Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Joint formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

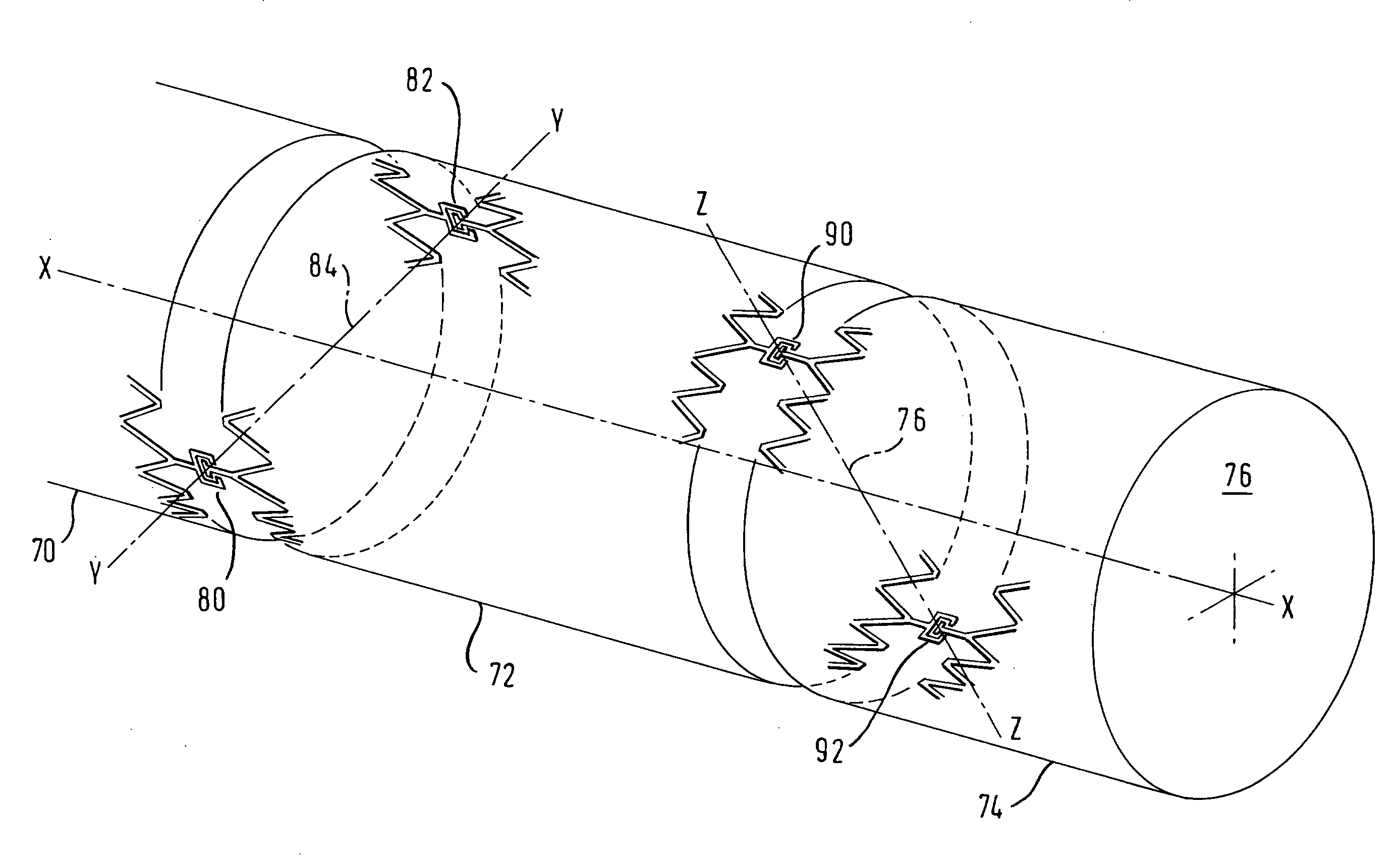

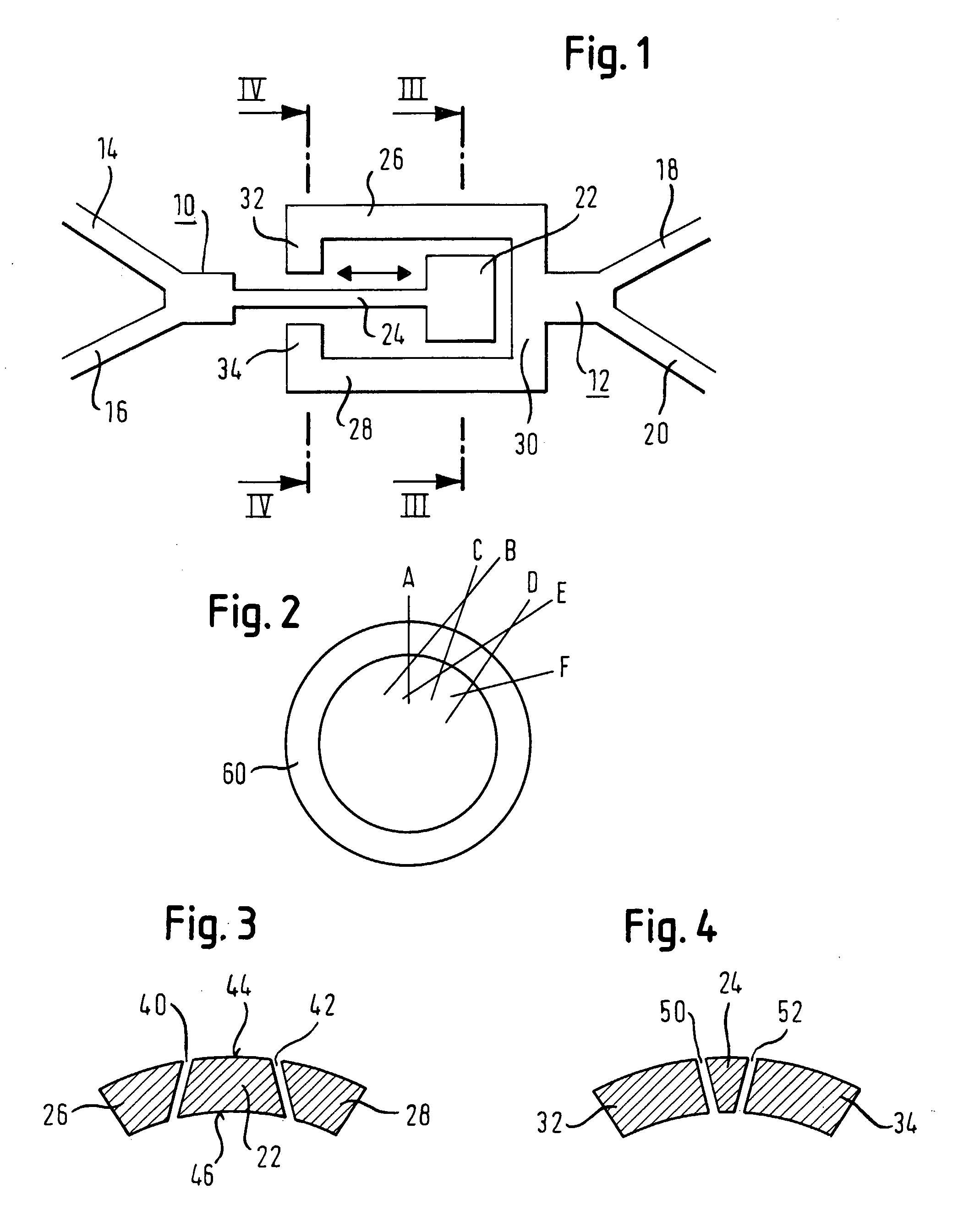

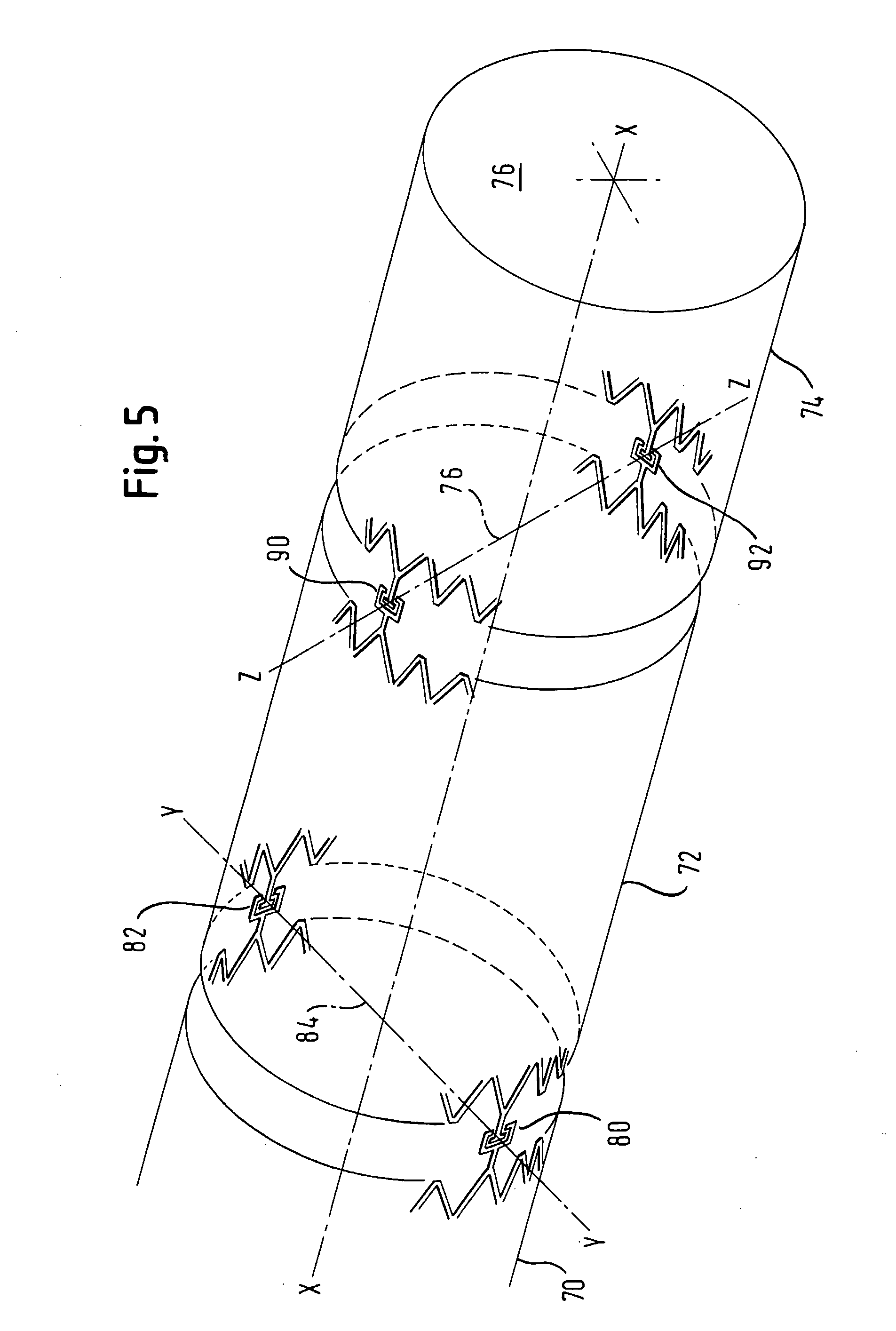

Flexible Intravascular Implant

InactiveUS20080195190A1High risk of damageHigh riskStentsBlood vesselsInsertion stentSacroiliac joint

The stent matrix of a stent incorporates joints that permit stress-free relative movement of first and second structural portions (10, 12) of the matrix as the facing surfaces of the joint between the structural portions slide relative to one another. The joints are formed in the thickness of an annular wall of the stent, and are created by a computer-controlled laser beam cutting procedure.

