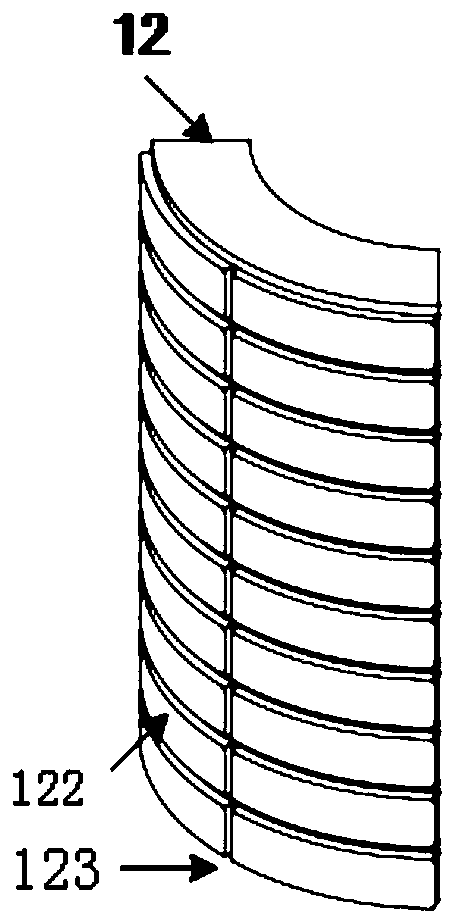

Demolding integrated mold for inner wall grid high rib barrel-shaped thin-wall part and forming method

InactiveCN109894562ARealize shape controlImprove fatigue resistanceForging/hammering/pressing machinesBarrel ShapedThick wall

The invention discloses a demolding integrated mold for an inner wall grid high rib barrel-shaped thin-wall part and a forming method. The mold comprises a convex mold and a concave mold, wherein theconvex mold comprises a convex mold mandrel and a plurality of convex mold inserts. The diameter of the periphery of the convex mold mandrel is gradually decreased from the top end to the bottom end.The convex mold inserts form a cylinder arranged on the periphery of the convex mold mandrel in a sleeving manner. A plurality of toroidal rib grooves and a plurality of vertical rib grooves are formed in the outer surface of each convex mold insert, and the toroidal rib grooves and the vertical rib grooves are arranged in a staggered manner to form a plurality of mesh blocks. The concave mold isarranged on the periphery of the convex mold in a sleeving manner. The forming method solves the problems of high cost, complex steps and the like of an existing forming method (for example, machininghigh ribs on a thick-wall barrel and fixing the high ribs to a panel by way of welding or riveting) of a metal barrel-shaped structural part, so that a large inner wall grid high rib barrel-shaped member is formed integrally.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Visible light-medium wave infrared dual-band common aperture optical system

ActiveCN112180578AAvoid ghost imagesImprove image qualityOptical elementsImaging qualityImage correction

The invention provides a visible light-medium wave infrared dual-band common aperture optical system, which solves the problems that a conventional dual-band imaging system is large in overall size and heavy in weight. The system comprises a main reflector, a light splitting element, a visible light subsystem and a medium wave infrared subsystem, the target light is reflected to the light splitting element through the main reflector, and the light splitting element is used for splitting the light into two paths which respectively enter the visible light subsystem and the medium wave infrared subsystem. The visible light subsystem comprises a first folding axis reflector, a second folding axis reflector, a primary image correction lens group, a collimating lens group and an objective lens group which are sequentially arranged along a light path; and the medium wave infrared subsystem comprises a medium wave infrared correction lens group, a fourth folding axis reflector and a projectionlens group which are sequentially arranged along a light path. The visible light subsystem and the medium wave infrared subsystem are divided into two paths in a mode of sharing the light splitting of the primary reflector and the secondary reflector, the visible light subsystem and the medium wave infrared subsystem are independently and synchronously imaged respectively, and the dual-band lenshas high imaging quality and completely meets the requirements of a system for target detection and imaging.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

