Heat-conduction epoxy resin composite material and preparation method thereof

A technology of epoxy resin and composite materials, which is applied in the field of polymer composite materials, can solve the problems of complex preparation, high cost of hyperbranched polymers, and decreased thermal conductivity of composite materials, achieving good stability, less addition, and guaranteed thermal conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

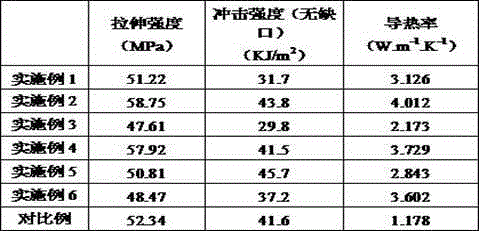

Examples

Embodiment 1

[0030] A heat-conducting epoxy resin composite material, according to the parts by mass, the preparation method is as follows:

[0031] 1 Put 0.6 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio: 3:1) was treated for 3 hours under the action of ultrasonic vibration and mechanical stirring, and then washed with a large amount of deionized water until neutral.

[0032] 2 Add the obtained carbon nanotubes into thionyl chloride, heat to 60° C. under ultrasonic vibration, reflux for 24 hours, and then distill off excess thionyl chloride under reduced pressure.

[0033] 3. Add the obtained carbon nanotubes to 40 parts of triethylenetetramine, stir and react with magnetic force at 120°C for 96 hours, filter, wash off excess triethylenetetramine with absolute ethanol, and dry under vacuum at 70°C to obtain aminated carbon nanotubes Tube.

[0034] 4 Add 2.0 parts of nano-aluminum nitride to absolute ethanol and heat it to 65°C with ult...

Embodiment 2

[0037] A heat-conducting epoxy resin composite material, according to the parts by mass, the preparation method is as follows:

[0038] 1 Put 2.0 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio: 3:1) was treated with ultrasonic vibration and mechanical stirring for 5 hours, and then washed with a large amount of deionized water until neutral.

[0039] 2 Add the obtained carbon nanotubes into thionyl chloride, heat to 65°C under ultrasonic vibration, and reflux for 18 hours, and then distill off excess thionyl chloride under reduced pressure.

[0040] 3. Add the obtained carbon nanotubes to 35 parts of triethylenetetramine, stir and react with magnetic force at 120°C for 96 hours, filter, wash off excess triethylenetetramine with absolute ethanol, and dry under vacuum at 70°C to obtain aminated carbon nanotubes Tube.

[0041] 4 Add 5.0 parts of nano-aluminum nitride to absolute ethanol and heat it to 65°C with ultrasonic vibra...

Embodiment 3

[0044] A heat-conducting epoxy resin composite material, according to the parts by mass, the preparation method is as follows:

[0045] 1 Put 1.5 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio is 3:1), under the action of ultrasonic vibration and mechanical stirring, treated for 4h, and then washed with a large amount of deionized water until neutral.

[0046] 2 Add the obtained carbon nanotubes into oxalyl chloride, heat to 70°C under ultrasonic vibration, reflux for 20 hours, and then distill off excess oxalyl chloride under reduced pressure.

[0047] 3 The obtained carbon nanotubes were added to 50 parts of ethylenediamine, stirred with magnetic force at 120°C for 96 hours, filtered, washed with absolute ethanol to remove excess ethylenediamine, and vacuum-dried at 70°C to obtain aminated carbon nanotubes.

[0048] 4 Add 6.0 parts of nano-aluminum nitride to absolute ethanol and heat it to 65°C with ultrasonic vibration, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com