Owner:ANGIOMED GMBH & CO MEDIZINTECHNIK KG

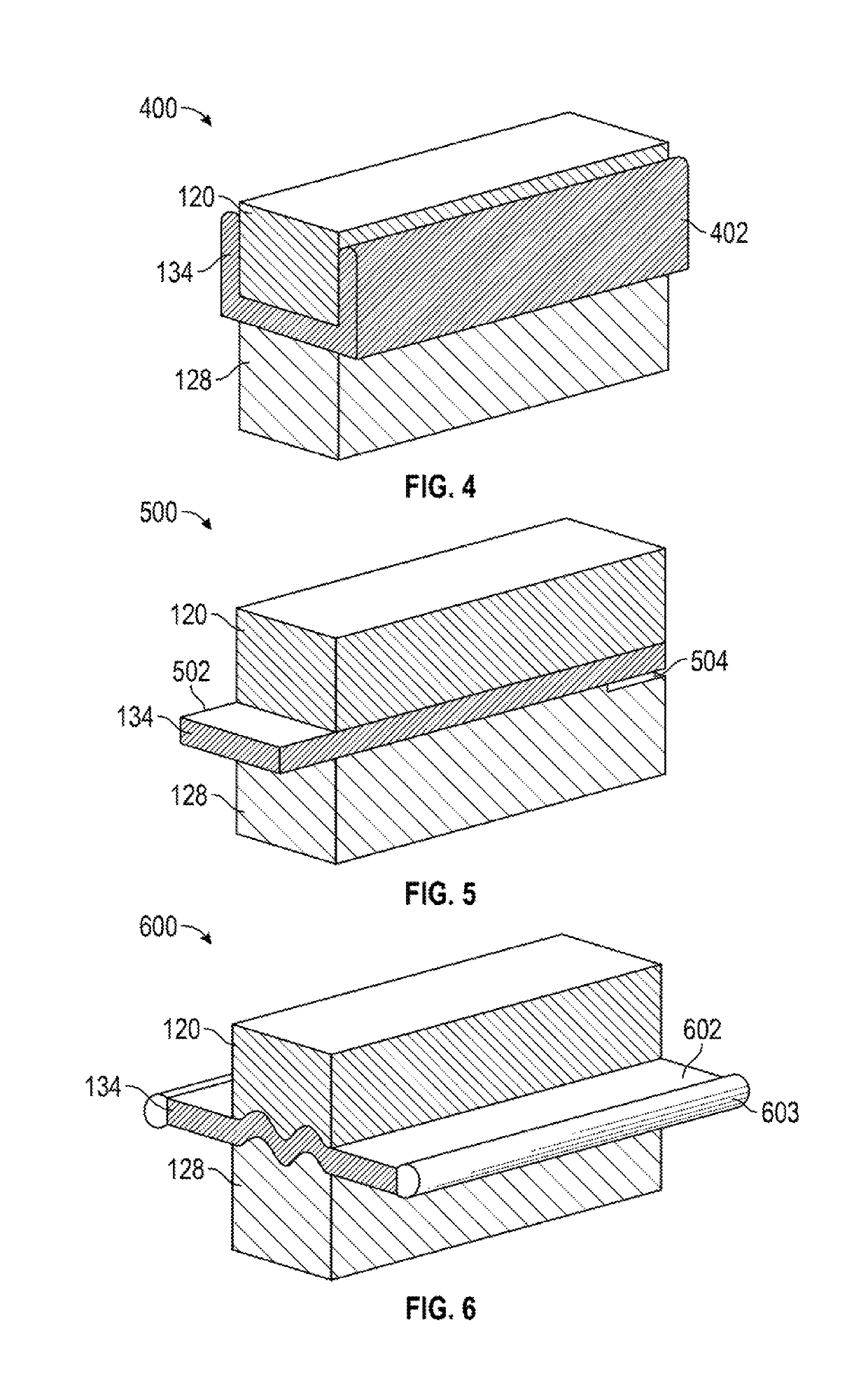

Joint seal system

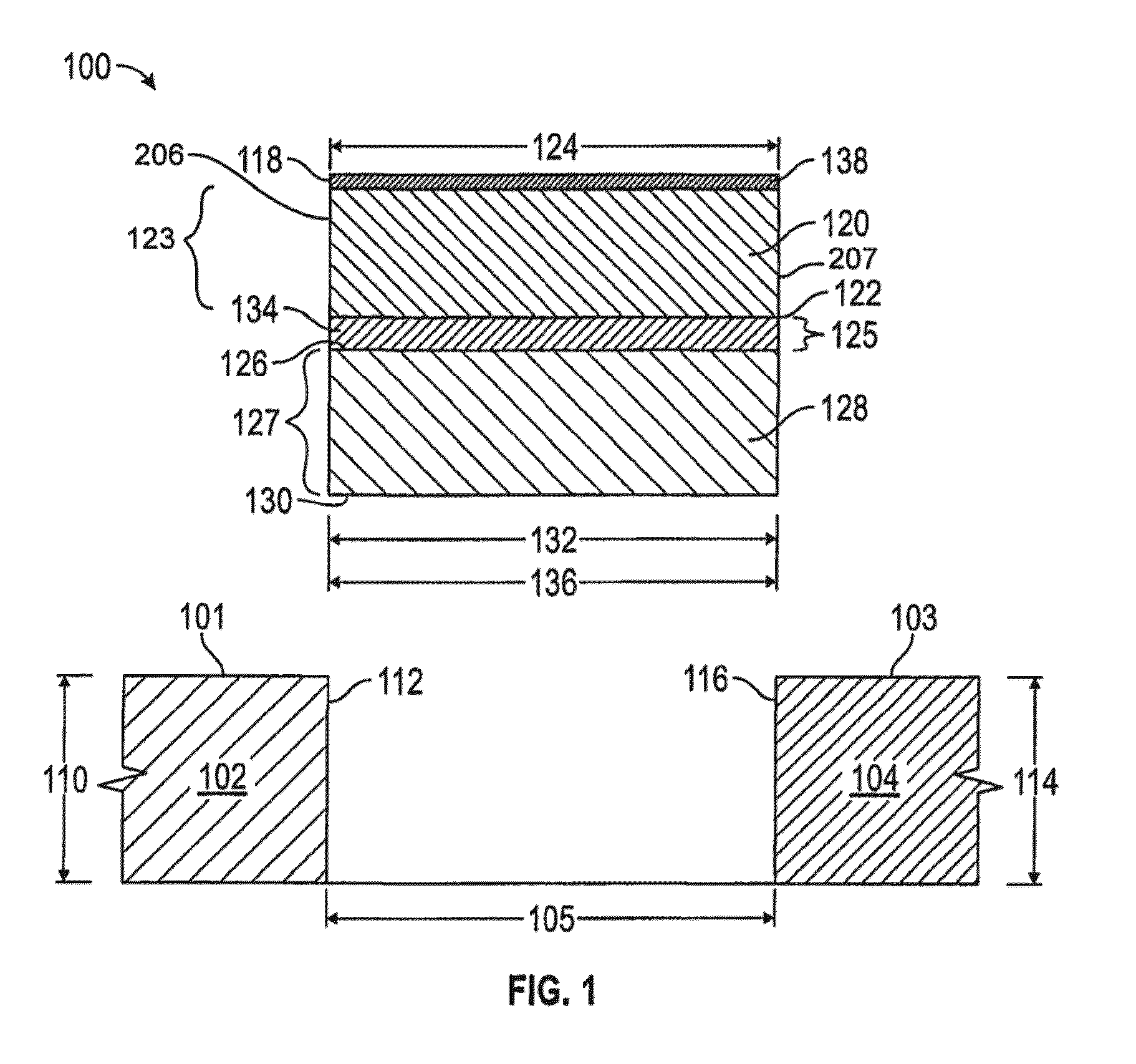

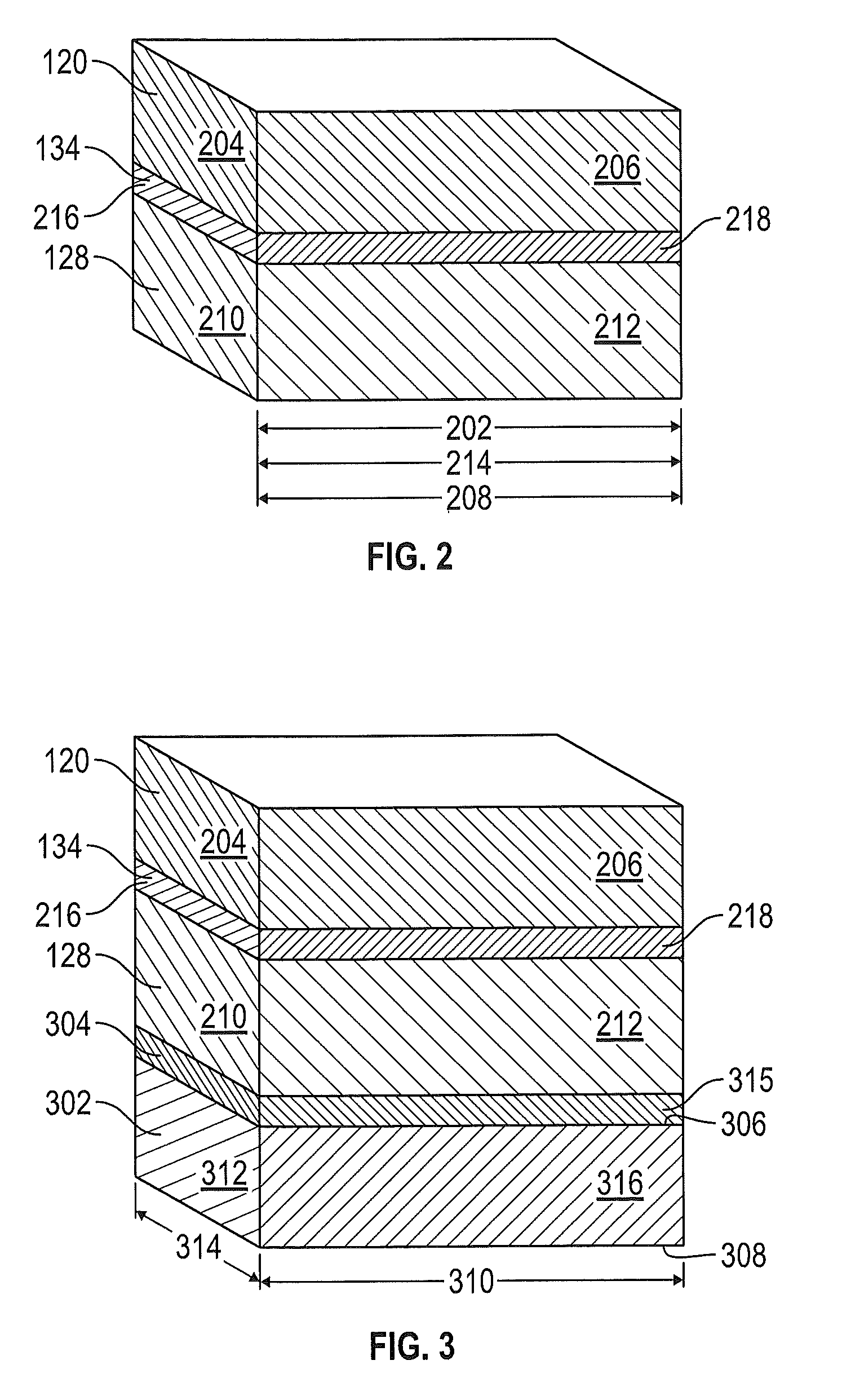

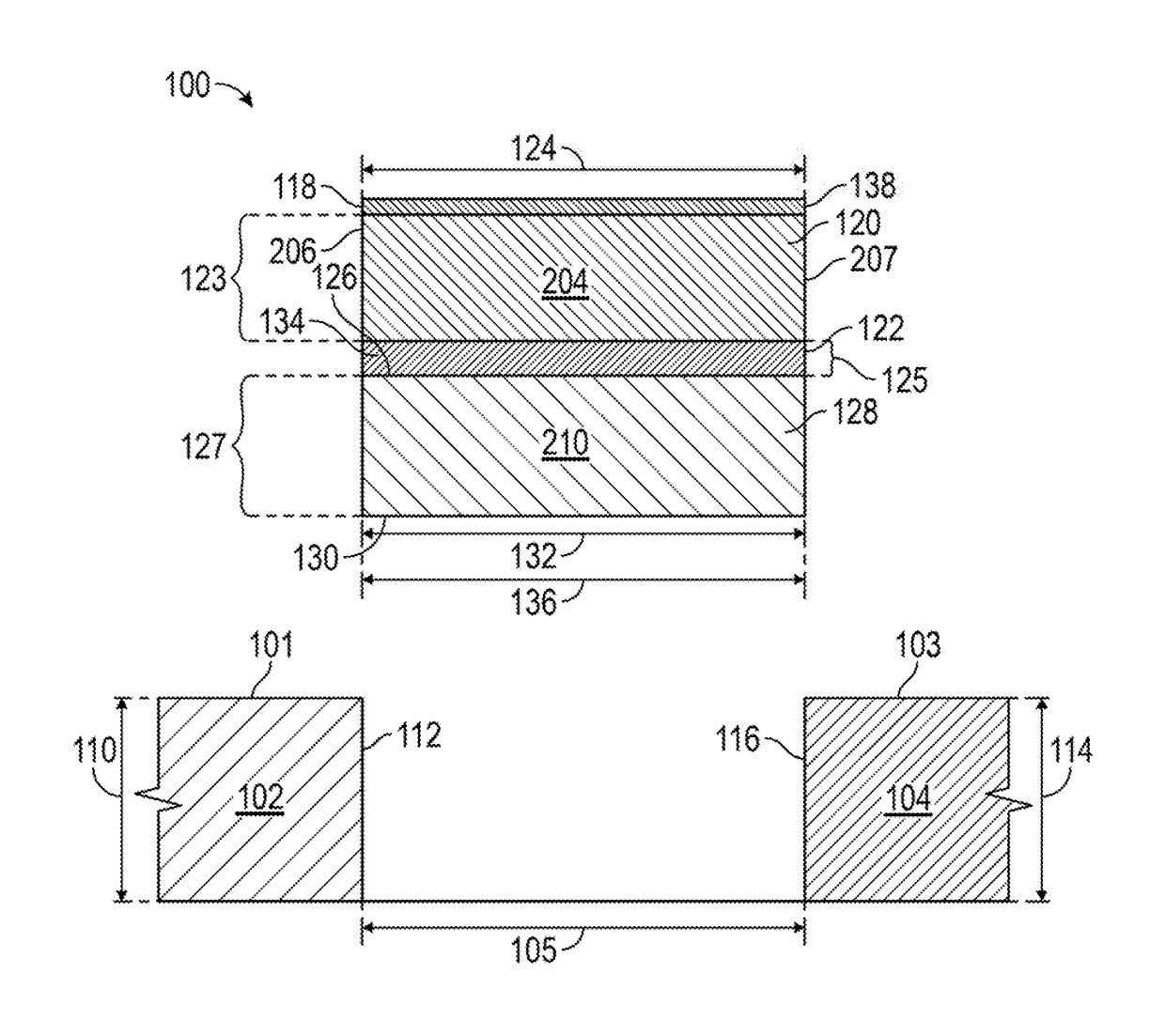

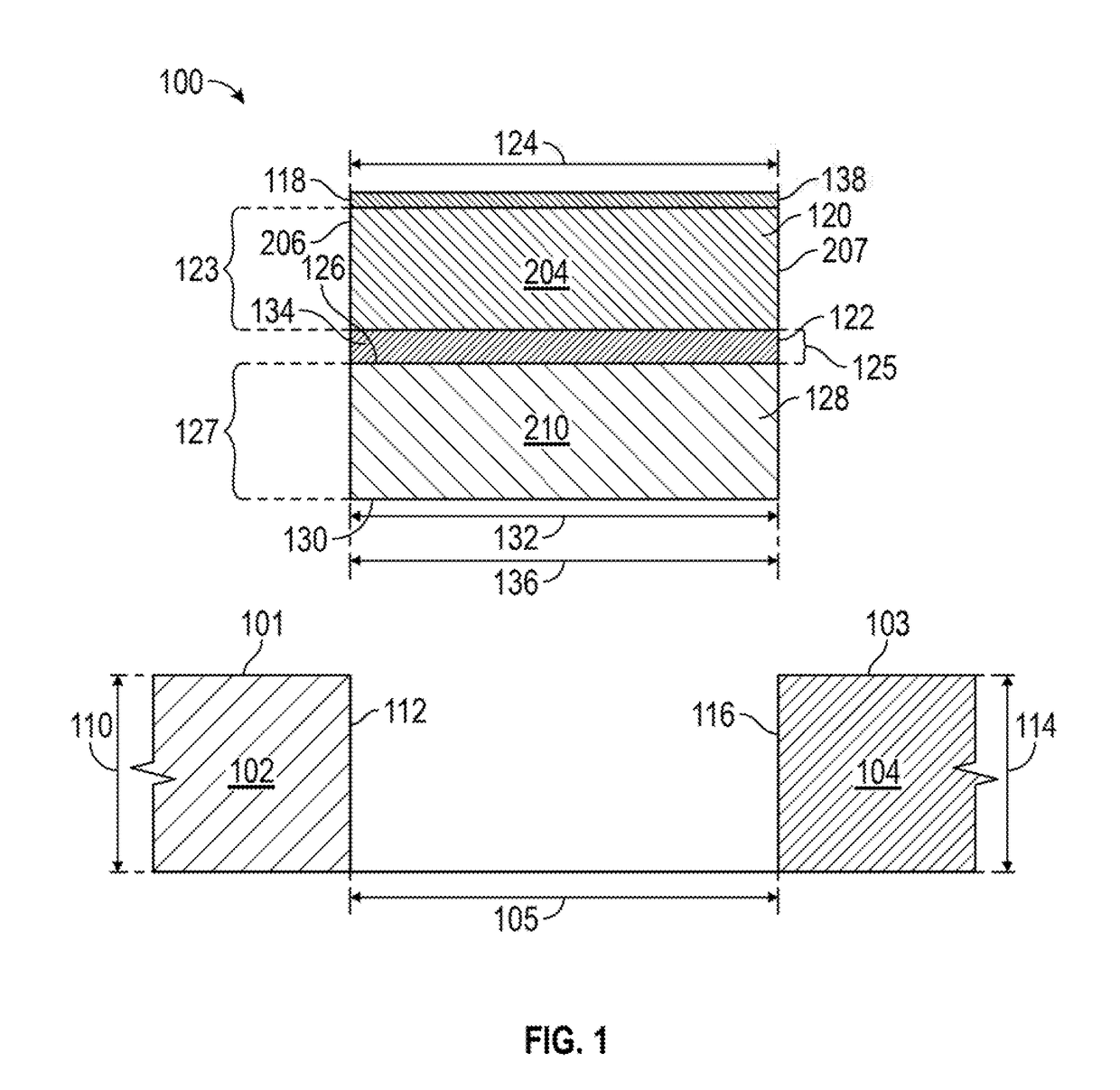

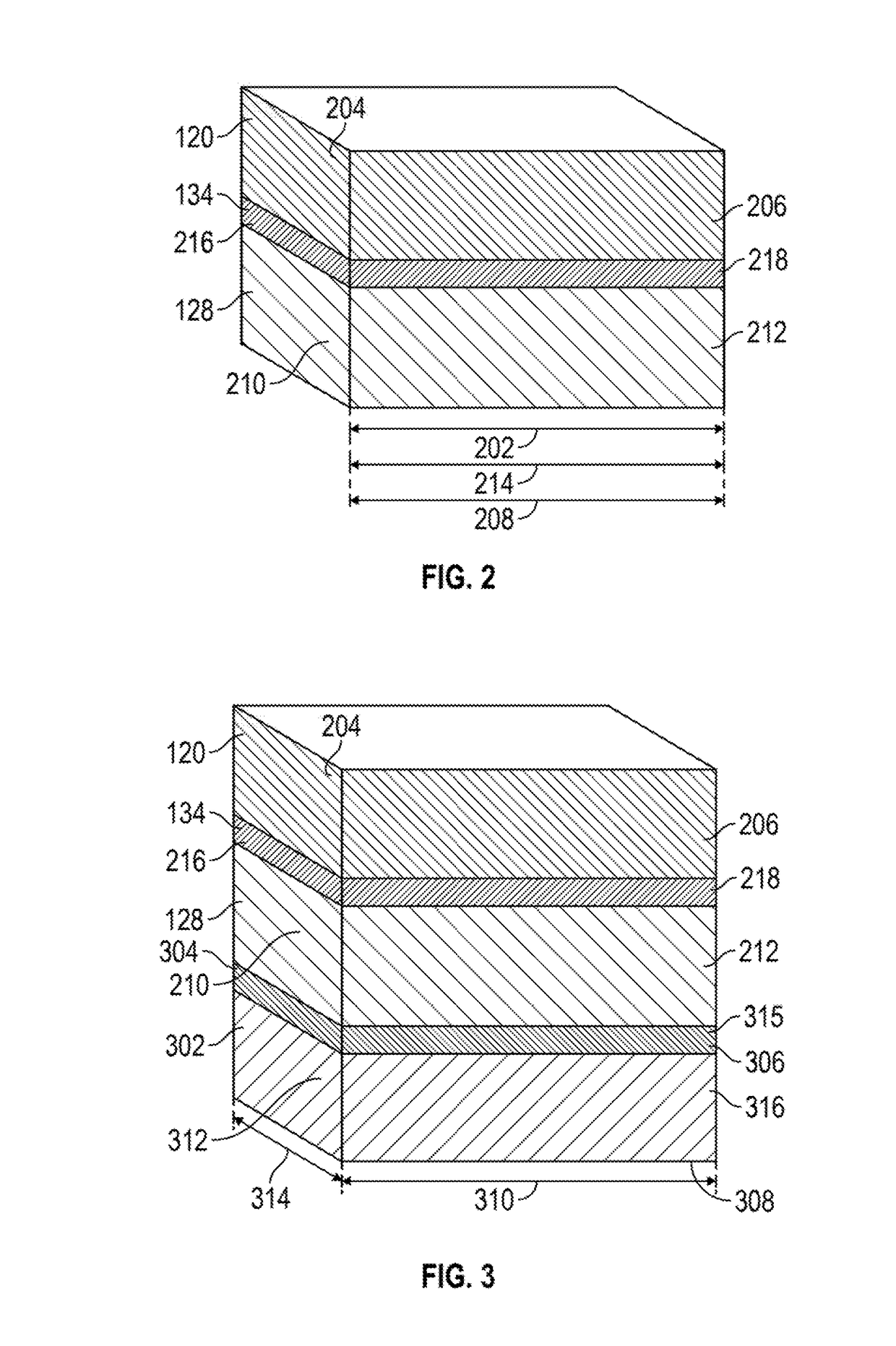

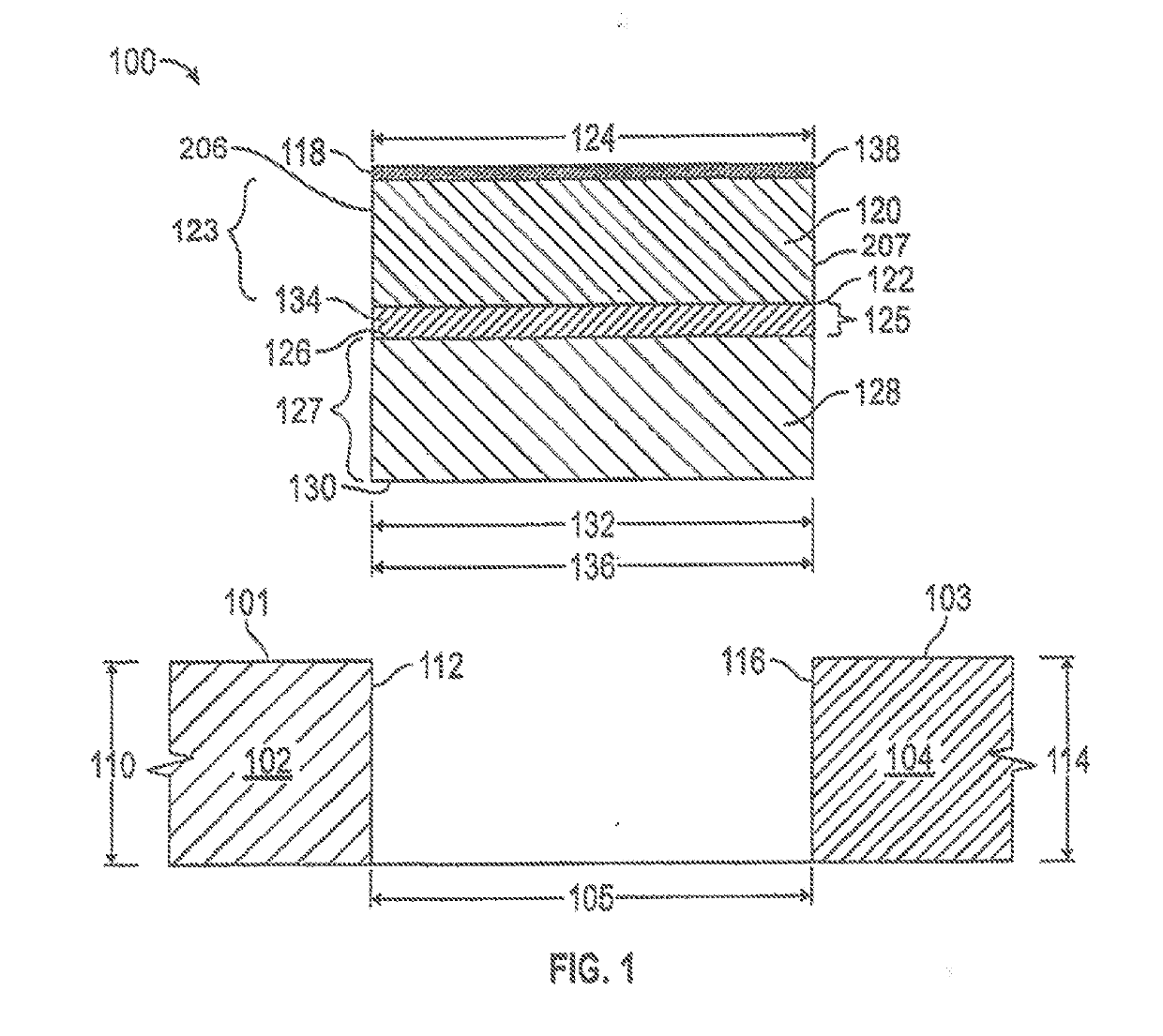

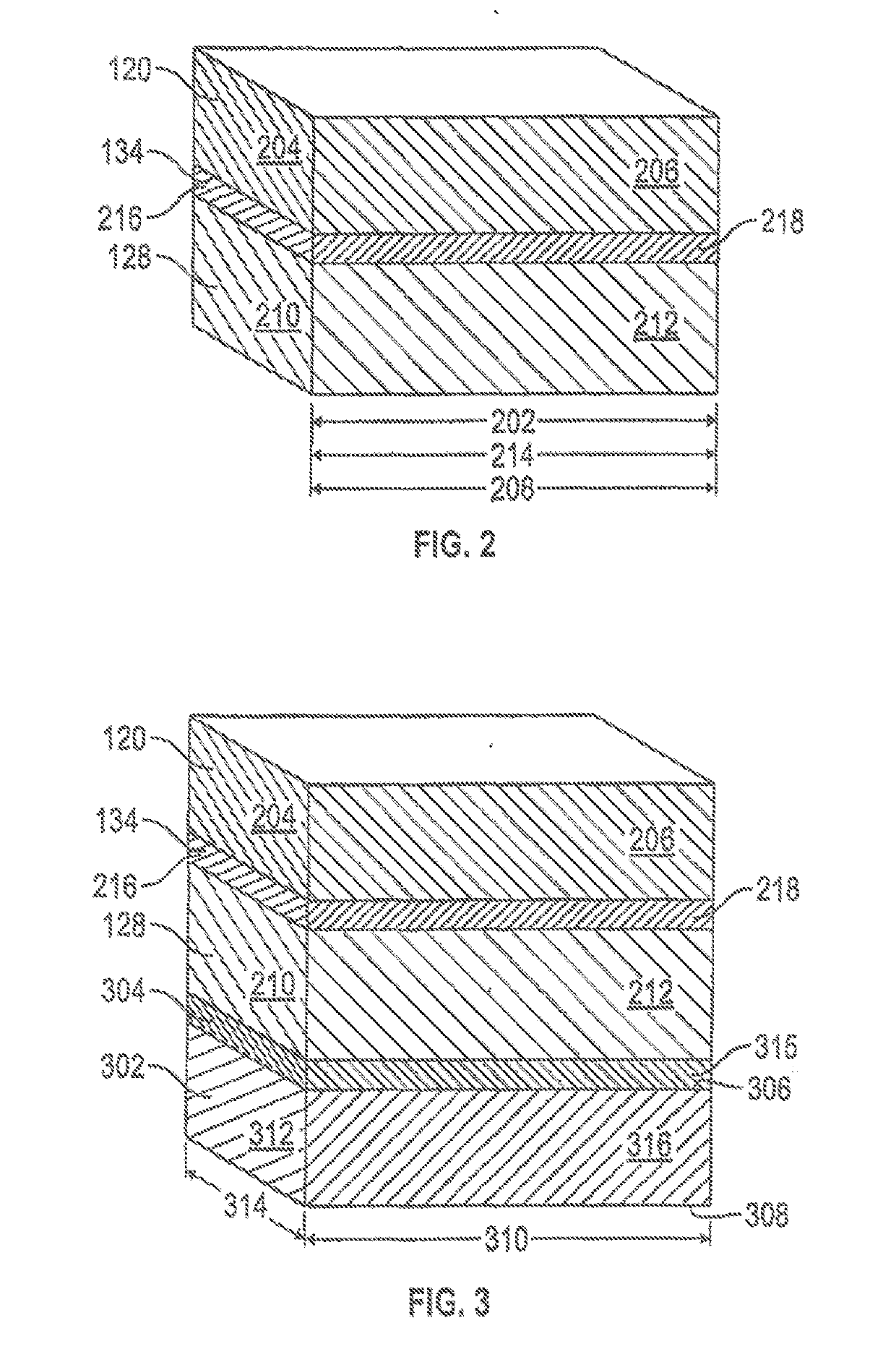

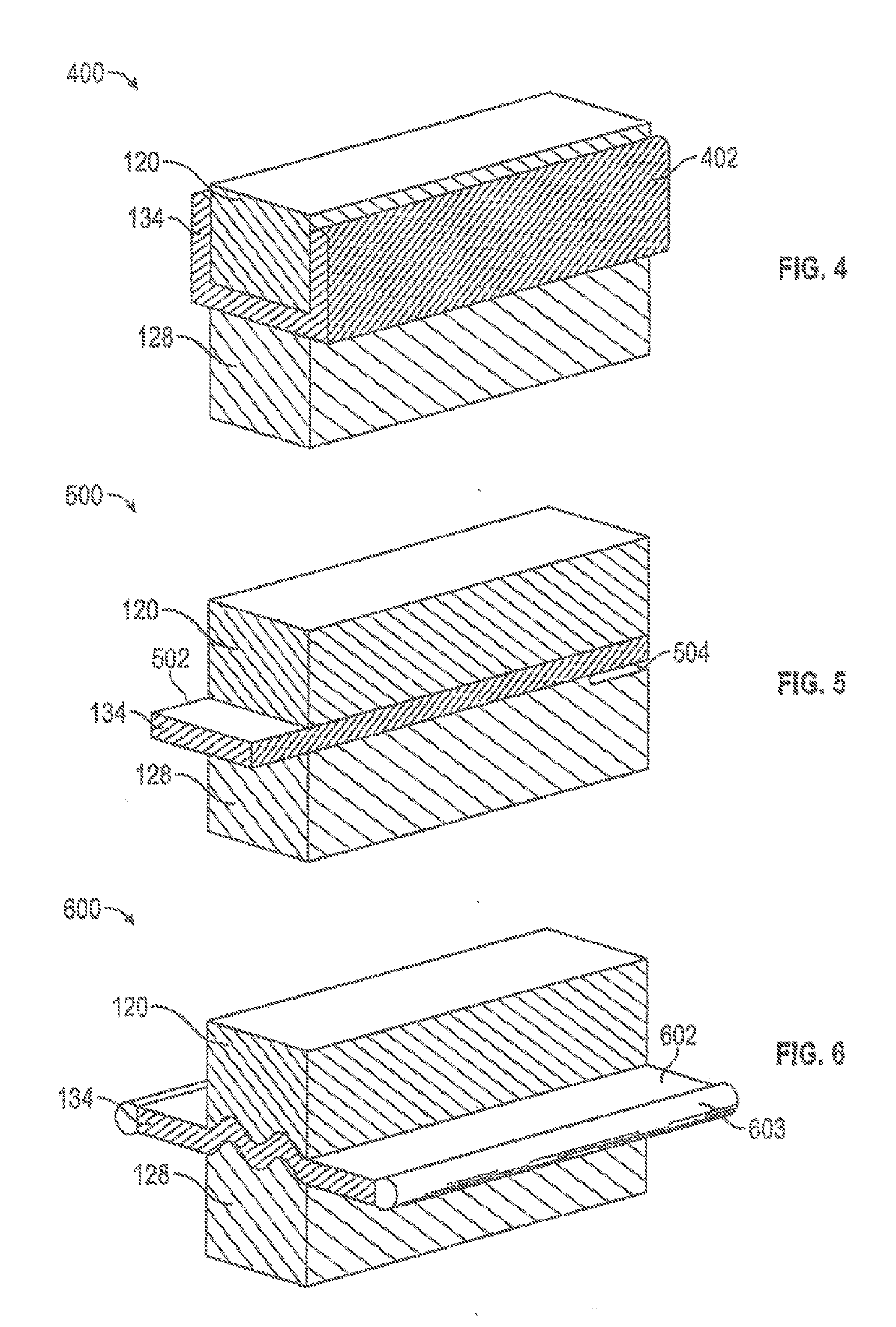

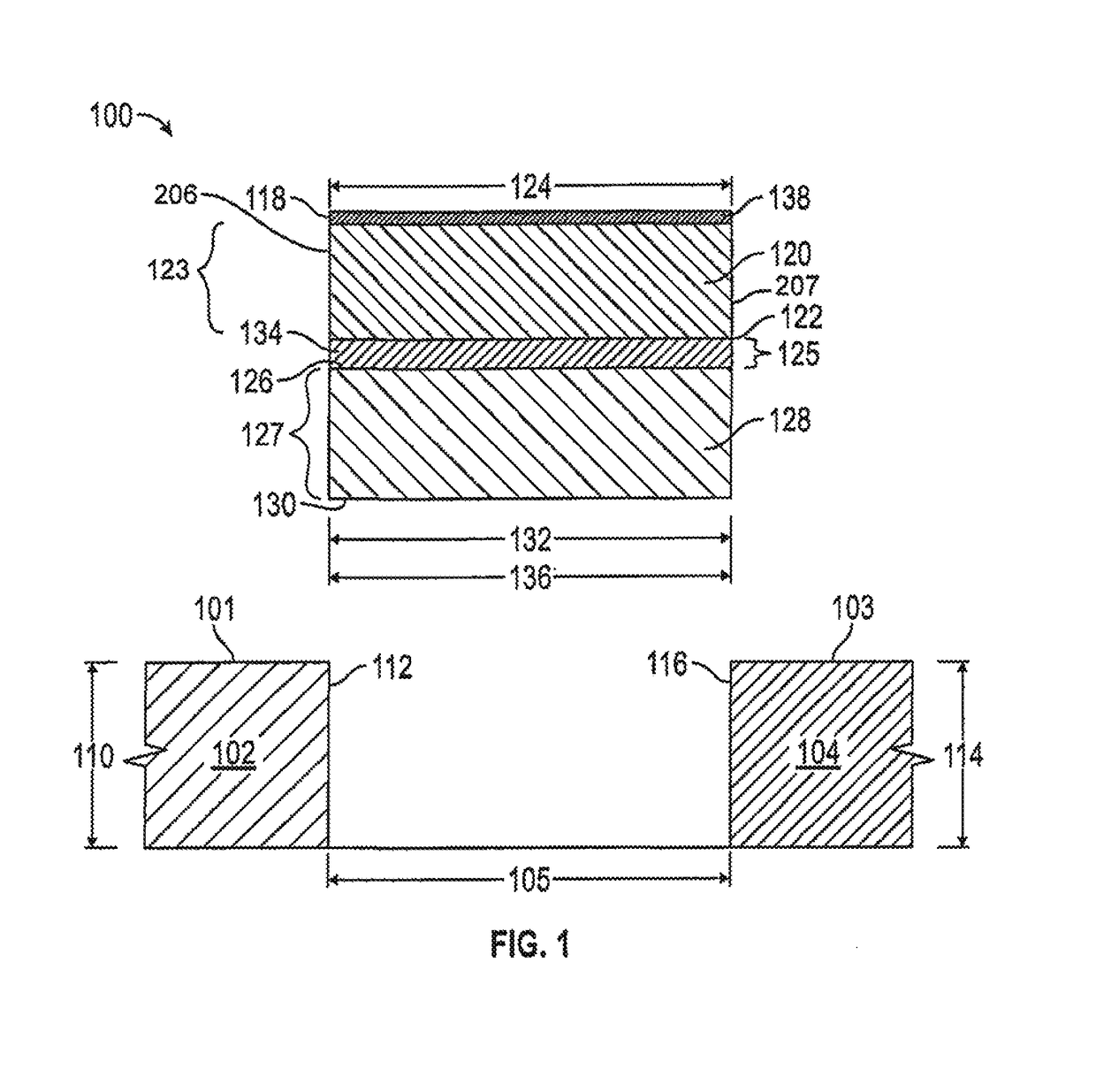

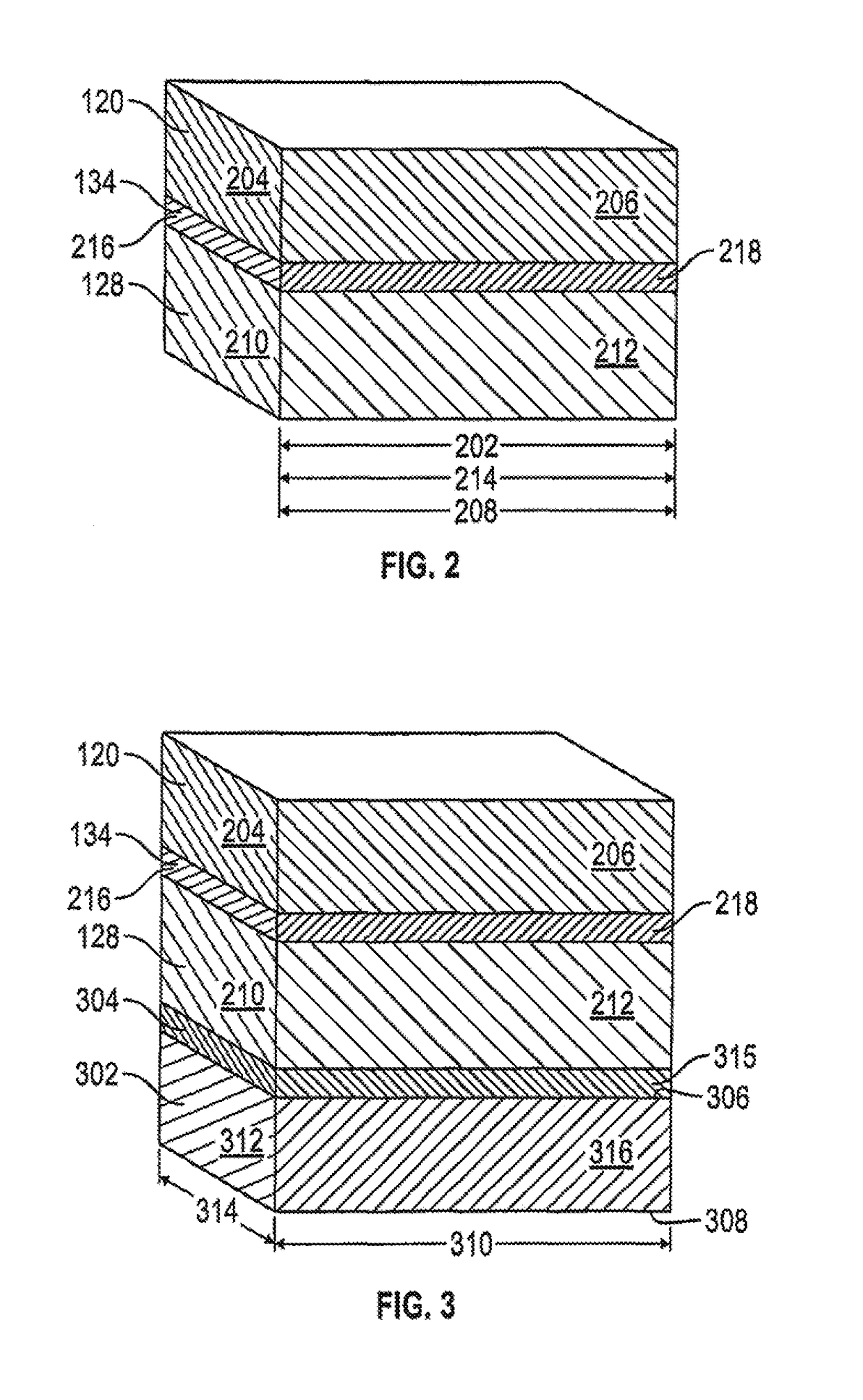

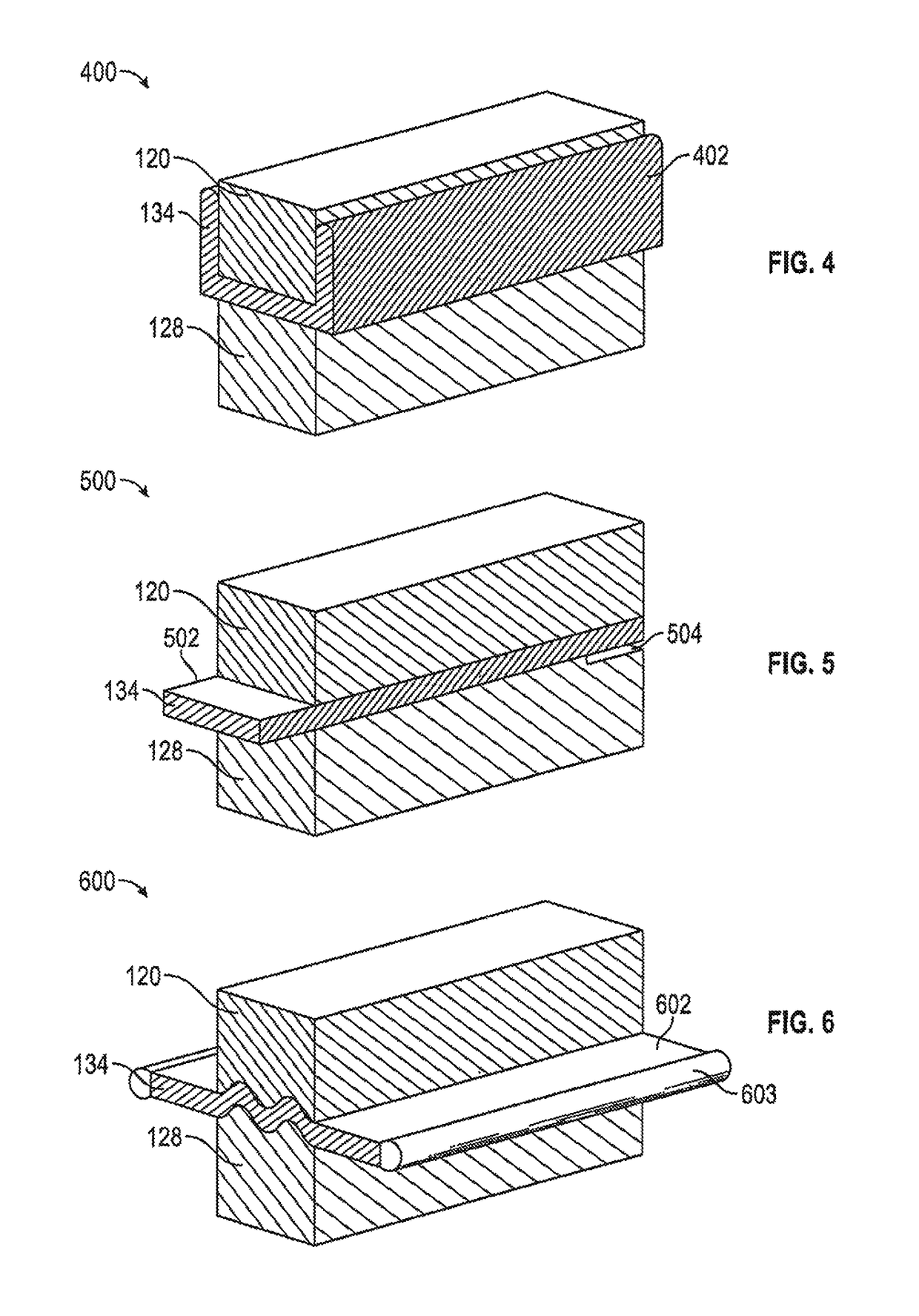

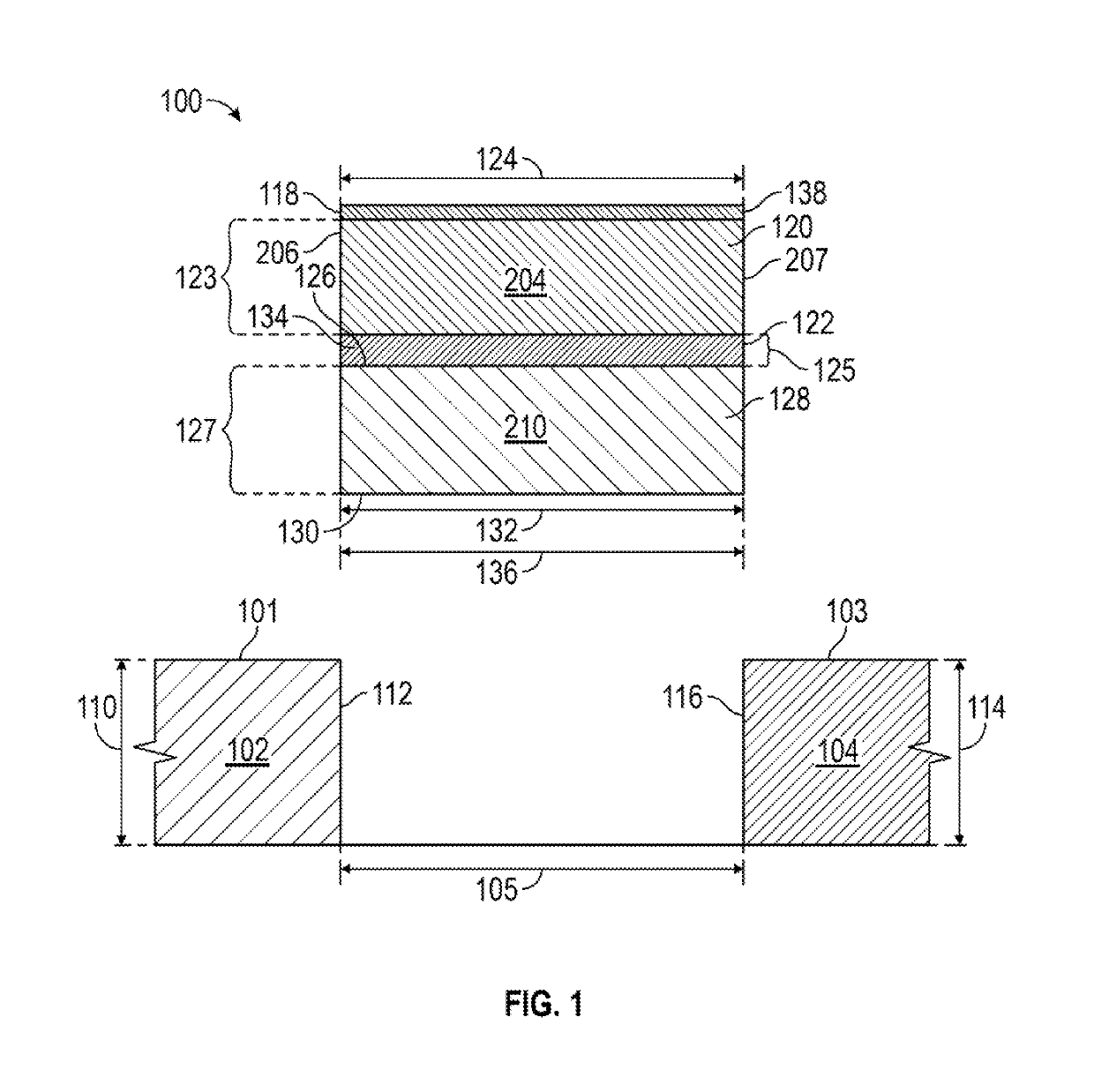

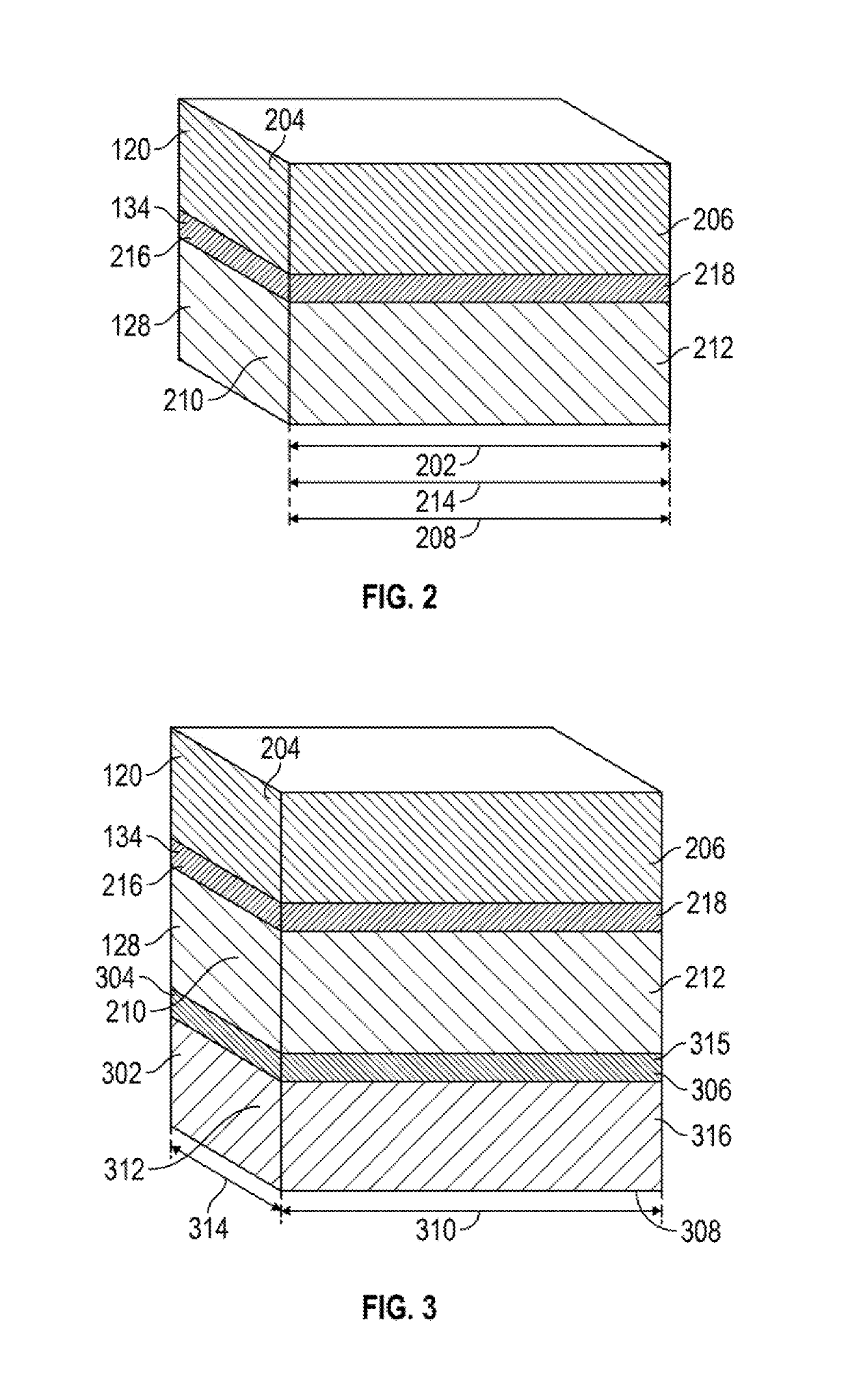

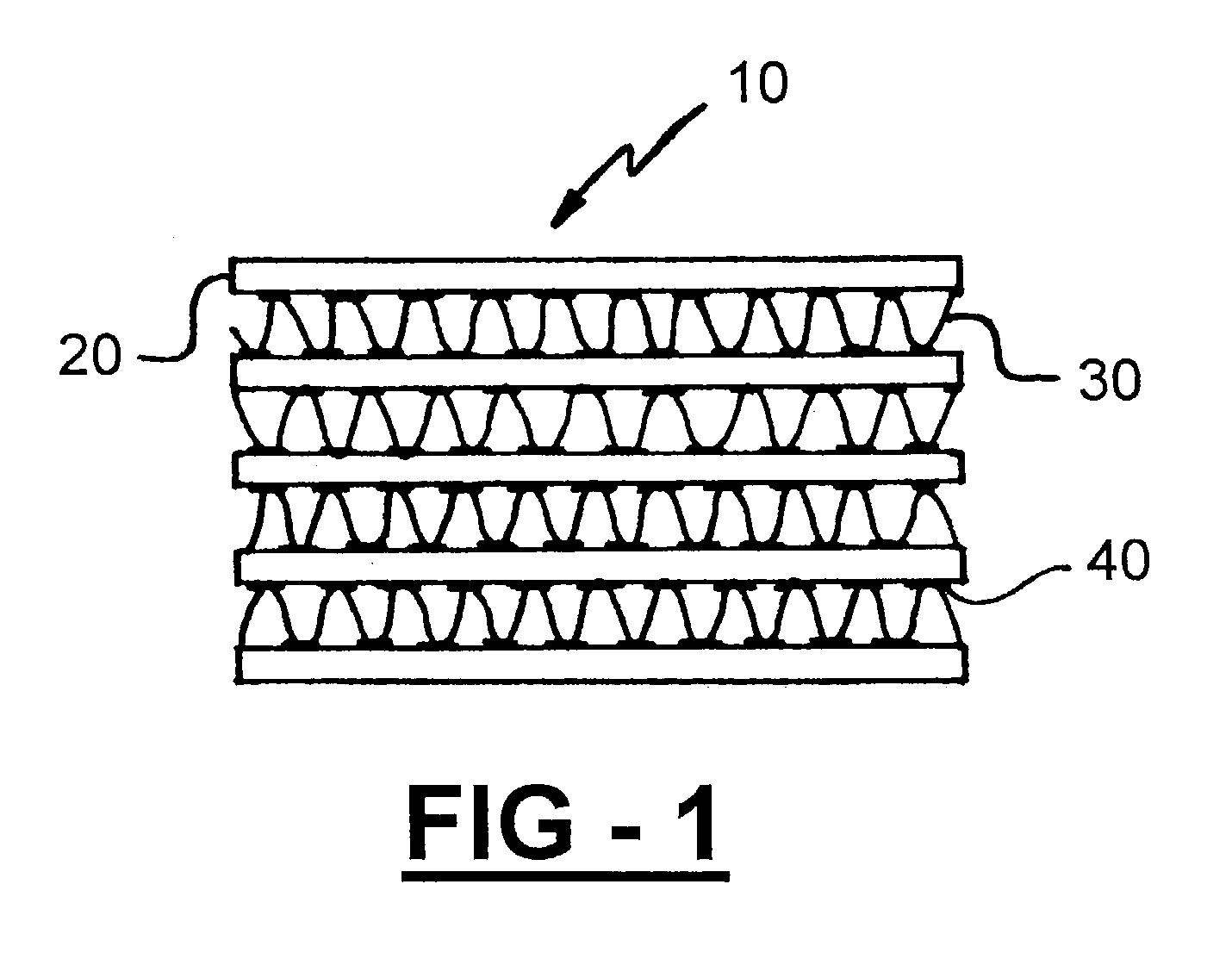

An integral multilayer joint seal system. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or may be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam and may be different in dimensions from the layers of foam. The joint may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

Joint seal system having internal barrier and external wings

An integral multilayer joint seal. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer which extends beyond the foam layers to provide a protective surface, a surface for attachment atop adjacent substrates, or a connecting tab for use with adjacent joint seals. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or lay be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam. The joint seal may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