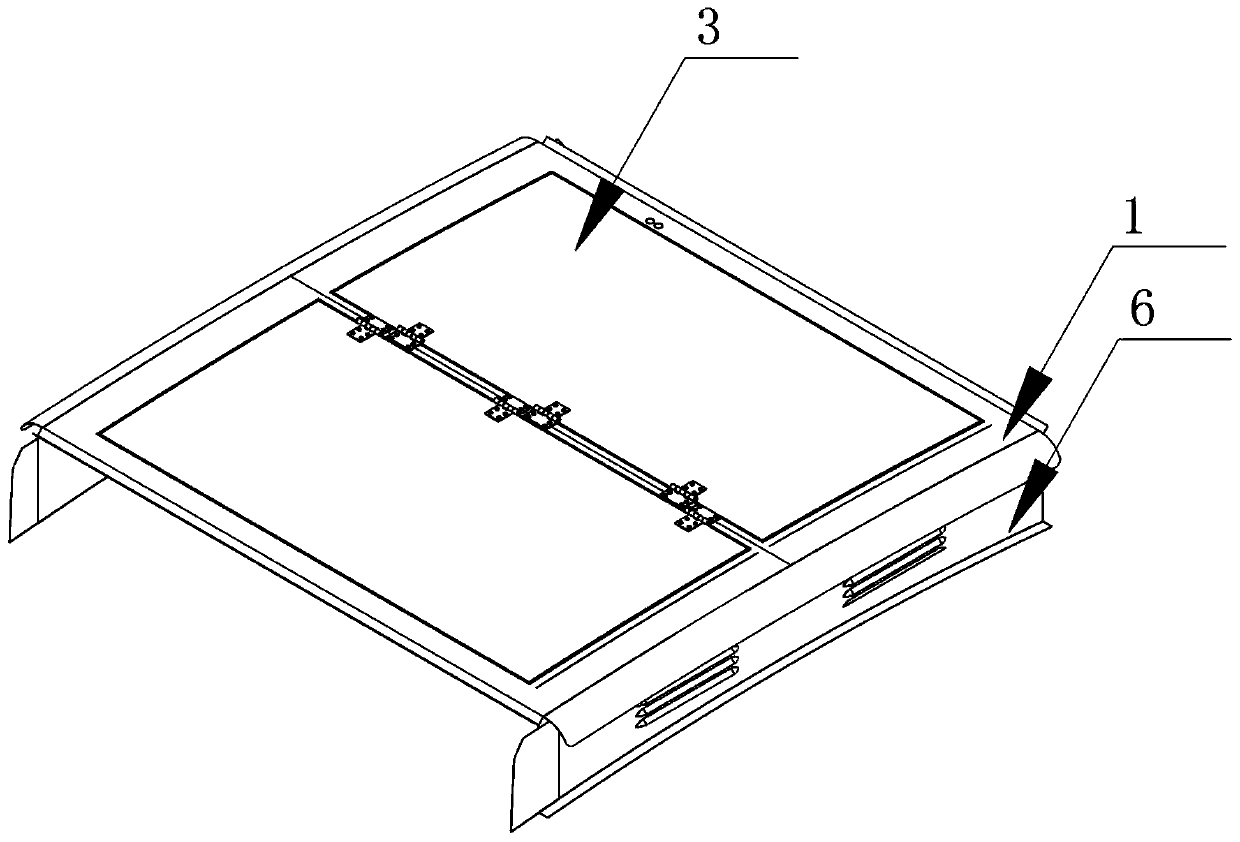

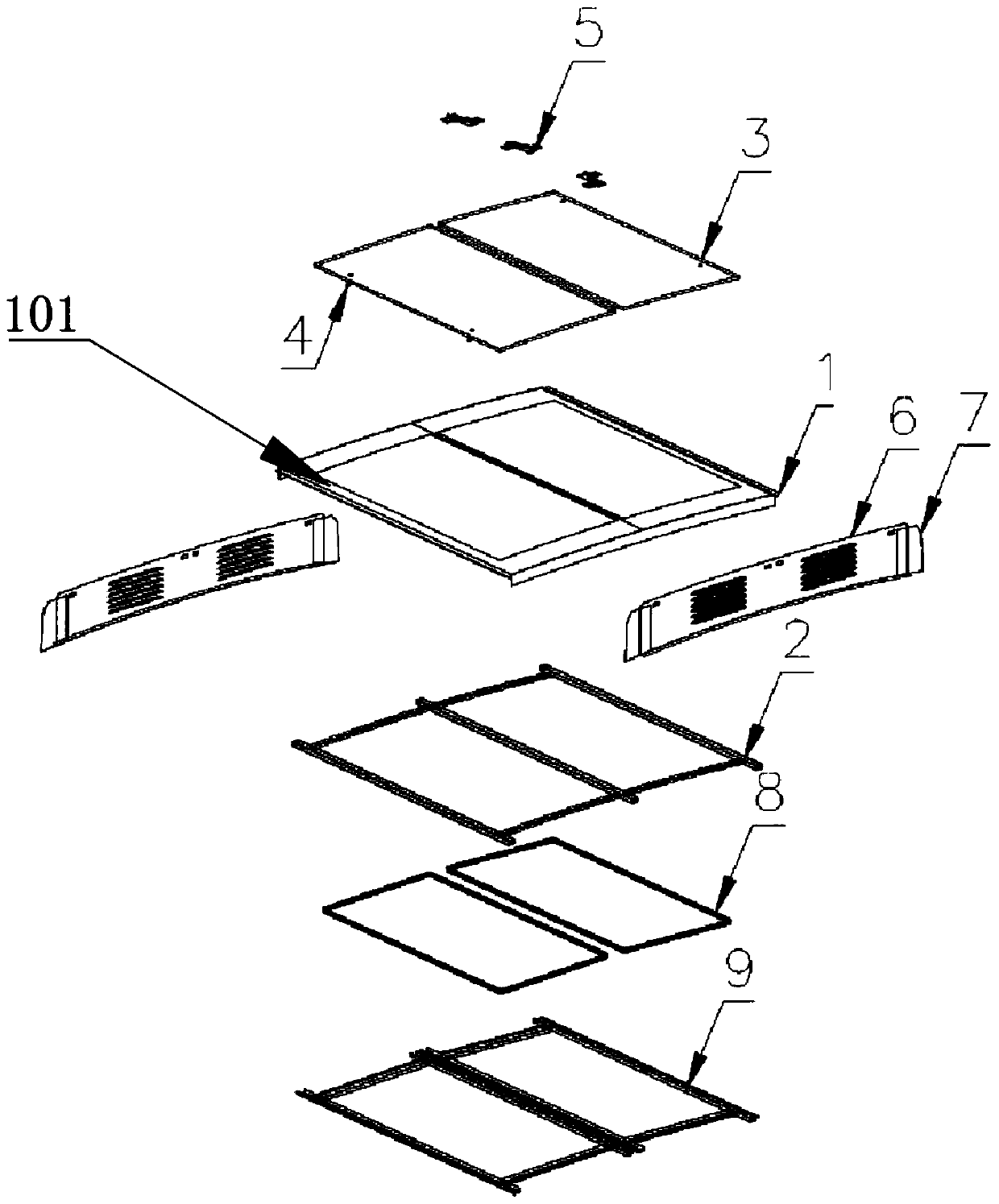

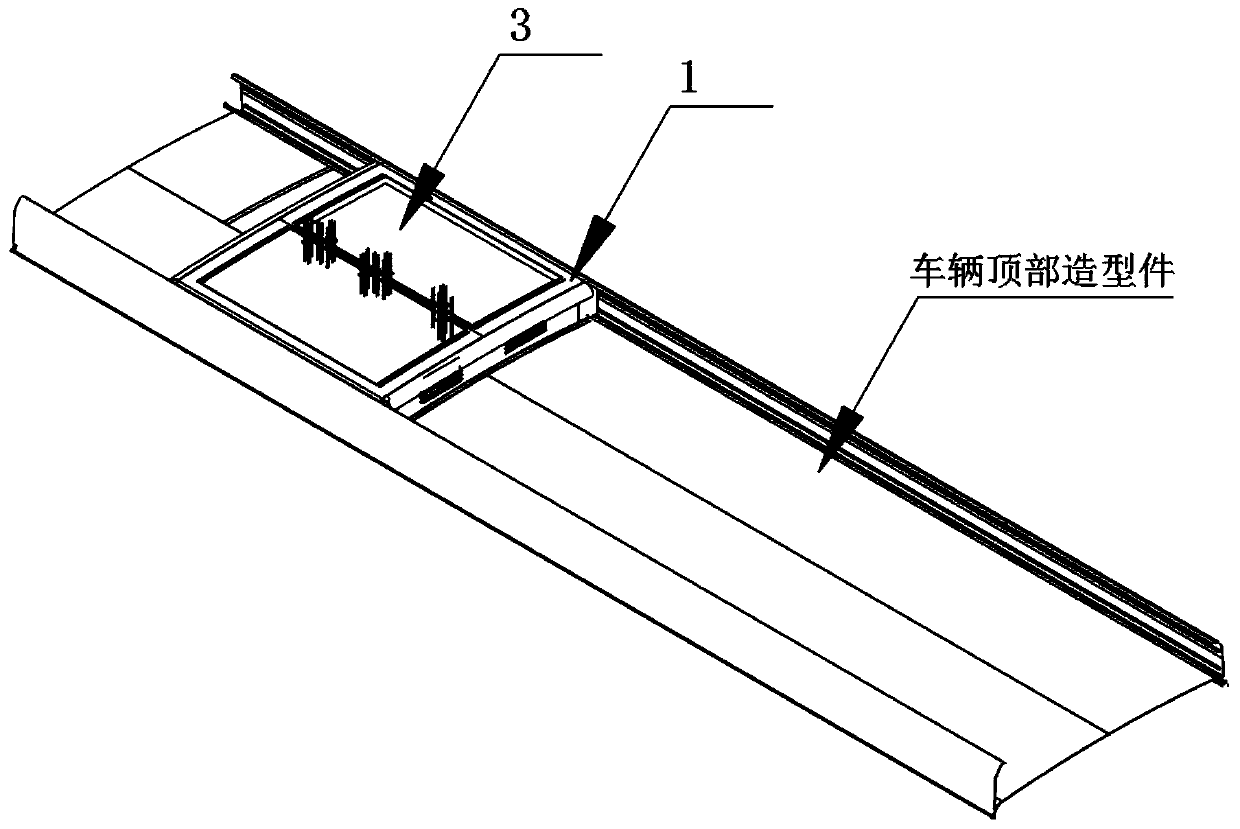

Top open type light-weight power battery cover assembly of low-entrance city bus

InactiveCN111477793AAvoid enteringReduce weightPropulsion by batteries/cellsCell component detailsPower batteryElectrical battery

The invention discloses a top open type light-weight power battery cover assembly of a low-entrance city bus. The assembly comprises a shell, an aluminum alloy rectangular pipe framework, two access doors and a drainage device; the shell is composed of an aluminum plate made of aluminum alloy; The two sides of the shell are bent and fixed to a passenger car roof modeling part through screws; and the two access doors are arranged on the two sides above the middle of the shell respectively. The assembly has the beneficial effects that the access doors on the top the cover are made of a light honeycomb aluminum plate material and are lighter than a common aluminum alloy cabin door; the size of the access doors can be reasonably designed in combination with the space for battery maintenance and even disassembly; the access doors are installed on the cover shell through hinges and locked through rotary locks; when maintenance is needed, maintenance can be conducted only by unlocking the locks and turning over the access doors, so that the access doors are very convenient to use; and according to the aluminum alloy drainage device, a sealing rubber strip is arranged on the edge of the notch of the drainage device, and when the access doors are closed, the access doors tightly press the sealing rubber strip to prevent water from entering the cover.

Owner:ANHUI ANKAI AUTOMOBILE

Hot-dip galvanized 420MPa-grade low-alloy high-strength steel for automobile and production method thereof

ActiveCN112725704ALow costEasy to prepareHot-dipping/immersion processesFurnace typesChemical compositionAlloy

The invention discloses hot-dip galvanized 420MPa-grade low-alloy high-strength steel for an automobile and a production method thereof. The hot-dip galvanized 420MPa-grade low-alloy high-strength steel for the automobile comprises the following chemical components in percentage by mass: 0.06-0.08% of C, less than or equal to 0.04% of Si, 1.15-1.25% of Mn, less than or equal to 0.018% of P, less than or equal to 0.005% of S, 0.020-0.050% of Alt, 0.040-0.055% of Nb, 0.020-0.030% of Ti, 0.0010-0.0030% of Ca and the balance Fe and inevitable impurities. The high-strength steel meets the conditions that the yield strength is greater than or equal to 449MPa and less than or equal to 520MPa and the yield ratio is greater than or equal to 0.90, has relatively high strength and yield ratio and can meet the requirements of the automobile industry on weight reduction, safety, energy conservation, environmental friendliness, corrosion resistance and the like.

Owner:BAOTOU IRON & STEEL GRP

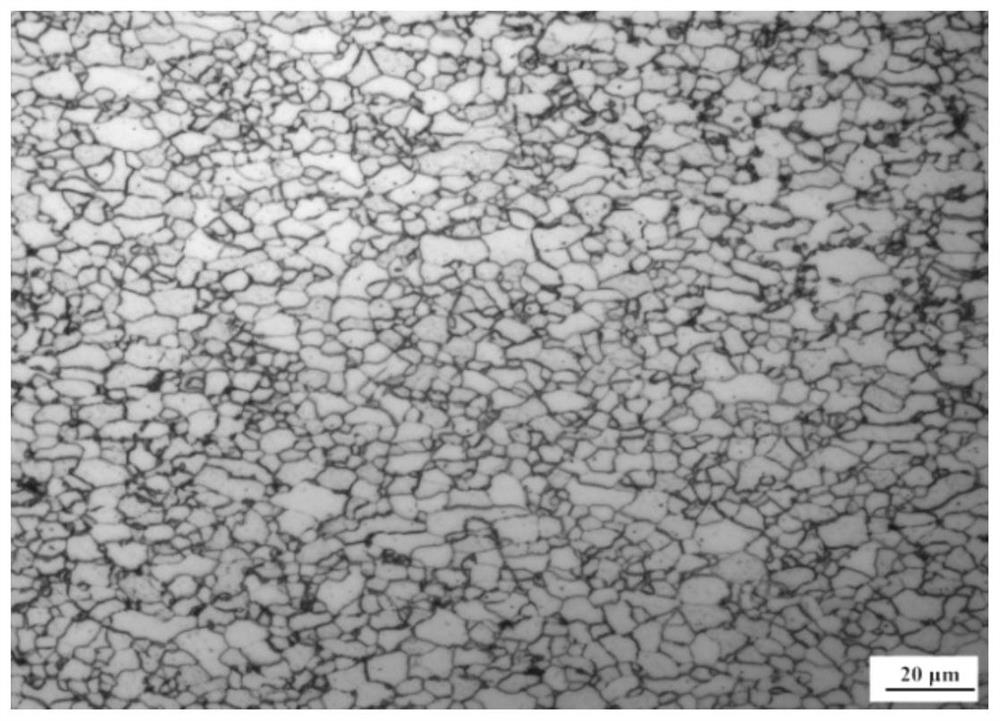

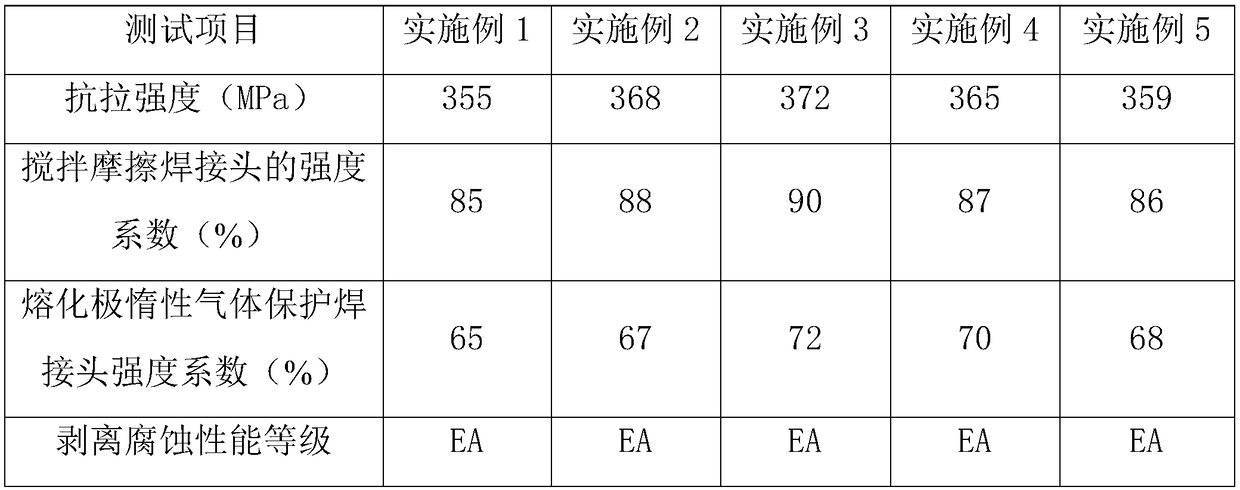

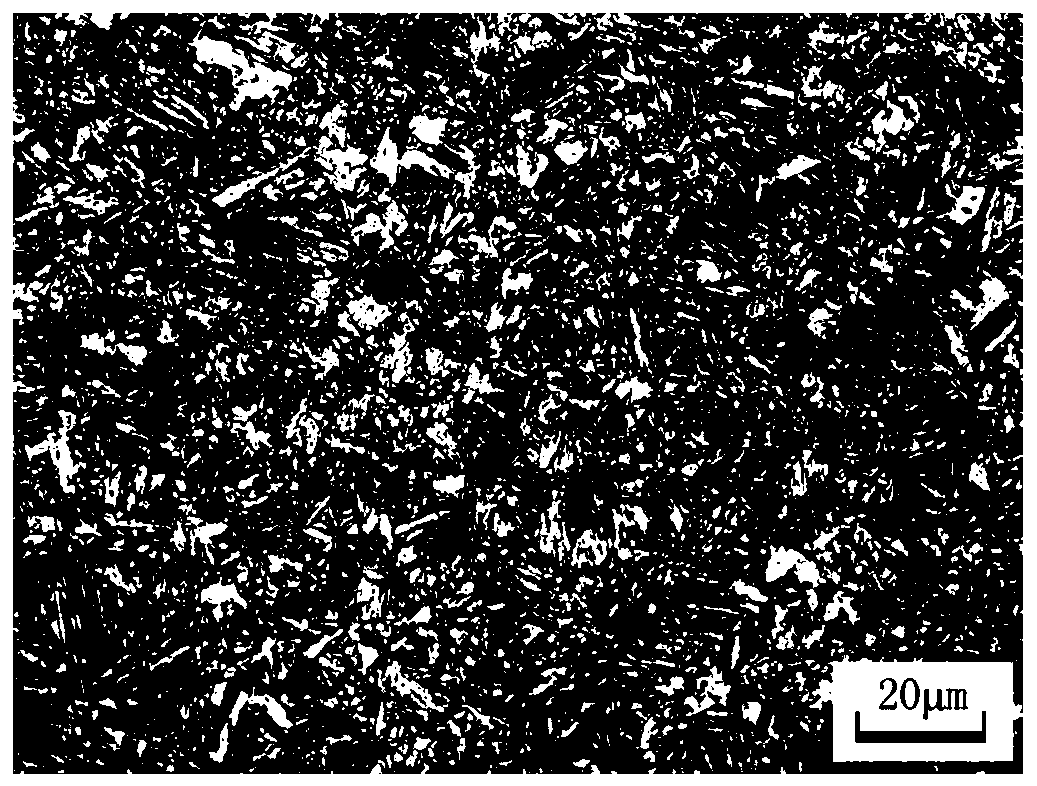

Aluminum alloy material for electric car power battery tray and preparation method thereof

