Thin weathering steel with tensile strength of not less than 800 MPa produced by short process, and method

A technology with a tensile strength of 800mpa, applied in the field of thin-gauge weathering steel with a tensile strength ≥ 800MPa, which can solve problems such as poor plate shape and coil shape, unstable rolling process, and not exceeding, and achieve excellent plate shape and coil shape , Uniform thickness, satisfying the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in detail below:

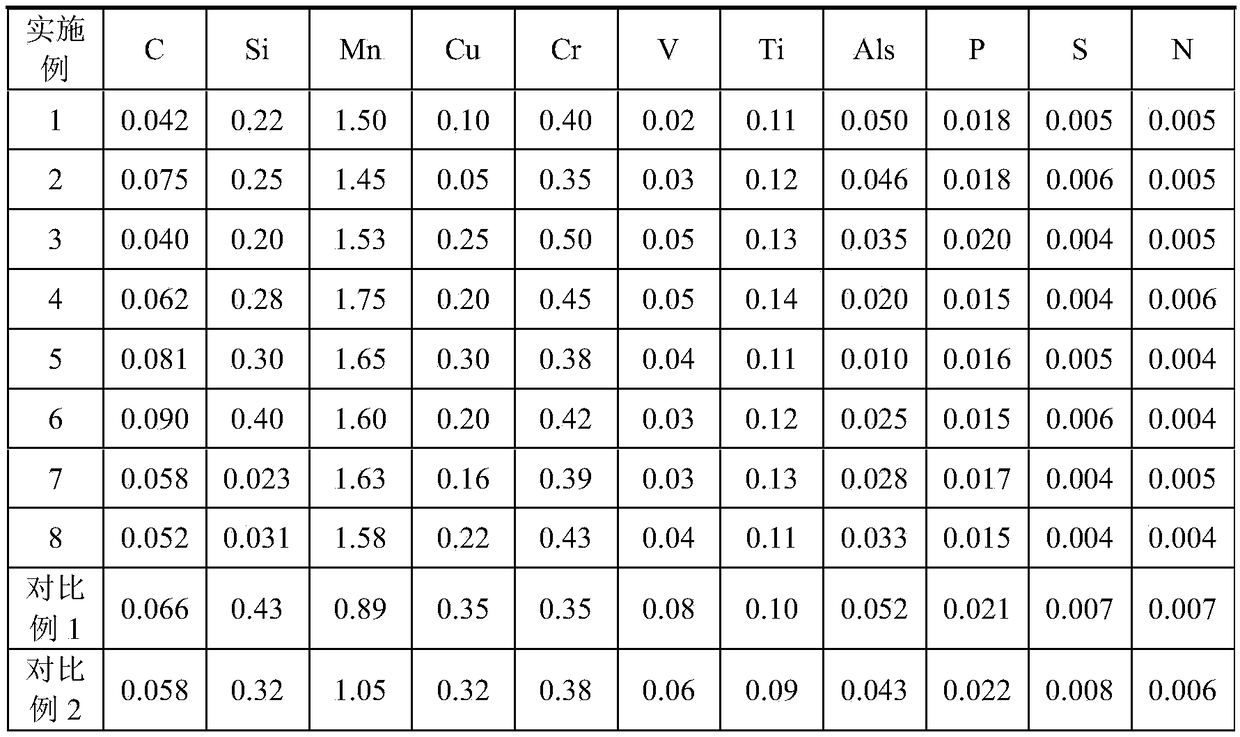

[0049] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

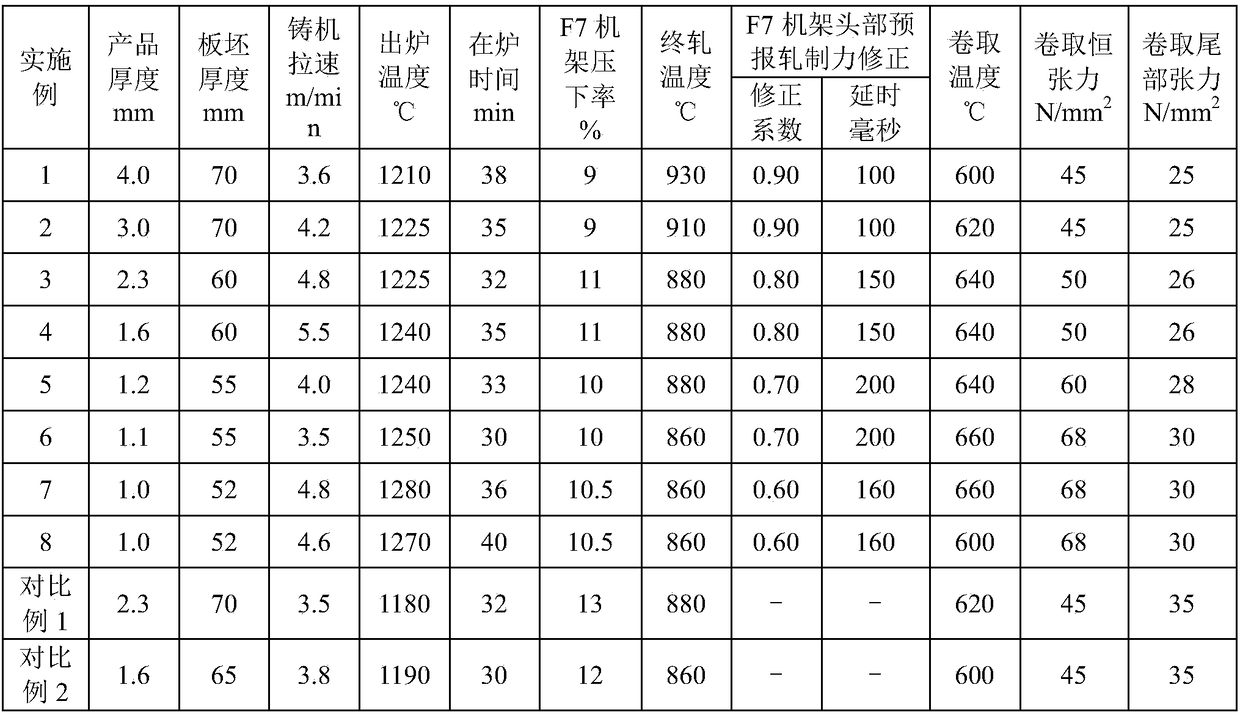

[0050] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0051] Table 3 is a list of mechanical performance testing and quality conditions of each embodiment of the present invention and comparative examples.

[0052] Each embodiment of the present invention all produces according to the following steps:

[0053] 1) Perform thin slab continuous casting after conventional smelting, control the temperature of molten steel in the tundish at 1539-1549°C, control the thickness of the thin slab at 52-70mm, and caster casting speed at 3.5-5.5m / min;

[0054] 2) Soak the thin slab, control the furnace temperature at 1210-1280°C, and keep in the furnace for not less than 30 minutes;

[0055] 3) Carry out two consecutive descaling passes, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com