LED vehicle lamp module heat dissipation control method and device

A technology of LED car lights and control methods, which is applied in the direction of lighting devices, fixed lighting devices, cooling/heating devices of lighting devices, etc., and can solve the problems of high set power and rotating speed of cooling fans, energy waste, and reduced fan life. To achieve the effect of increasing LED luminous flux output, ensuring driving safety and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

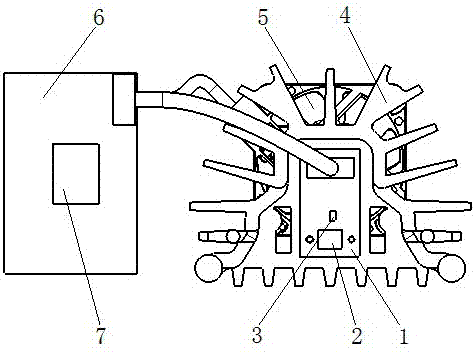

[0031] Such as figure 1 , the conventional LED car light module includes a PCB board 1 carrying a light source, the PCB board 1 is an aluminum substrate, a copper substrate, a steel substrate or a multi-layer FR4, and the PCB board 1 is equipped with a light source LED chip 2 and a temperature sensor 3 , the PCB board 1 is surrounded by a cooling fin group 4, and the back of the PCB board 1 is equipped with a cooling fan 5; the driving module 6 and the controller 7 are electrically connected to the light source LED chip 2, the temperature sensor 3 and the cooling fan 5;

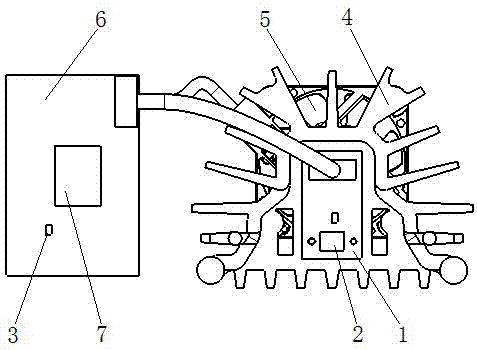

[0032] Such as figure 2 As shown, when the heat dissipation fan 5 is not working, the temperature sensor 3 directly installed on the PCB board 1 can accurately measure the temperature of the light source area in the LED lamp module, but once the heat dissipation fan 5 is turned on, the heat dissipation area of the fan will Directly corresponding to the temperature sensor 3 will cause the temperature senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com