Method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing

A converter steelmaking and converter gas technology, which is used in the manufacture of converters, reducing gas emissions, etc., to achieve the effects of reducing smelting costs, reducing oxygen consumption, and alleviating the atmospheric greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

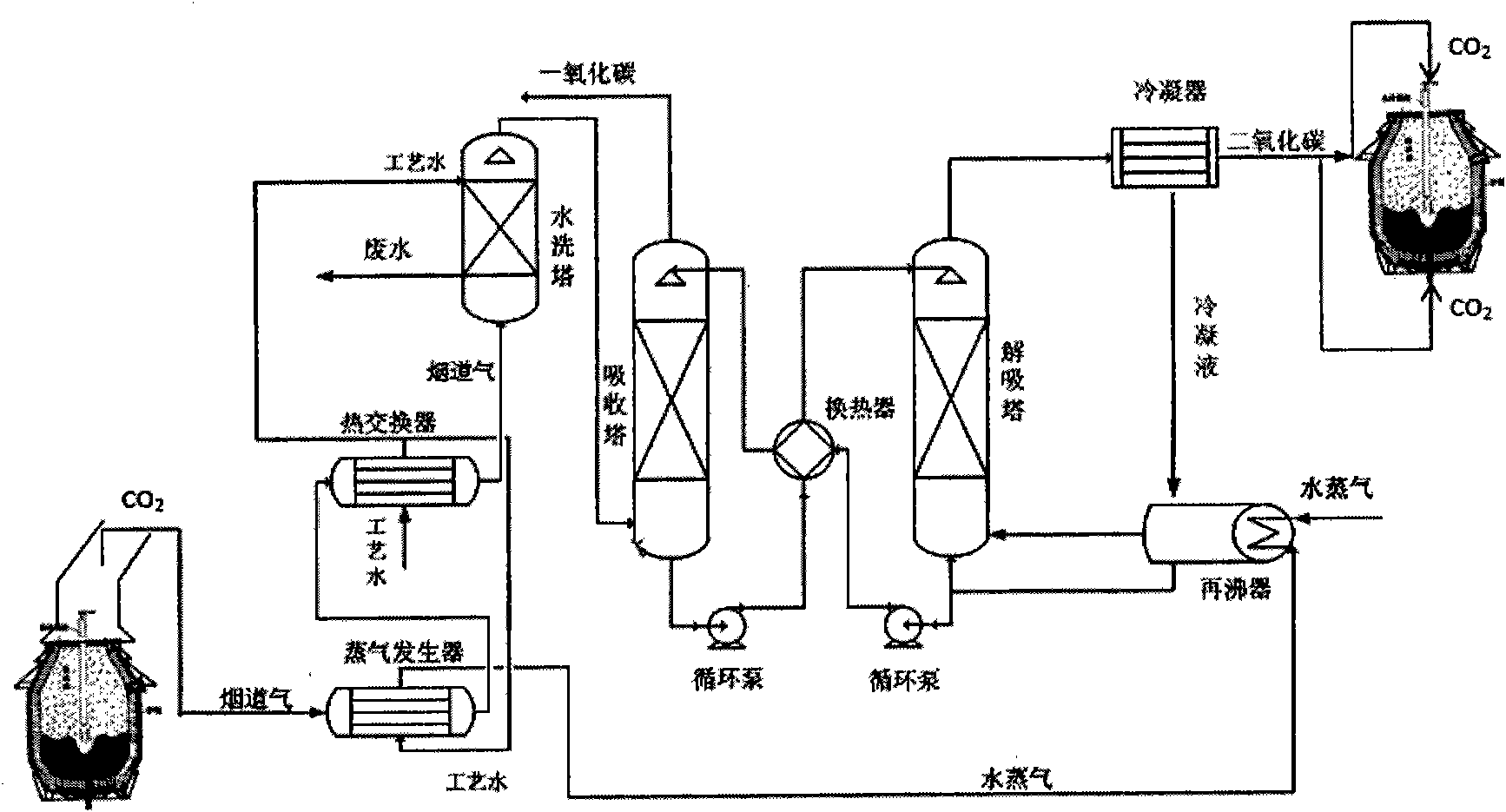

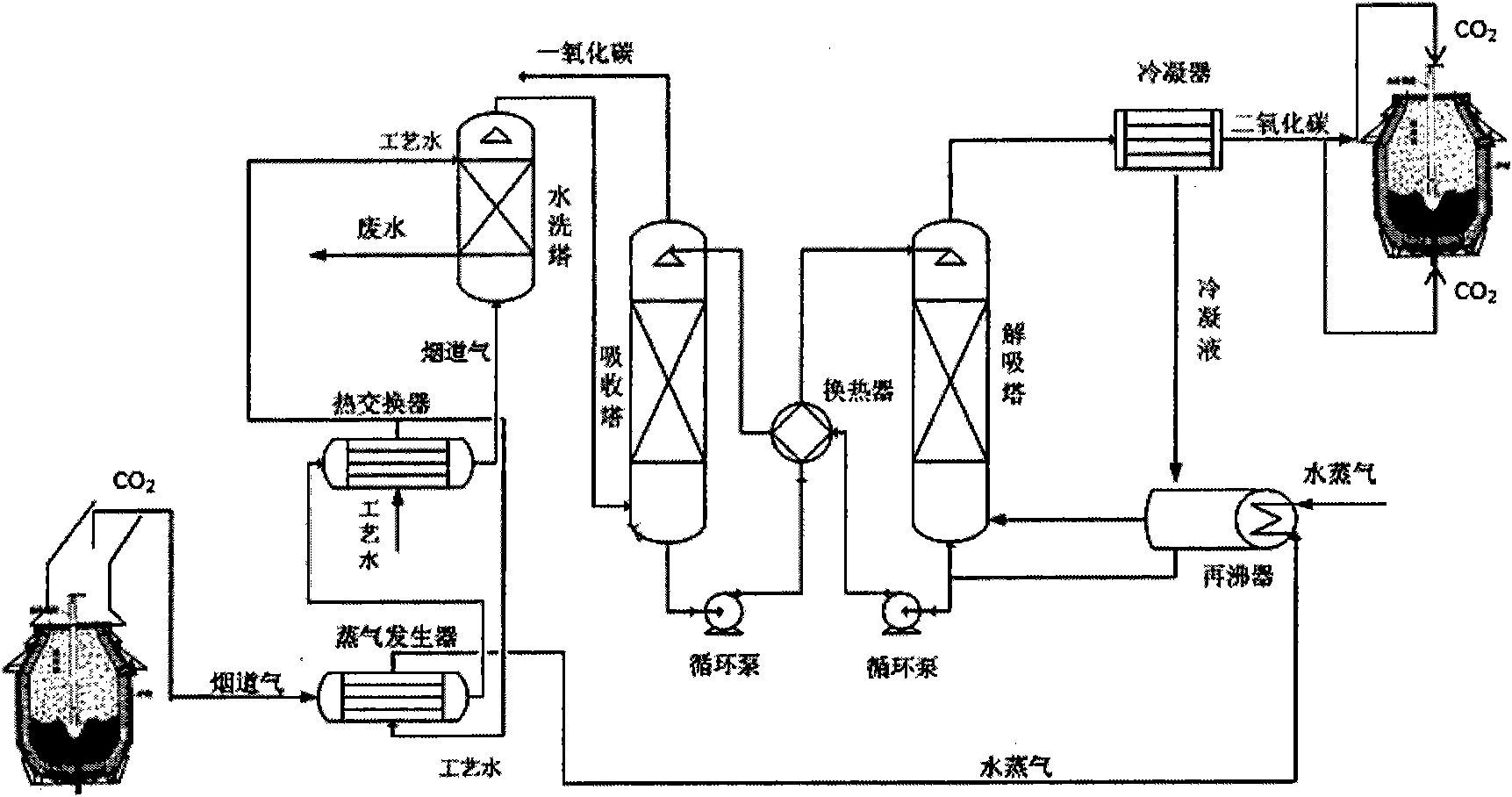

Image

Examples

Embodiment Construction

[0012] 1.100 tons converter smelting process:

[0013] Separation and Recovery of CO from Converter Gas Using Adsorption and Desorption Devices 2 gas, recovery of CO 2 The flow rate is 2000~4500m 3 / h, using this CO 2 As a source of reblowing air. The average concentration of CO in converter gas is 65-85%.

[0014] Early stage of smelting: using higher concentration CO 2 The injection volume controls the early temperature and promotes the dephosphorization reaction. Top blown CO 2 -O 2 CO in the mixed gas 2 Concentration is 10%, O 2 The concentration is 90%, the top blowing mixed gas flow rate is 22000~24000m 3 / h, the pressure is 0.7~0.9MPa; the bottom blowing adopts CO 2 -N 2 Mixed injection, CO 2 Concentration is 50%, N 2 Concentration is 50%, bottom blowing flow rate is 180~300m 3 / h, the pressure is 0.4~0.7MPa, and the injection time is determined according to the slag in the furnace.

[0015] Middle stage of smelting: After the slag removal task is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com