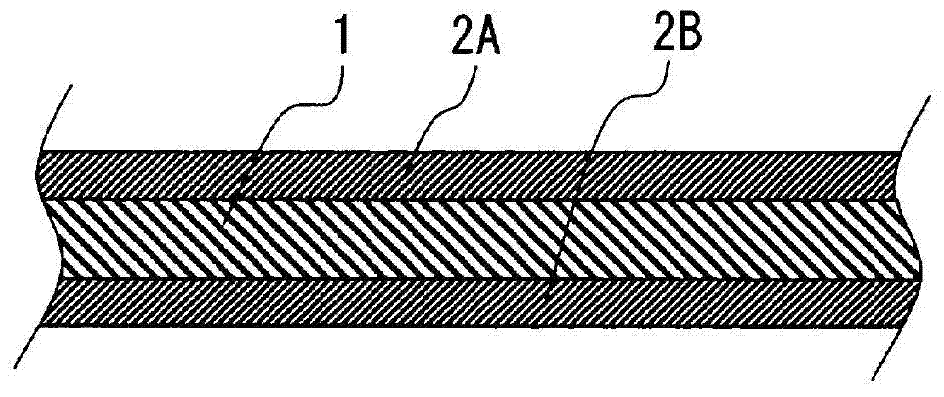

Laminate for inner liner, and tyre using same

A technology of laminate and air liner, applied in pneumatic tires, special tires, tire parts, etc., can solve the problems of insufficient adhesiveness of rubber layer and air liner, and achieve the effect of light weight and sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] First, in a pressurized reaction vessel, 2 parts by mass of ethylene-vinyl alcohol copolymer (EVOH) having an ethylene content of 44 mol% and a degree of saponification of 99.9% (MFR at 190°C and a load of 2160g: 5.5g / 10 min.) and 8 parts by mass of N-methyl-2-pyrrolidone, and the mixture was heated and stirred at 120° C. for 2 hours to completely dissolve EVOH. To the mixture, 0.4 parts by mass of propylene oxide was added as an epoxy compound and then heated at 160° C. for 4 hours. After heating, the mixture was precipitated in 100 parts by mass of distilled water, and then N-methyl-2-pyrrolidone and unreacted propylene oxide were sufficiently washed with a large amount of distilled water to obtain modified EVOH.

[0046] Further, the obtained modified EVOH was pulverized into small particles with a size of about 2 mm by a pulverizer, and washed again with a large amount of distilled water. The pellets after washing were vacuum-dried at room temperature for 8 hours,...

Embodiment 2

[0059] (Synthesis of Soft Resin)

[0060] A maleic anhydride-modified hydrogenated styrene-ethylene-butadiene-styrene block copolymer was synthesized by a known method and pelletized. For the maleic anhydride-modified hydrogenated styrene-ethylene-butadiene-styrene block copolymer obtained, the Young's modulus at 23°C was 3 MPa, the styrene content was 20%, and the maleic anhydride The amount is 0.3meq / g. Young's modulus was measured in a similar manner to the modified EVOH described above.

[0061] (Manufacture of resin composition)

[0062] A resin composition was prepared by kneading the above-mentioned modified EVOH and a soft resin through a twin-screw extruder. Here, the content of the soft resin in the resin composition was 20% by mass. When the obtained sample of the resin composition was frozen and then cut into pieces by using a microtome to be measured by a transmission electron microscope, the average particle diameter of the soft resin in the resin composition...

Embodiment 3 to 9 and comparative example 1

[0073] Examples 3 to 9 and Comparative The inner liner of Example 1 was produced in a similar manner to that of Example 1 and the like.