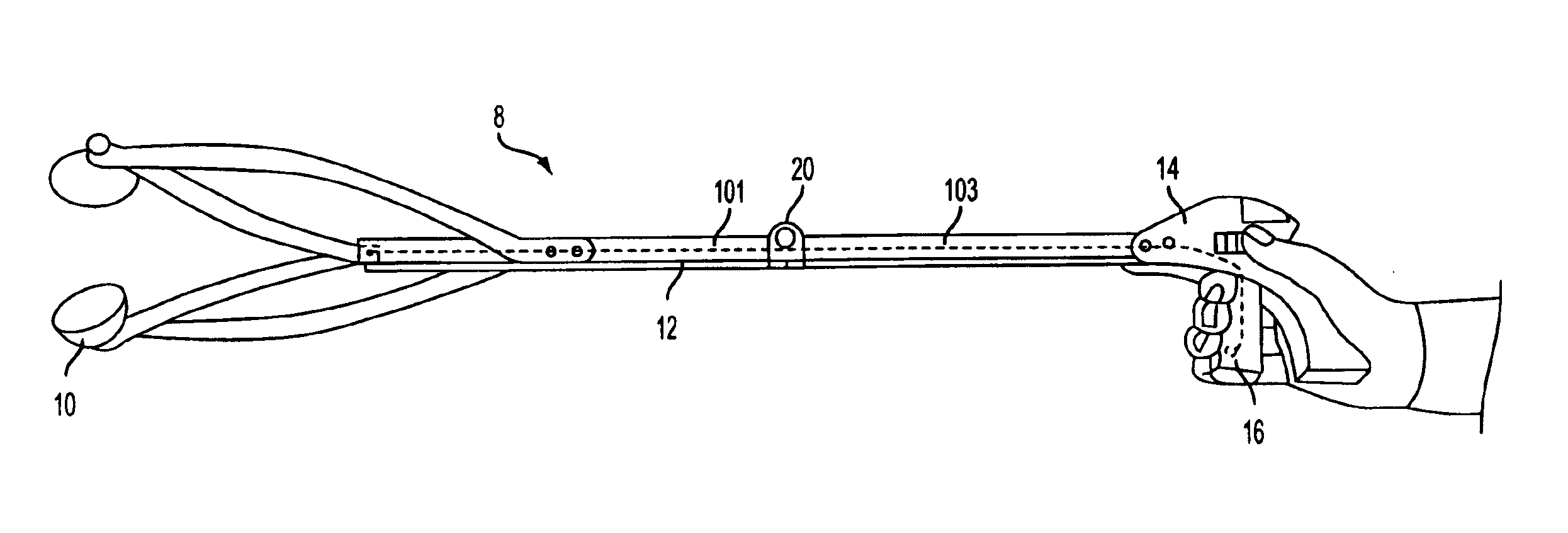

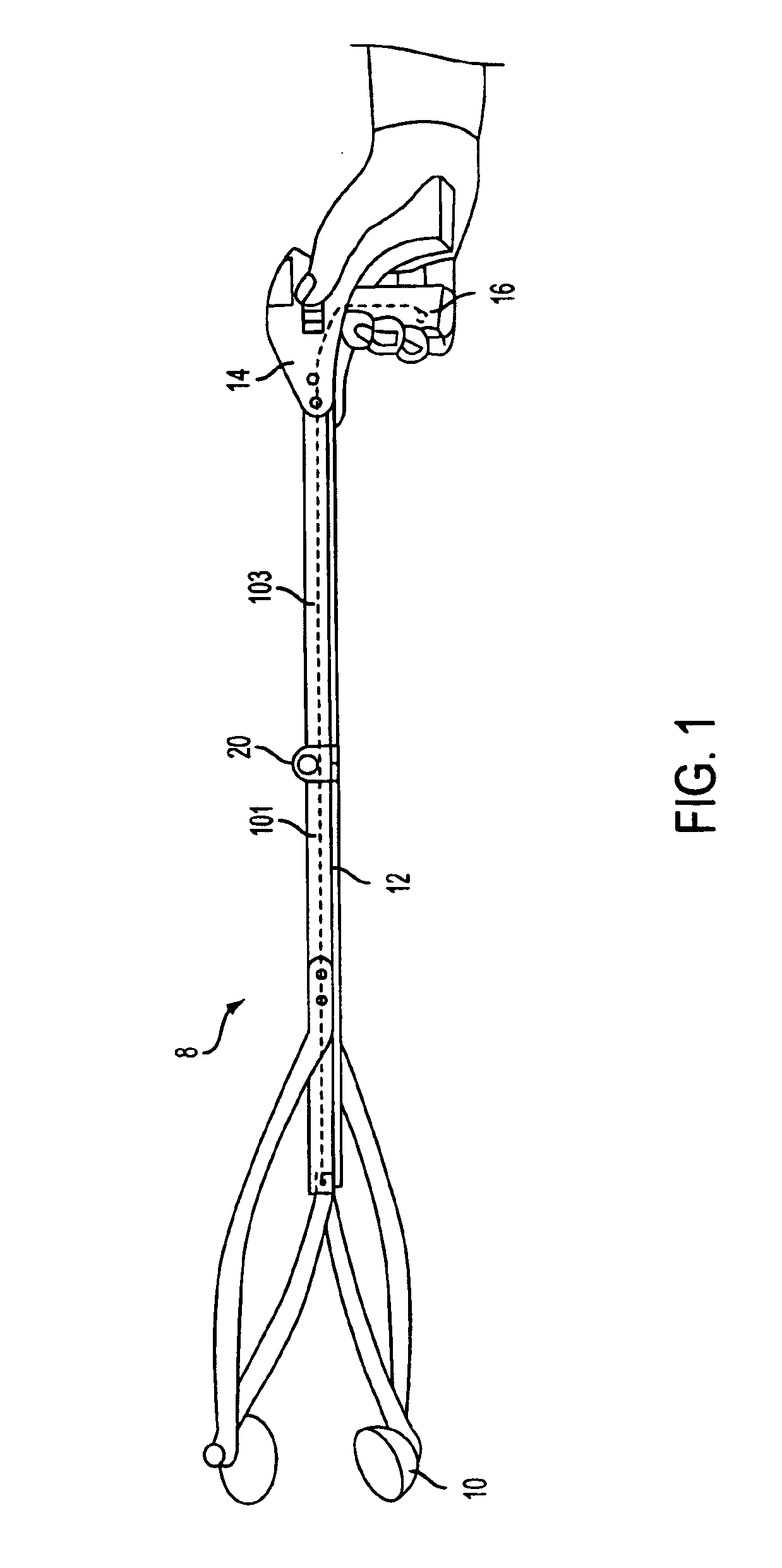

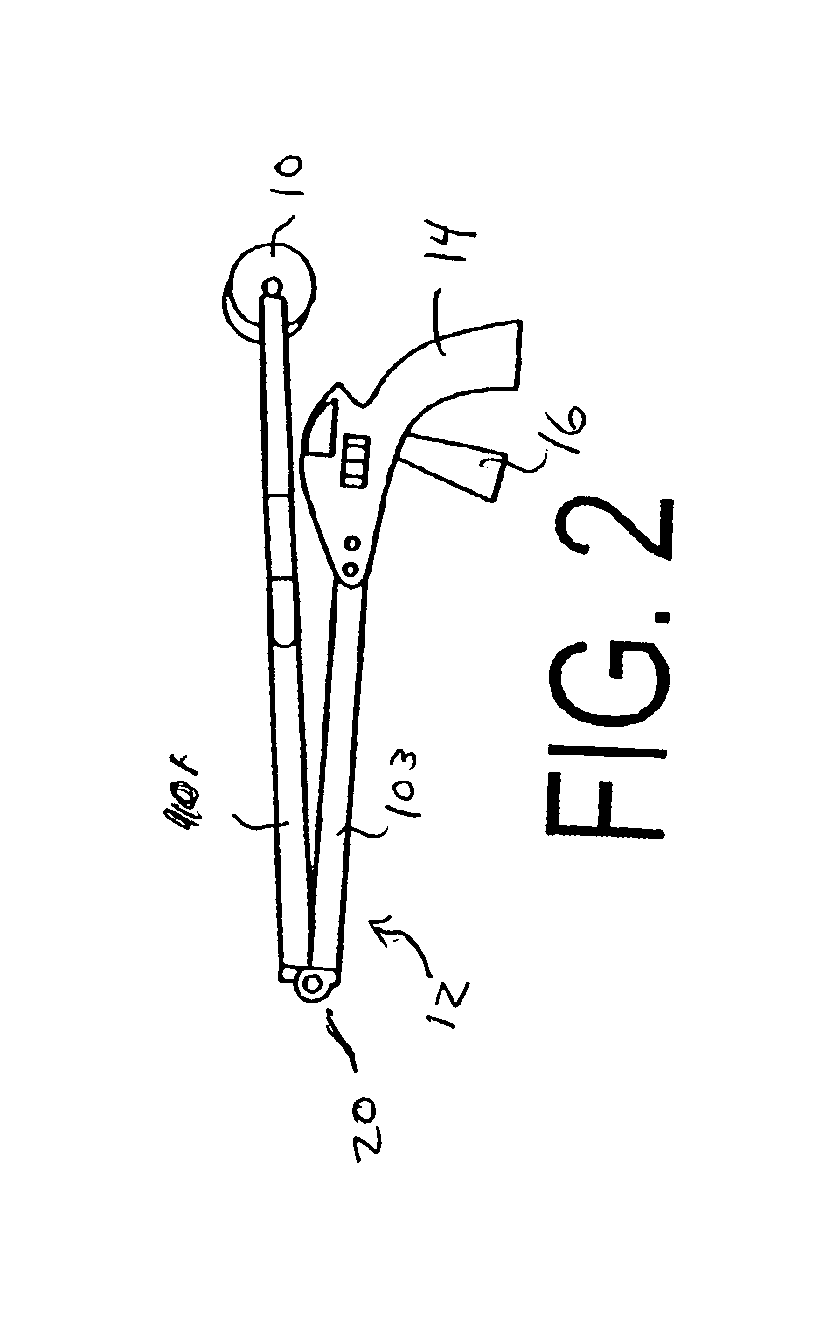

Hinge for extended grabber tool

An elongate engagement tool that has engagement elements located on a distal end of a first rod, a handle on the proximate end of second rod, a controller on the handle to control the engagement elements, and a linkage between the controller and engagement elements to control the engagement elements is disclosed. The rods are connected together by a locking hinge. A locking pin is received by the knuckles of the hinges has a plurality of axial segments. The profiles of the axial segments alternate from round disks to aster shaped disks that closely fit into the apertures formed by the knuckles. When the locking pin is moved to a first locked position where the aster shaped profiled sections are aligned with the apertures in the corresponding knuckles to the hinge is locked. Movement of the pin to a second free position where the round axial sections are aligned with the apertures in the knuckles provides for limited rotational movement.

Owner:ONTEL PRODS

Joint seal system with winged barrier

An integral multilayer joint seal. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer which extends beyond the foam layers to provide a protective surface, a surface for attachment atop adjacent substrates, or a connecting tab for use with adjacent joint seals. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or may be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam. The joint seal may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

Joint seal system

An integral multilayer joint seal. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer which extends beyond the foam layers to provide a protective surface, a surface for attachment atop adjacent substrates, or a connecting tab for use with adjacent joint seals. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or may be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam. The joint seal may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

Joint seal system having internal barrier and external wings

An integral multilayer joint seal. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer which extends beyond the foam layers to provide a protective surface, a surface for attachment atop adjacent substrates, or a connecting tab for use with adjacent joint seals. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or may be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam. The joint seal may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

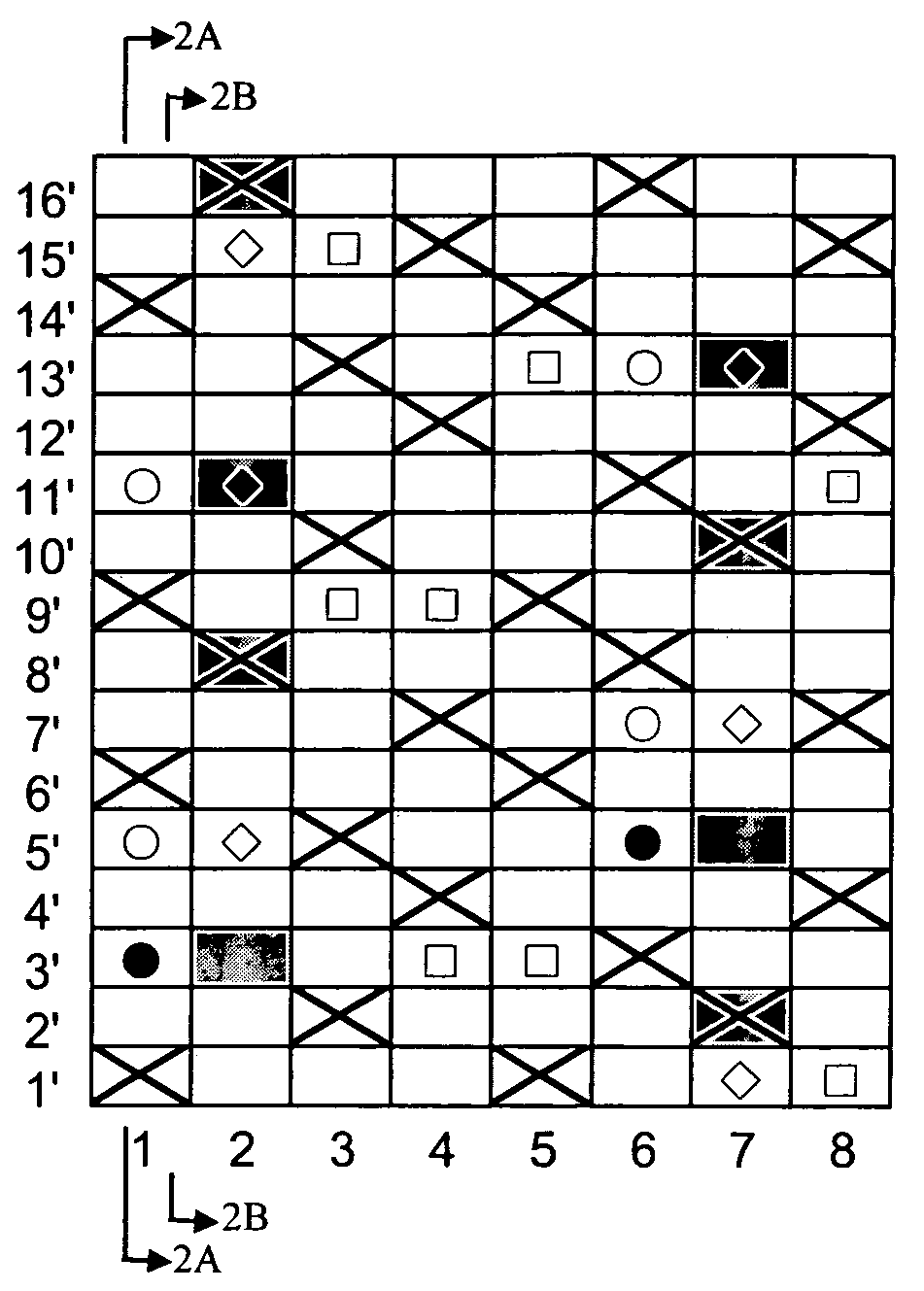

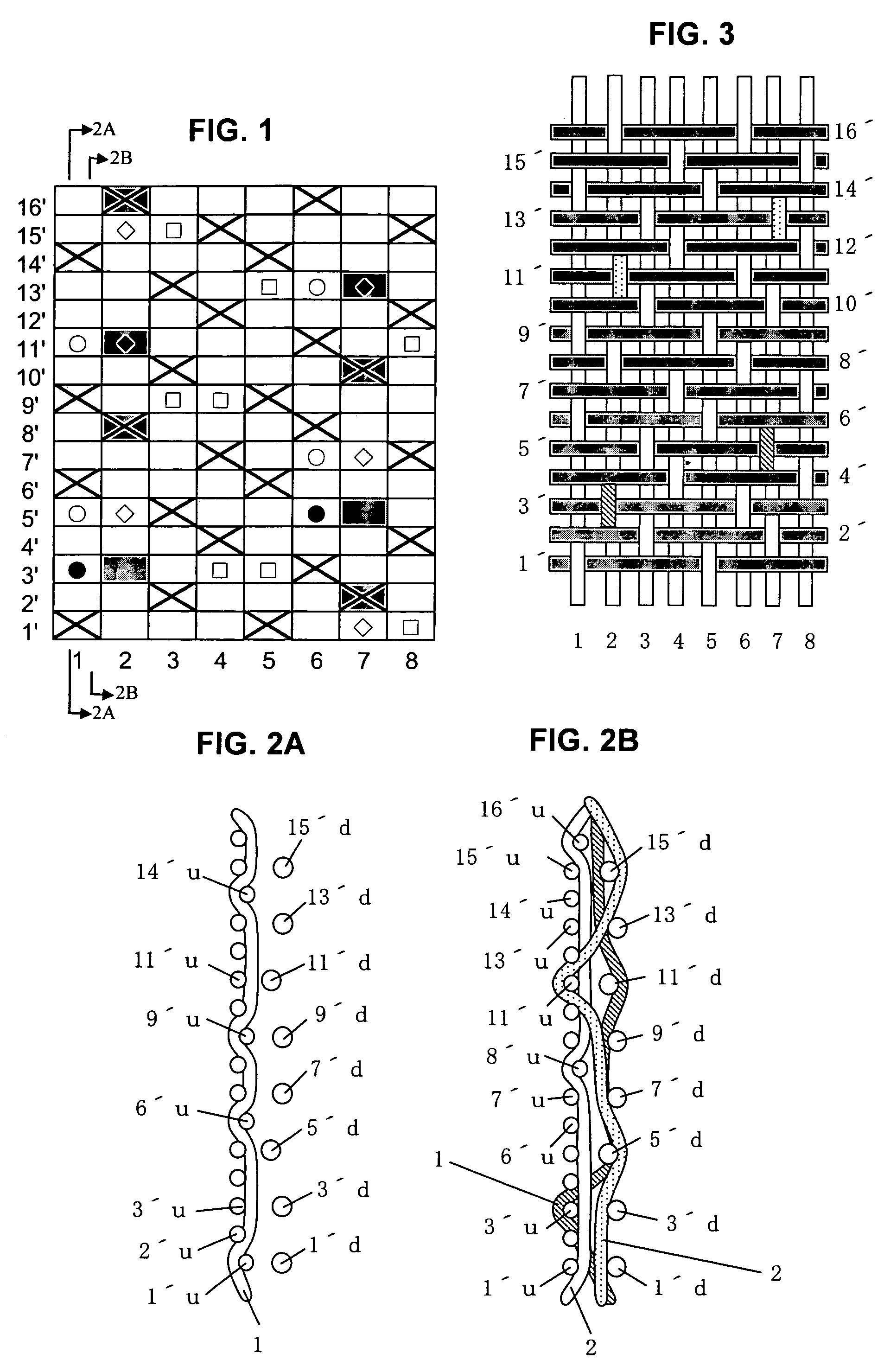

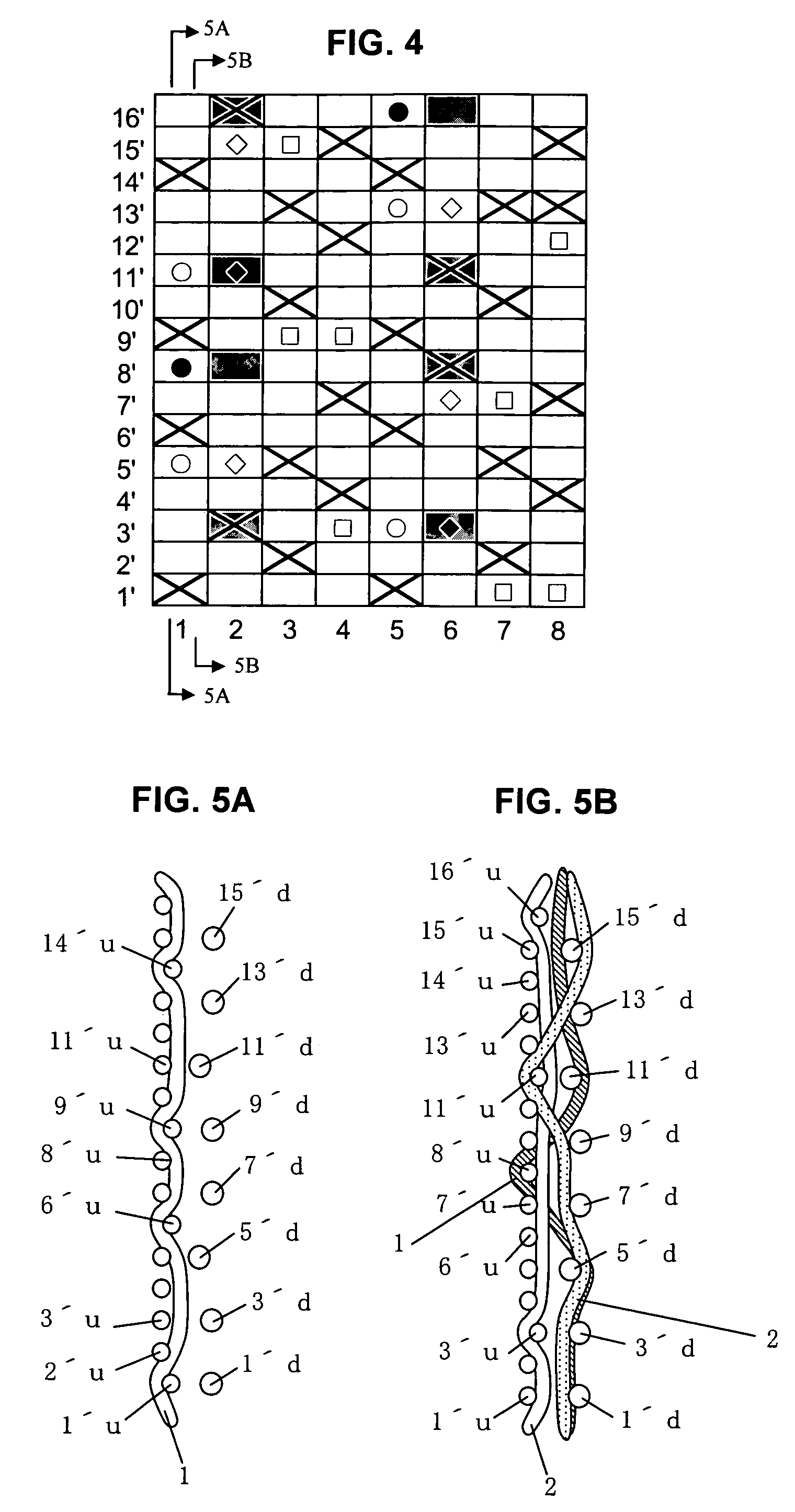

Industrial two-layer fabric

ActiveUS7357157B2Satisfactory propertyImprove surface propertiesPaper/cardboardMachine wet endYarnEngineering

In a repeating unit of a two-layer fabric, a first upper surface side warp forms a first upper surface side warp design. A second upper surface side warp forms a latent portion in which the second upper surface side warp passes between the two layers of the fabric. A first lower warp binding yarn and a second lower warp binding yarn form first and second knuckles respectively by passing over one or two upper surface side wefts at a position not adjacent to two knuckles of the second upper surface side warp in the latent portion. The first and second knuckles are formed at different positions. The first lower warp binding yarn, second upper surface side warp and second lower warp binding yarn cooperatively form a second upper surface side warp design similar to the first upper surface side warp design.

