Submerged arc sintered flux and production method thereof

A technology for sintering flux and production method, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of prone to transverse cracks and terminal cracks, untimely after-sales service, long order cycle, etc., to achieve transition The effect of smoothing, cost reduction, and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

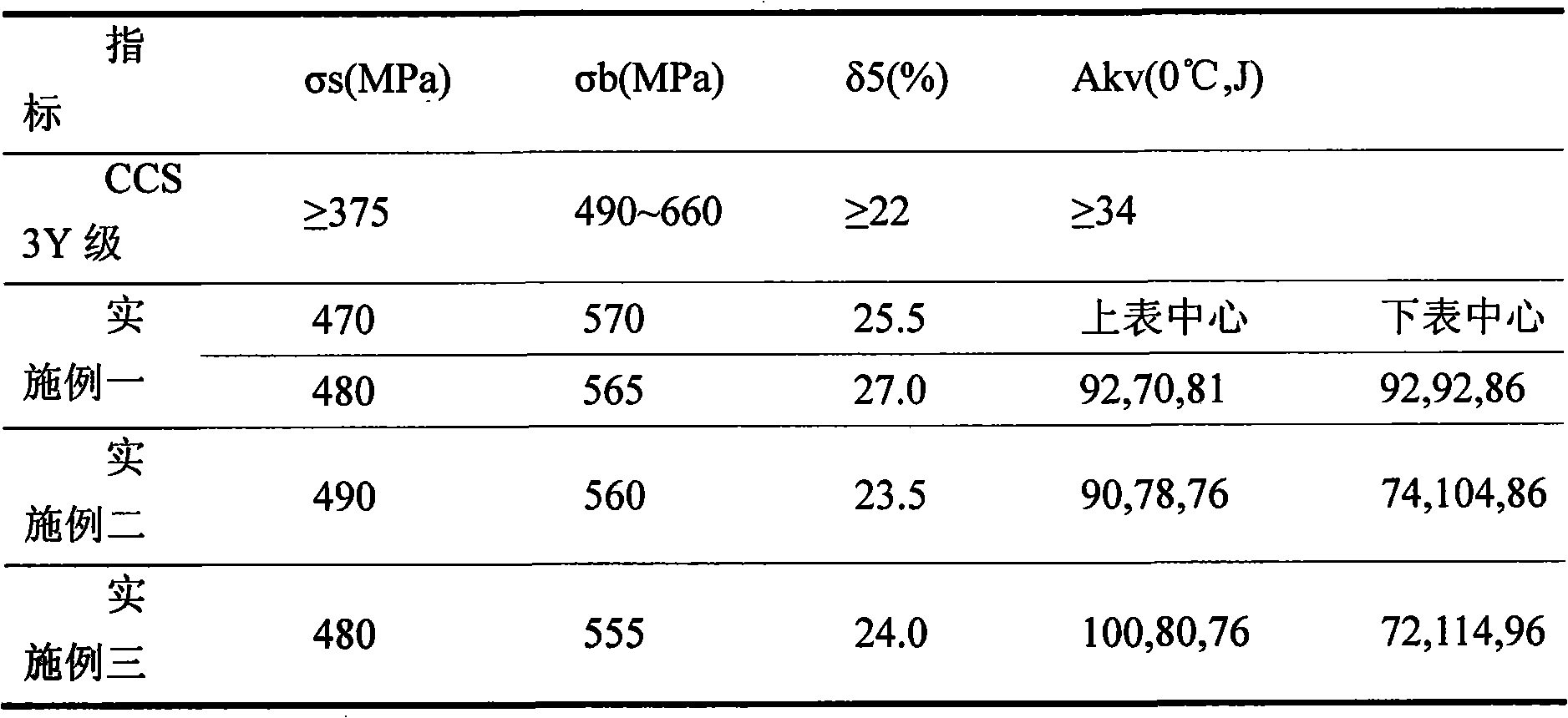

Examples

Embodiment 1

[0030] Flux: Multi-wire single-sided submerged arc sintered flux, its chemical composition (mass percentage):

[0031] Upper surface flux:

[0032] CaO 8%, MgO 17%, Al 2 O 3 11%, MnO 4%, SiO 2 12%, TiO 2 8%, Fe 2 O 3 36%, rare earth ferrosilicon 2%, ferro-titanium 1%, borax 0.5%, ferromanganese 0.5%;

[0033] Backing flux:

[0034] CaO 18%, MgO 33%, Fe 2 O 3 7%, MnO 12%, SiO 2 18%, TiO 2 8%, Na 2 O 4%.

Embodiment 2

[0036] Flux, its chemical composition (mass percentage):

[0037] Upper surface flux:

[0038] CaO 5%, MgO 20%, Al 2 O 3 7%, MnO 6%, SiO 2 10%, TiO 2 10%, Fe 2 O 3 38%, rare earth ferrosilicon 2%, ferro-titanium 1%, borax 0.5%, ferromanganese 0.5%;

[0039] Backing flux:

[0040] CaO 15%, MgO 35%, Fe 2 O 3 5%, MnO 15%, SiO 2 15%, TiO 2 10%, Na 2 O 5%.

Embodiment 3

[0042] Flux, its chemical composition (mass percentage):

[0043] Upper surface flux:

[0044] CaO 10%, MgO 15%, Al 2 O 3 14%, MnO 3%, SiO 2 15%, TiO 2 5%, Fe 2 O 3 34%, rare earth ferrosilicon 2%, ferro-titanium 1%, borax 0.5%, ferromanganese 0.5%;

[0045] Backing flux:

[0046] CaO 20%, MgO 30%, Fe 2 O 3 10%, MnO 10%, SiO 2 20%, TiO 2 5%, Na 2 O 5%.

[0047] Using the FCB method special welding wire of the present invention, its chemical composition is shown in Table 1;

[0048] Table 1 Chemical composition of welding wire (%)

[0049] C

Si

Mn

S

P

Cu

0.055

0.021

0.60

0.019

0.014

<0.05

[0050] Test plate: high-strength marine steel plate DH32, thickness 20mm, its chemical composition is shown in Table 2.

[0051] Table 2 DH32 chemical composition

[0052] C

Si

Mn

S

P

Cu

0.12

0.35

1.10

0.020

0.023

<0.05

[0053] Welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com