The invention relates to the technical field of aluminum alloy machining, in particular to an aluminum alloy material for an electric car power battery tray and a preparation method thereof. The aluminum alloy material comprises, by mass, 1.00-1.18% of Mg, 0.82-1.00% of Si, 0.88-1.02% of Cu, 0.64-0.82% of Mn, 0.05-0.25% of Zr, less than or equal to 0.3% of Fe, less than or equal to 0.15% of othertotal impurities, and the balance Al. The aluminum alloy material provided by the invention is uniform in texture and fine in grain, has high strength, tensile strength, impact toughness, stress corrosion cracking resistance, weldability and other performance, the tensile strength is greater than 350 MPa, the exfoliation corrosion performance is not less than the grade EA, and the strength coefficient of a friction stirring welding head is greater than 85%. The aluminum alloy material is applied to the car power battery tray and can meet the requirements for light weight of cars.

Owner:LVMEI ALUMINUM

A kind of 1000mpa grade hot-rolled automobile beam steel and its manufacturing method

The invention discloses 1000 MPa-grade hot-rolled automotive frame steel and a producing method thereof. The raw materials of the steel comprise the chemical components including, by mass, 0,10-0.20%of C, not greater than 0.10% of Si, 1.5-1.7% of Mn, not greater than 0.005% of S, not greater than 0.015% of P, 0.045-0.055% of Nb, 0.08-0.10% of Ti, not greater than 40 ppm of N, 0.025-0.060% of Als,not greater than 0.002% of H and the balance Fe. According to a hot-rolled steel plate produced through the method, the yield strength is greater than or equal to 750 MPa, the tensile strength is greater than or equal to 1000 MPa, the elongation is greater than or equal to 10%, and cold bend positions are free of cracks and a good cold bend effect is achieved under the conditions that the wide cold bend is 180 degrees and the cold bend flexual center diameter D is equal to 4t (thickness). The technological flow adopted by the method is simple, no equipment needs to be additionally arranged, and the steel has the advantages of being capable of being produced on a large scale, economical, feasible and stable in performance.

Owner:武汉钢铁有限公司

High-iron rare-earth aluminum-alloy fireproof warning cable

ActiveCN107403663AReal-time monitoring of core temperatureAchieve safe useConductive materialInsulated cablesEnvironmental resistanceEpoxy

The invention relates to the technical field of cables, in particular to an aluminum-alloy cable and a high-iron rare-earth aluminum-alloy fireproof warning cable. The high-iron rare-earth aluminum-alloy fireproof warning cable comprises at least two high-iron rare-earth aluminum alloy conductors, insulation protection layers, an external protection layer, a water blocking layer, a fireproof layer, a filling layer, a warning layer and a temperature monitoring module, wherein the insulation protection layer is arranged on an outer surface of each high-iron rare-earth aluminum alloy conductor and comprises an epoxy resin layer and tungsten oxide nanoparticles, the tungsten oxide nanoparticles are dispersed in the epoxy resin layer, and the temperature monitoring module is used for monitoring a temperature of at least one high-iron rare-earth aluminum alloy conductor in real time. By the high-iron rare-earth aluminum-alloy fireproof warning cable, a better fireproof effect can be achieved, a core temperature of the cable is monitored in real time, a warning is timely given out, and the safe application of the cable is achieved; infrared radiation also can be absorbed very well to achieve a better heat absorption and heat insulation effect; and moreover, the requirement of an environmental-friendly cable is reached, the light demand is satisfied, and the cable manufacturing cost is greatly reduced.