Owner:NIPPON FILCON

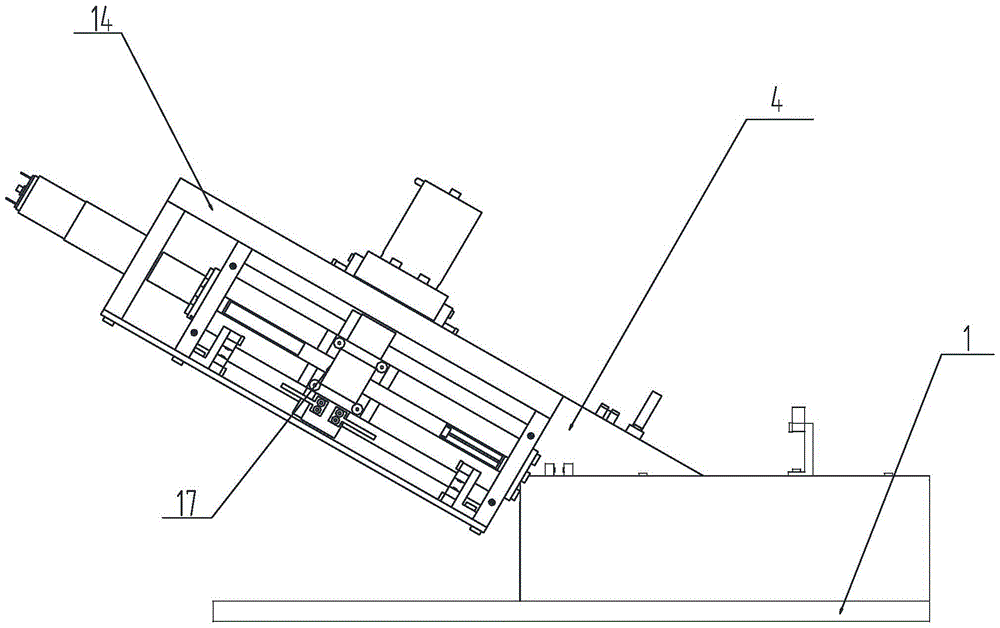

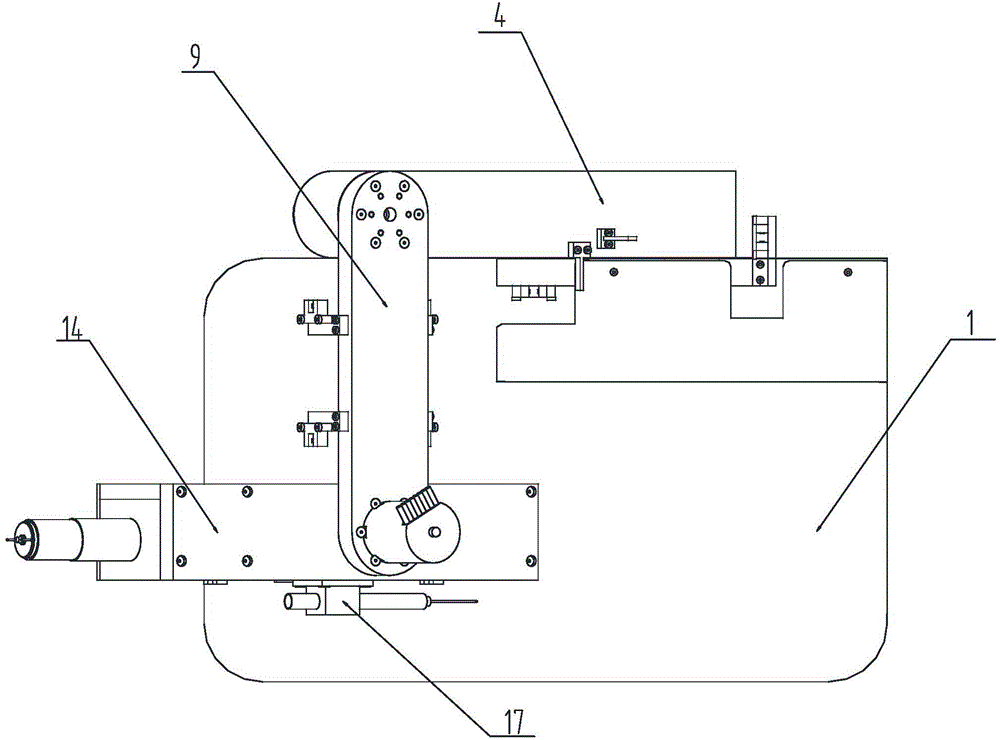

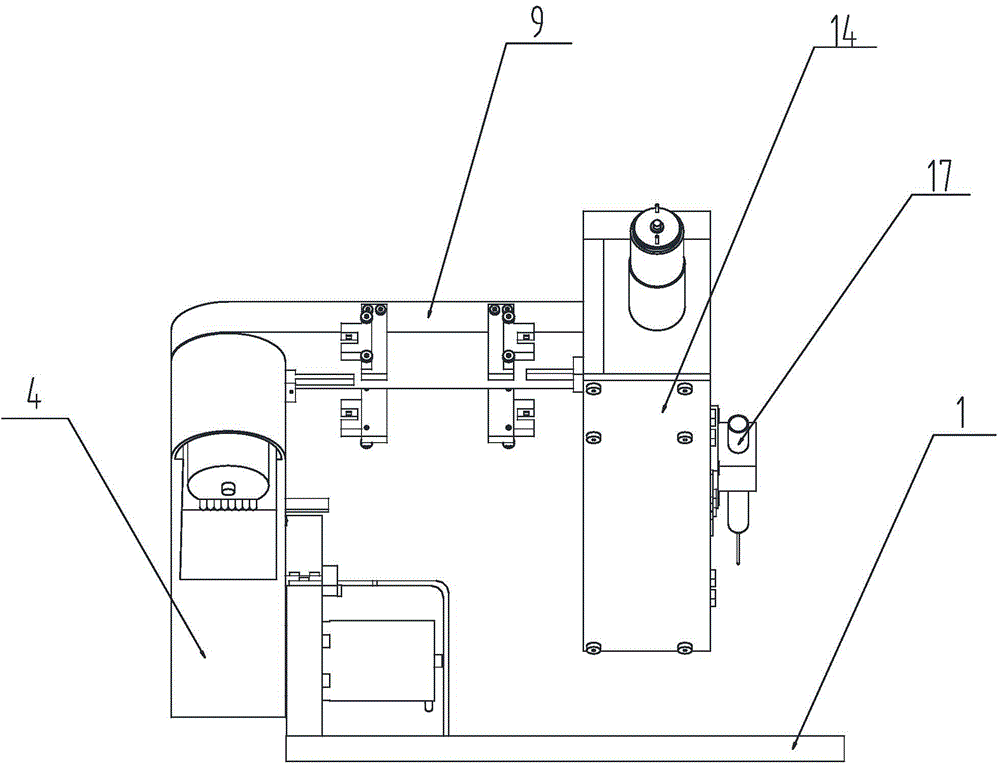

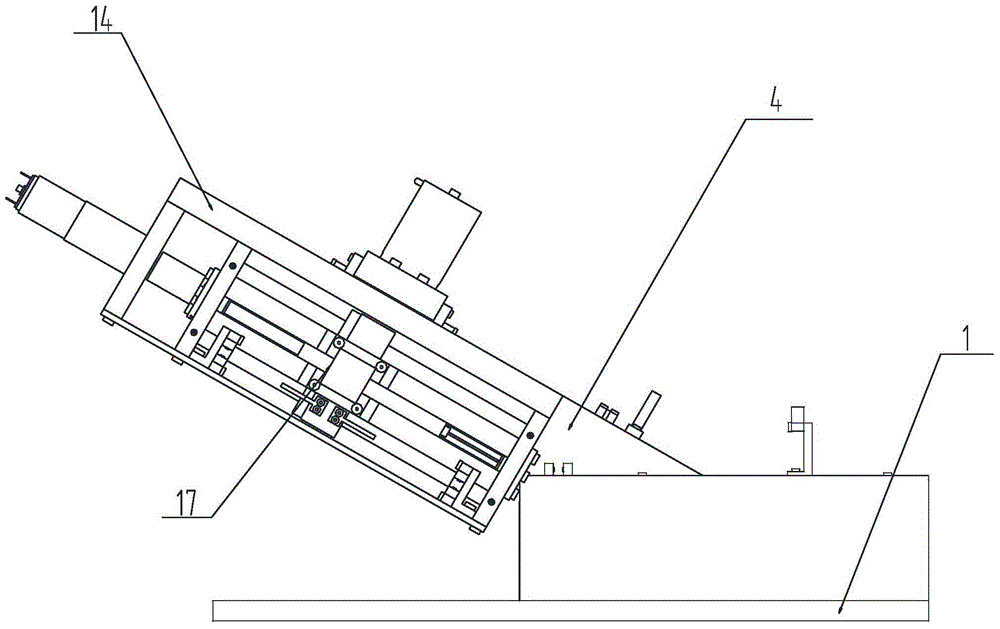

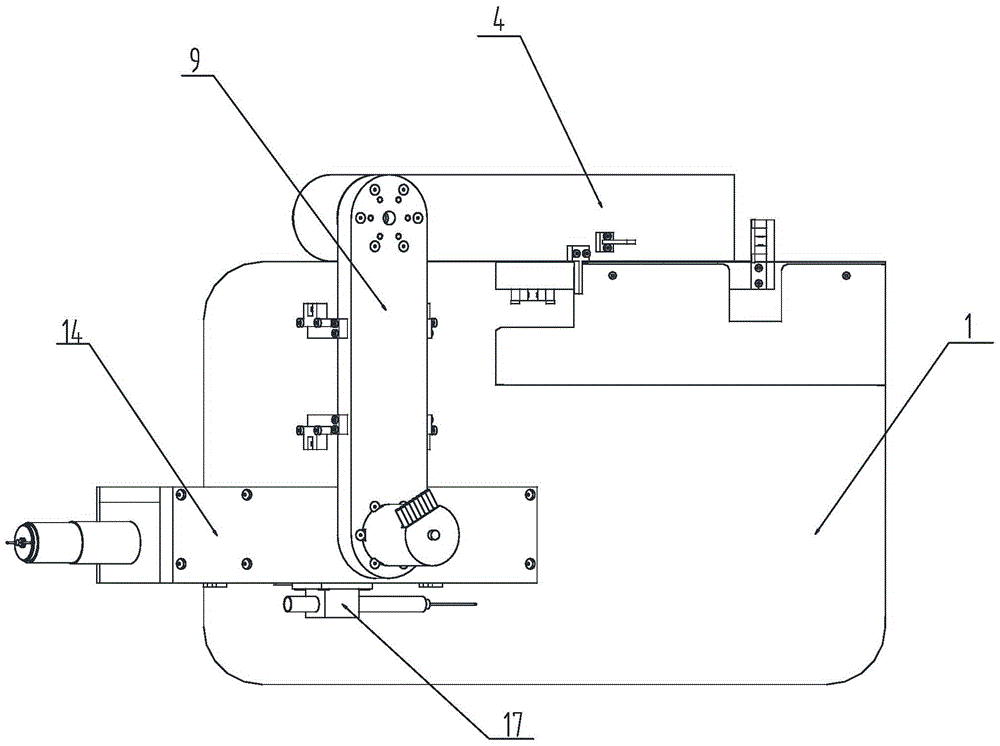

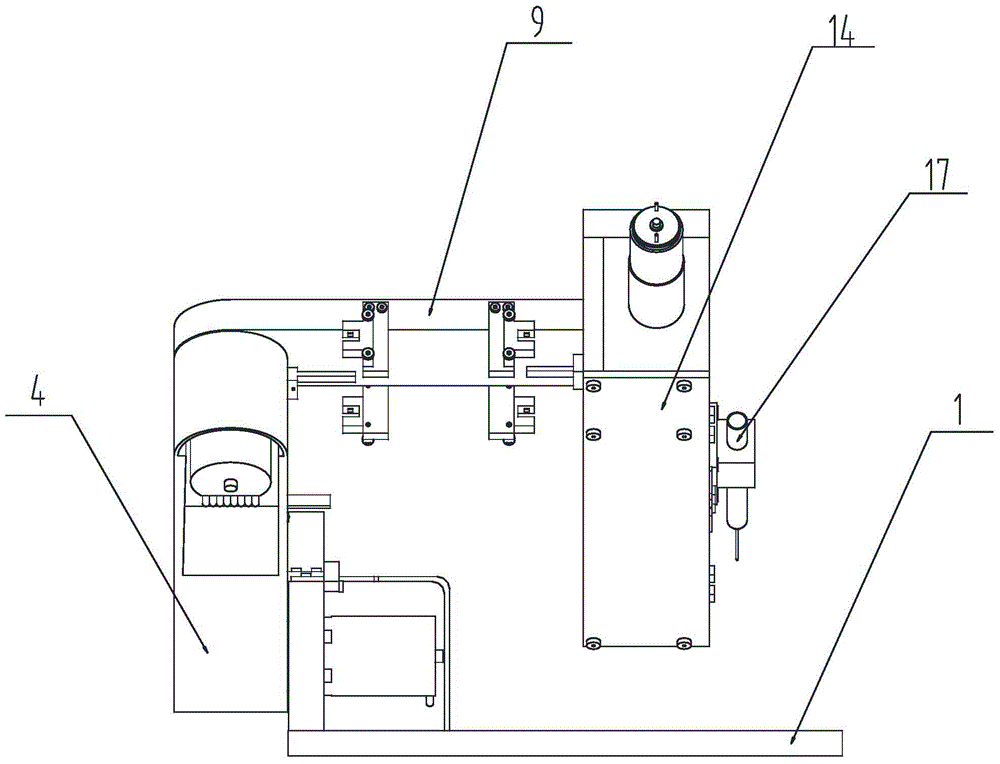

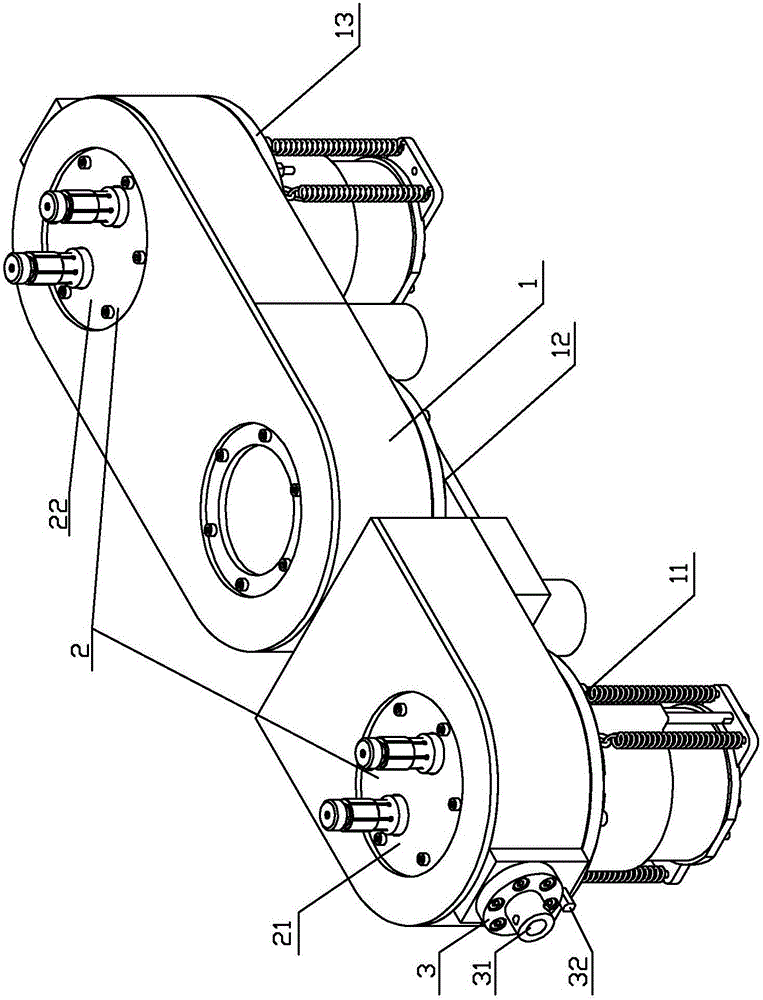

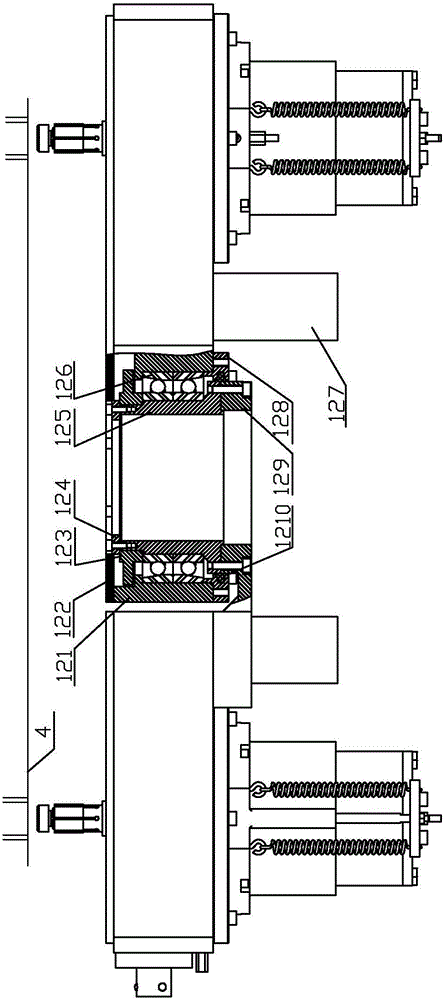

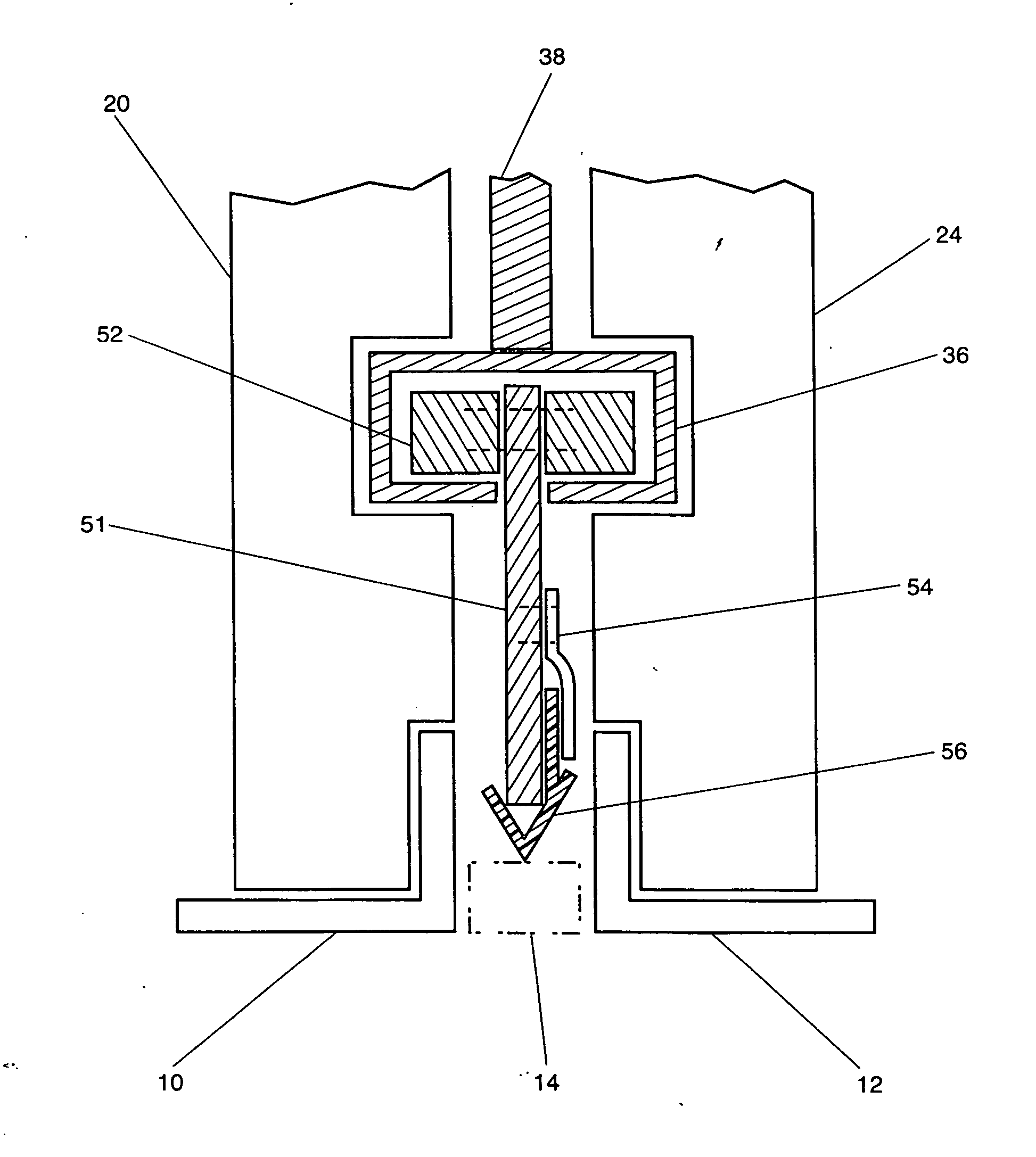

Three-degree-of-freedom front arm blood collection robot

ActiveCN104473653ACompact structureLarge working spaceDiagnostic recording/measuringSensorsBlood collectionBall screw

The invention provides a three-degree-of-freedom front arm blood collection robot and solves the defect of manual needle insertion for blood drawing at present. The three-degree-of-freedom front arm blood collection robot comprises a worktable, wherein a first drive arm, a second drive arm and a needle inserting mechanism are arranged on the worktable, the first drive arm and the worktable form rotatable connection through a first joint, the second drive arm and the first drive arm form rotatable connection through a second joint, the needle inserting mechanism and the second drive arm form rotatable connection through a third joint, the needle inserting mechanism comprises a rectangular frame, a driving motor, a ball screw, a guide sliding rail and a movable sliding table, the driving motor is connected with the ball screw, bearings are sheathed between the two ends of the ball screw and the rectangular frame, a screw hole and a sliding hole are formed in the movable sliding table, a nut is connected into the screw hole in a penetrating manner, the nut is sheathed on the ball screw to form thread connection, a guide sliding barrel is connected into the sliding hole in a penetrating manner, the guide sliding barrel is sheathed on the guide sliding rail to form sliding connection, and the side part of the movable sliding table is fixedly connected with a blood drawing needle. The three-degree-of-freedom front arm blood collection robot adopts mechanical blood drawing, the needle inserting accuracy is high and the safety is high.

Owner:SHANDONG UNIV OF SCI & TECH

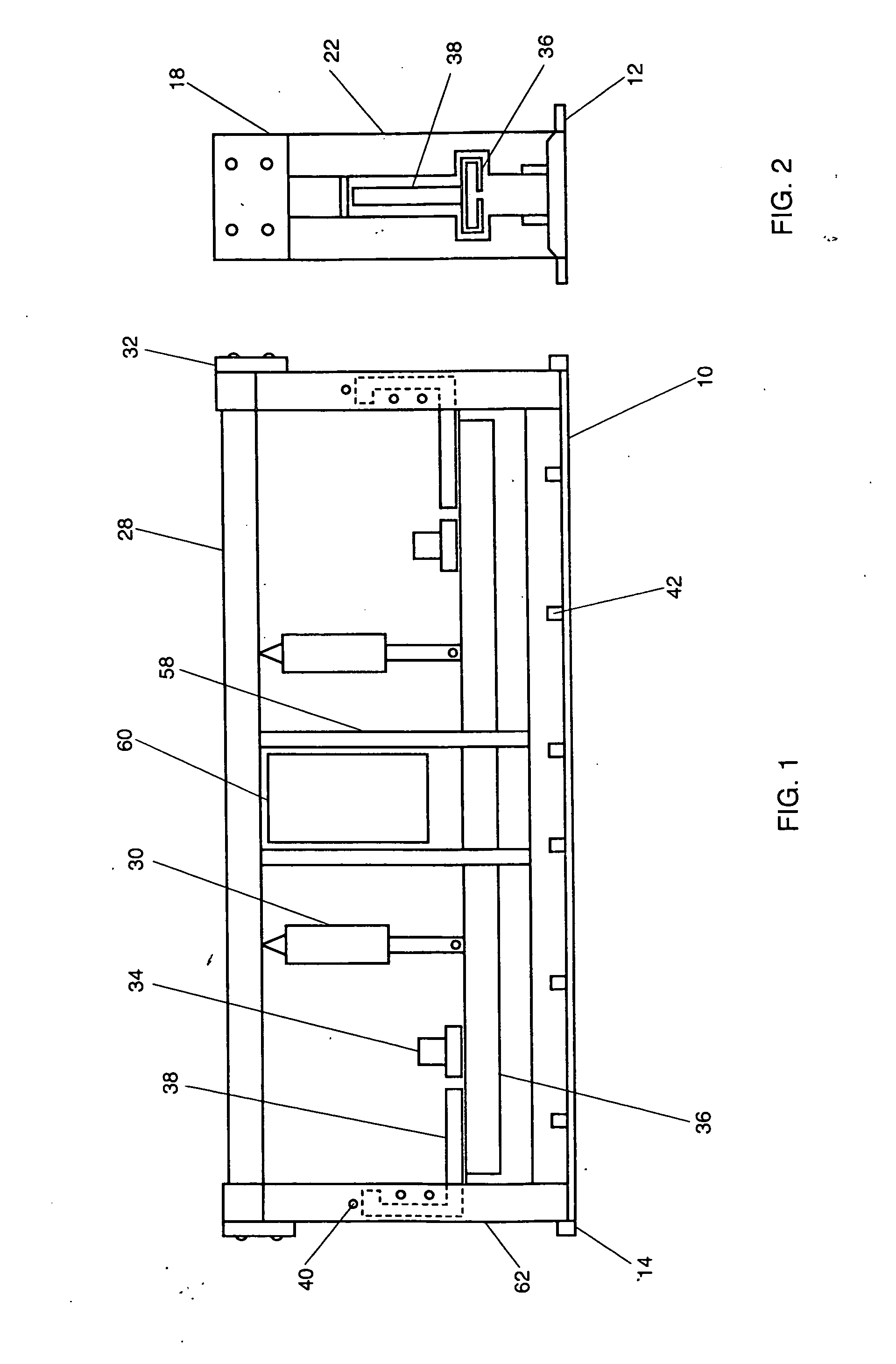

Vacuum gate valve having a limb element

InactiveUS7980529B2Simply designed driveLittle particle generationOperating means/releasing devices for valvesSlide valveSacroiliac jointGate valve

A vacuum gate valve includes a closure disk for gas-tight closing of an opening. A connecting rod with which the closure disk is coupled is linearly adjustable by means of a linear drive unit and the closure disk is thus displaceable between a position uncovering the opening and an intermediate position pushed over the opening. At least two limbs are pivotably mounted at one limb end on the back of the closure disk via a first joint and at the other limb end on a support via a second joint to press the closure disk into the closed position. The limbs, the back and the support form an articulated parallelogram. Each of the limbs forms, with the respective first and second joints, a common integral part which includes a resilient material, the first joint and the second joint being formed by a flexible section on the limb.

Owner:VAT HLDG AG

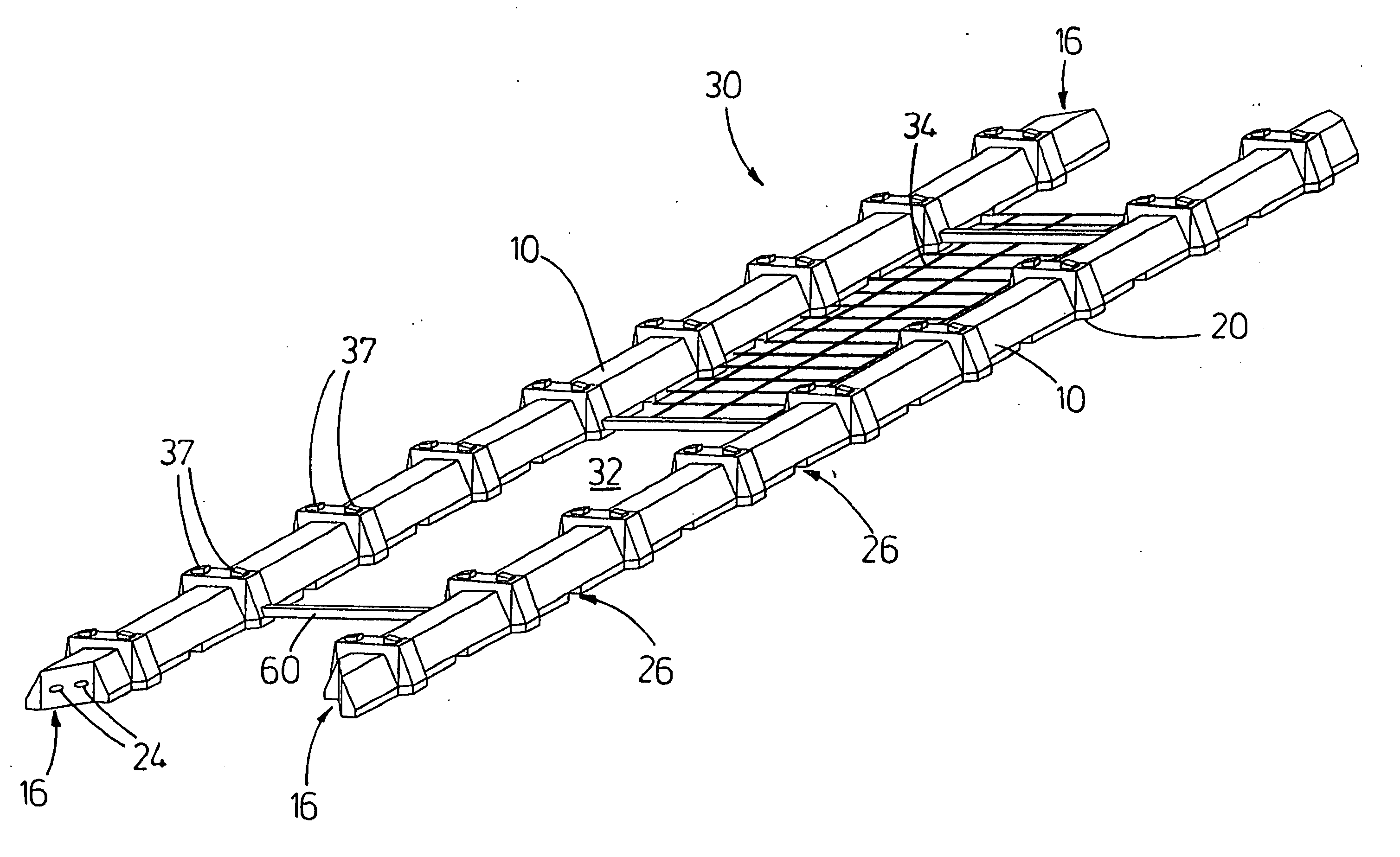

Rail sleeper and ballast-free track structure

InactiveUS20050252985A1Facilitate rapid installationEasy to replaceBallastwayRail fastenersEngineeringMechanical engineering

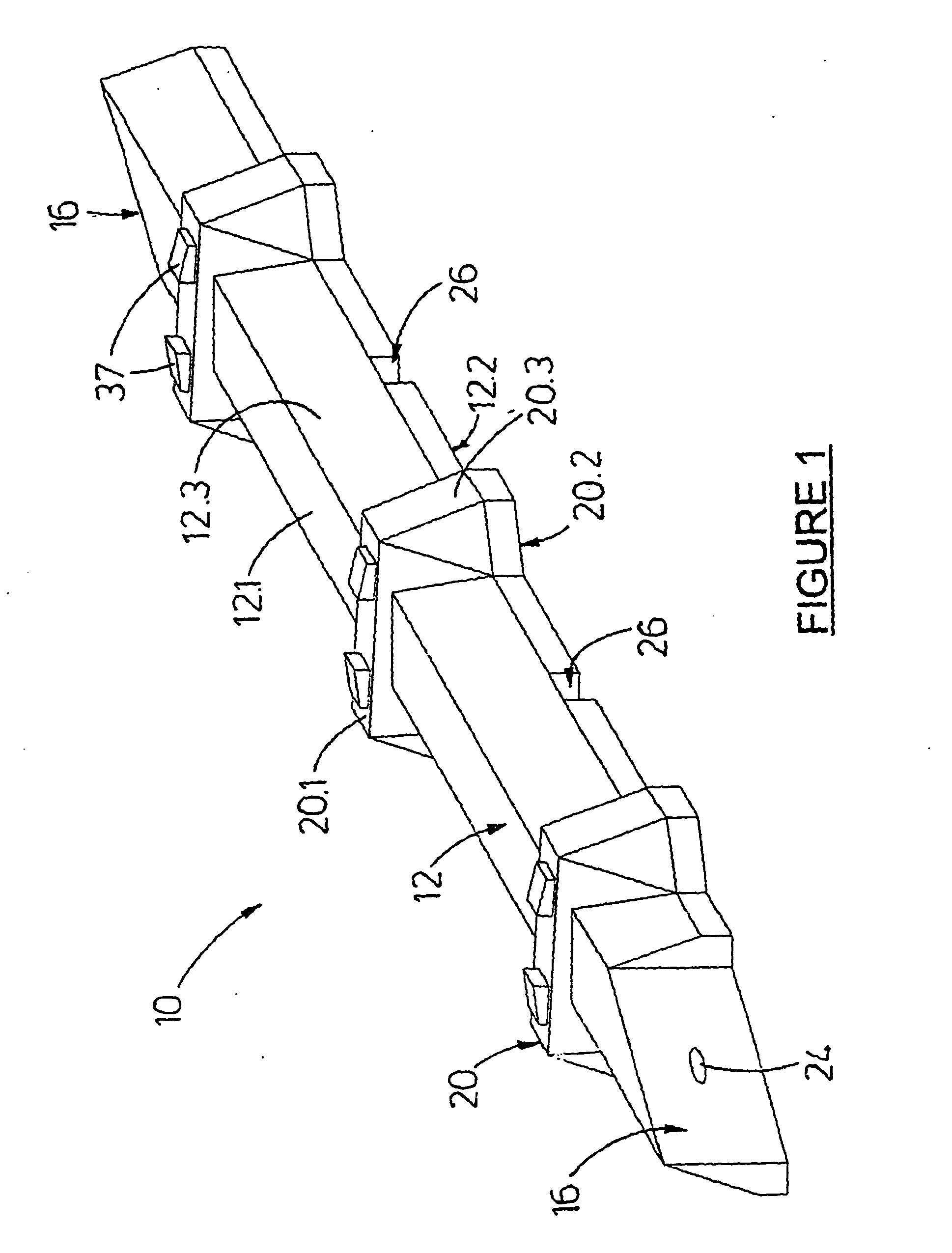

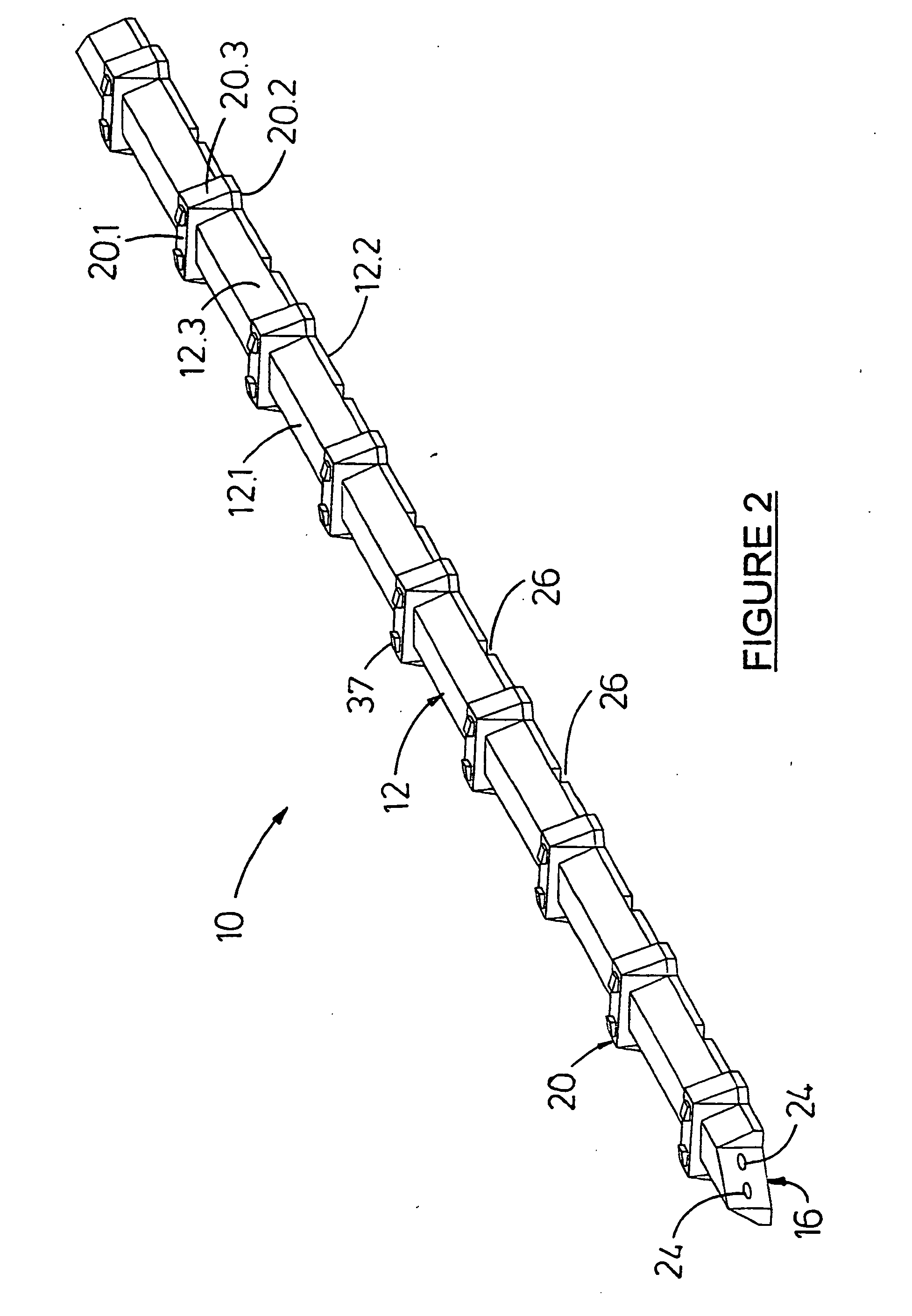

According to one aspect of the invention there is provided a prefabricated rail sleeper [10] suitable for use in erecting a track structure [30]. The rail sleeper [10] comprises an elongate body portion [12] for supporting rails [14], the body portion [12] including a top surface [12,1], a bottom face [12.1] and at least two side faces [12.3], and terminating at least at one end thereof in a transition joint formation [16] dimensioned matingly to engage a complimentarily dimensioned transition joint formation [16] of an adjacent rail sleeper [10] in use so as to form a substantially continuous track structure. The sleeper [10] also includes a series of block formations [20], each of which is at least partially outwardly flared and extending beyond the side faces [12.3] of the body portion [12] so as to increase shear interlock of the sleeper [10] with the track bed to reduce longitudinal creep; as well as a series of transverse drainage ducts [26] extending underneath the rail sleeper [10] for allowing rainwater drainage between different side faces [12.3] of the body portion [12] and away from the rail sleeper. The invention extends to a ballast-free track structure [30] comprising at least two rail sleepers [10] according to the invention wherein the sleepers are located in spaced parallel orientation on a ballast-free track bed so as to define a centre drain [32] between the sleepers; and including a mesh [34] located between the sleepers [10] for reinforcing the centre drain [32].