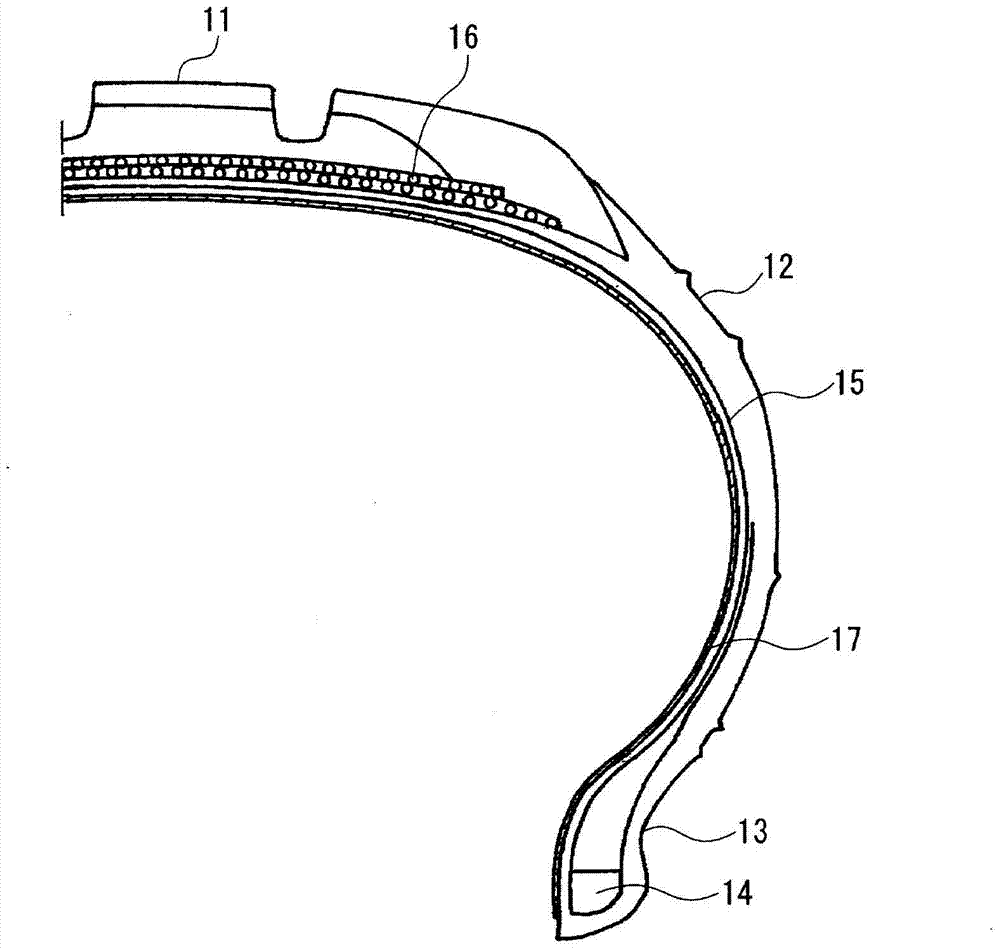

[0074] For each test innerliner, its weight is measured. By using each test innerliner, a tire having a tire size of 195 / 65R15 was produced and the presence or absence of bladder peeling (peeling of the bladder due to innerliner-to-bladder adhesiveness) at the time of tire vulcanization was evaluated. Further, each test tire was mounted on a rim having a size of 6JJ to prepare a tire wheel, the applied air pressure was 160 kPa (relative pressure) and the tire load was 4.0 kN, and the tire was driven on an indoor drum tester at 80 km / h to evaluate the The presence or absence of peeling of the inner liner after the drum durability test. These results are listed in Tables 2 and 3 in combination.

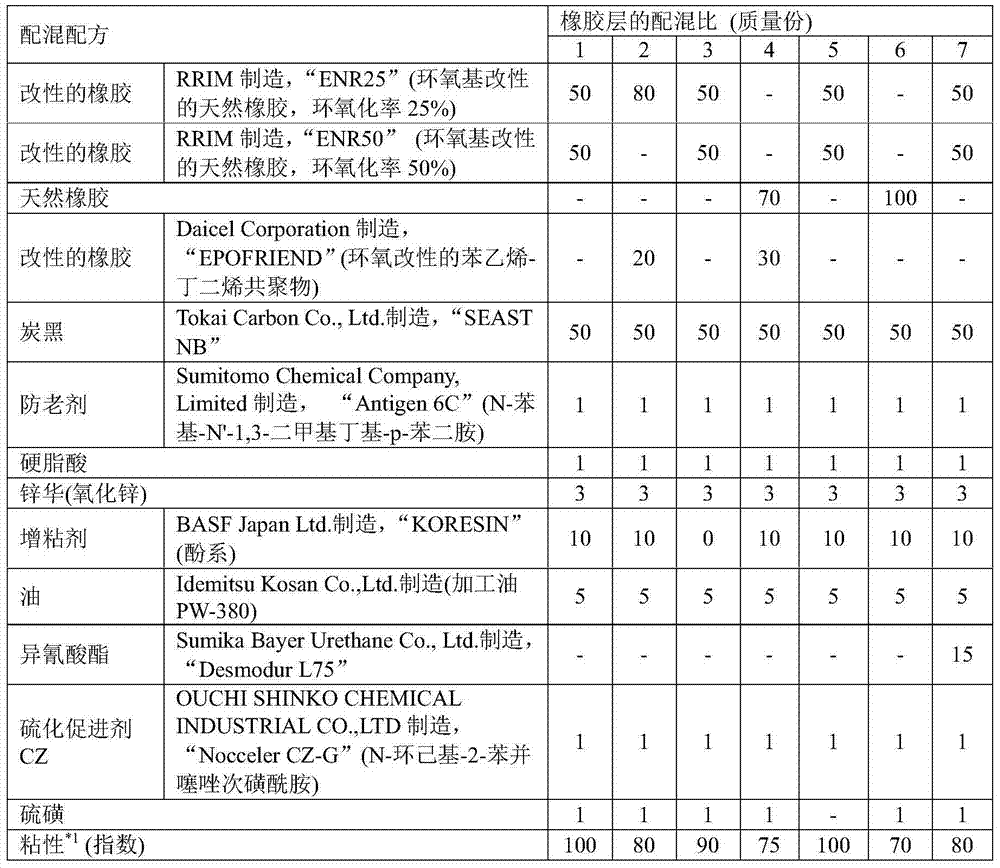

[0075] [Table 2]

[0076]

[0077] *2) See above table 1

[0078] *3) Film 1: 7-layer film of EVOH and TPU, Film 2: 5-layer film of resin com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com