Owner:ANHUI HUABAO CABLE

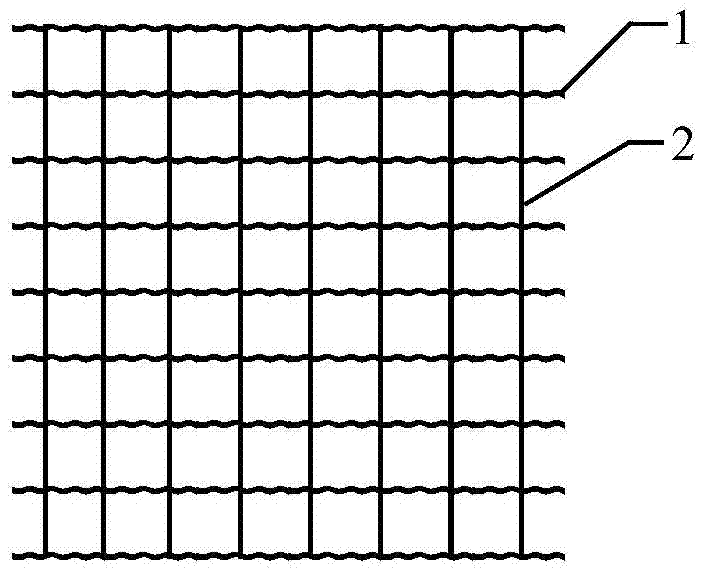

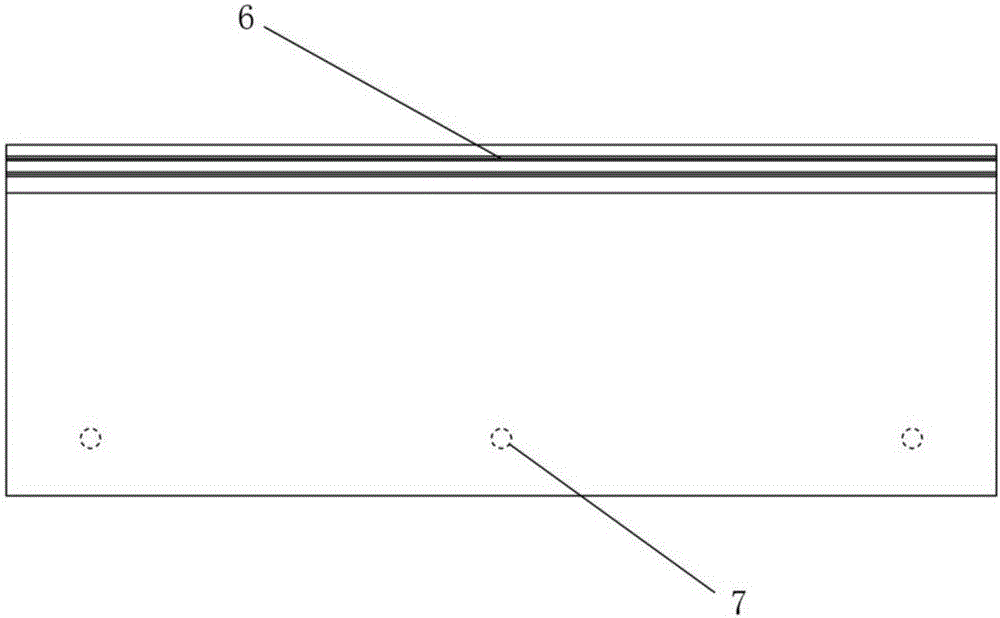

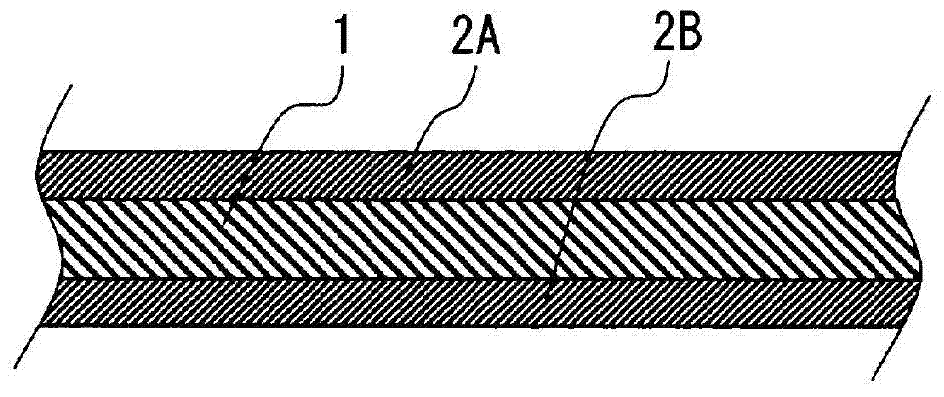

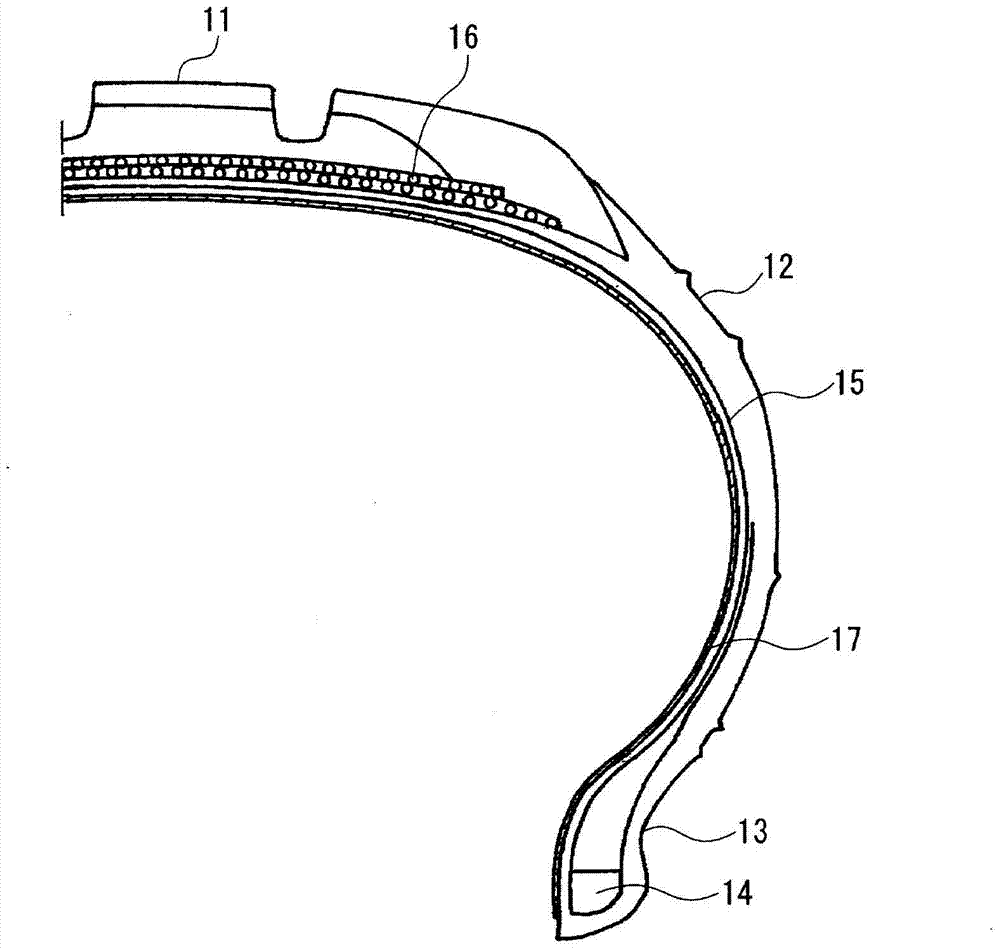

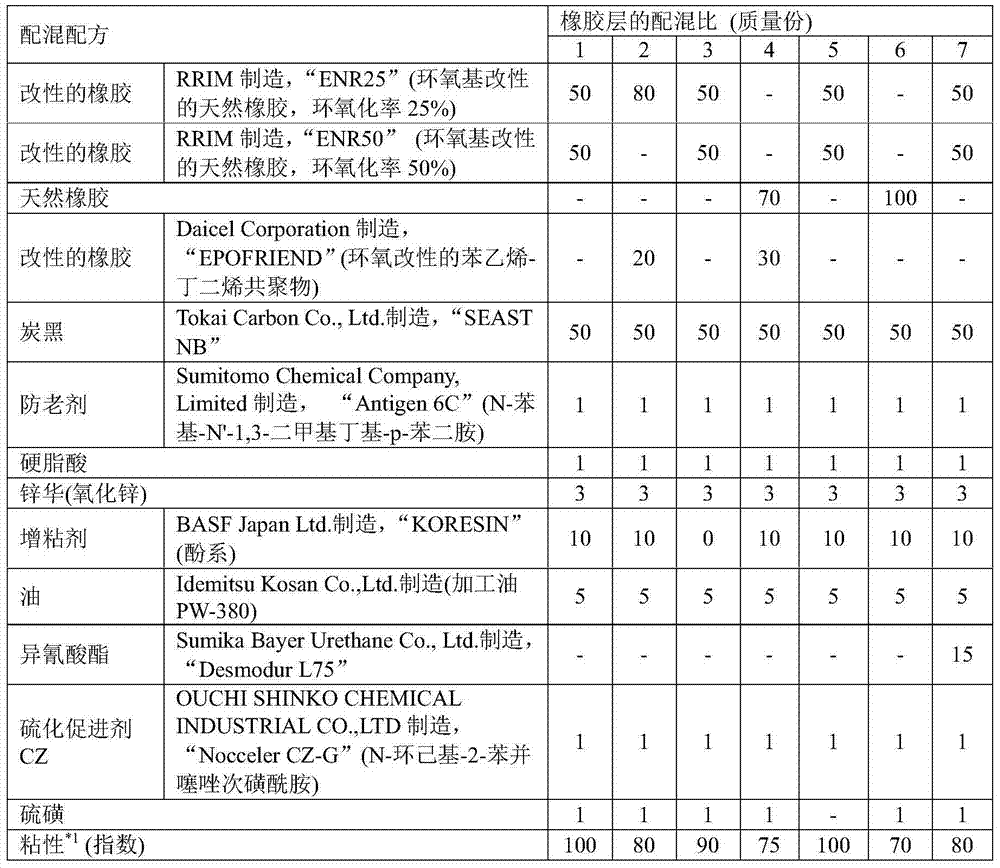

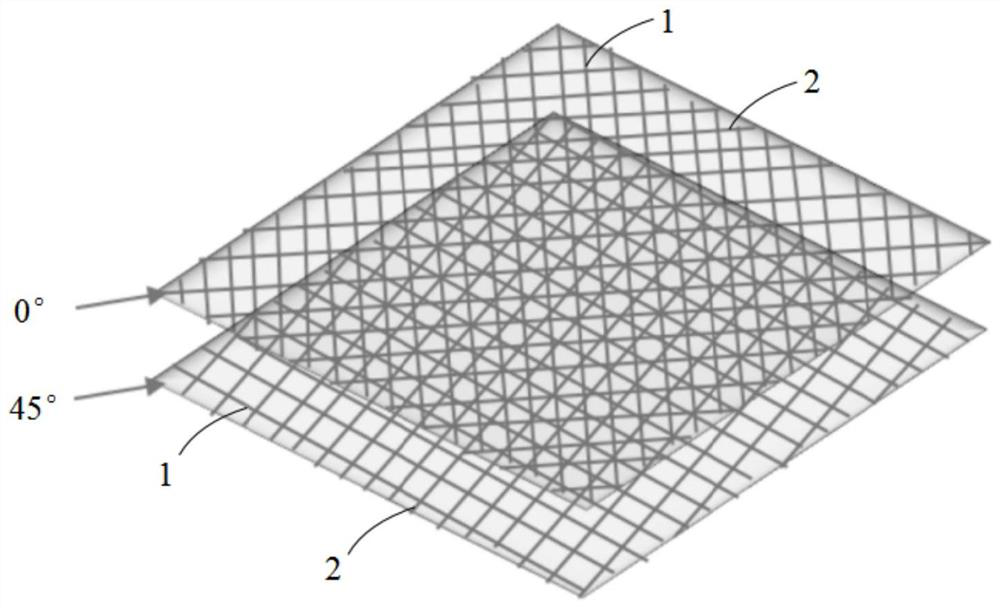

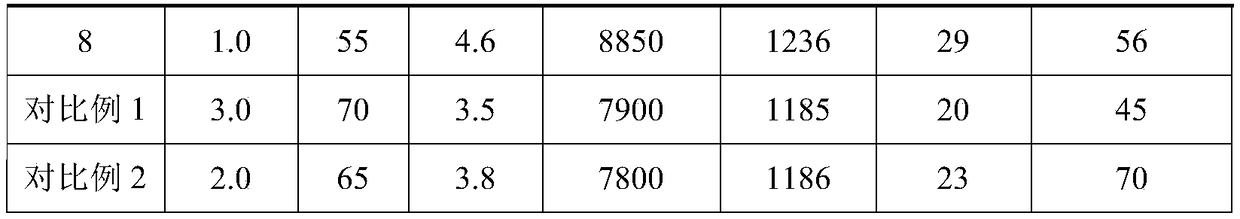

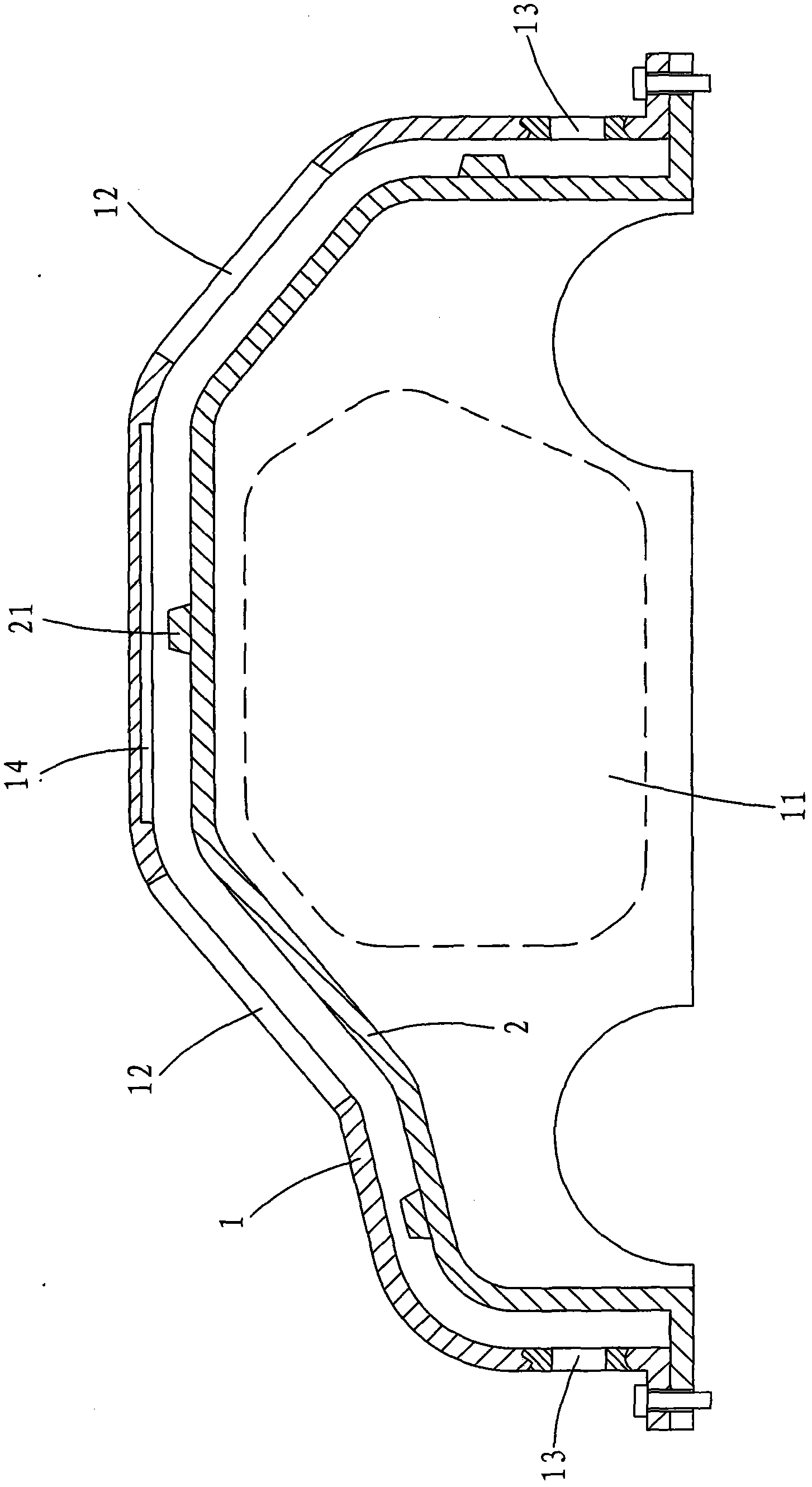

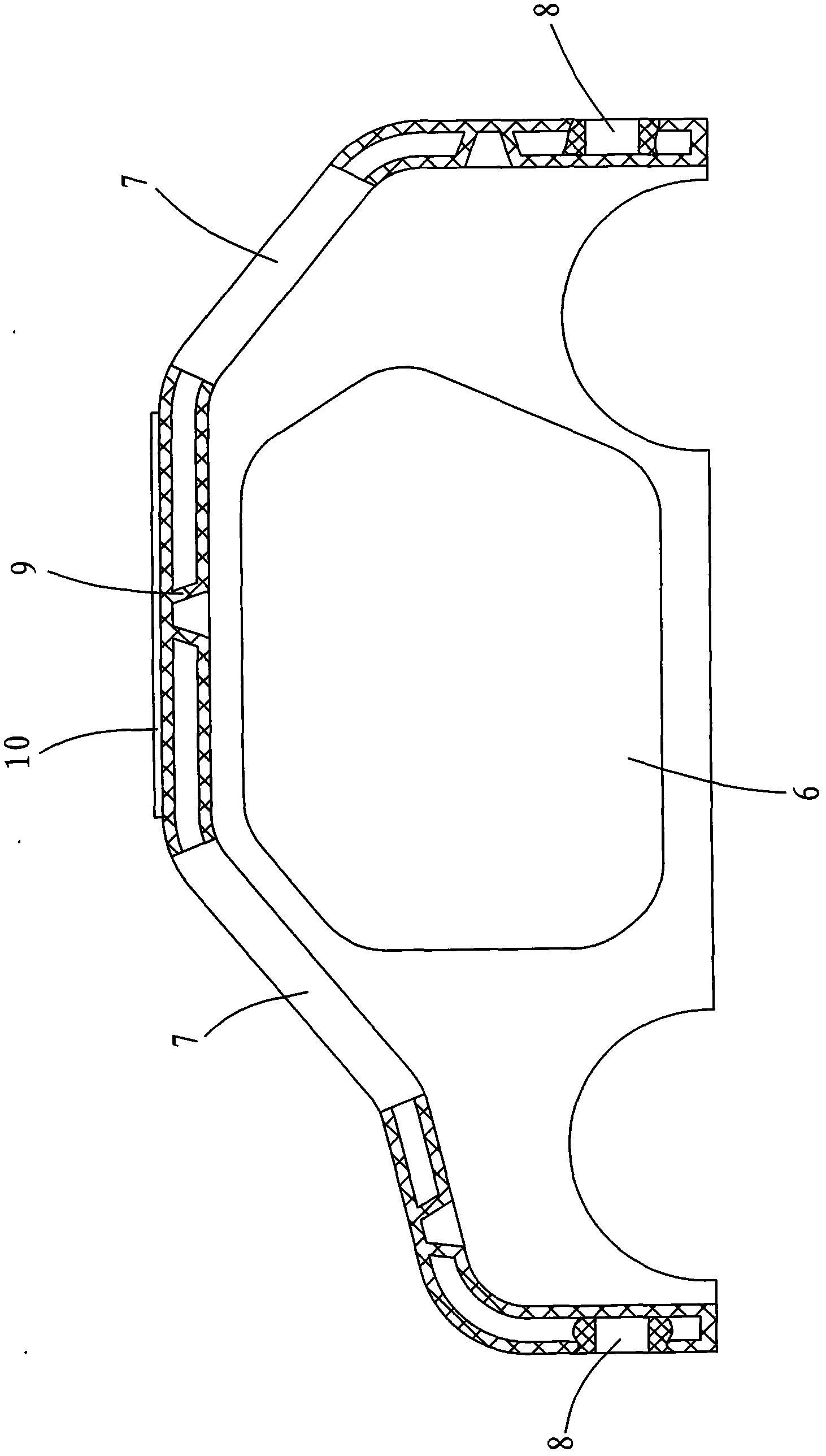

Laminate for inner liner, and tyre using same

ActiveCN104507707AFull durabilityStay cohesiveWithout separate inflatable insertsAdhesive articlesCross-linkElastomer

Provided are: a laminate for an inner liner, the laminate using a resin film and being capable of ensuring sufficient adhesion between the resin film and an adjacent member such as a carcass; and a tyre which uses the laminate. The laminate for an inner liner comprises: a gas barrier layer (1) formed from a thermoplastic resin or from a resin material comprising a mixture of a thermoplastic resin and a thermoplastic elastomer; and rubber layers (2A, 2B) disposed on either side of the gas barrier layer (1). The rubber layers include at least a diene elastomer, the diene elastomer being modified by a compound comprising a functional group that is compatible with the resin material, and at least one of the rubber layers includes a cross-linking agent.