Owner:HIGHFLYER INVESTMENTS & TRADING 6

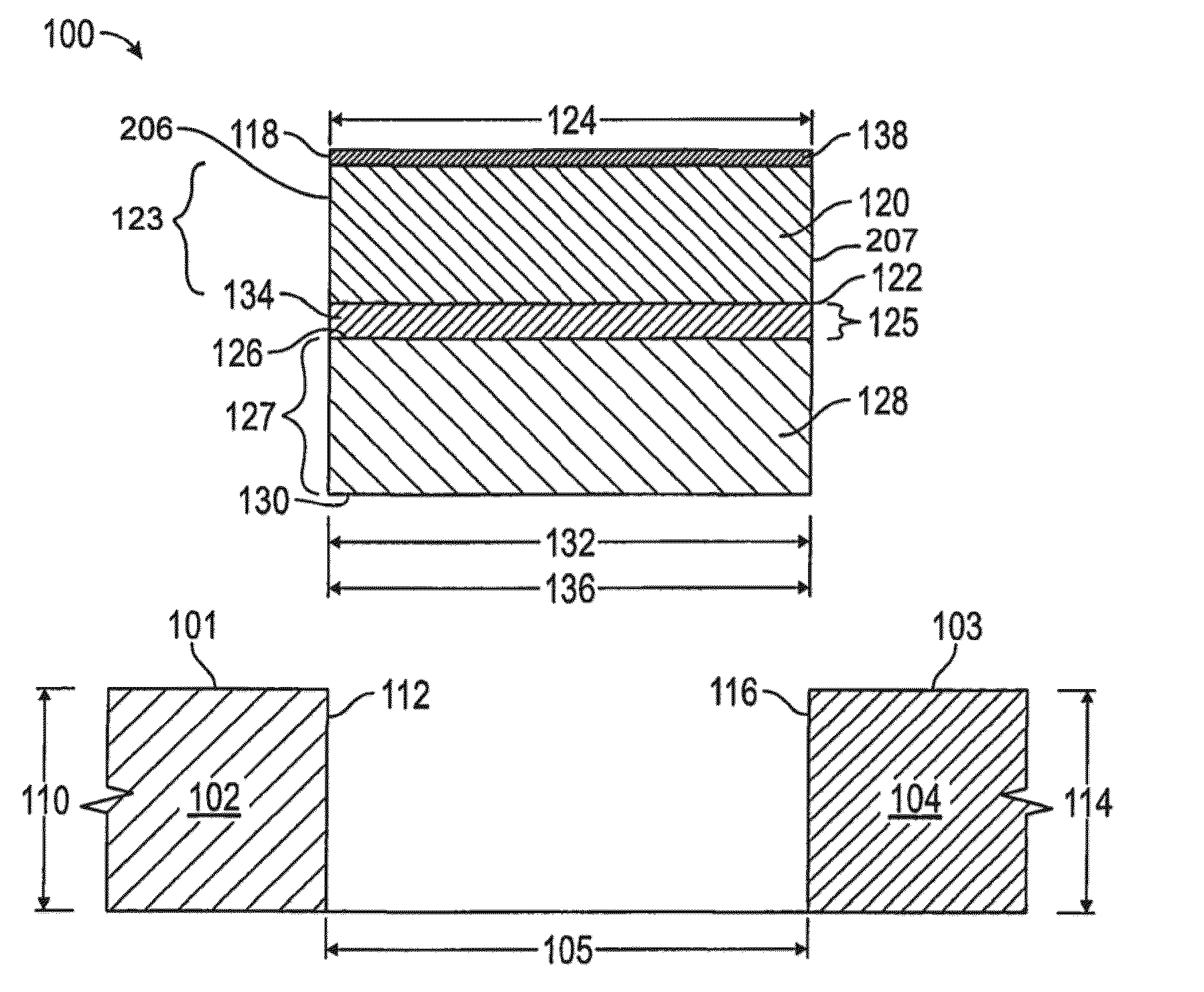

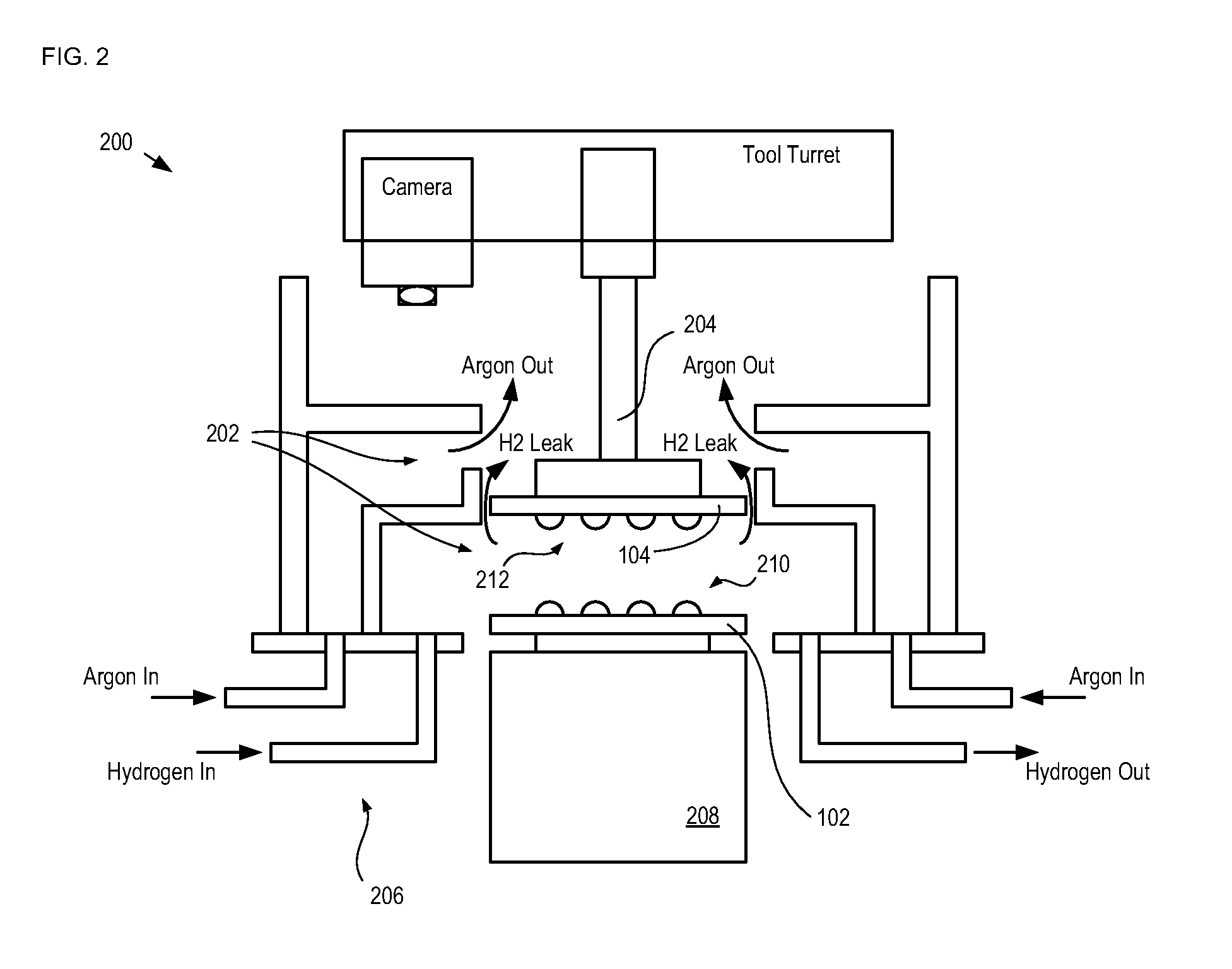

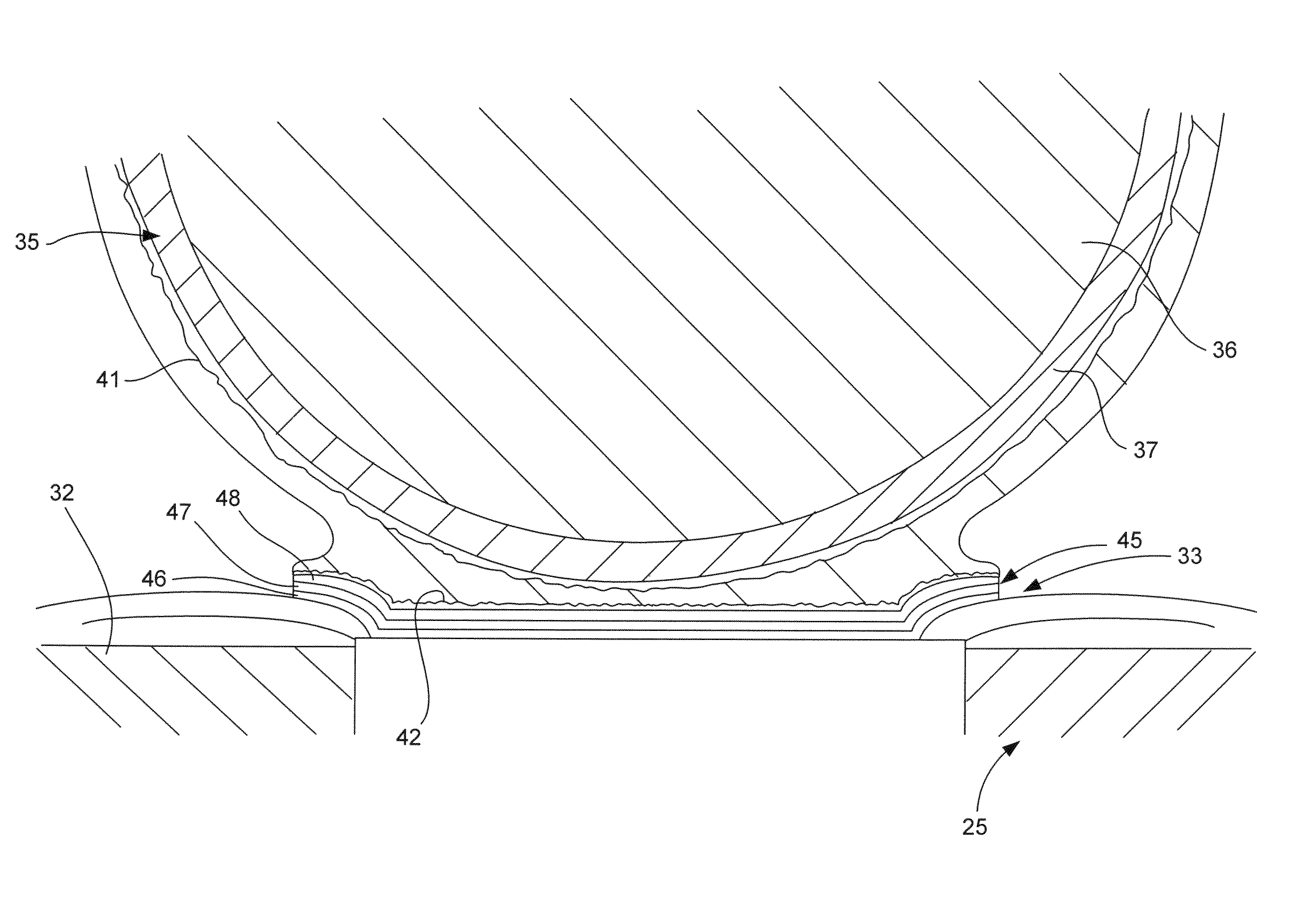

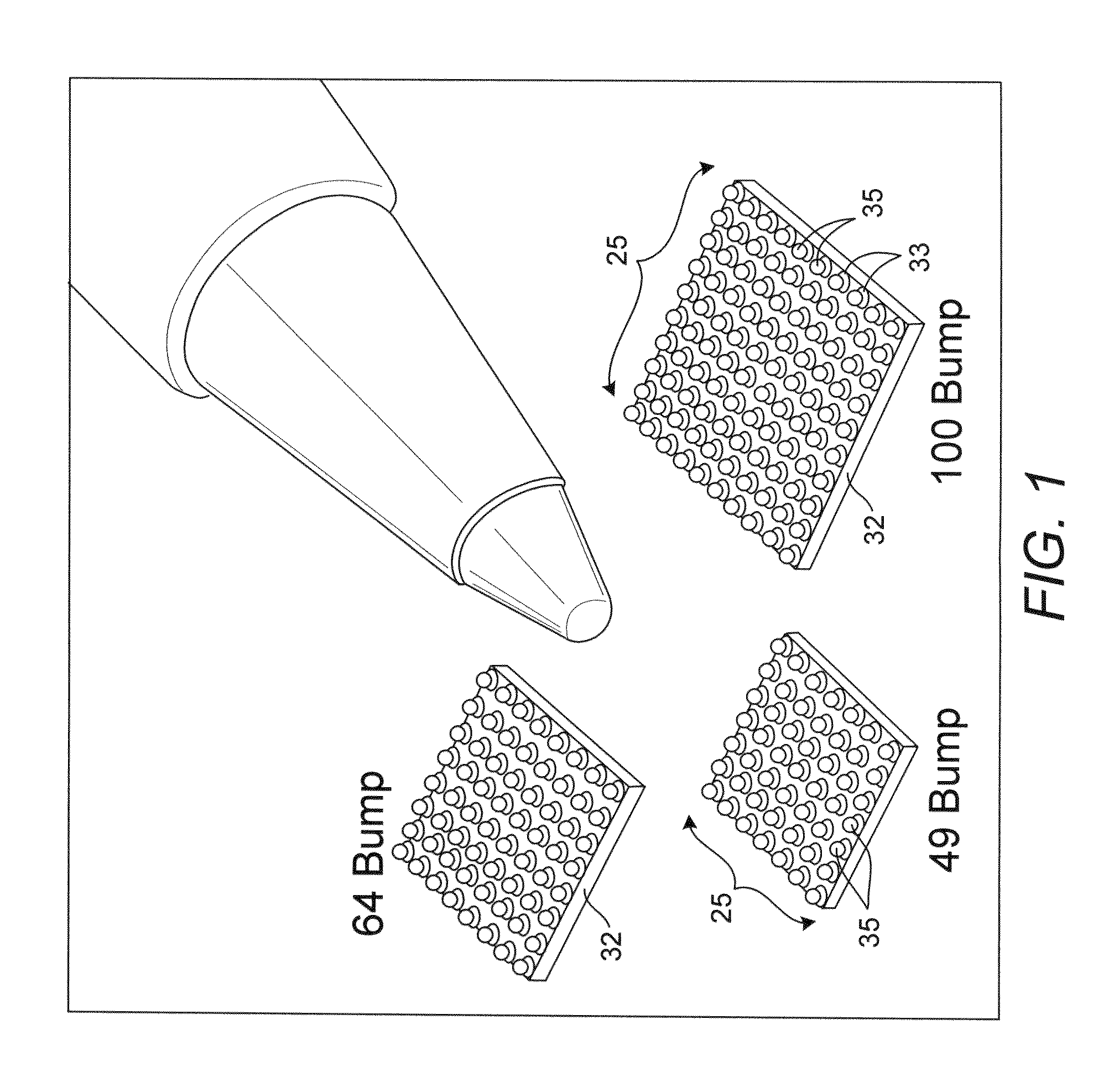

Process for Hybrid Integration of Focal Plane Arrays

InactiveUS20130153645A1Reduce surface oxideLower surface energySemiconductor/solid-state device detailsSolid-state devicesFocal Plane ArraysMelting temperature

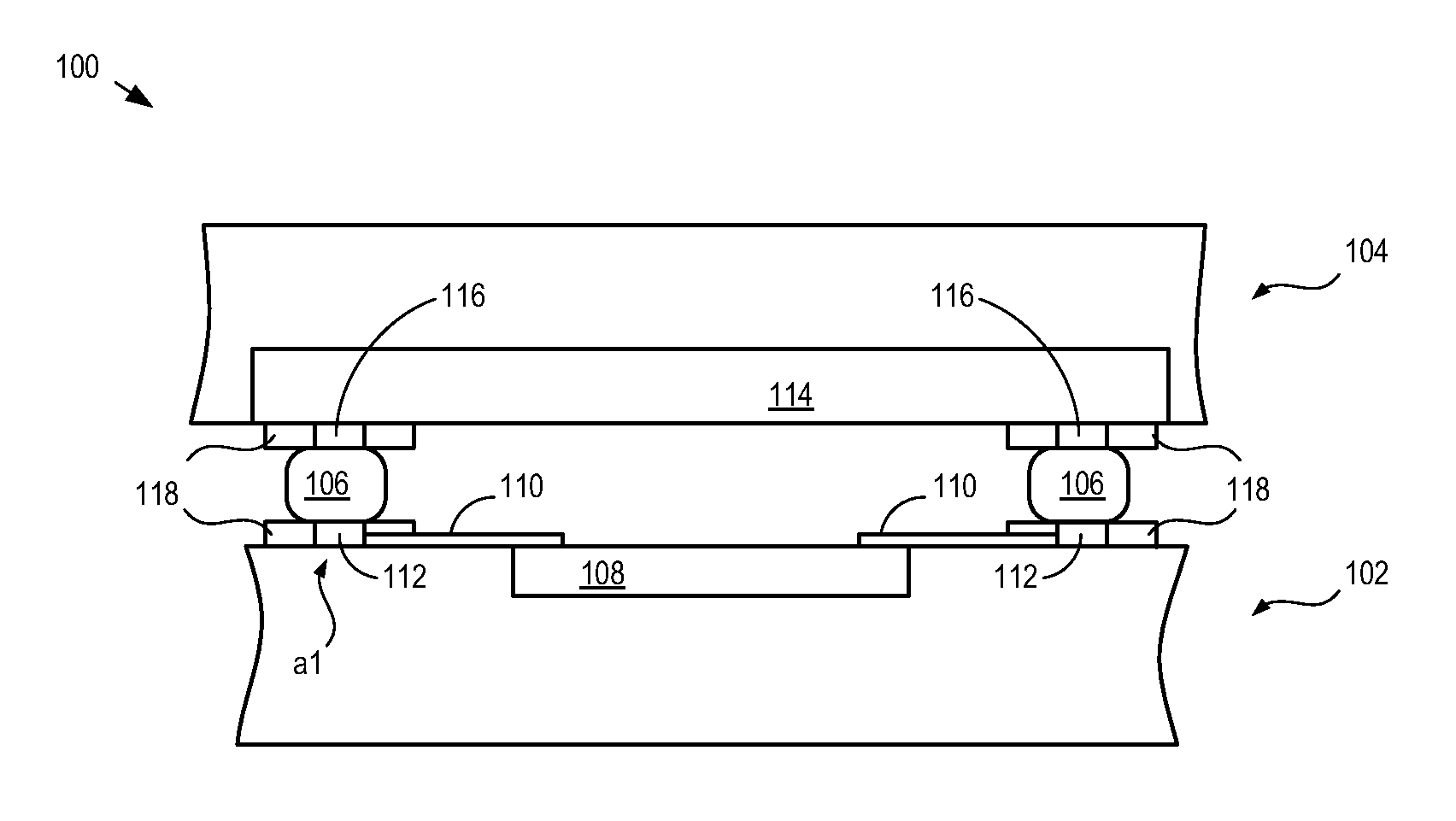

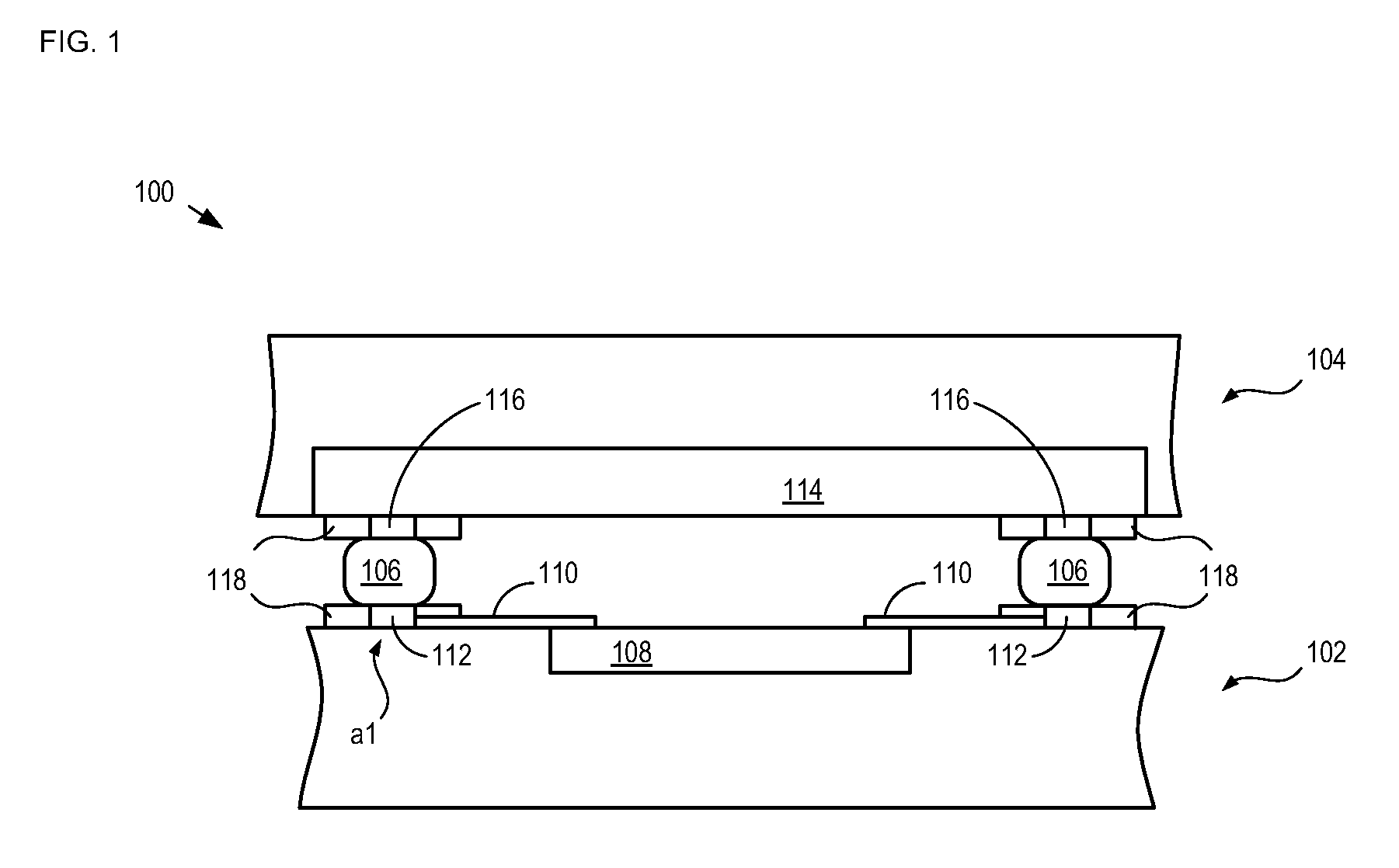

A method for aligning a first substrate relative to a second substrate by enabling reflow of low-melting-temperature solder bumps is disclosed. Reflow of the solder bumps induces a force that moves one substrate relative to the other to improve alignment accuracy between bond pads located on each substrate. The method further enables reduction of surface oxide on the solder bumps that would otherwise inhibit reliable solder joint formation.

Owner:PRINCETON LIGHTWAVE INC

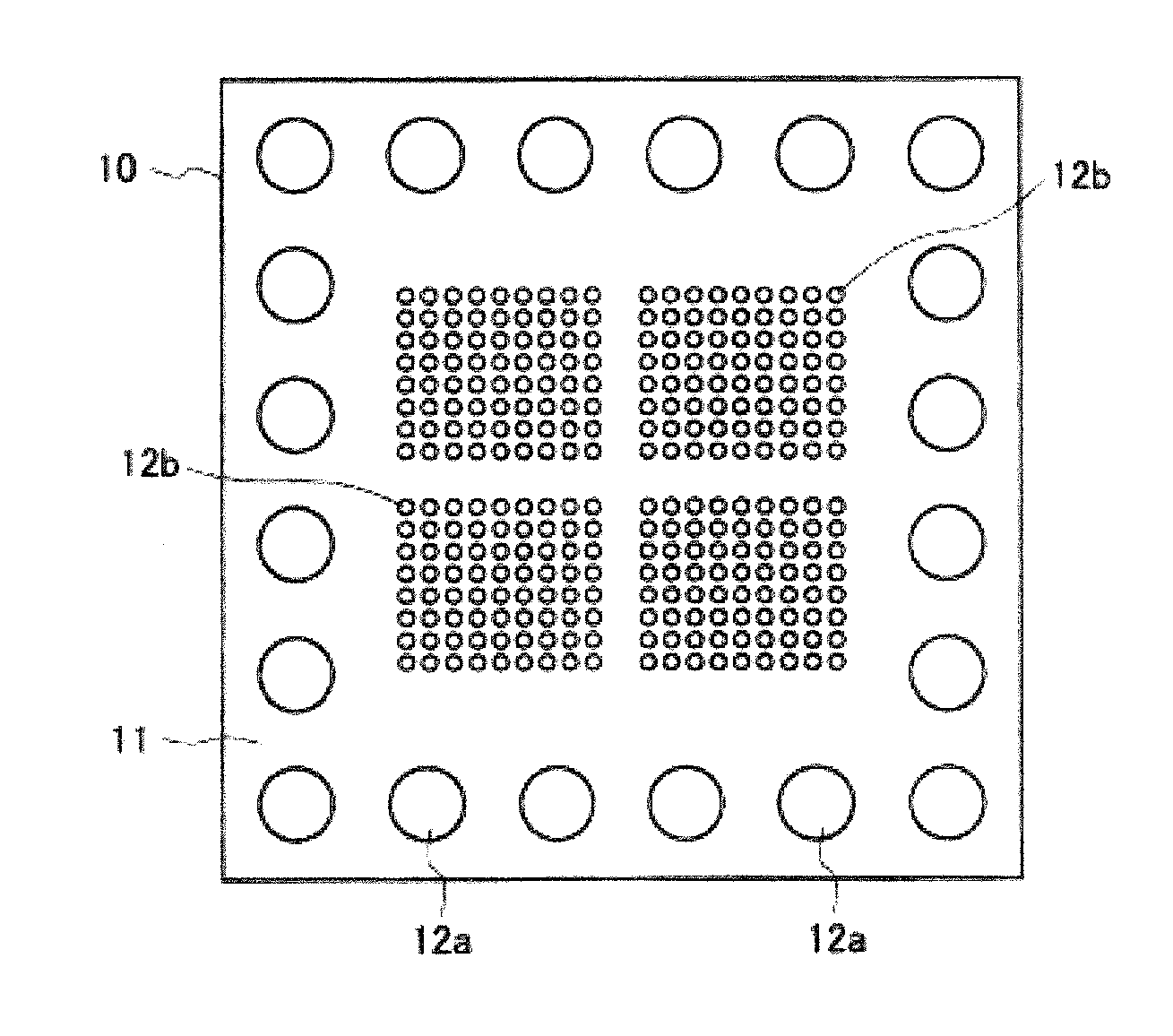

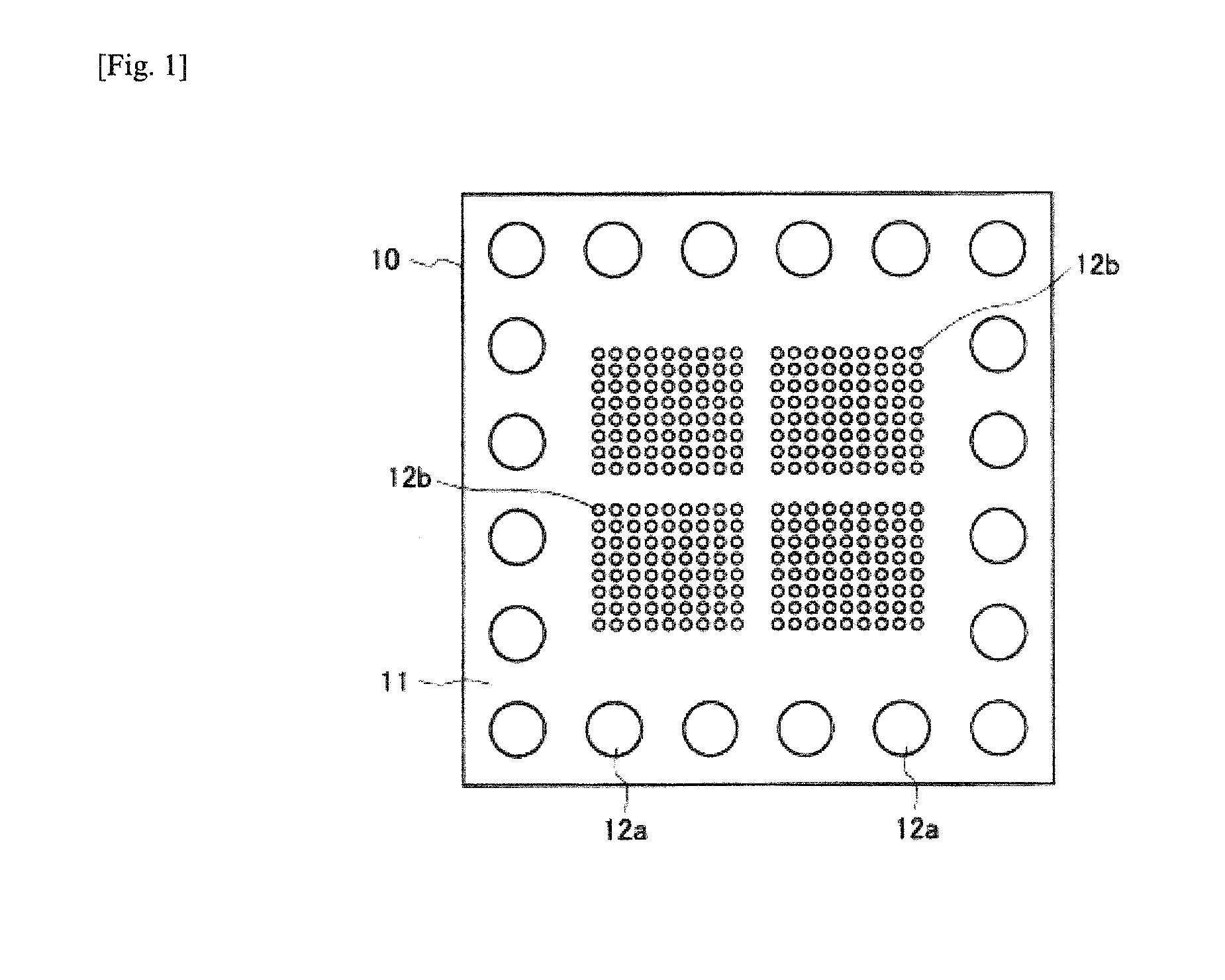

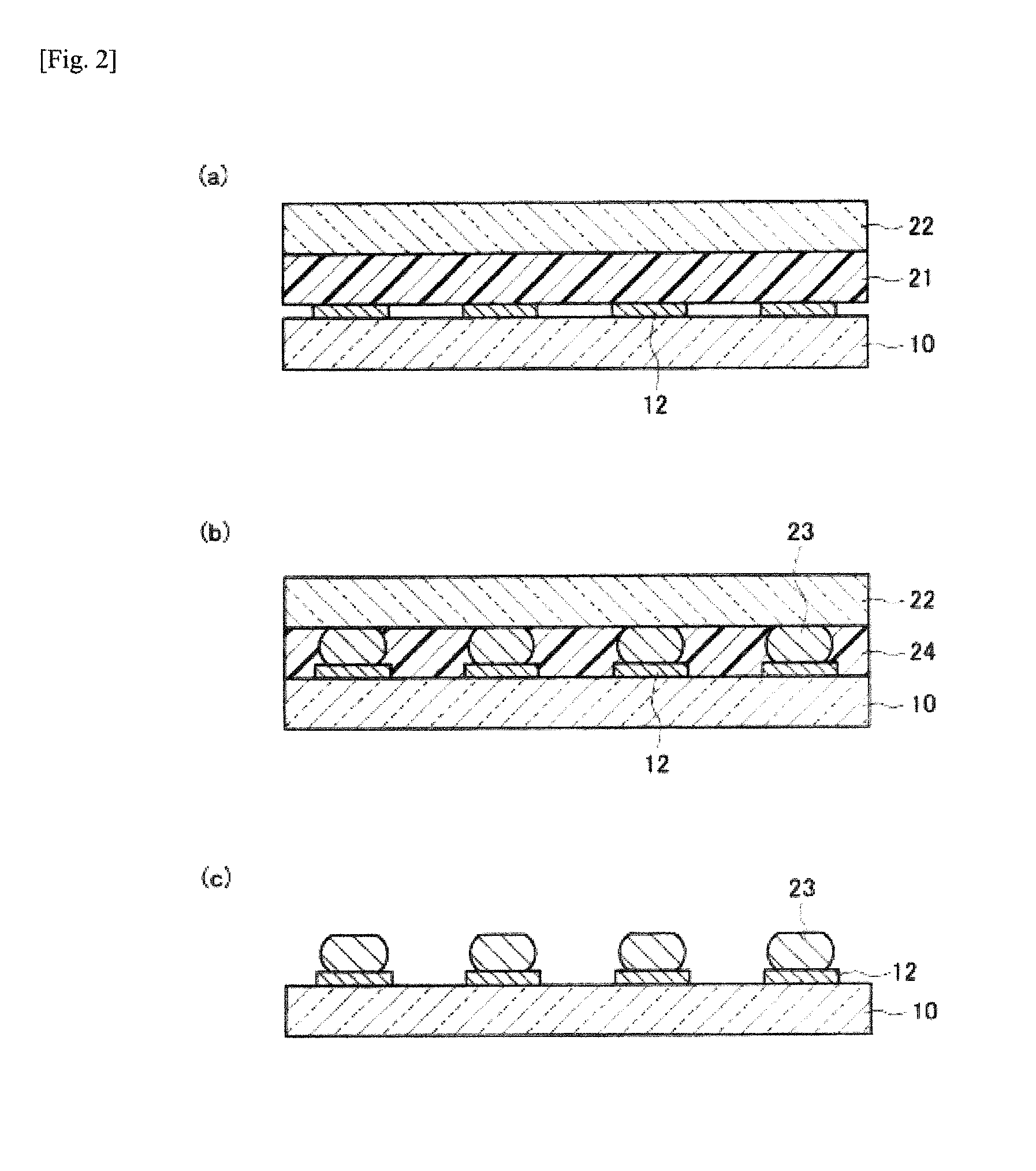

Reflow film, solder bump formation method, solder joint formation method, and semiconductor device

ActiveUS20140252607A1Excellent storage propertiesGood transportabilitySemiconductor/solid-state device detailsPrinted circuit aspectsSolventSolder paste

The present invention relates to a reflow film containing a thermoplastic resin which is dissolvable in a solvent, and solder particles, wherein the solder particles are dispersed in the film, and also relates to a solder bump formation method which comprises: (A) a step of mounting the reflow film on the electrode surface side of a substrate, (B) a step of mounting and fixing a flat plate, (C) a step of heating, and (D) a step of dissolving and removing the reflow film, and herewith, a reflow film is provided which, by causing localization of the solder component on the electrodes of the substrate by self-assembly, exhibits excellent storage properties, transportability and handling properties during use, and can form solder bumps or solder joints selectively on only the electrodes.

Owner:RESONAC CORP

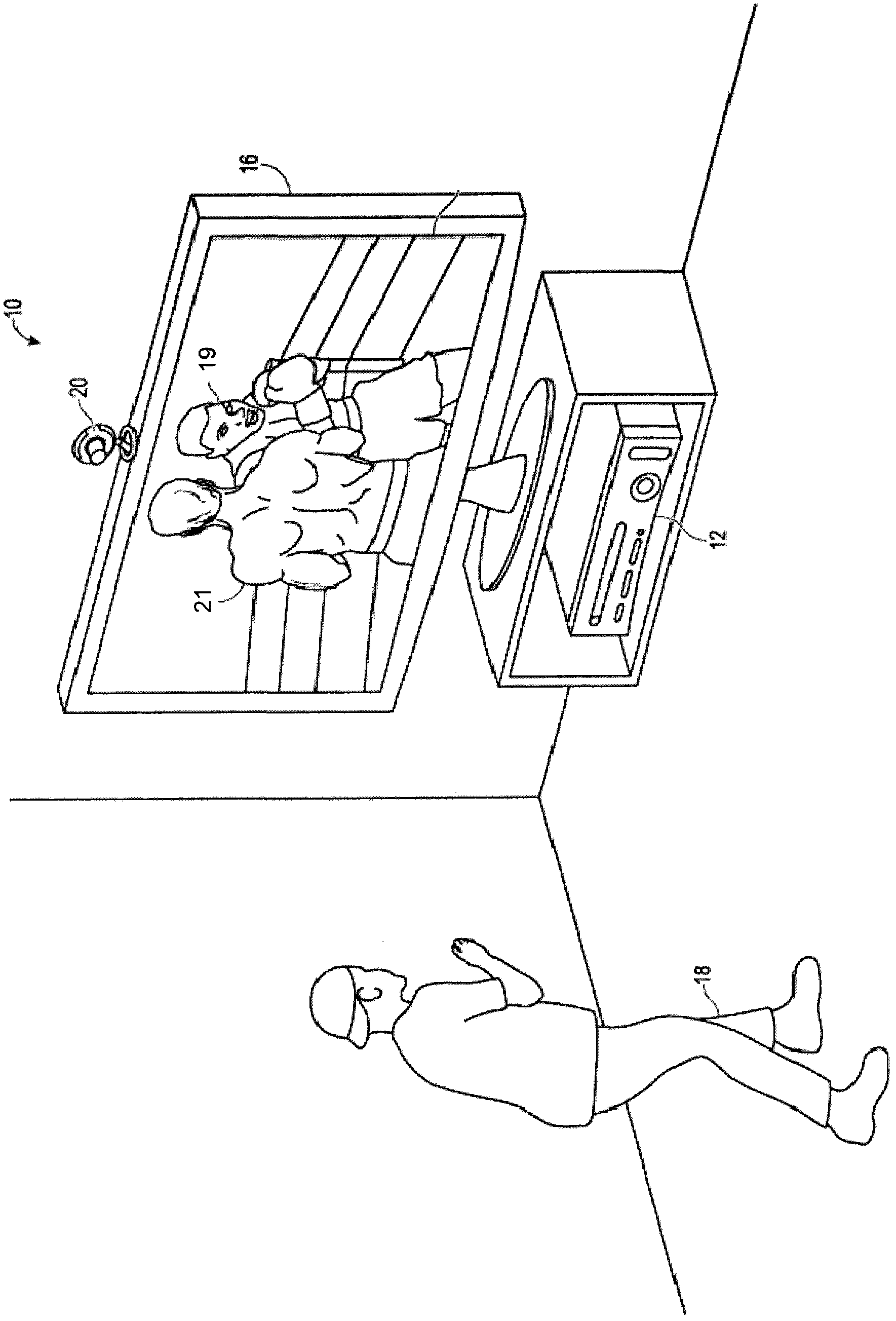

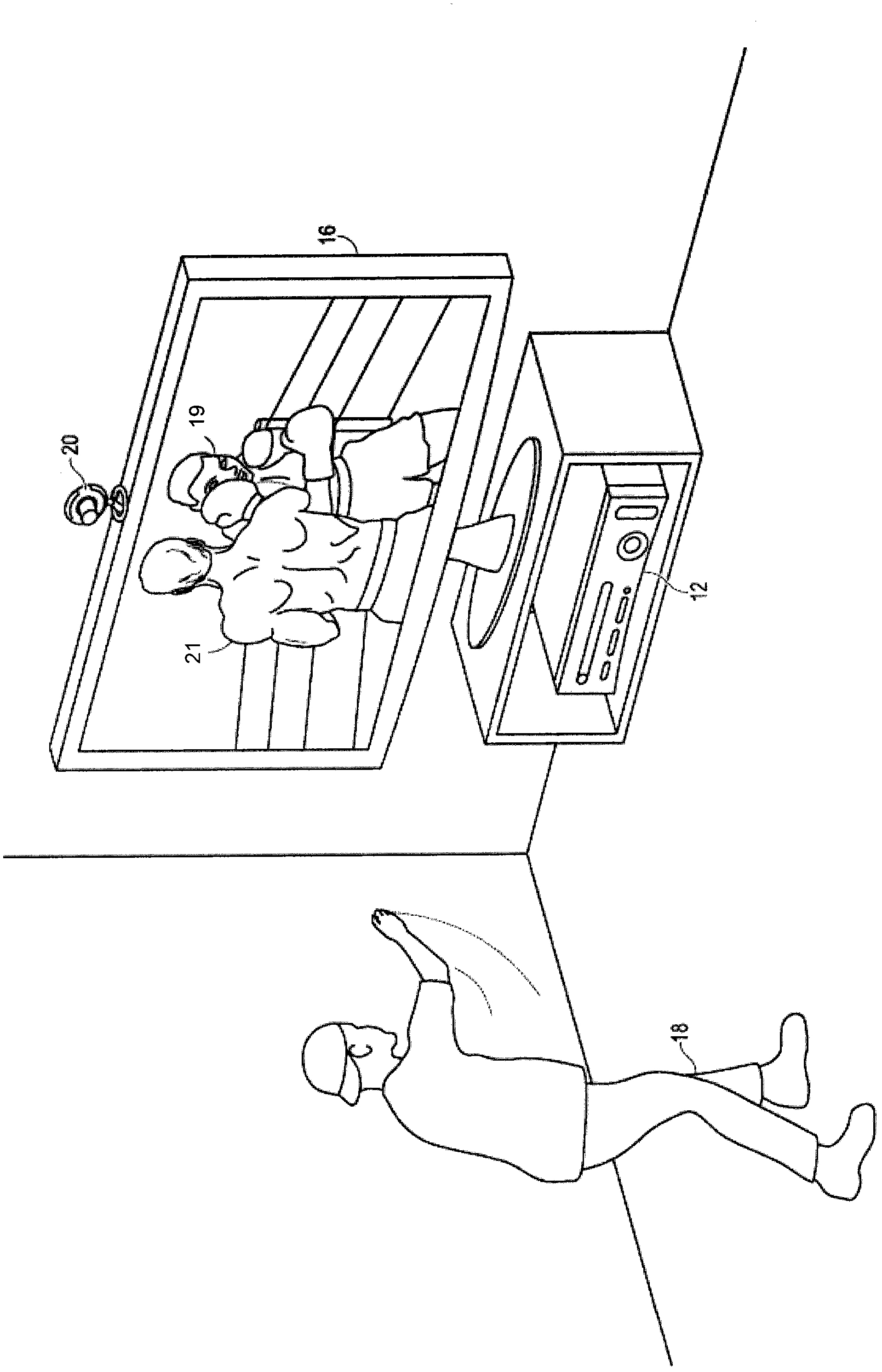

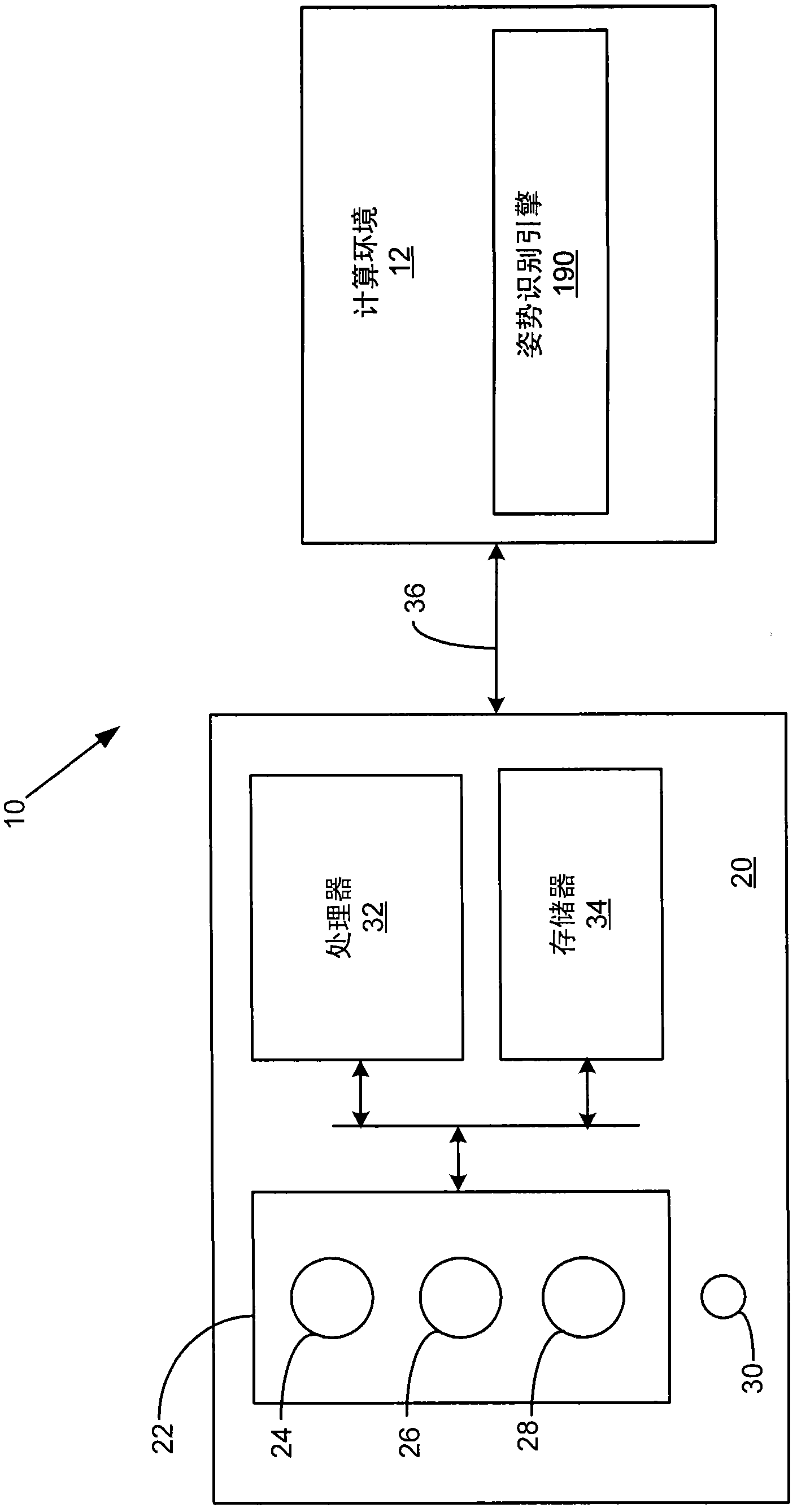

Gesture detection based on joint skipping

ActiveCN102129551AInput/output for user-computer interactionCharacter and pattern recognitionPostural orientationComputer science

A system is disclosed for detecting or confirming gestures performed by a user by identifying a vector formed by non-adjacent joints and identifying the angle the vector forms with a reference point. Thus, the system skips one or more intermediate joints between an end joint and a proximal joint closer to the body core of a user. Skipping one or more intermediate joints results in a more reliable indication of the position or movement performed by the user, and consequently a more reliable indication of a given gesture.

