Method for producing zinc powder by treating zinc-containing miscellaneous material through electric furnace

A technology of miscellaneous materials and zinc powder, which is applied in the field of recycling and utilization of non-ferrous metal smelting waste, to achieve the effect of low output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

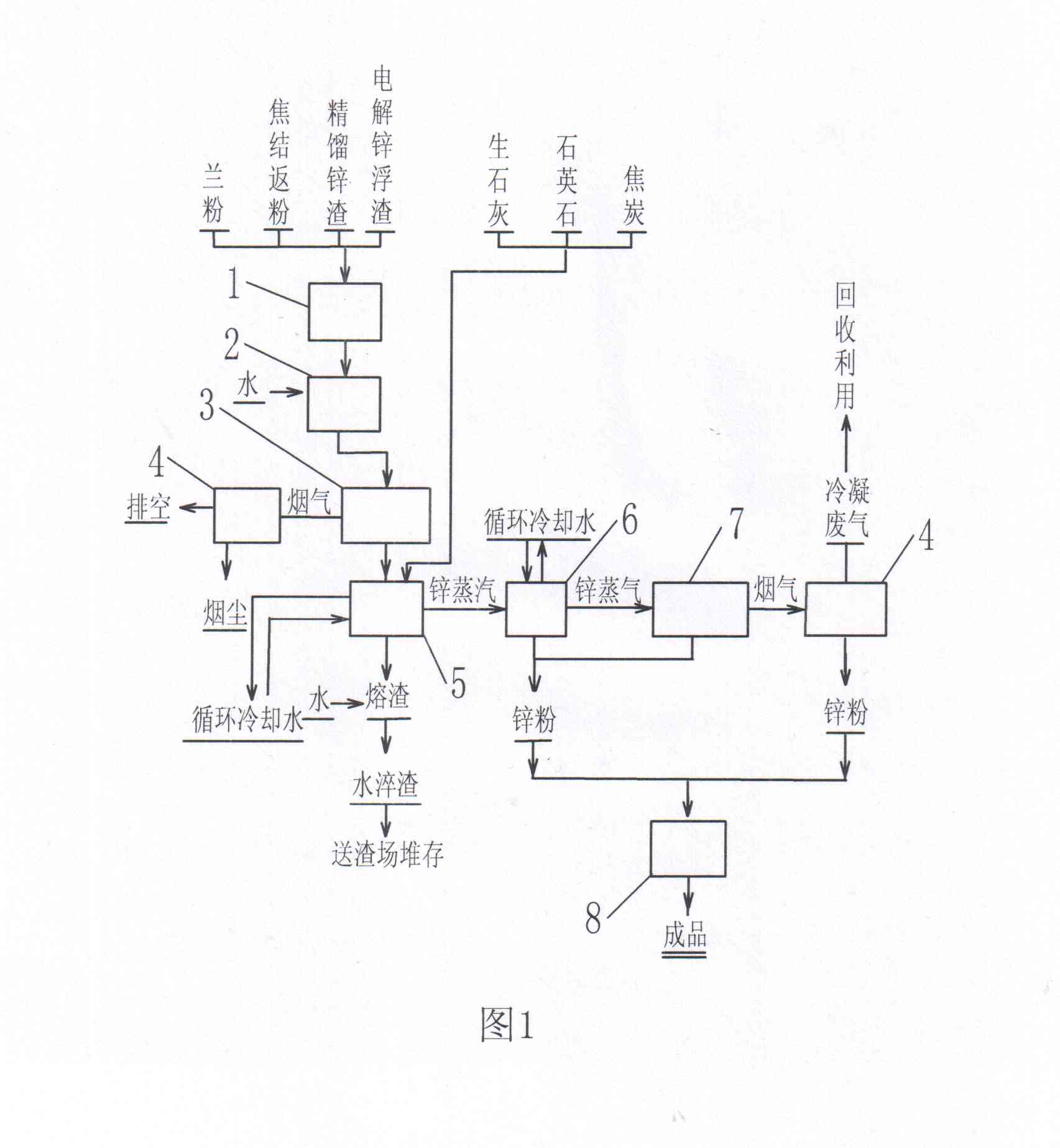

Image

Examples

Embodiment 1

[0074] Quantitative batching of zinc-containing miscellaneous materials: 32 parts of coke powder, 22 parts of wet blue powder, 22 parts of electrolytic zinc scum and 24 parts of rectified zinc slag are taken according to the mass ratio, and mixed as zinc-containing miscellaneous materials after quantitative batching process 1 material;

[0075] Operation method of zinc powder production process: The above zinc metallurgical zinc-containing miscellaneous materials are stored in different material storage bins in the material preparation workshop. The wet blue powder is stored separately, and after being naturally dried, it is dispersed with a looser. After the scattered wet blue powder, coke powder, electrolytic zinc scum and rectification zinc slag are weighed and dosed by a quantitative feeder, It is sent to the intermediate silo by the chain bucket conveyor, and then granulated. The granulated zinc-containing miscellaneous material mixture is sent to a baking kiln for roast...

Embodiment 2

[0080] Quantitative batching of zinc-containing miscellaneous materials: Take 28 parts of coke powder, 23 parts of wet blue powder, 23 parts of electrolytic zinc scum and 26 parts of rectified zinc slag according to the mass ratio, and mix them as zinc-containing miscellaneous materials after quantitative batching;

[0081] The operation method of the zinc powder preparation process is as in Example 1.

Embodiment 3

[0082] Example 3. Quantitative batching of zinc-containing miscellaneous materials: 34 parts of coke powder, 20 parts of wet blue powder, 20 parts of electrolytic zinc scum and 26 parts of rectified zinc slag are taken according to the mass ratio, and mixed as zinc-containing miscellaneous materials after quantitative batching process ;

[0083] Zinc powder preparation process operation method is as embodiment 1

[0084] Technical features of the present invention:

[0085] 1) 100% use of zinc-containing miscellaneous materials;

[0086] The intermediate zinc-containing miscellaneous materials produced by the existing pyro-method and hydro-method zinc smelting systems meet the requirements of the mixture ingredients for zinc powder produced by electric arc furnaces, and do not contain sulfides and sulfates, so that the smelting waste gas does not contain sulfur dioxide, which can be used for The recovery of carbon monoxide in smelting waste gas creates extremely favorable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com