Owner:BRIDGESTONE CORP

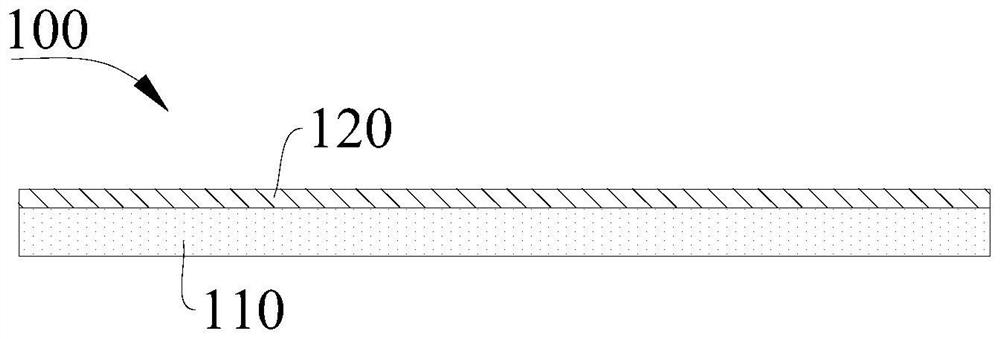

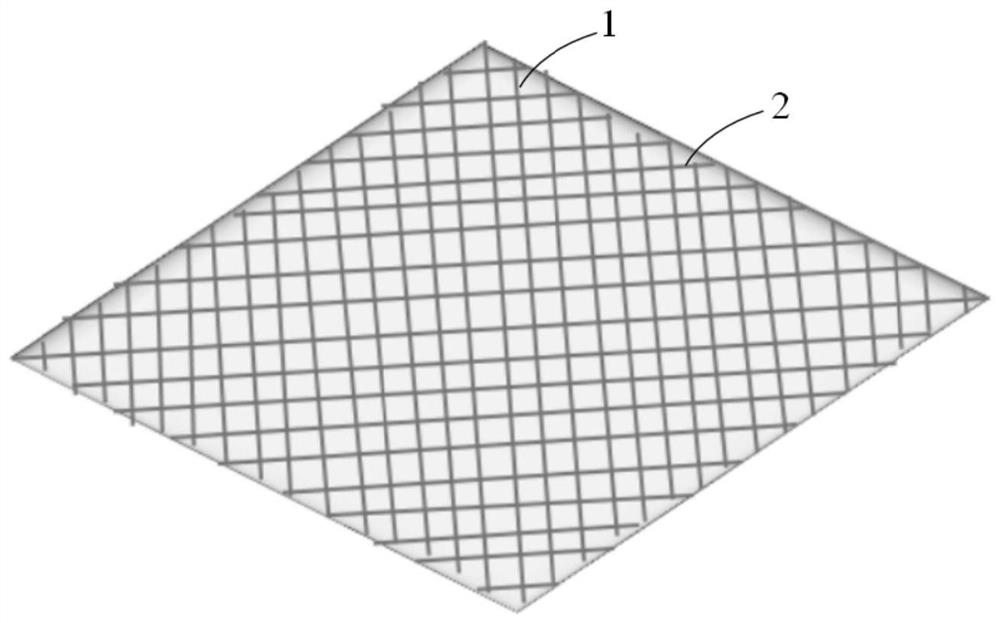

Supporting assembly, manufacturing method thereof and display device

PendingCN114523735AThe overall thickness is thinImprove bending reliabilitySynthetic resin layered productsLaminationFiberCarbon fibers

The invention provides a supporting assembly, a manufacturing method thereof and a display device. The supporting assembly comprises a carbon fiber layer, the carbon fiber layer comprises at least one carbon fiber woven layer, and the carbon fiber woven layer comprises a carbon fiber woven base layer and resin materials distributed in gaps and on the surface of the carbon fiber woven base layer, the carbon fiber woven base layer in each carbon fiber woven layer is formed by weaving at least two fibers in different directions; the first high polymer material layer is arranged on one side of the carbon fiber layer. Therefore, after the material formed by weaving the fibers in the at least two different directions is infiltrated by the resin, the strength is high, and the requirement of the supporting assembly on the strength can be met; the carbon fiber layer has good bending performance, and the bending reliability is higher.