Owner:MICROSOFT TECH LICENSING LLC

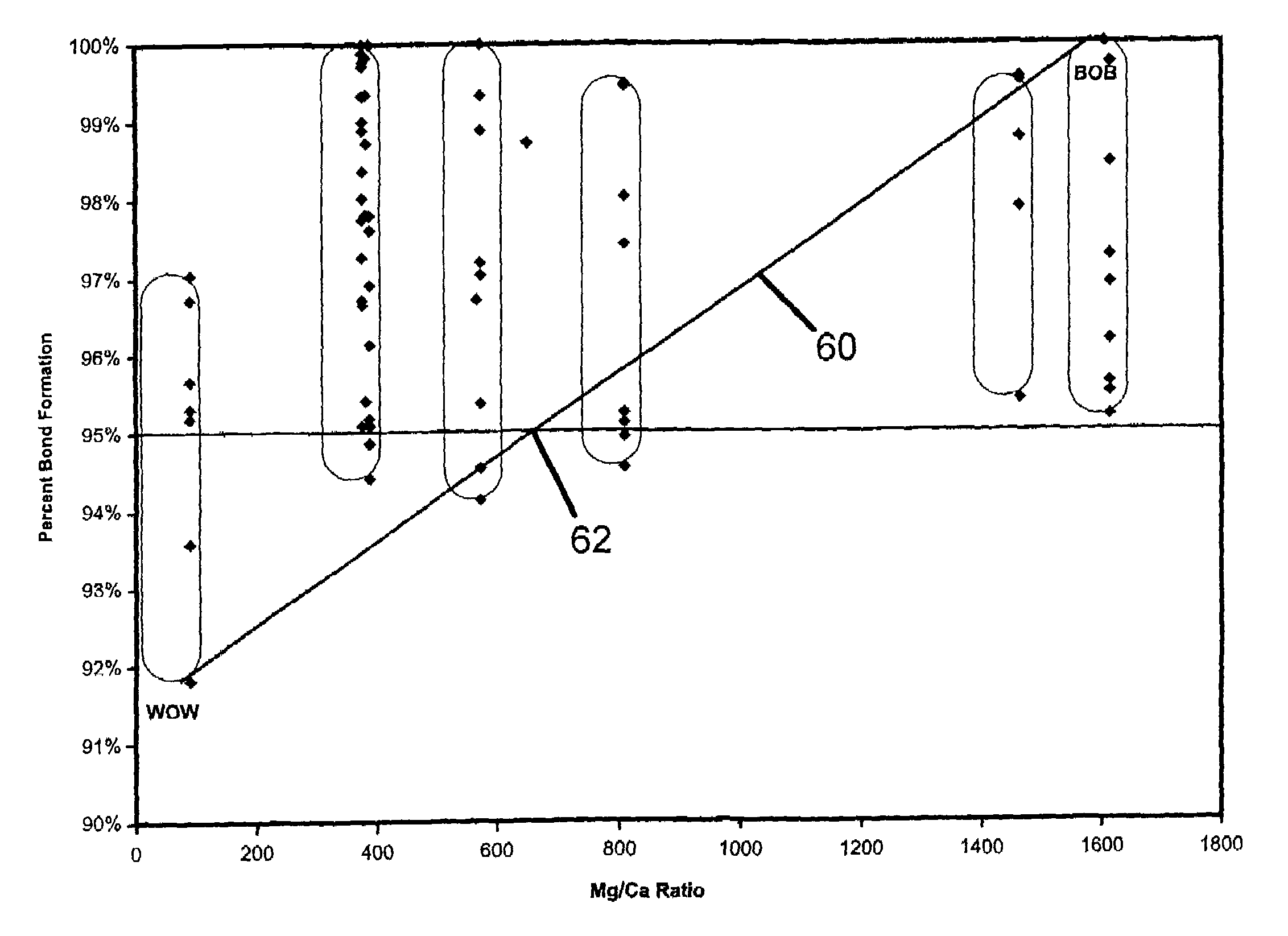

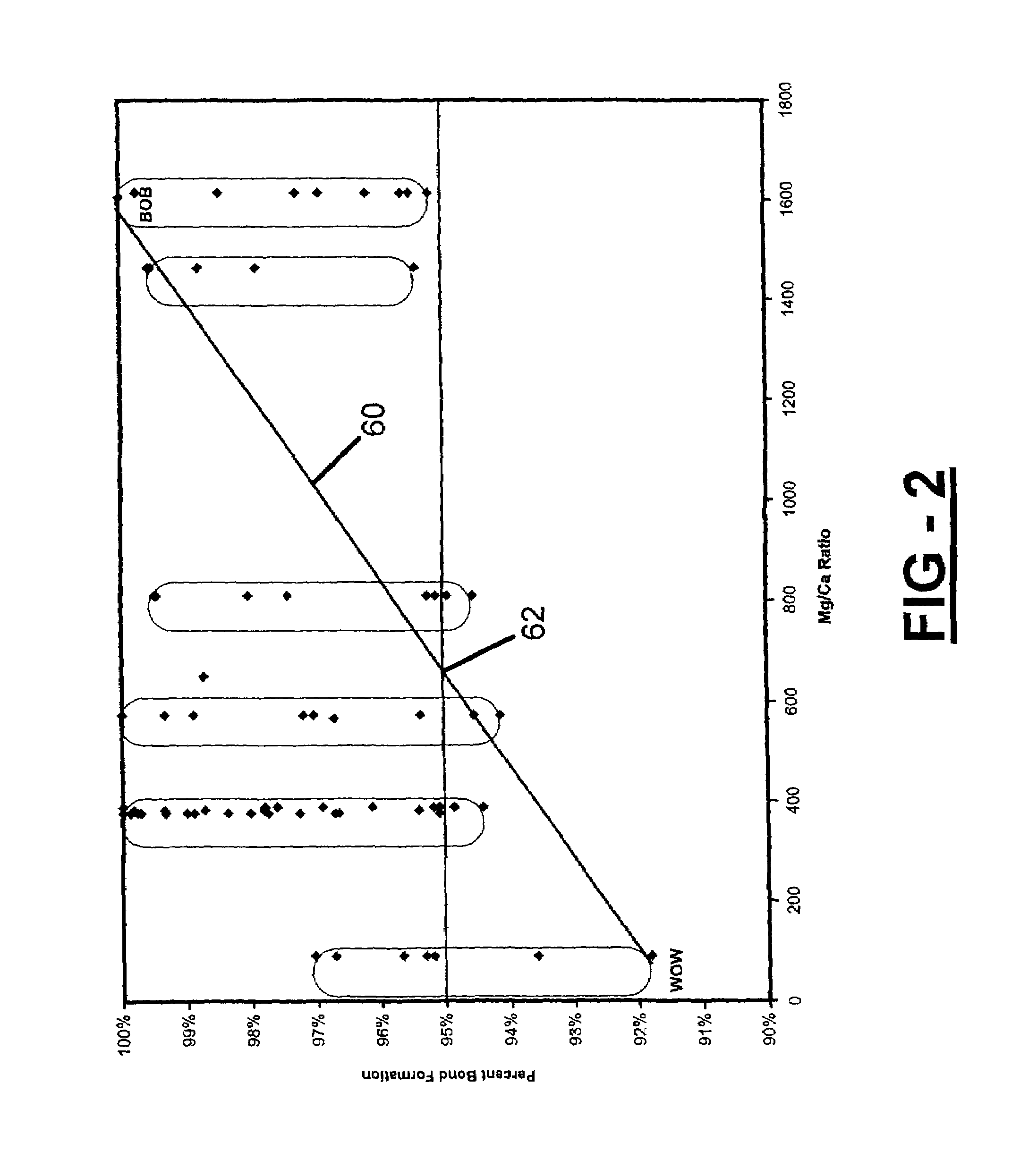

Vacuum brazing method for aluminum-based material

InactiveUS6957762B2Electron beam welding apparatusWelding/cutting media/materialsJoint formationBrazing

A vacuum brazing method is disclosed for joining aluminum stock materials to each other. The typical cladding material utilized includes aluminum and a melting point lowering agent such as silicon. In addition, the cladding material typically includes magnesium to provide for enhanced wetting of the cladding material into the joint area. It has been found that adjusting the ratio of magnesium to calcium to a level of equal to or greater than 625 to 1 provides greatly enhanced brazed joint formation and reliability of the vacuum brazing method.

Owner:DELPHI TECH INC

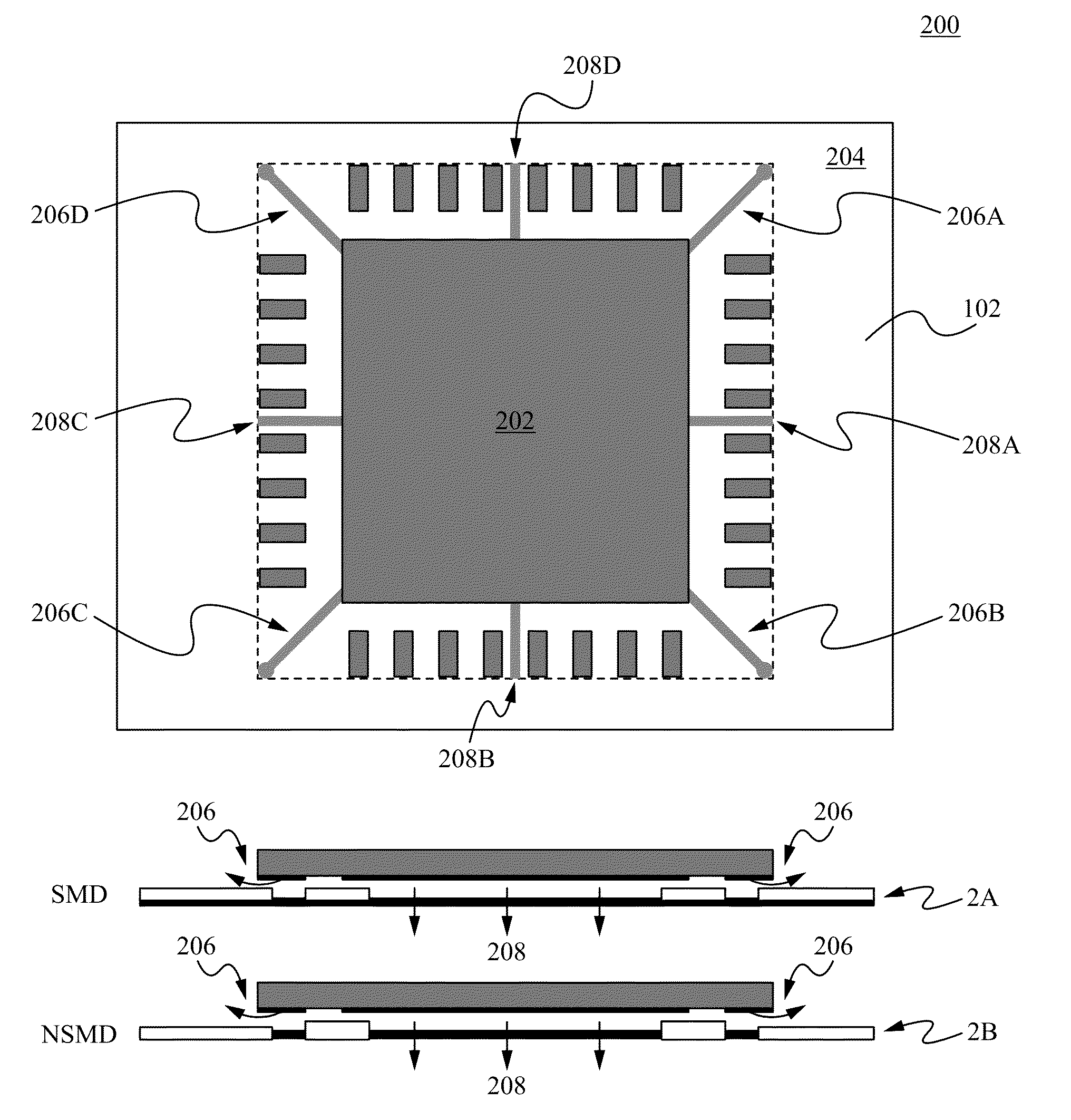

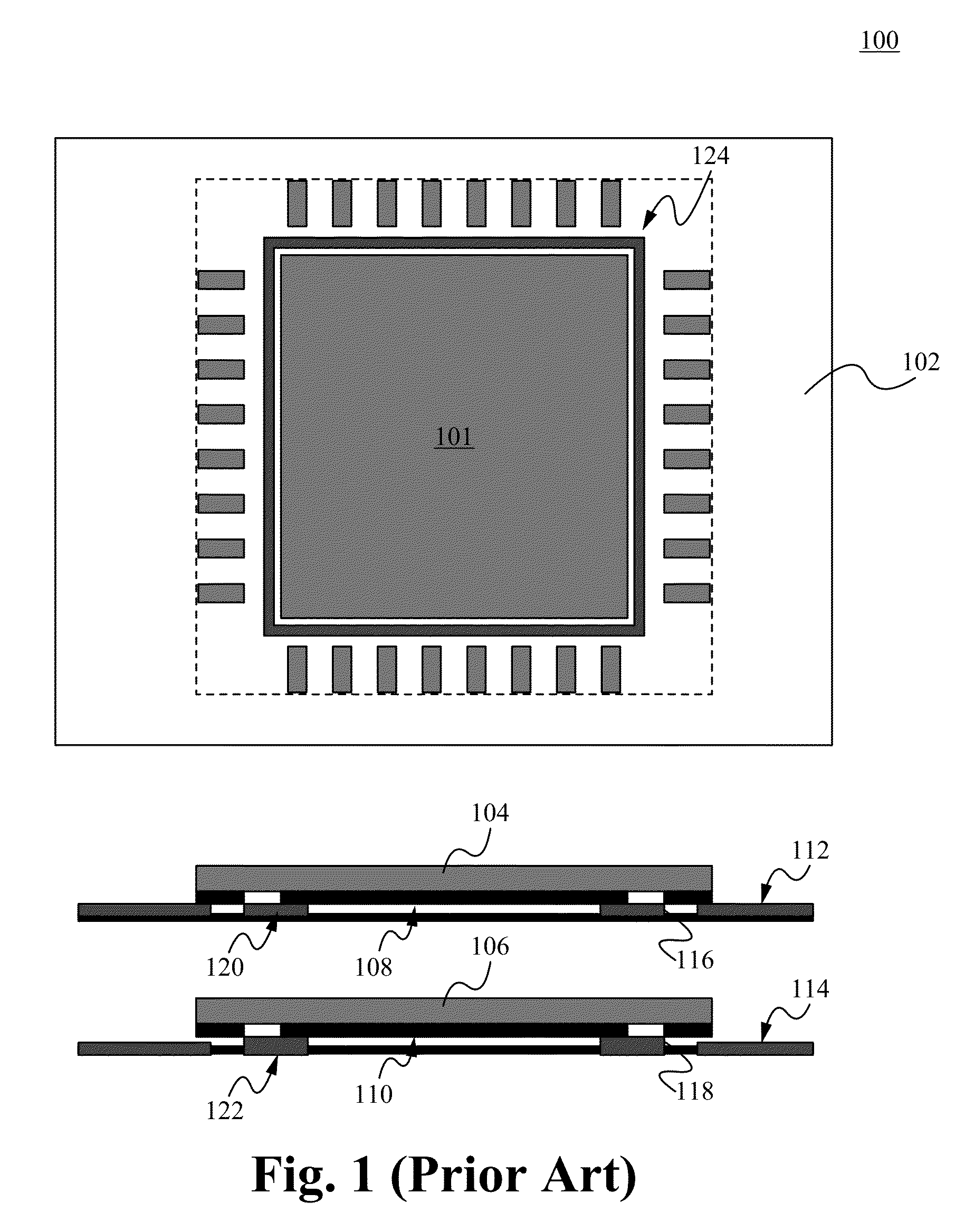

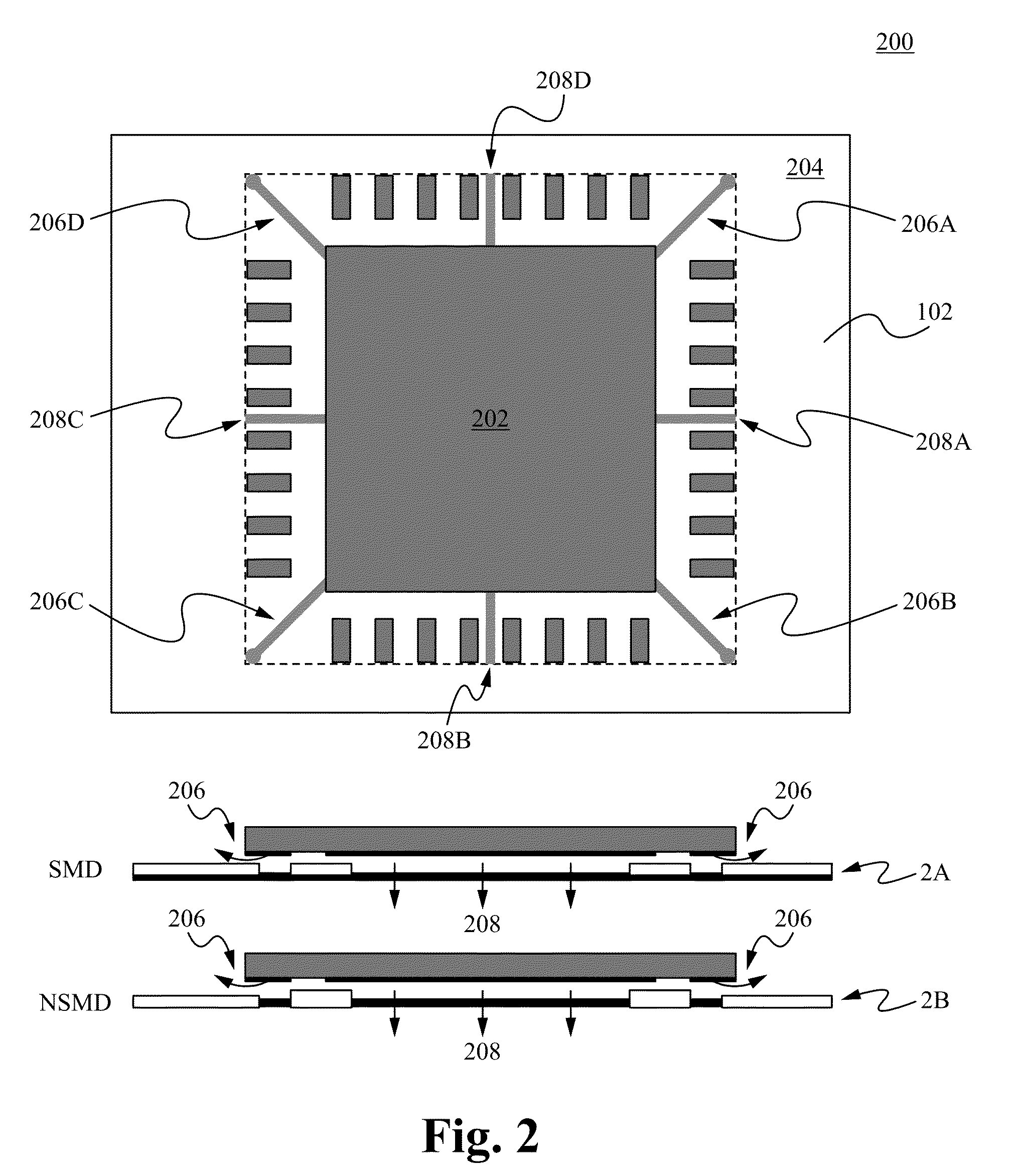

High strength solder joint formation method for wafer level packages and flip applications

ActiveUS20090057897A1More crack resistantHigh strength jointFinal product manufactureSemiconductor/solid-state device detailsContact padSolder ball

A Micro SMDxt package is provided that configured for mounting to a circuit board. The SMDxt package includes a silicon-based IC having an array of contact pads on one side of thereof, and a die electrically attached to the silicon-based IC. A plurality of solder balls is included, each of which has a polymeric core surrounded by a metallic shell that in turn is surrounded by a layer of solder material. Further, each solder ball is positioned in contact with a corresponding contact pad of the package. An intertwined intermetallic fusion layer is formed through the fusion between material components of the contact pads and the solder material, via heat treatment. The intermetallic fusion extends between and from an outer surface of the metallic shell of each solder to an outer surface of a corresponding contact pad to form a high strength intermetallic solder joint therebetween.

Owner:NAT SEMICON CORP

Welding method of ocean platform module wall board gas shielded flux-cored down weld

InactiveCN101823186AControl welding deformationFast welding speedArc welding apparatusWelding/cutting media/materialsCarbon Dioxide / HeliumShielding gas

The invention provides a welding method of an ocean platform module wall board gas shielded flux-cored down weld, comprising the following steps of: preparing a welding joint groove and cleaning; assembling interfaces at the joint of two wall boards; preheating a welded position before welding; and carrying out preparing working procedures such as setting a welding method and welding parameters, setting welding materials and setting shielding gas and parameters, welding working procedure and treatment working procedure after welding, wherein the welding materials in the preparing working procedure before welding are set to be flux-cored welding wire, and the shielding gas is set to be CO2. The welding method has the improvement in that the welding joint groove in the preparing working procedure before welding is I-shaped, and the welding way is set to be vertical down weld. The invention can improve the welding speed, achieves attractive welded joint formation, greatly lowers the welding distortion, reduces the workload for wall welding deformation correction after welding and welded joint polishing, and efficiently improves the working efficiency.

Owner:CHINA NAT OFFSHORE OIL CORP +1

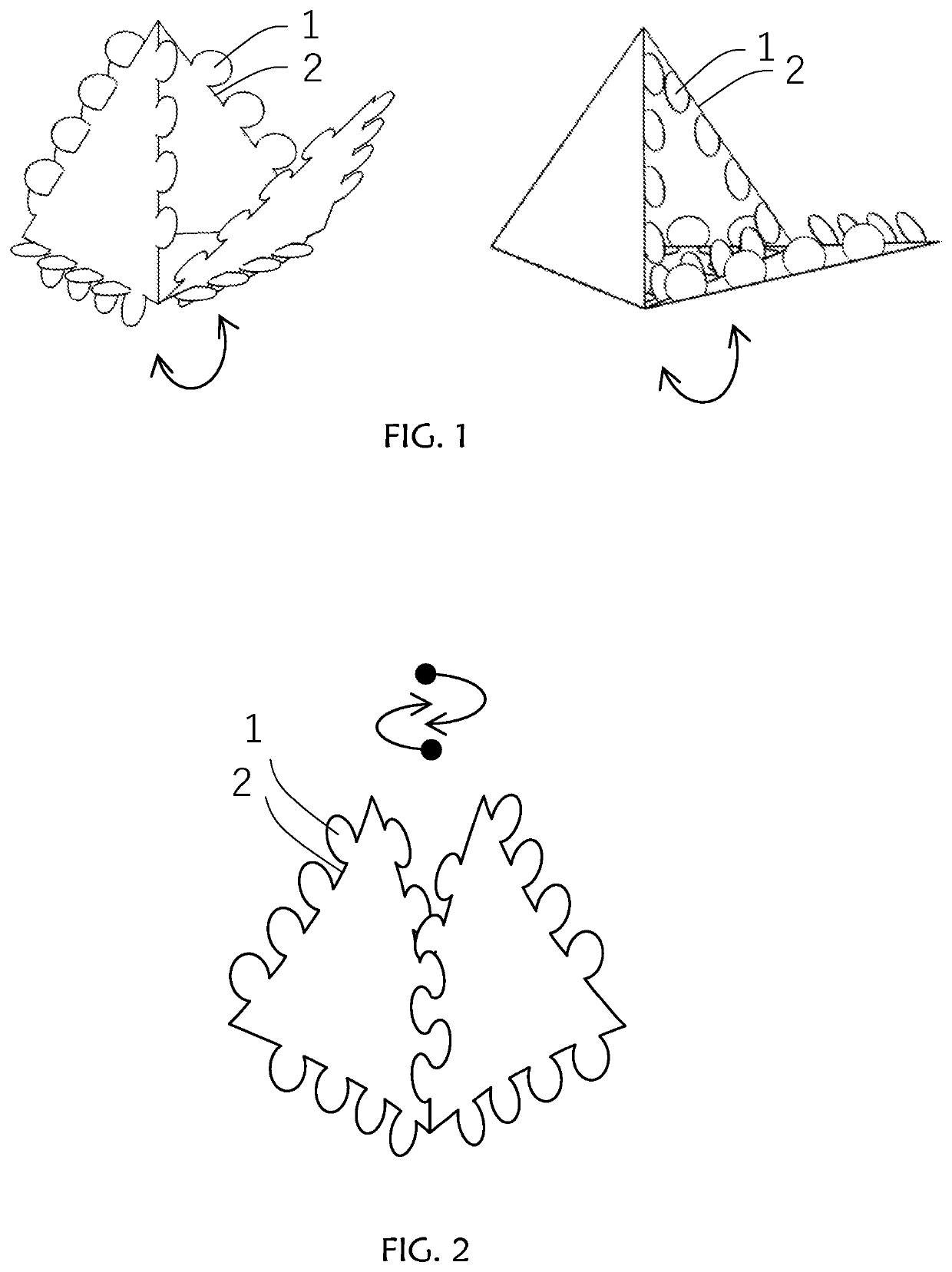

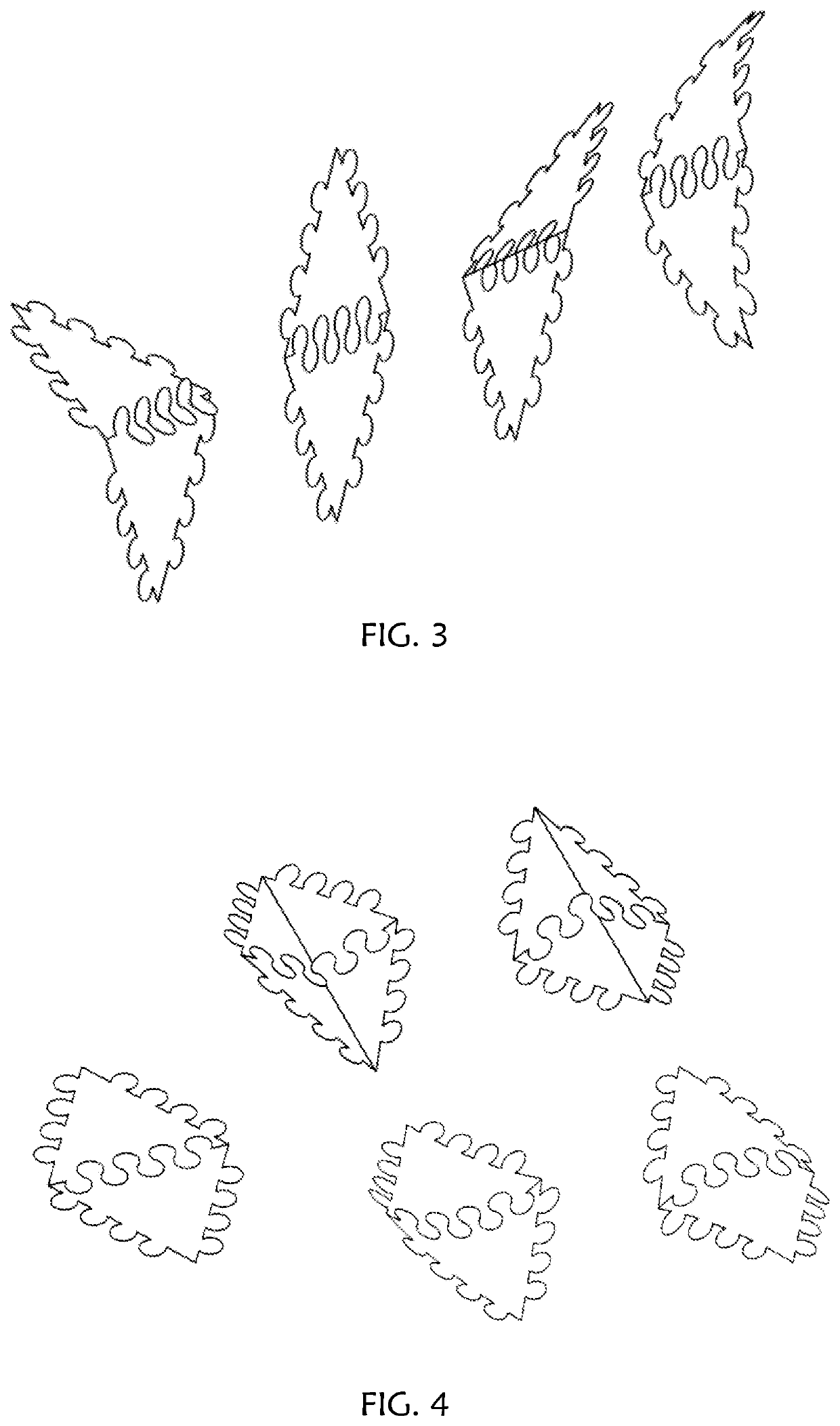

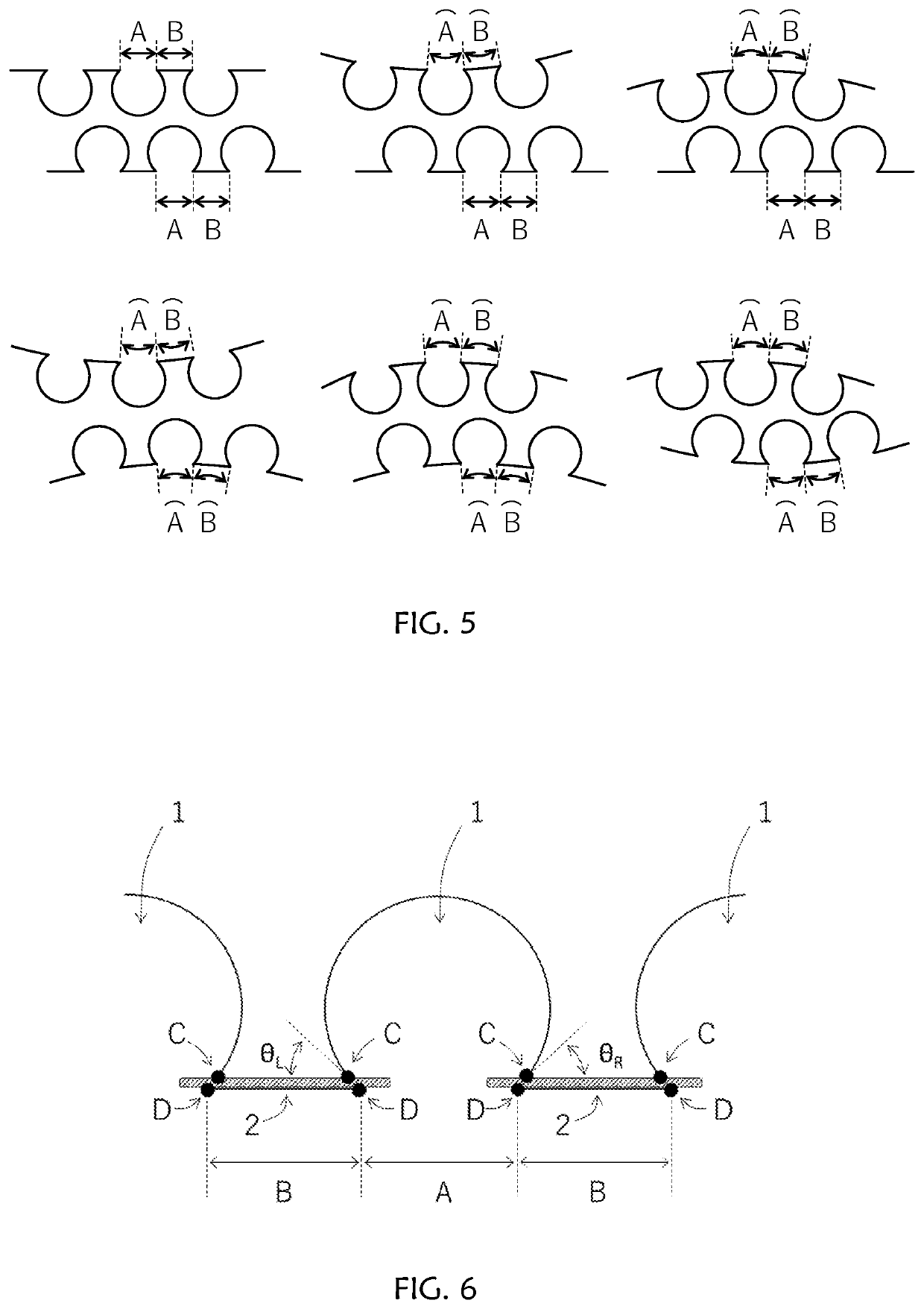

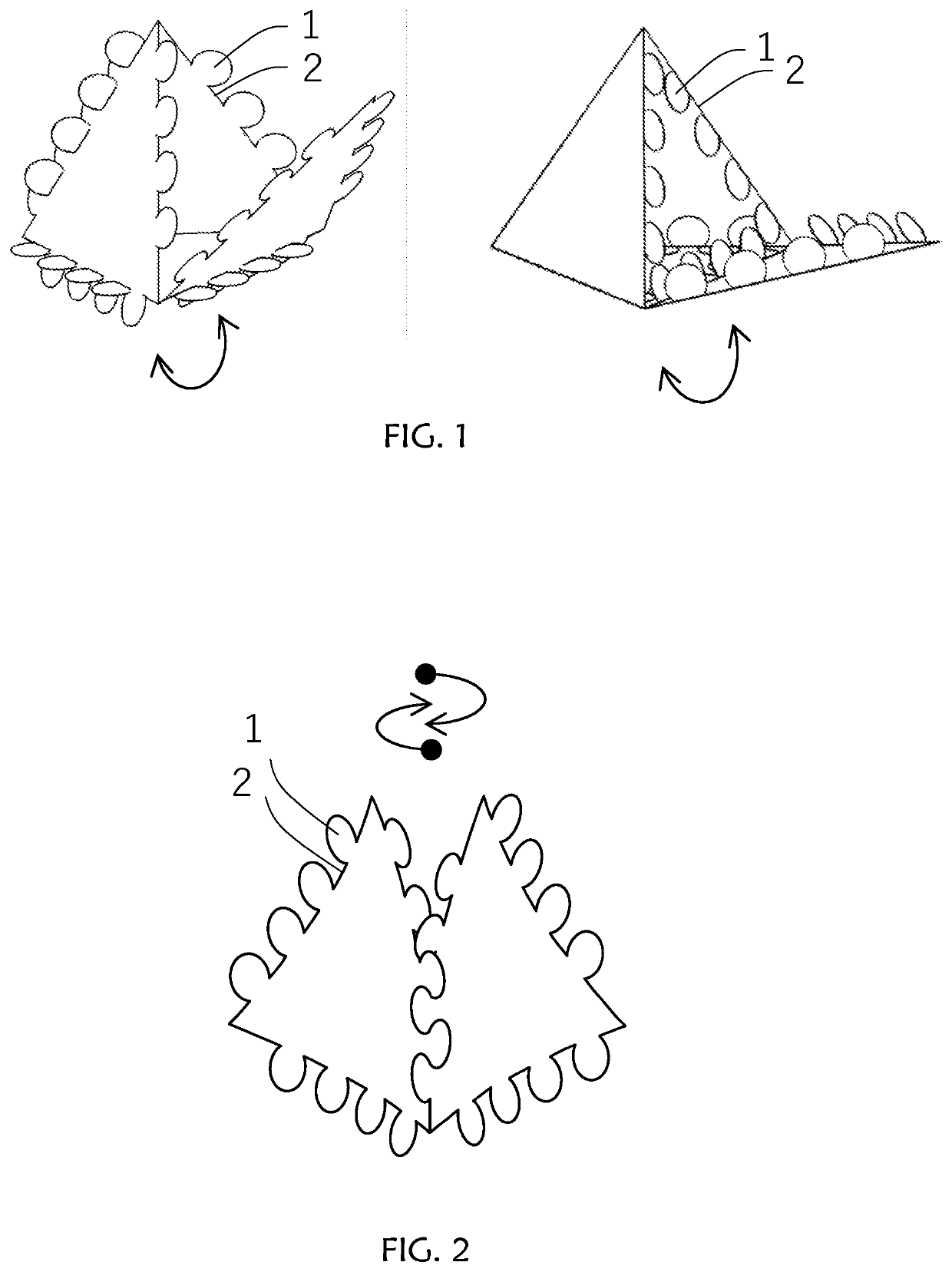

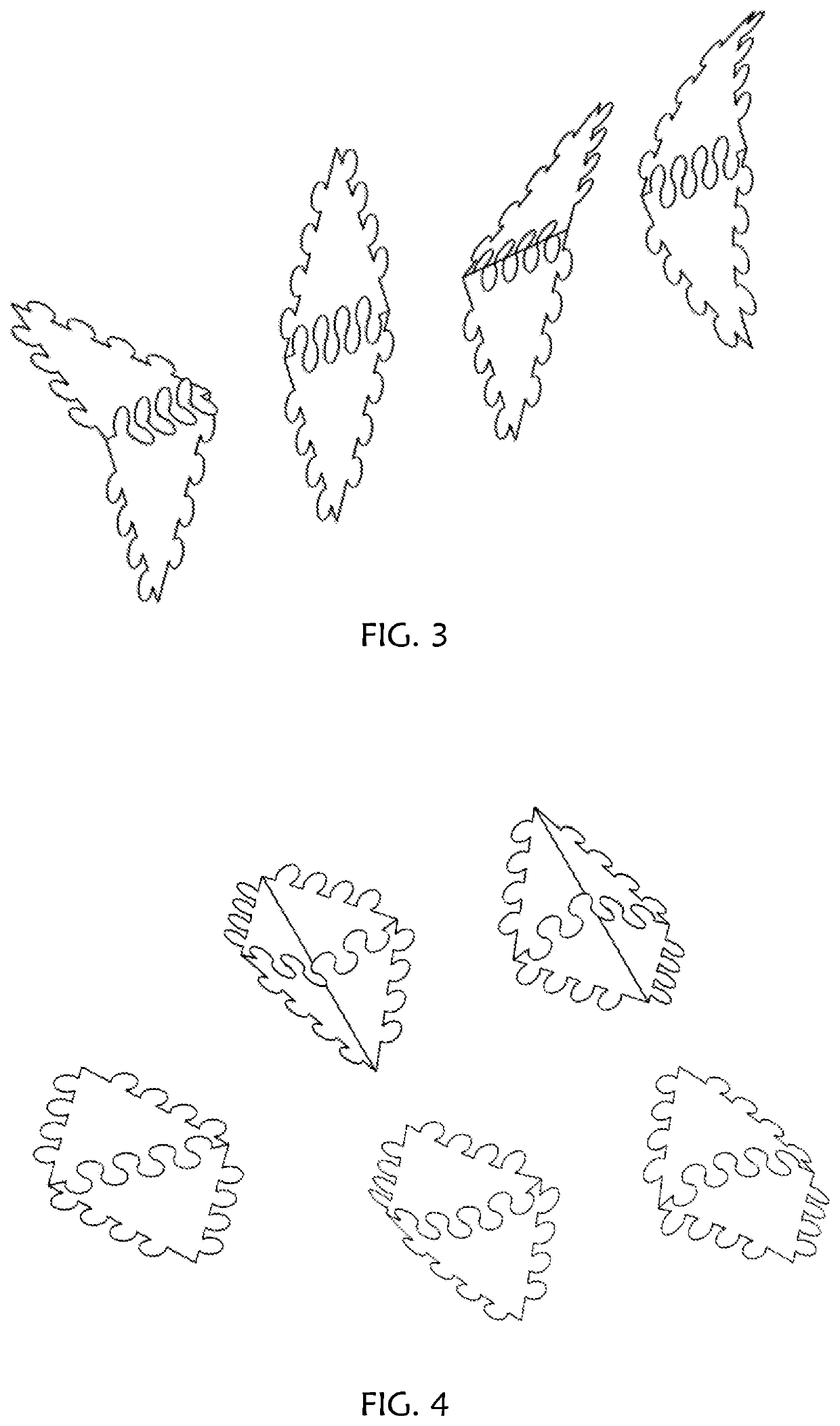

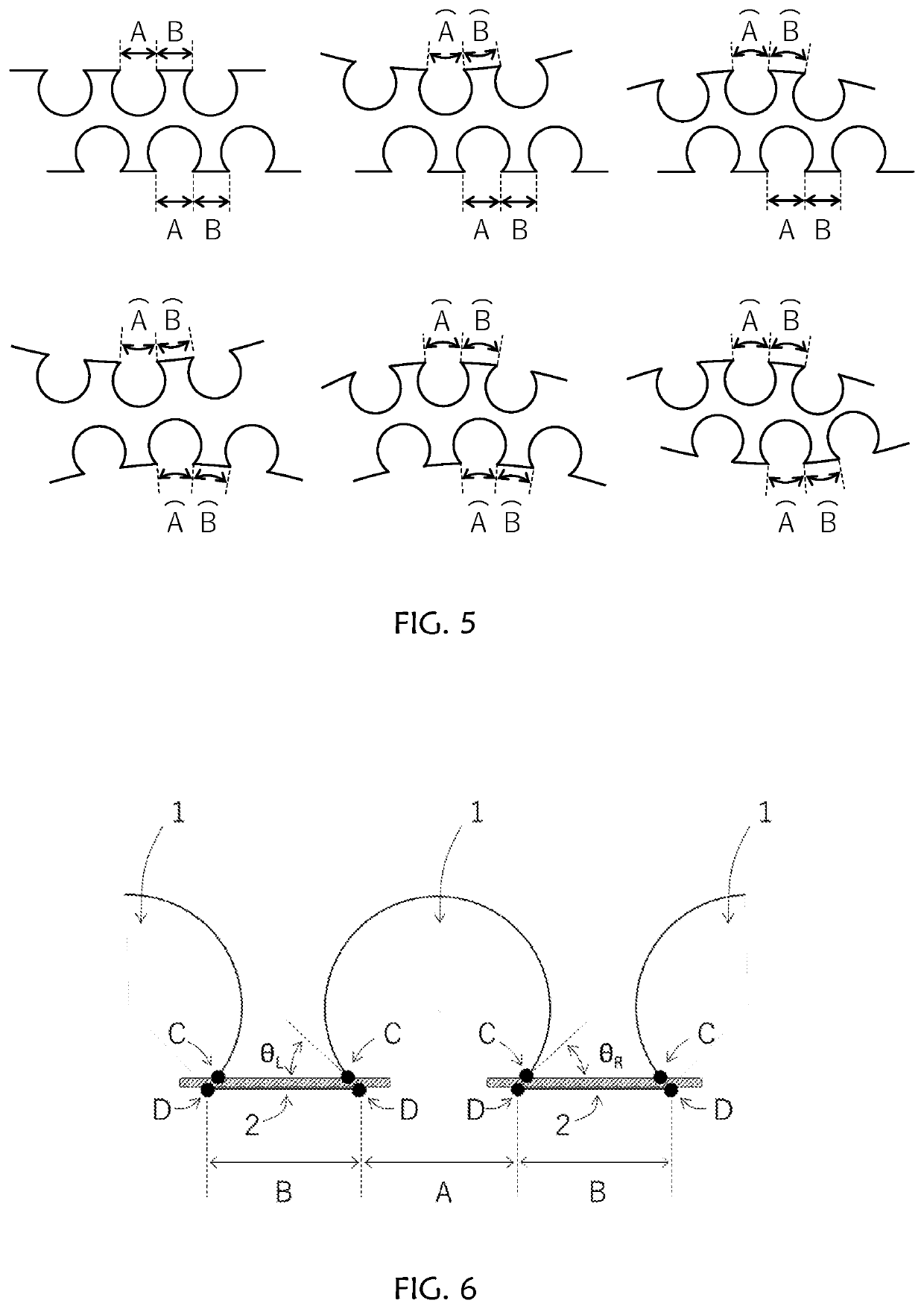

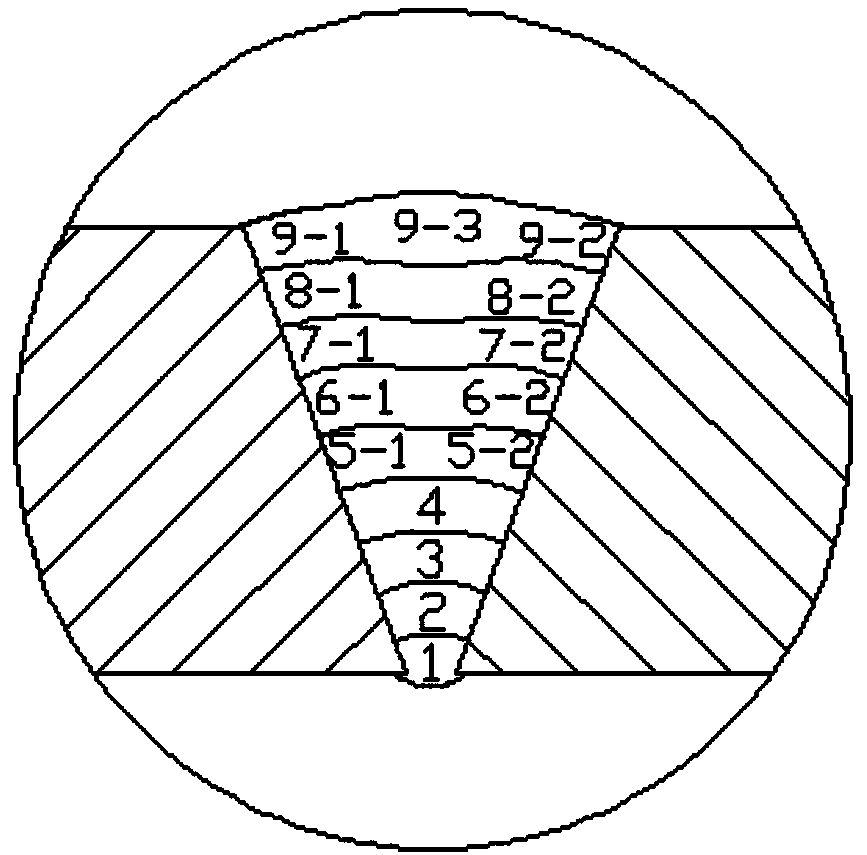

Geometric construction panel

A panel and a system for use in building a lightweight structure are provided. The panel, made of a film or a sheet capable of being curved or bent with fingers, includes a body in a geometric shape circumscribed by straight or curved edges, and at least one joint formation along the edge for panel connection. The joint formation has tabs separated by at least one gap. Each tab expands bilaterally and proximally from the body at its base, and each gap is positioned along the edge so as to accept the base of the tab. The joint formations along the edges of varied curvatures are alignedly, hingedly, and detachably interlocked with each other by twisting the panels with fingers to individually hook the tab at the gap. The panels are assembled into geometric structures having flat or curved faces.

Owner:LAL LAL INC

Three degrees of freedom forearm blood collection robot

ActiveCN104473653BCompact structureLarge working spaceDiagnostic recording/measuringSensorsBlood collectionBall screw

The invention provides a three-degree-of-freedom front arm blood collection robot and solves the defect of manual needle insertion for blood drawing at present. The three-degree-of-freedom front arm blood collection robot comprises a worktable, wherein a first drive arm, a second drive arm and a needle inserting mechanism are arranged on the worktable, the first drive arm and the worktable form rotatable connection through a first joint, the second drive arm and the first drive arm form rotatable connection through a second joint, the needle inserting mechanism and the second drive arm form rotatable connection through a third joint, the needle inserting mechanism comprises a rectangular frame, a driving motor, a ball screw, a guide sliding rail and a movable sliding table, the driving motor is connected with the ball screw, bearings are sheathed between the two ends of the ball screw and the rectangular frame, a screw hole and a sliding hole are formed in the movable sliding table, a nut is connected into the screw hole in a penetrating manner, the nut is sheathed on the ball screw to form thread connection, a guide sliding barrel is connected into the sliding hole in a penetrating manner, the guide sliding barrel is sheathed on the guide sliding rail to form sliding connection, and the side part of the movable sliding table is fixedly connected with a blood drawing needle. The three-degree-of-freedom front arm blood collection robot adopts mechanical blood drawing, the needle inserting accuracy is high and the safety is high.

Owner:SHANDONG UNIV OF SCI & TECH

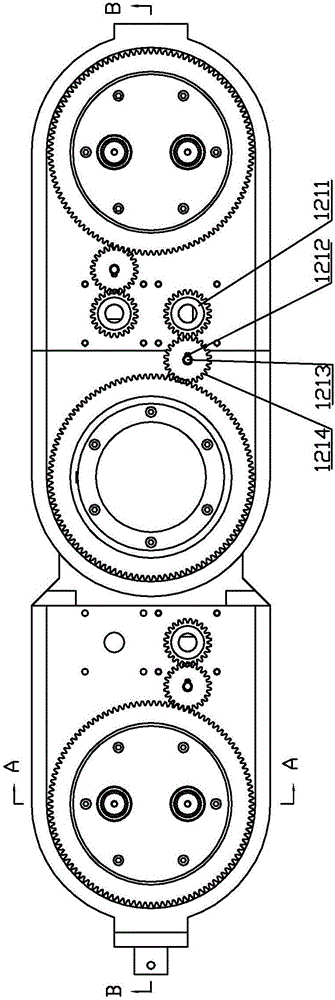

Joint type crawling robot for detecting heat pipe of steam generator

InactiveCN105945962AImprove work efficiencyExpand the detection rangeManipulatorControl engineeringJoints types

The invention relates to a joint type crawling robot for detecting a heat pipe of a steam generator, in particular to a joint type crawling robot. After a toe of a conventional robot PEGASYS is fixed, the detected heat pipe is a single heat exchange pipe; when the robot is used for detecting different heat pipes, the position of the toe is changed for at least two times; after being fixed, the conventional robot PEGASYS is small in detecting area and inconvenient to operate; when a conventional robot ZR-100 performs safety detection on the heat pipe, the problem that the robot is large in overall dimension and easy to limit by the type of a pipe plate exists. According to the joint type crawling robot disclosed by the invention, the structures of a left rotating joint, a middle rotating joint and a right rotating joint are the same, and the three rotating joints form a three-freedom-degree mechanical arm; a toe module comprises a left toe assembly and a right toe assembly, wherein the left toe assembly is arranged in the left rotating joint; the right toe assembly is arranged in the right rotating joint, an interface of a detecting tool is formed in the outer wall of the left rotating joint or the outer wall of the right rotating joint. The joint type crawling robot disclosed by the invention is used for heat pipe detection.

Owner:HARBIN INST OF TECH

Systems for Attaching Wood Products

The present invention is a system of building materials with surface regions destined for joint formation that are treated with an adhesive partially comprised of a mixture of epoxy resin (96.0-99.9 parts) and hardener (4.0-0.1 parts), such that the epoxy resin / hardener mixture constitutes 50-100% of the adhesive. In an alternative embodiment, the adhesive may have epoxy resin (96.0-99.9 parts) such that the epoxy resin constitutes 45-95% of the adhesive. The remainder of the adhesive may be one or more of the following: hardeners, plasticizing agents, diluents, thickeners, fillers, colorants, opacifying agents, preservatives, and surfactants.

Owner:WEYERHAEUSER NR CO

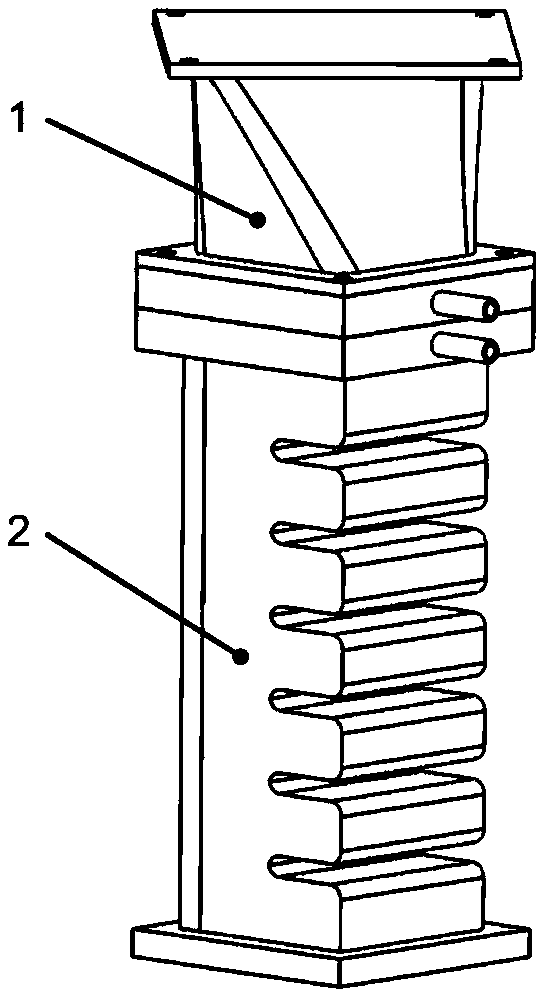

Rotary fully-flexible mechanical arm

InactiveCN109108956AIncrease flexibilityFlexible adjustment of bending directionProgramme-controlled manipulatorArmsEngineeringSilica gel

The invention discloses a rotary fully-flexible mechanical arm. A flexible joint and a flexible mechanical arm are connected. The lateral curved face of the flexible joint is sealed and connected between the upper bottom face and the lower bottom face in a wrapped mode, so that the whole flexible joint forms an airtight air chamber, an external air source injects air into the air chamber or exhausts air in the air chamber, and the height of the flexible joint is changed while the flexible joint rotates. The outer side of a mechanical arm body is of a rack-shaped structure arranged in the extension direction of the flexible joint. A small hollow air chamber is formed inside each tooth of the rack-shaped structure. The small air chambers at the teeth communicate with one another through communication cavities inside the middle of the mechanical arm body in a penetrating mode so that the integral mechanical arm airtight air chamber can be formed. One end of a mechanical arm silicone tubeis connected with the mechanical arm airtight air chamber, and the other end of the mechanical arm silicone tube is connected to the external air source. A node silicone tube is connected with negative pressure. The flexible joint drives the flexible mechanical arm to rotate, and the flexible mechanical arm is bent in different directions. According to the rotary fully-flexible mechanical arm, themechanical arm bending direction can be changed and adjusted, the flexibility of the flexible mechanical arm is greatly improved, and the application prospects are broad.

Owner:ZHEJIANG UNIV

Escape routes

ActiveUS9171809B2Reducing/avoiding voidRelieve pressurePrinted circuit assemblingFinal product manufactureMetallurgyJoint formation

Methods of and devices for providing escaping routes for the flux and gases generated to move away from the solder joint in the process of solder joint formation.

Owner:FLEXTRONICS AP LLC

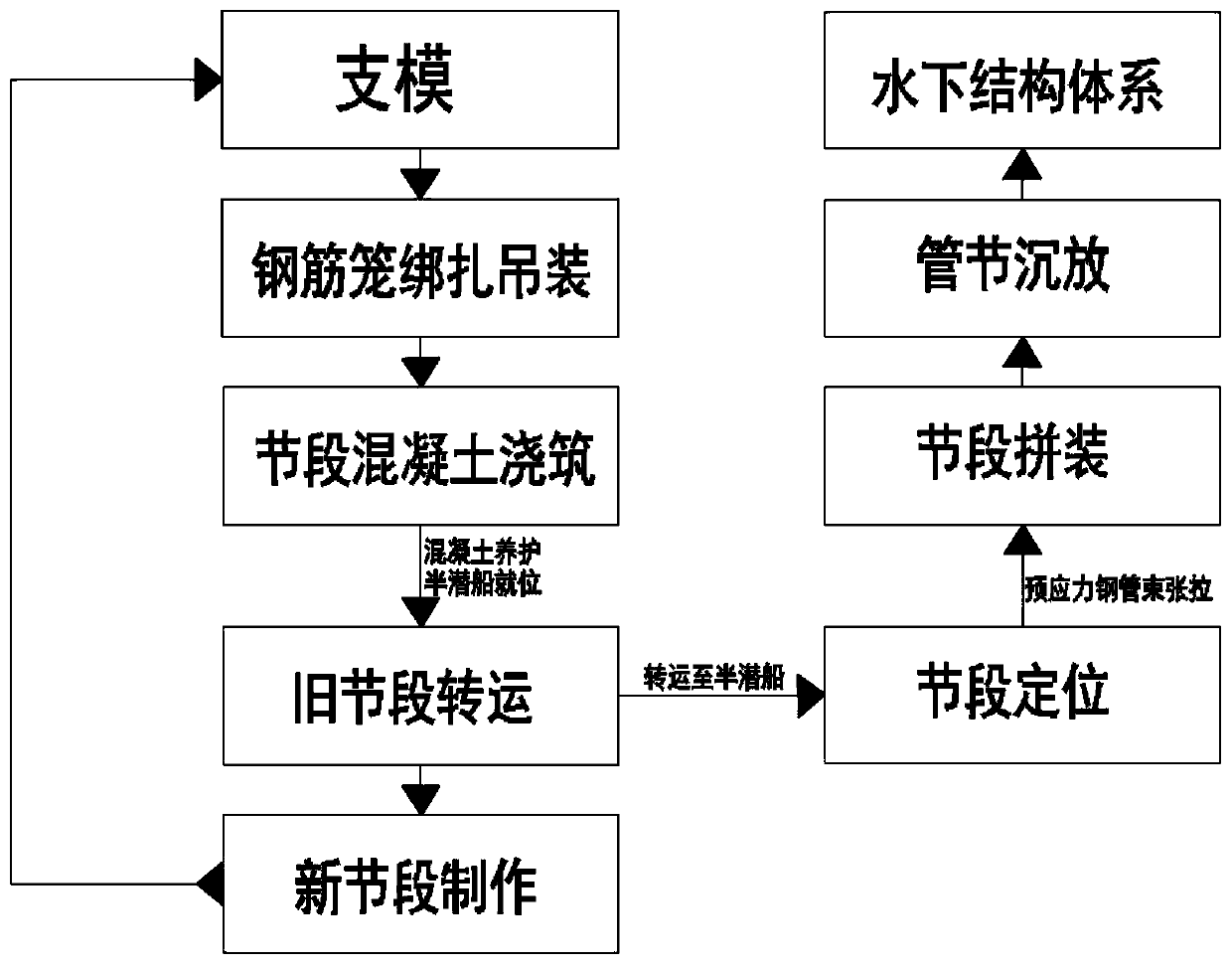

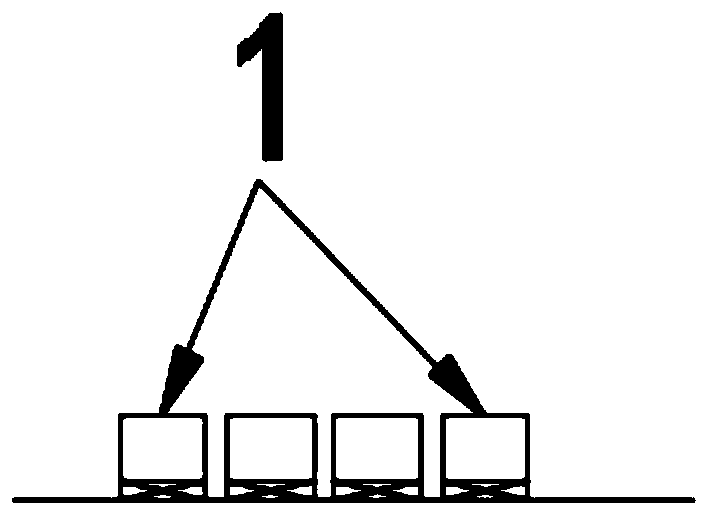

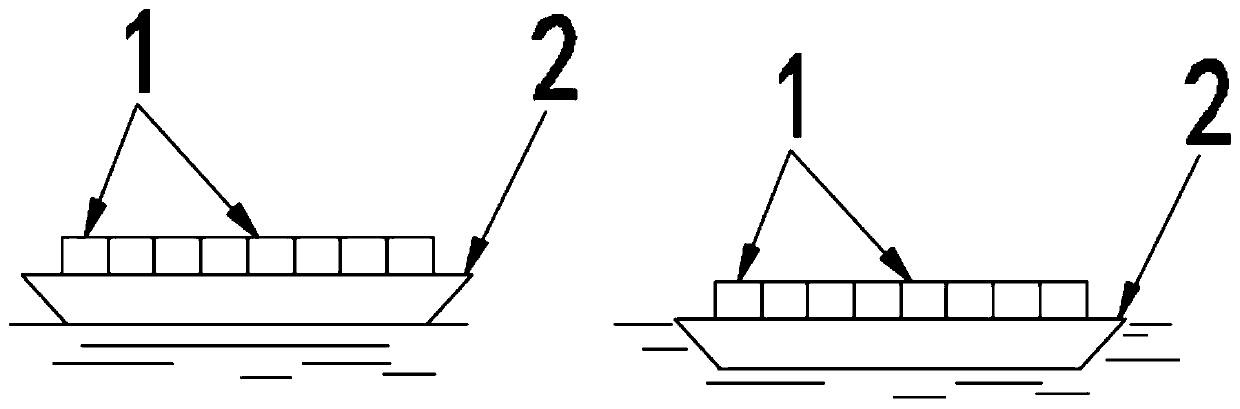

Segmental precast and sinking technology for underwater construction

InactiveCN111231104ASolve the difficulty of constructionReduce construction difficultyArtificial islandsCeramic shaping apparatusMarine engineeringButt joint

The invention discloses a segmental precast and sinking method for underwater construction. The method comprises steps as follows: a step of segmental precast: precast of reinforcing steel bars, rolled steel and / or concrete is performed in a precast site, and precast segments (1) of the reinforcing steel bars, the rolled steel and / or the concrete are obtained; a step of pipe joint formation: two or more precast segments (1) are subjected to assembling butt joint and tensioning treatment on a semi-submerged ship (2), and single pipe joints are obtained; and a step of pipe joint sinking and buttjoint: the semi-submerged ship (2) is transported to the sinking position of water surface in a floating manner and then dives, multiple single pipe joints are sunken and subjected to underwater buttjoint, and an underwater structural system is formed. According to the scheme, the problem of large construction difficulty of underwater pipe sinking can be solved, and the effect of reducing the construction difficulty of underwater pipe sinking is realized.