Owner:BOE TECH GRP CO LTD +1

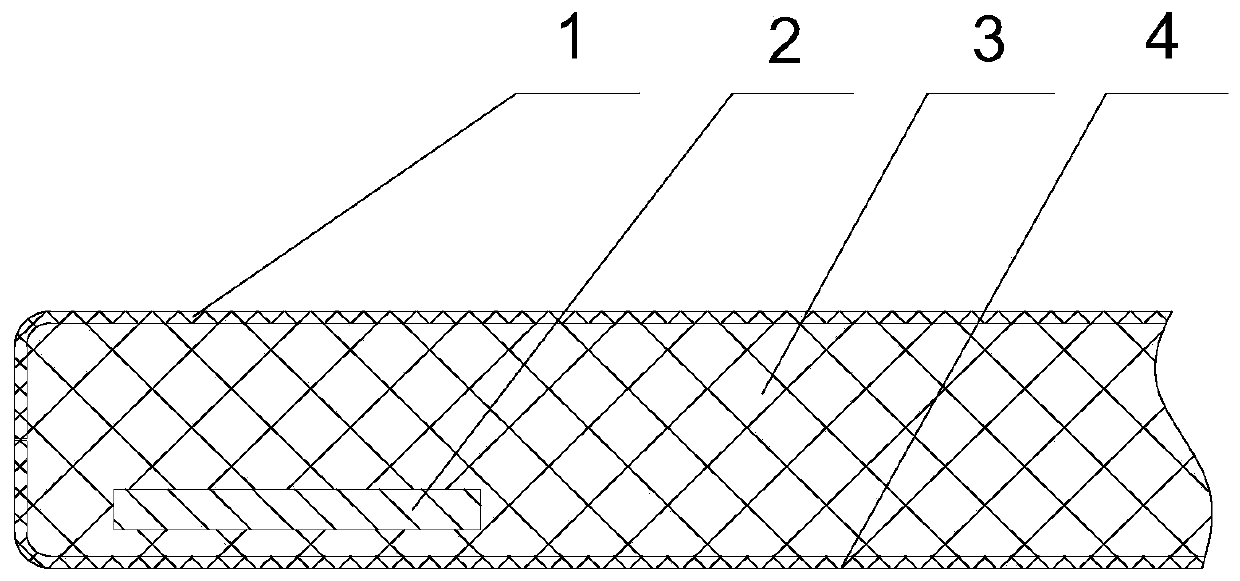

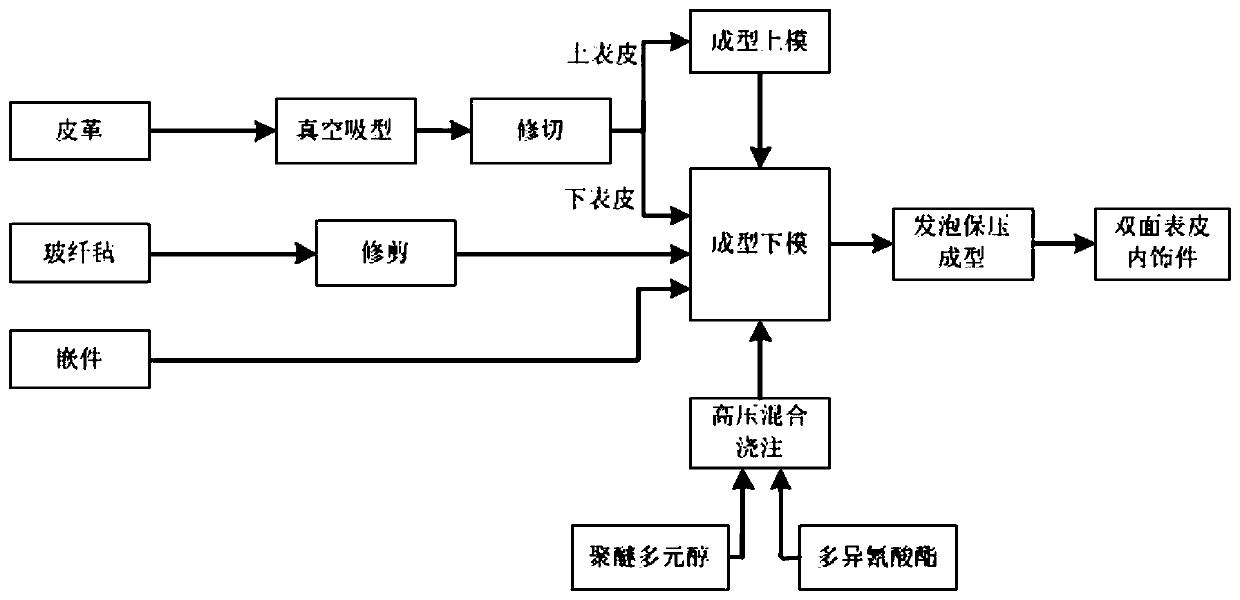

Dual-face surface foaming car interior trim part and forming process thereof

PendingCN110356335AEasy to implementImprove molding efficiencySuperstructure subunitsGlass fiberEngineering

The invention discloses a dual-face surface foaming car interior trim part. The part comprises an upper surface, a foaming layer, an insert and a lower surface. The foaming layer is a glass fiber reinforced polyurethane foaming layer, the insert is the insert embedded in the foaming layer during forming, the upper surface and the lower surface completely wrap the foaming layer and the insert, andthrough one-time forming of the glass fiber reinforced polyurethane, the integrated car interior trim part is subjected to composite molding. According to the dual-face surface foaming car interior trim part, one-time foaming molding is achieved, the aim is easily achieved, the forming efficiency is high, the cost is low, and the combination strength is high. According to the dual-face surface foaming car interior trim part, the raw material cost of the one-time molded product is small, and the weight is small. The invention further discloses a forming process of the dual-face surface foamingcar interior trim part. The product is attractive in appearance, small in weight, and capable of reducing product weight, and meeting the car lightweight needs, meanwhile, the labor efficiency is improved in a multiplied manner, and the cost is reduced.

Owner:扬州市邗江扬子汽车内饰件有限公司

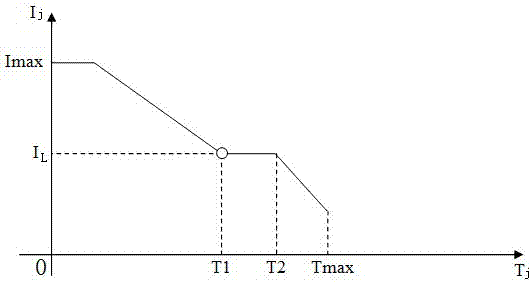

LED vehicle lamp module heat dissipation control method and device

InactiveCN107504426AIncreased luminous flux outputLower requirementLighting heating/cooling arrangementsSemiconductor devices for light sourcesTemperature controlIlluminance

The invention relates to the field of vehicle illuminating lamp heat dissipation, in particular to an LED vehicle lamp module heat dissipation control method and device. According to the LED vehicle lamp module heat dissipation control method, the standard work temperature TL, the standard work current IL and the limit working temperature Tmax of an LED vehicle lamp module, and the limit rotation speed rmax of a heat dissipation fan are set, and the heat dissipation fan is controlled according to the temperature Tj in the LED vehicle lamp module; when Tj is smaller than or equal to TL, the heat dissipation fan does not work; when Tj is larger than TL and r is smaller than rmax, a controller controls the heat dissipation fan to be started, r is equal to f(Tj), and Ij is equal to IL; when Tj is larger than TL and r is equal to rmax, the controller controls the current Ij of the LED vehicle lamp module to be lowered gradually till r is smaller than rmax; and when Tj is equal to Tmax, Ij is lowered to 0. According to the LED vehicle lamp module heat dissipation control method and device, the temperature is controlled to below the limit temperature through the controllable heat dissipation fan, the requirement for a heat dissipation assembly is lowered, the size can be reduced, and the lightweight need is also met. Meanwhile, on the premise that the heat dissipation ability can be met, LED luminous flux output is further increased, illuminance is improved, and driving safety is ensured.

Owner:SAIC MOTOR

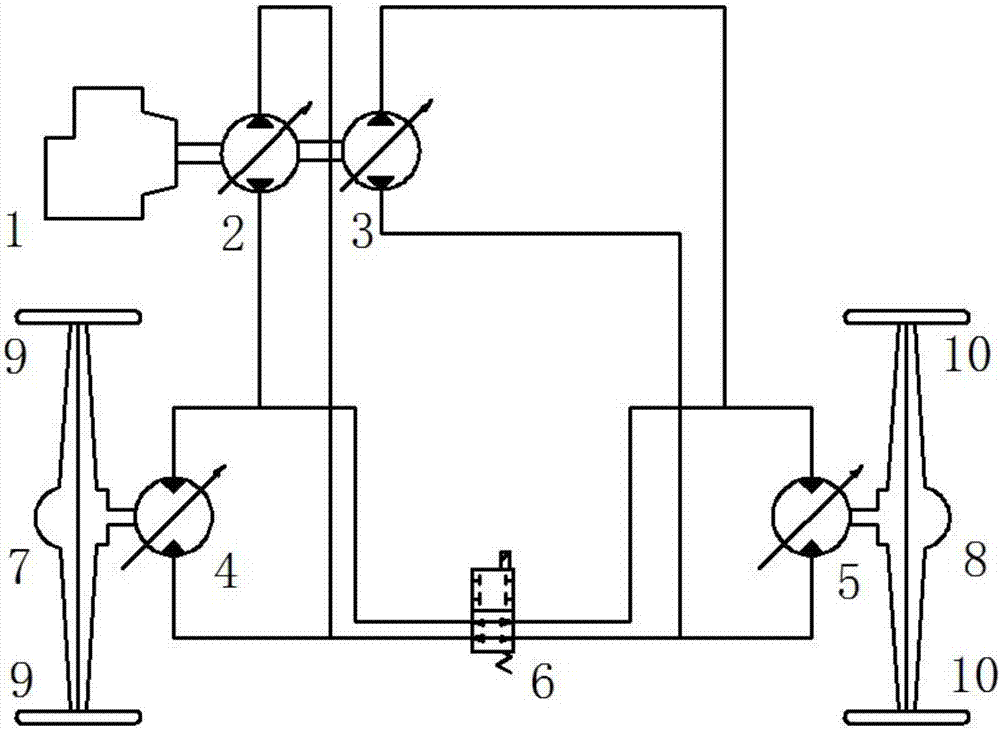

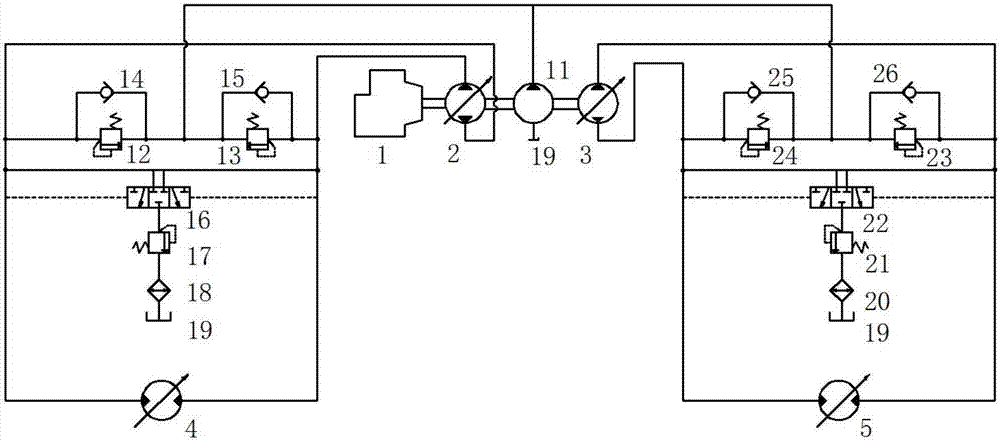

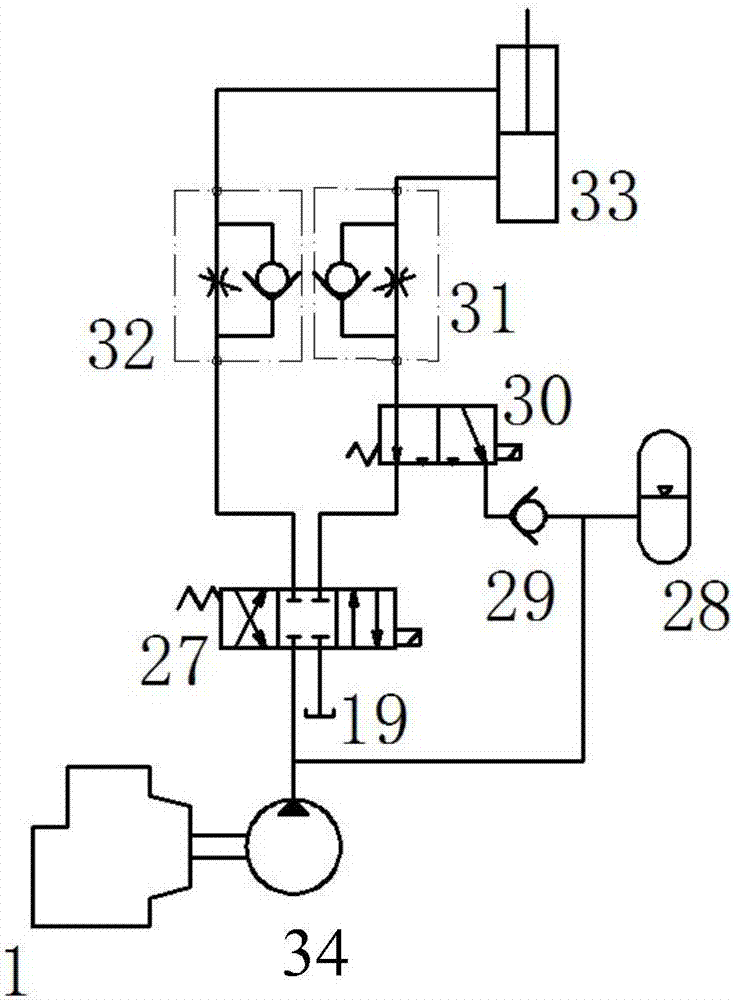

Driving system of seedling transplanter

ActiveCN106900234AGuaranteed passabilityOptimizing Layout FlexibilityTransplantingFertiliser equipmentsGear pumpControl engineering

The invention relates to a driving system of a seedling transplanter, the driving system includes a travelling driving hydraulic system and a seedling box lifting energy recovery hydraulic system, the travelling driving hydraulic system includes a driving main loop, an oil compensating loop and a cooling loop; a front wheel plunger pump and a rear wheel plunger pump are driven to work by an engine via a belt, the front wheel plunger pump and the rear wheel plunger pump are swashplate type, the size and the direction of the dip angle of a swash plate can be regulated by change of displacement, oil-suction direction and oil pressing direction of the pumps, the front wheel plunger pump and the rear wheel plunger pump have dual functions of change of flow rate and direction, a power element of the seedling box lifting energy recovery hydraulic system is gear pump driven by the engine, the oil outlet of the gear pump is connected with a three-position four-way directional control valve, the three-position four-way directional control valve is used to control the flow direction of hydraulic oil so as to control lifting and descending of a seedling box, a reversing valve is O-type meso-position function, and is used to lock the position of an oil cylinder, an oil outlet of a rodless cavity of a lifting oil cylinder is equipped with a two-position solenoid directional valve which is used to change the direction of the hydraulic oil, and an energy accumulator is mounted on one oil outlet of the reversing valve to store and release energy.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

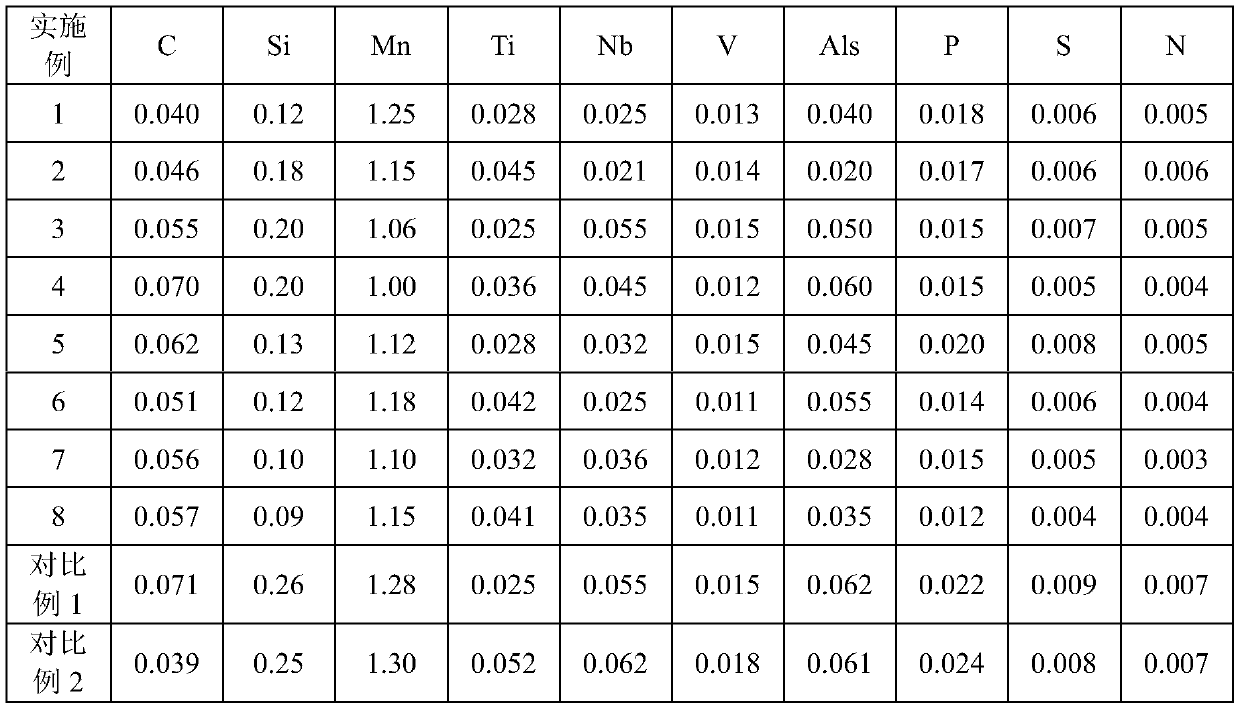

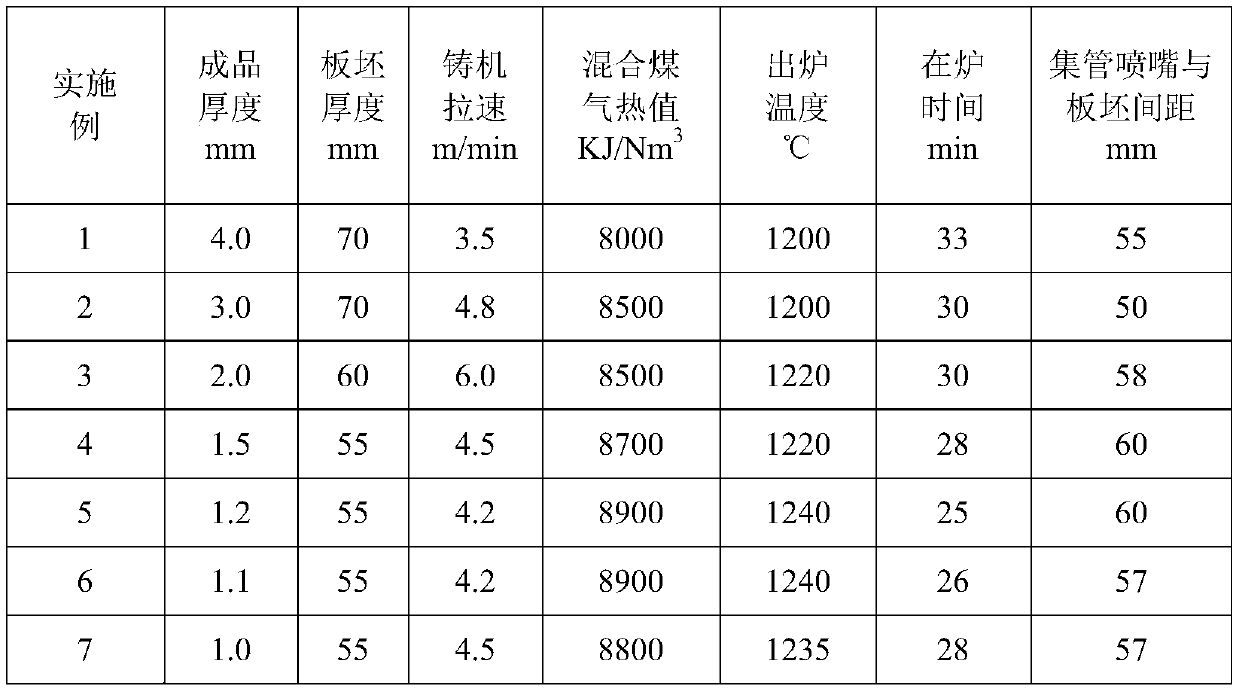

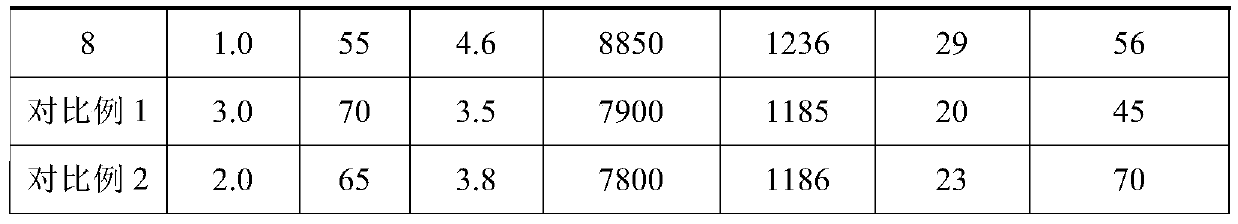

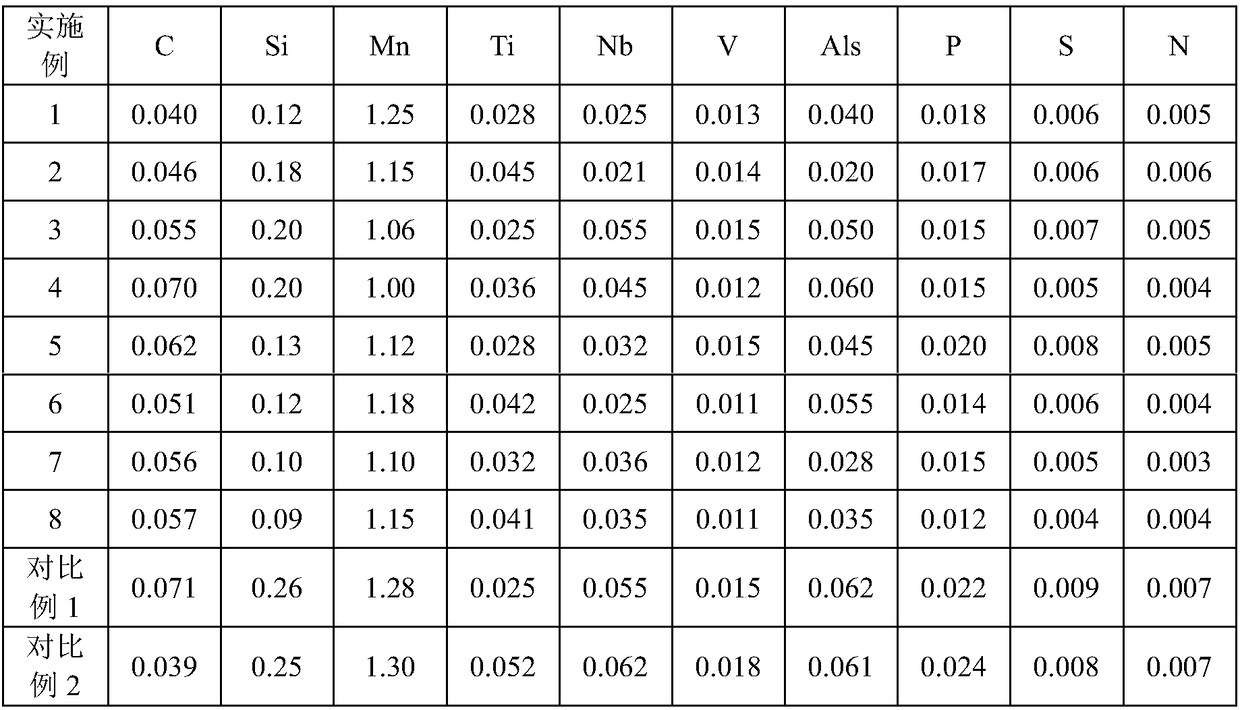

500mpa grade thin-gauge hot-rolled automotive structural steel and method produced by short process

The invention discloses 500 MPa class thin-specification hot-rolled automobile structural steel produced by using a short process. The components of the 500 MPa class thin-specification hot-rolled automobile structural steel are as follows by weight percentage, 0.040-0.070% of C, no more than 0.20% of Si, 1.0-1.25% of Mn, 0.025-0.045% of Ti, 0.025-0.055% of Nb, no more than 0.015% of V, 0.020-0.060% of Als, no more than 0.020% of P, no more than 0.008% of S, no more than 0.006% of N. A production method comprises the steps that a thin slab billet is casted continuously after conventional smelting, uniform heating is conducted on the thin slab billet, twice descaling is conducted, and seven times finishing rolling is conducted; and the laminar flow is cooled to the coiling temperature, coiling is conducted, and leveling is conducted. According to the500 MPa class thin-specification hot-rolled automobile structural steel and the method, the shortcomings that the plate shape and coil shape are bad, and the rolling process is unstable in the rolling process of 500 MPa class thin-specification hot-rolled automobile structural steel using a short process are overcome, the high-stabilityand large-scale production of the 500 MPa class thin-specification hot-rolled automobile structural steel rolled by using a short process is achieved, the plate shape and the roll shape are excellent,the rolling process is stable, the original variety yield is increased to more than 90%, and the purpose of replacing cold rolling products is achieved.