Owner:BEIJING JIUZHOU ARTERY TUNNEL TECH CO LTD

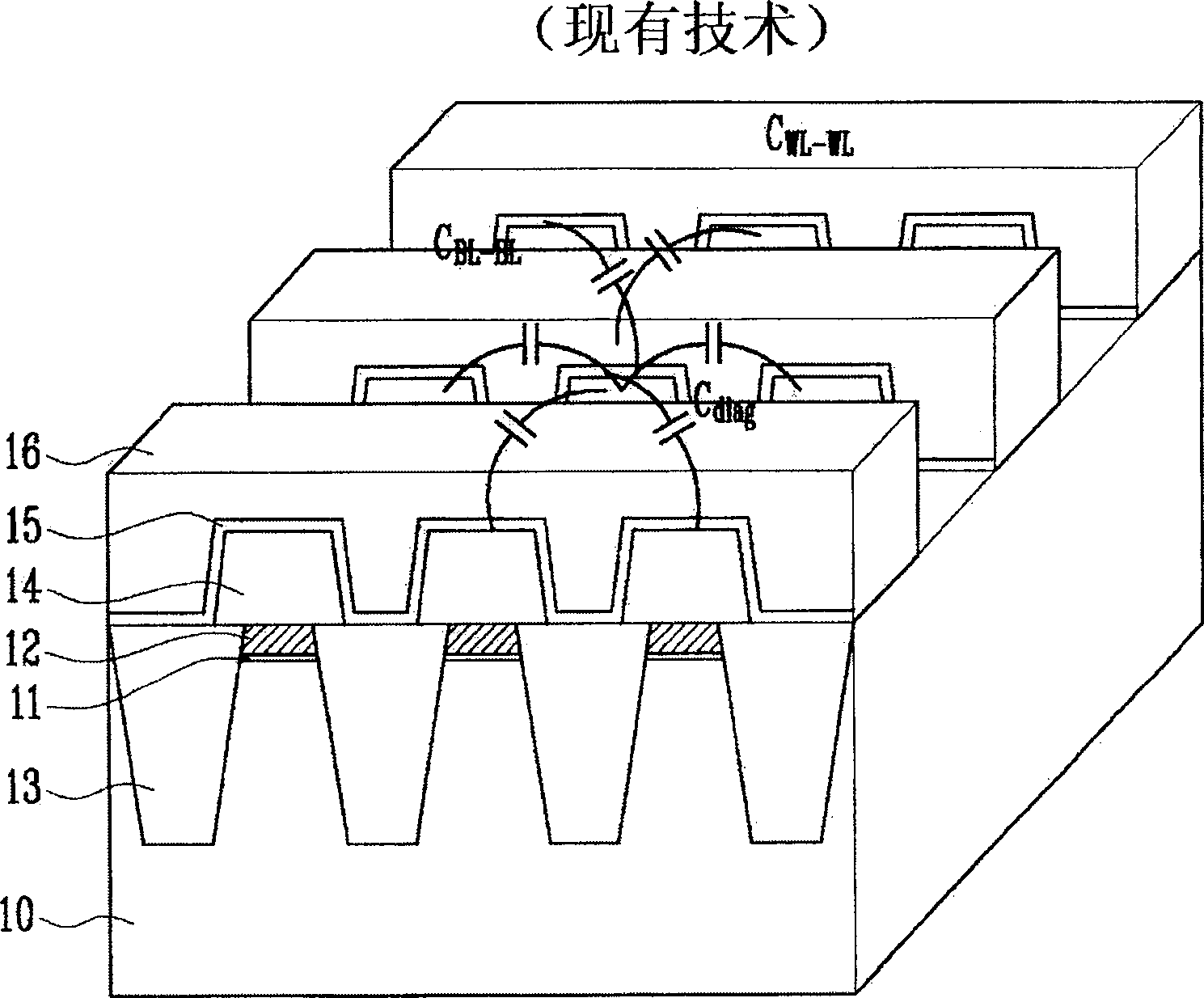

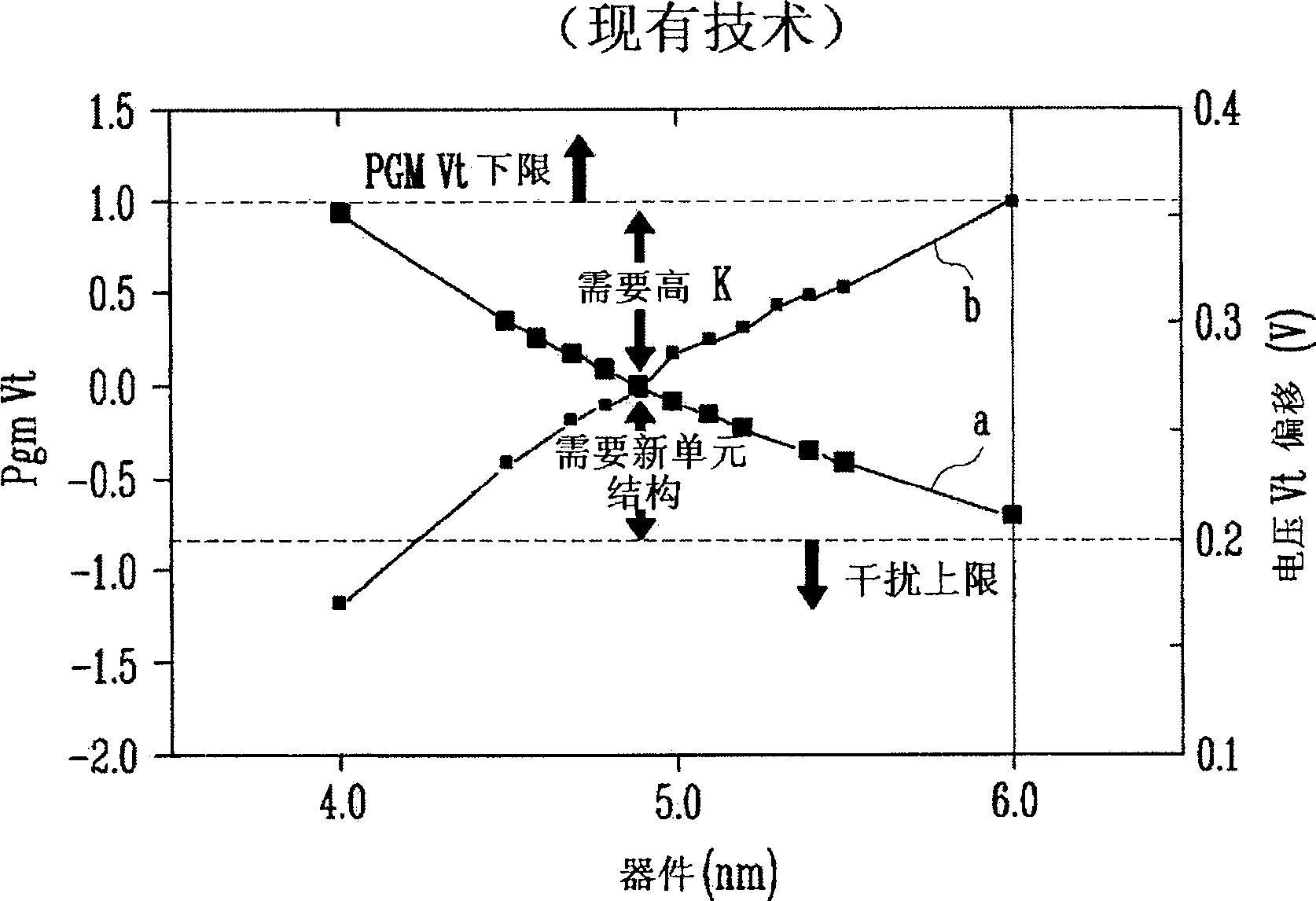

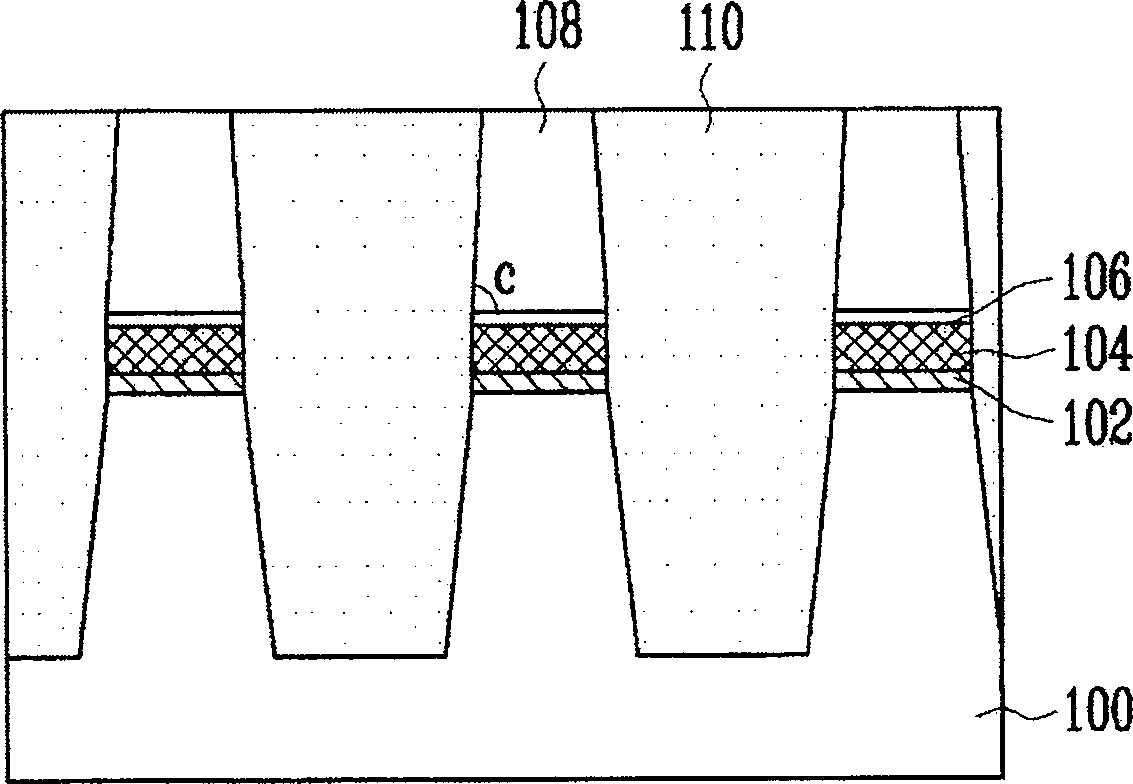

Method of manufacturing NAND flash memory device

InactiveCN100514607CReduce areaReduce electrical interferenceSolid-state devicesSemiconductor/solid-state device manufacturingIsolation layerEngineering

Owner:SK HYNIX INC

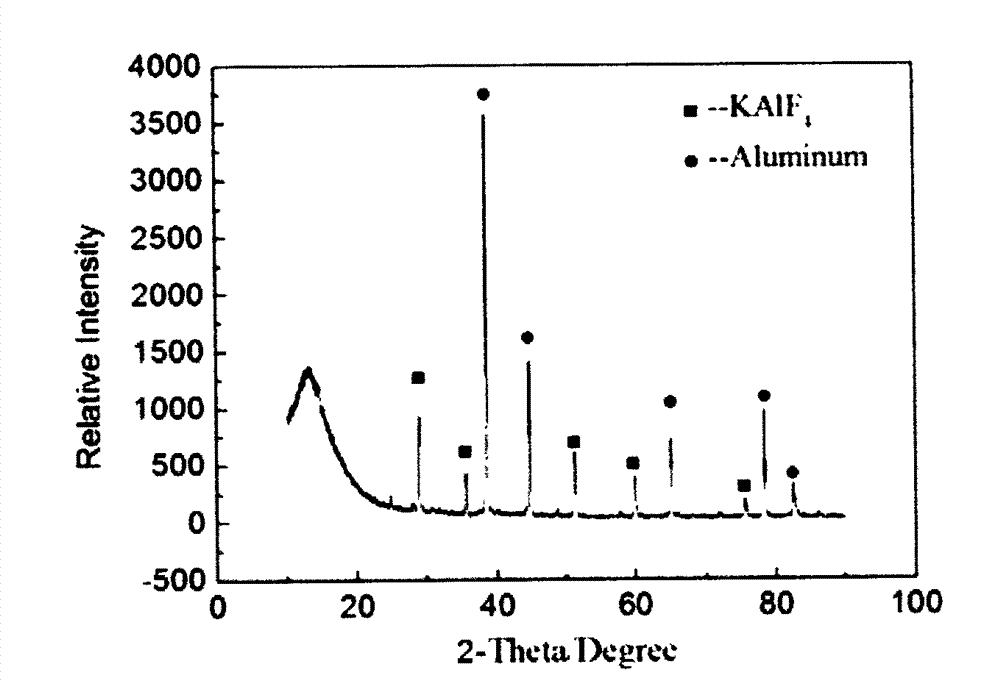

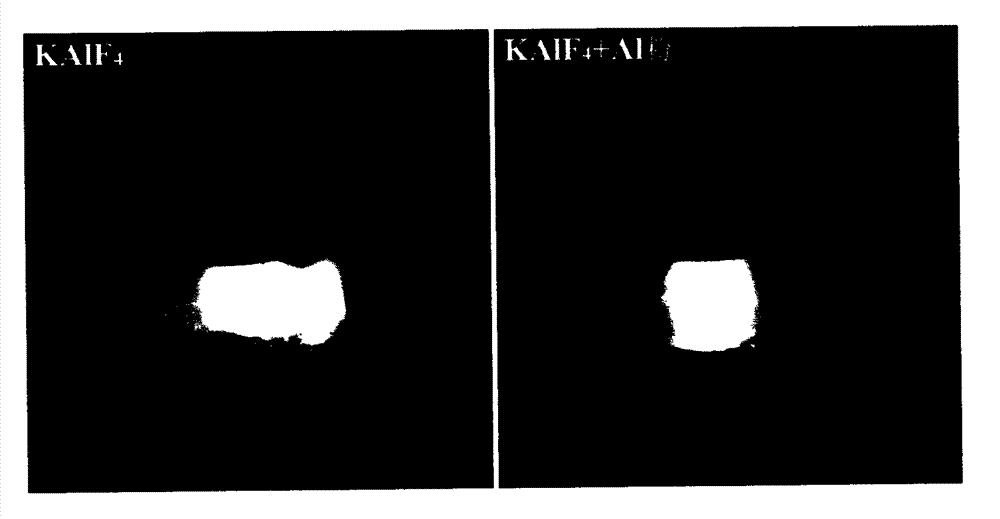

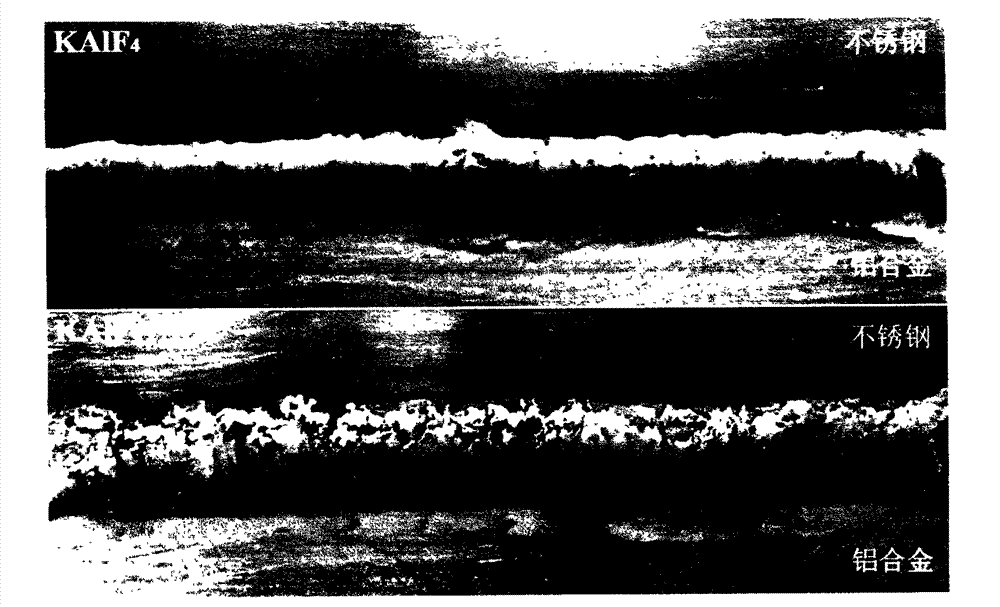

Soldering flux for aluminum and steel dissimilar metal alternating-current arc melt brazing

InactiveCN103203564AGood wetting and spreadingImprove stabilityWelding/cutting media/materialsSoldering mediaPotassium sodium tartrateAlternating current

The invention relates to a soldering flux for aluminum and steel dissimilar metal alternating-current arc melt brazing and a manufacturing method thereof. The method comprises the steps of first enabling KAlF4 powder and aluminum powder to be mixed at a mass ratio of (4-7):(3-6), then enabling the mixture to be mixed with acetone into uniform suspension solution, enabling potassium sodium tartrate which is 0.5%-1% the total mass of the KAlF4 powder and the aluminum powder to be added into distilled water to be dissolved, finally adding the suspension solution into the distilled water to mix evenly, and obtaining the soldering flux. The soldering flux has effects of stabilizing alternating-current arc, promoting wetting spreading, improving welded joint formation and improving joint performance, and high-quality reliable connection of aluminum and steel dissimilar metals is achieved finally.

Owner:HARBIN INST OF TECH

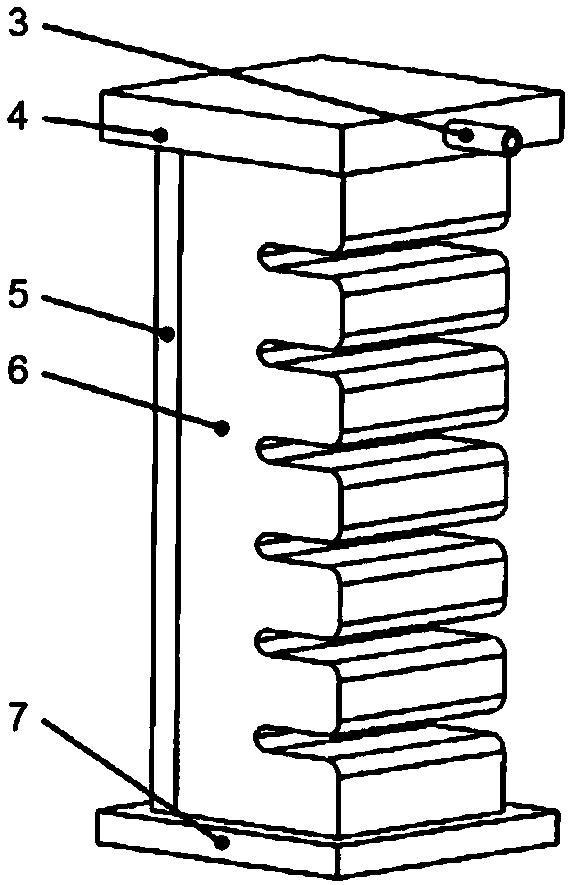

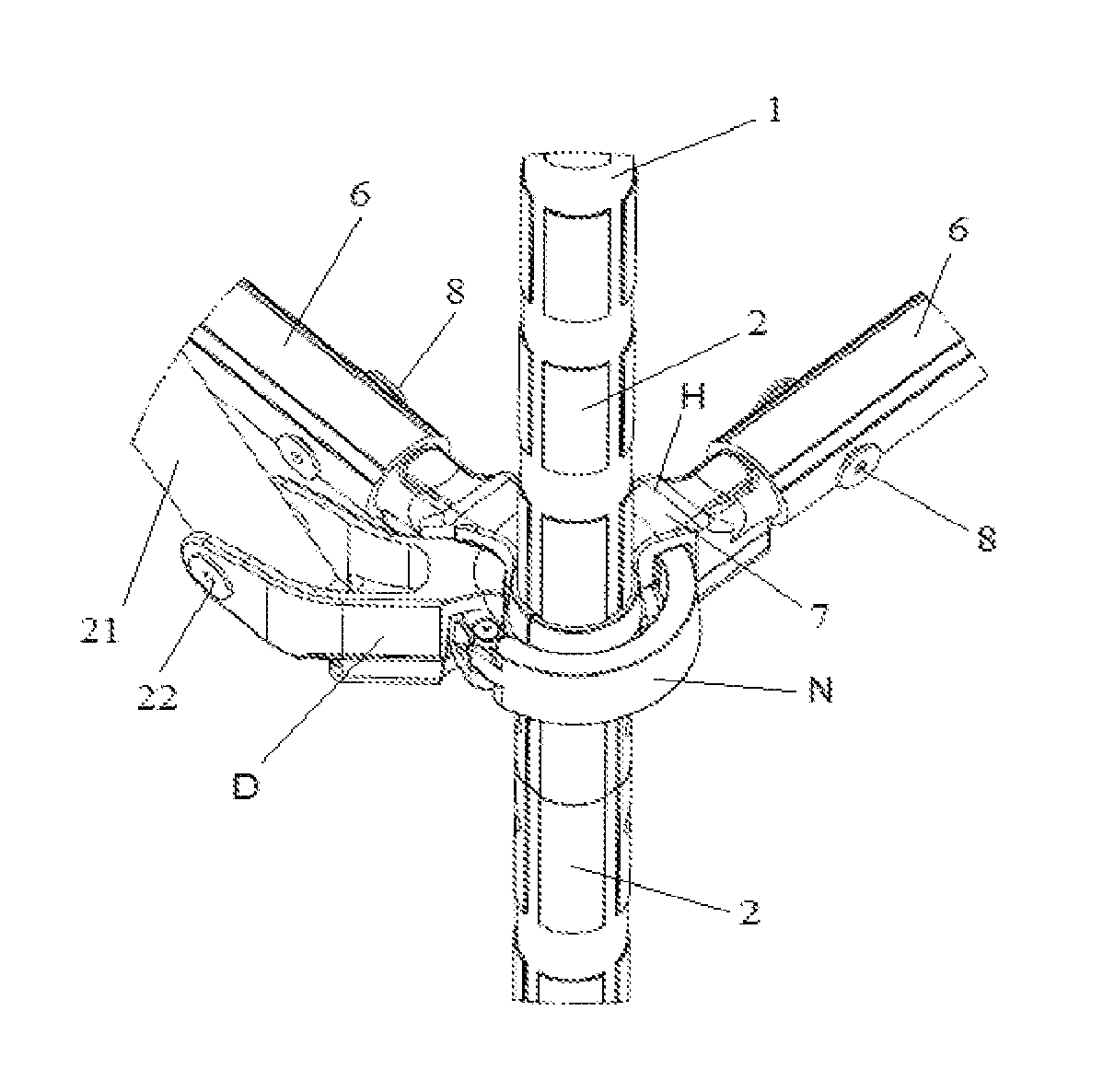

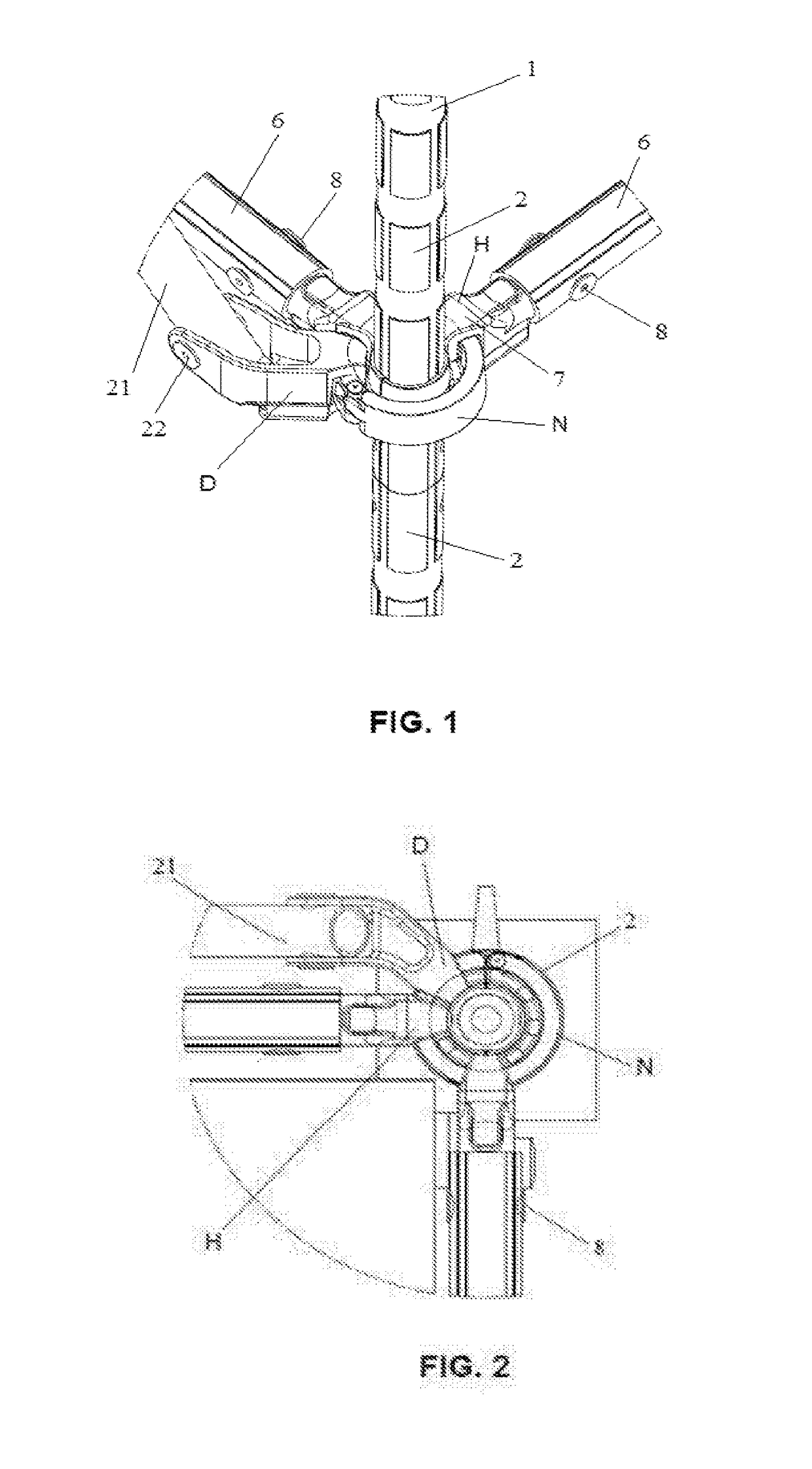

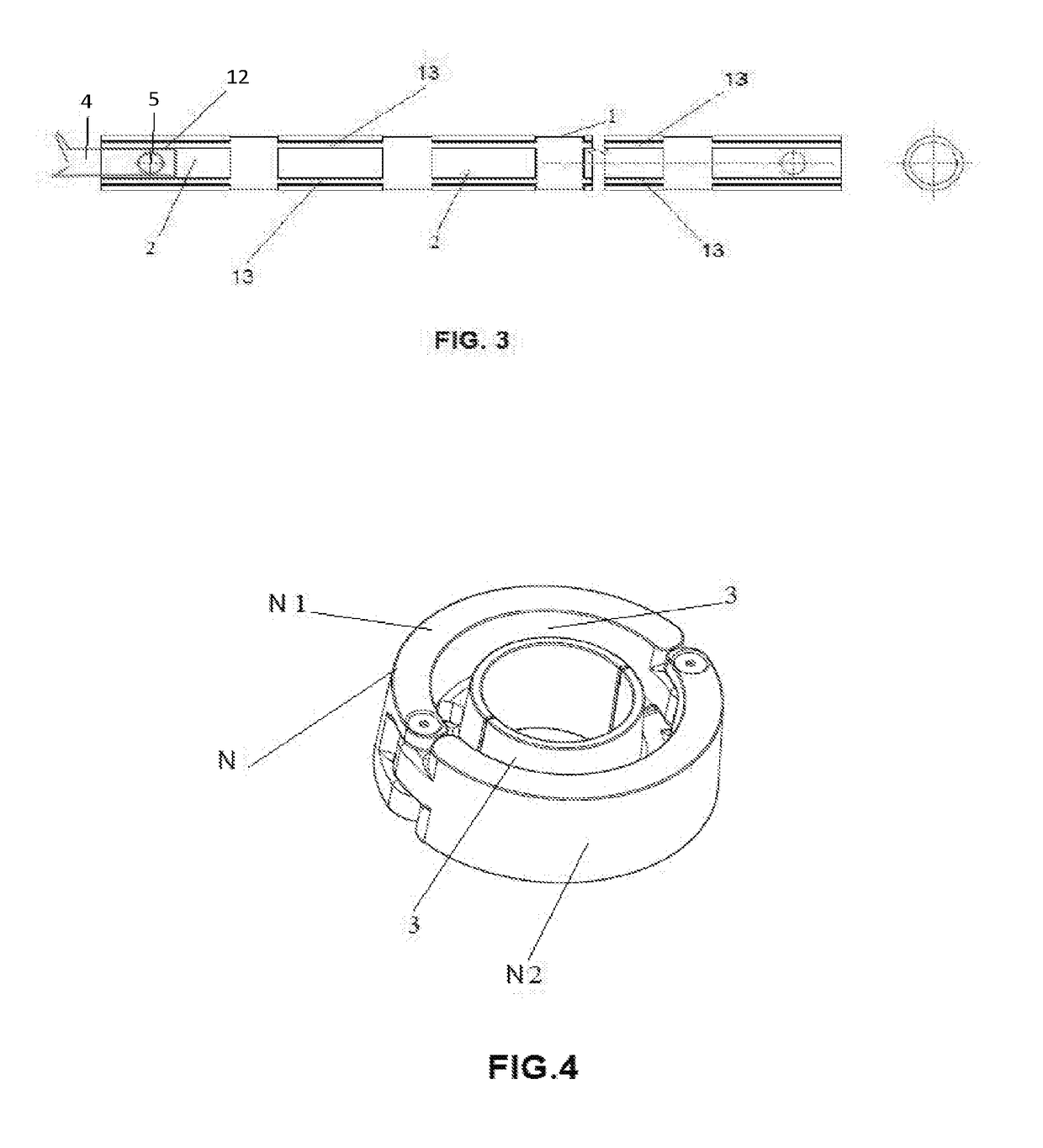

Articulated dismountable modular scaffolding

Articulated dismountable modular scaffolding of the type assembled at the workplace by means of parts comprising a structure that can be assembled and disassembled, characterised by the fact it is made up by the following interconnected parts:Vertical Tubes (1),Joints (N). The joints (N) are the points where vertical [bars] converge with horizontal or diagonal ones, being formed by two symmetrical, semi-circular semi-joints.Horizontal Tubes (6),The horizontal fastening (H) has a catch (9) in its lower part, as a latch (9)Diagonal Tubes (21),Diagonal Fastenings (D), located at each end of the diagonal tube (21),

Owner:AYUDAME A AYUDARTE SL

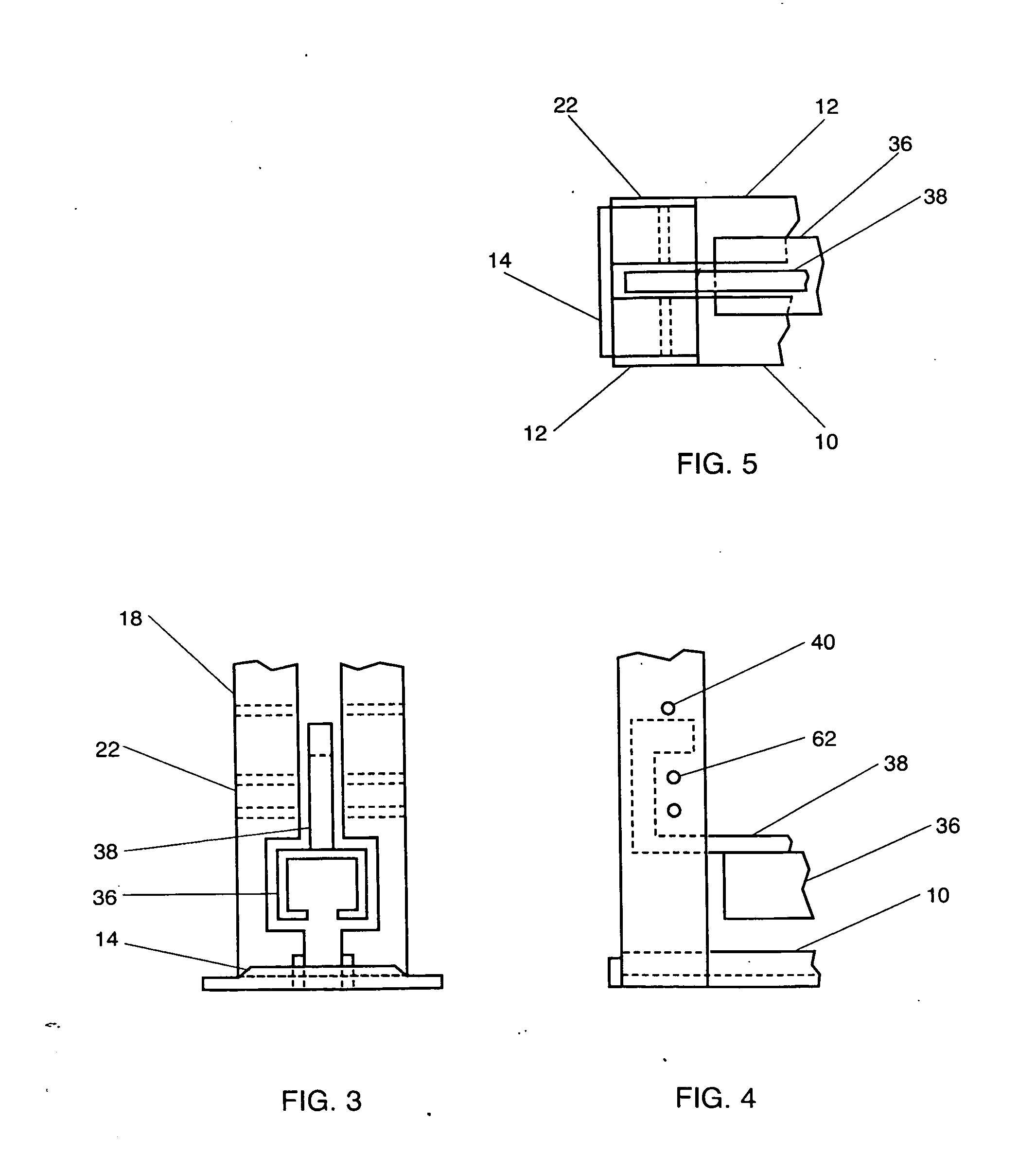

Concrete joint inserter tool

A concrete crack control joint insertion tool to insert joint forming materials into a concrete mixture or alternatively providing means to create a crack control joint without the use of ancillary material.Crack control joint in fresh concrete is formed beneath a rectangular structure supporting linear actuators that drive a blade alone or carrying joint forming materials into a precise location and depth. Crack control joint formation is repeatable completed in a single motion and with continued precise accuracy of placement.

Owner:SIMONS BRYCE PATRICK +1

Geometric construction panel

A panel and a system for use in building a lightweight structure are provided. The panel, made of a film or a sheet capable of being curved or bent with fingers, includes a body in a geometric shape circumscribed by straight or curved edges, and at least one joint formation along the edge for panel connection. The joint formation has tabs separated by at least one gap. Each tab expands bilaterally and proximally from the body at its base, and each gap is positioned along the edge so as to accept the base of the tab. The joint formations along the edges of varied curvatures are alignedly, hingedly, and detachably interlocked with each other by twisting the panels with fingers to individually hook the tab at the gap. The panels are assembled into geometric structures having flat or curved faces.

Owner:LAL LAL INC

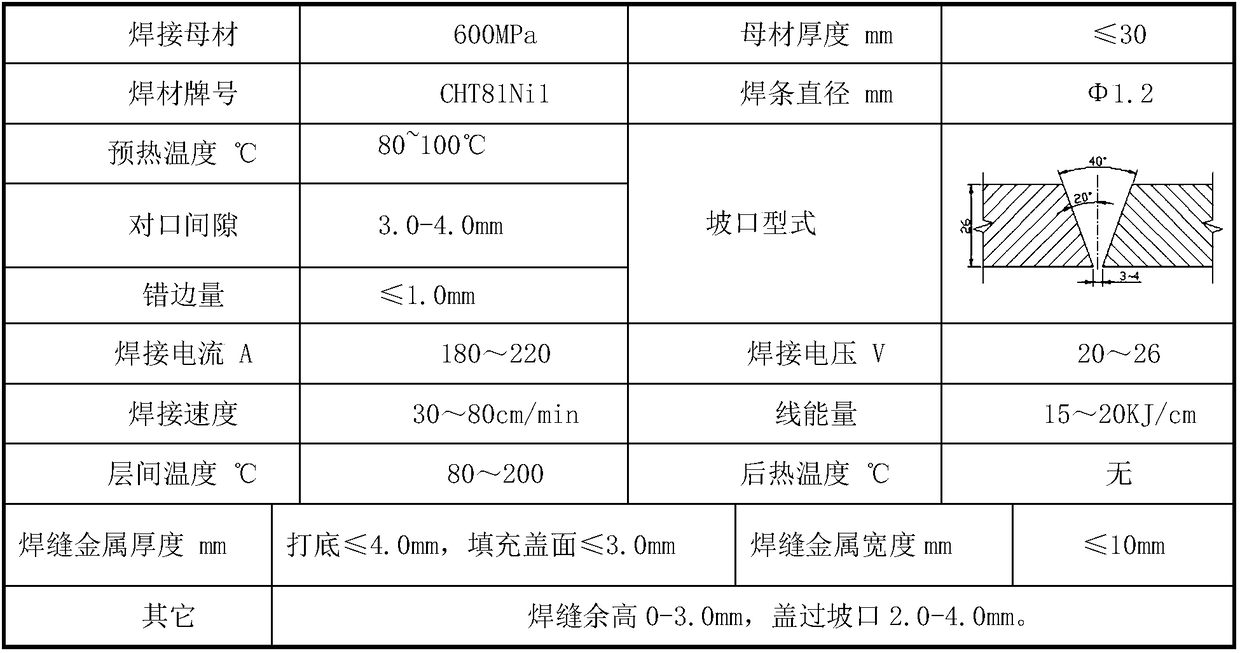

Technology suitable for automatically welding high-strength pressure steel pipes in water tunnel

PendingCN109332854AGuaranteed mechanical propertiesStable welding processWelding accessoriesSocial benefitsElectricity

The invention discloses a technology suitable for automatically welding high-strength pressure steel pipes in a water tunnel. The technology includes the following steps that a, one-sided inward grooves are both milled on the ring surfaces to be welded of the two steel pipes; b, the two steel pipes are aligned; c, preheating is conducted on the two sides of a welded joint; d, rails are installed on the inner walls of the steel pipes and further located on the two sides of the welded joint; e, a welding tractor is installed on the rails; f, welding technological parameters and moving trajectories of the welding tractor are confirmed; g, back welding is conducted; h, back welding fusion lines are trimmed; and i, filling and cosmetic welding are carried out. The technology has the beneficialeffects that welded joint formation is attractive, quality is good, molding and low temperature impact toughness are good, and the technology is particularly suitable for high-strength water and electricity steel welding. Meanwhile, the automation process of the welding technology of the pressure steel pipes in the tunnel is greatly accelerated through the technology, the labor intensity of welders is relieved, construction efficiency is high, and the independence on skill levels of the welders is lowered and the social benefits and economic benefits are good.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com