Owner:武汉钢铁有限公司

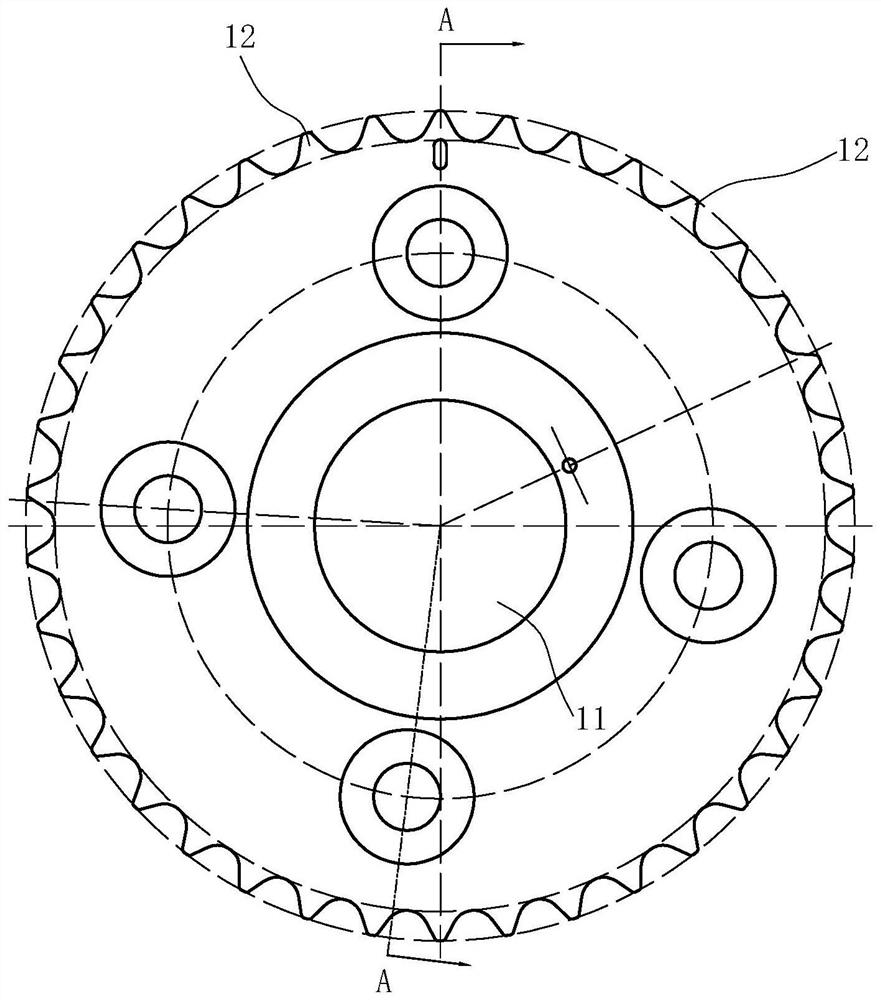

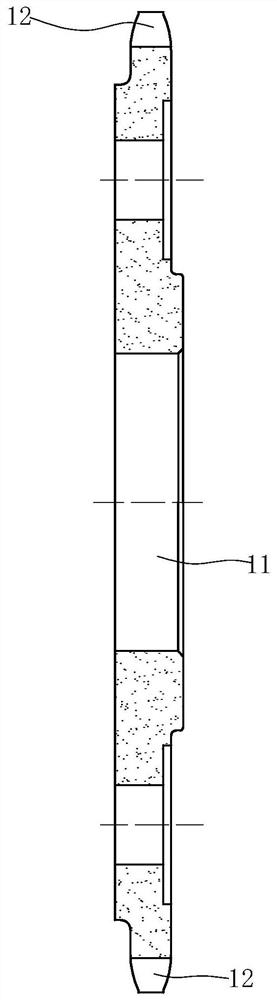

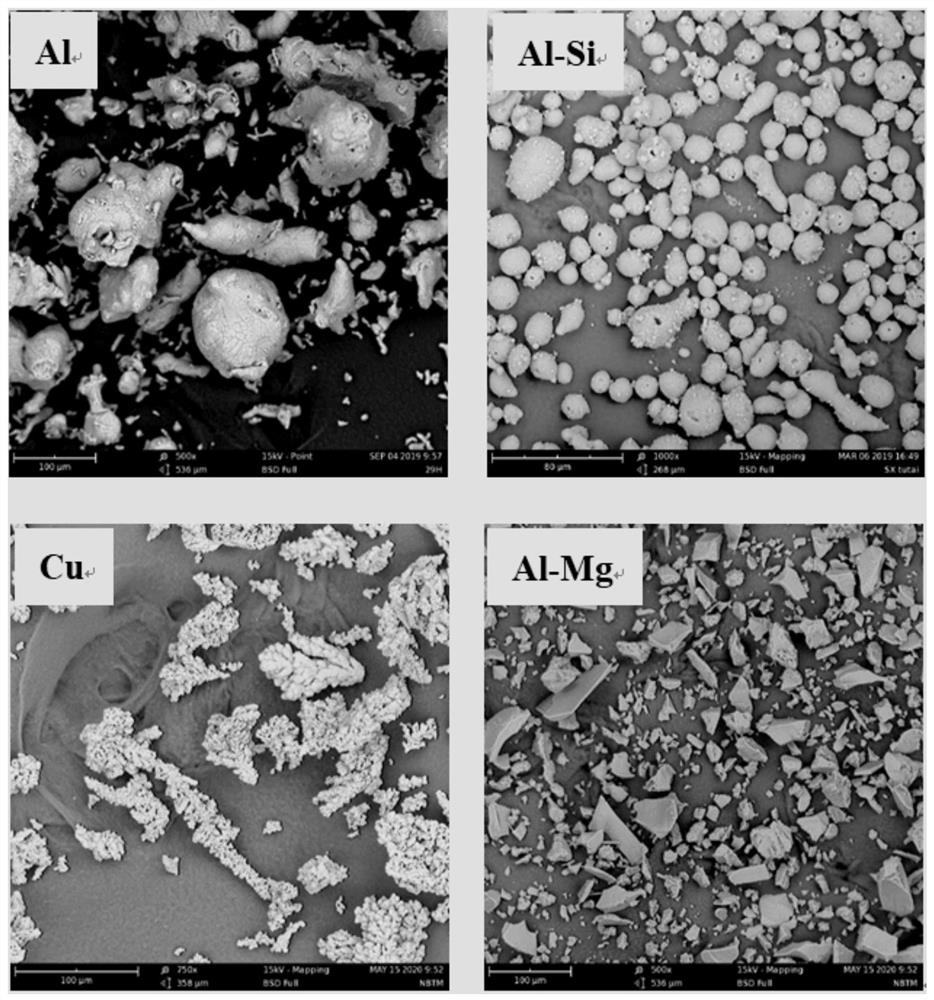

Powder metallurgy aluminum alloy chain wheel or gear and preparation method

PendingCN112760526AConducive to lightweightReduce weightTurbinesOther manufacturing equipments/toolsGear wheelSprocket

The invention relates to a powder metallurgy aluminum alloy chain wheel or gear and a preparation method, and the powder metallurgy aluminum alloy chain wheel or gear is characterized by comprising the following chemical components in percentage by mass: 0.1%-7% of Cu, 0.1%-5% of Mg, 0.1%-40% of Si, 0%-10% of Zn, 0%-1% of Sn, 0%-10% of a reinforcement phase and the balance of Al. The preparation method is simple, machining is convenient, the prepared powder metallurgy aluminum alloy chain wheel or gear is light in weight, meanwhile, the advantages of light weight, corrosion resistance and high hardness are achieved, the requirement for light weight of an automobile is met, and energy conservation and emission reduction are facilitated.

Owner:NBTM NEW MATERIALS GRP

500 MPa class thin-specification hot-rolled automobile structural steel produced by using short process and method for producing 500 MPa class thin-specification hot-rolled automobile structural steel

The invention discloses 500 MPa class thin-specification hot-rolled automobile structural steel produced by using a short process. The components of the 500 MPa class thin-specification hot-rolled automobile structural steel are as follows by weight percentage, 0.040-0.070% of C, no more than 0.20% of Si, 1.0-1.25% of Mn, 0.025-0.045% of Ti, 0.025-0.055% of Nb, no more than 0.015% of V, 0.020-0.060% of Als, no more than 0.020% of P, no more than 0.008% of S, no more than 0.006% of N. A production method comprises the steps that a thin slab billet is casted continuously after conventional smelting, uniform heating is conducted on the thin slab billet, twice descaling is conducted, and seven times finishing rolling is conducted; and the laminar flow is cooled to the coiling temperature, coiling is conducted, and leveling is conducted. According to the500 MPa class thin-specification hot-rolled automobile structural steel and the method, the shortcomings that the plate shape and coil shape are bad, and the rolling process is unstable in the rolling process of 500 MPa class thin-specification hot-rolled automobile structural steel using a short process are overcome, the high-stabilityand large-scale production of the 500 MPa class thin-specification hot-rolled automobile structural steel rolled by using a short process is achieved, the plate shape and the roll shape are excellent,the rolling process is stable, the original variety yield is increased to more than 90%, and the purpose of replacing cold rolling products is achieved.

Owner:武汉钢铁有限公司

One-step molding process of double-layer plastic vehicle shell

InactiveCN102729383ASimple structureSimplify the manufacturing processDomestic articlesCoatingsCooling chamberEngineering

The invention provides a one-step molding process of a double-layer plastic vehicle shell, and the process comprises the steps of: (1) manufacturing a concave die and a convex die respectively based on the contour of a vehicle shell, and manufacturing various loose cores additionally; (2) inserting various the loose cores into the concave die, and adding powdered plastics into the concave die and the convex die; (3) conducting die closing; (4) shifting the dies into a heating chamber, and making them rotate ceaselessly along a main shaft and an auxiliary shaft that are mutually perpendicular, as well as conducting heating; (5) shifting the dies into a mist cooling chamber for mist cooling; (6) shifting the dies into an aeration and pressure maintaining chamber for aeration, pressure maintaining and shaping; (7) shifting the dies into a wind cooling chamber for wind cooling; (8) dismantling all loose cores and releasing the dies so as to obtain a double-layer plastic vehicle shell product with reserved various accessory mounting holes; and (9) shaping the various accessory mounting holes of the product through shaping dies. In the invention, the whole double-layer plastic vehicle shell is molded in one step through the above rotational molding process, so that the manufacturing process and the die structure are greatly simplified. And the molding process of the invention has the advantages of convenient manufacturing, high production efficiency, low manufacturing cost, and good product performance, etc.

Owner:应革

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com