Exhaust gas purification device for internal combustion engine

a technology of exhaust gas purification device and internal combustion engine, which is applied in the direction of exhaust treatment electric control, electrical control, machines/engines, etc., can solve the problems of engine oil dilution, difficult to evaporate injection fuel, and increase the rotation speed of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

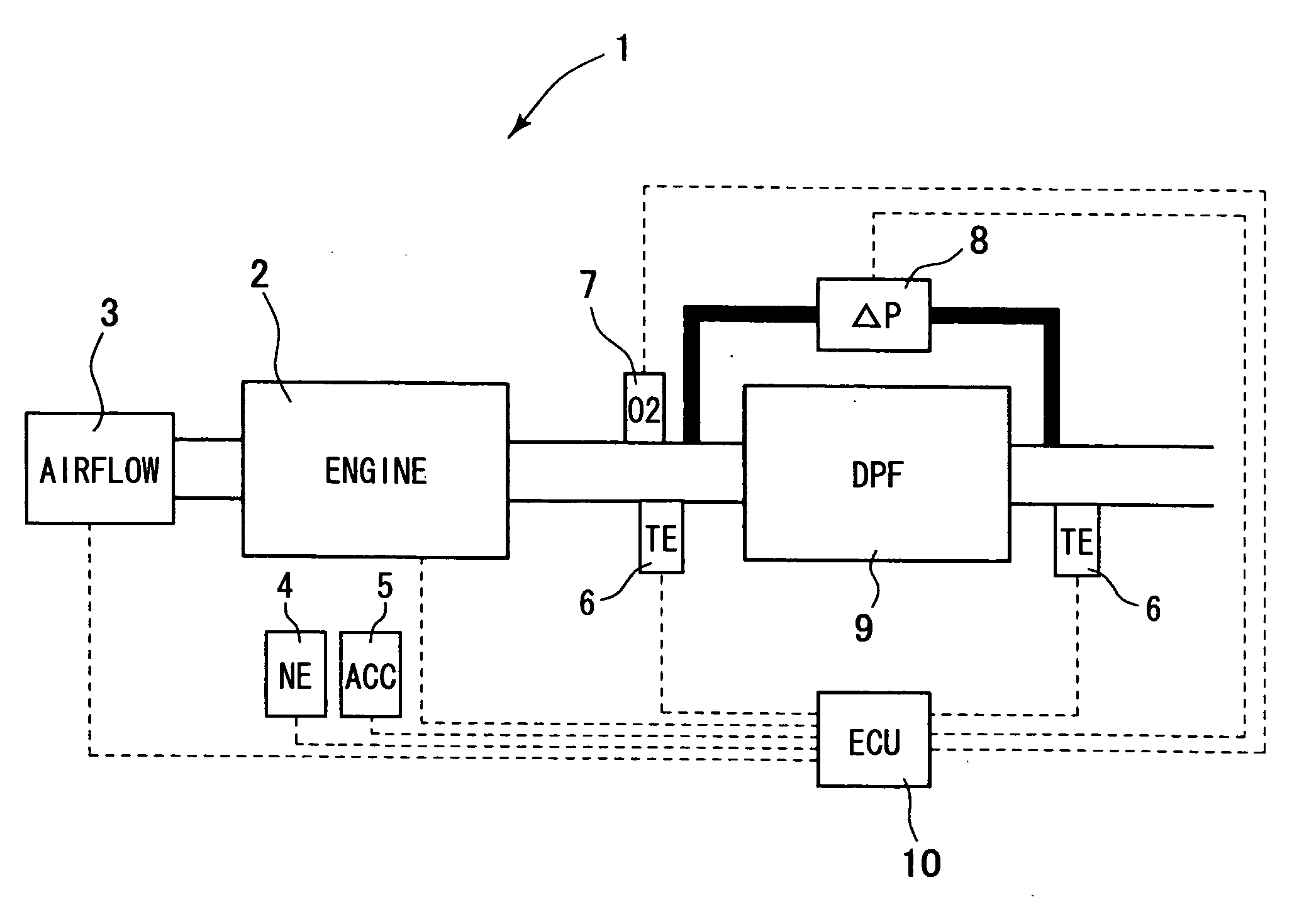

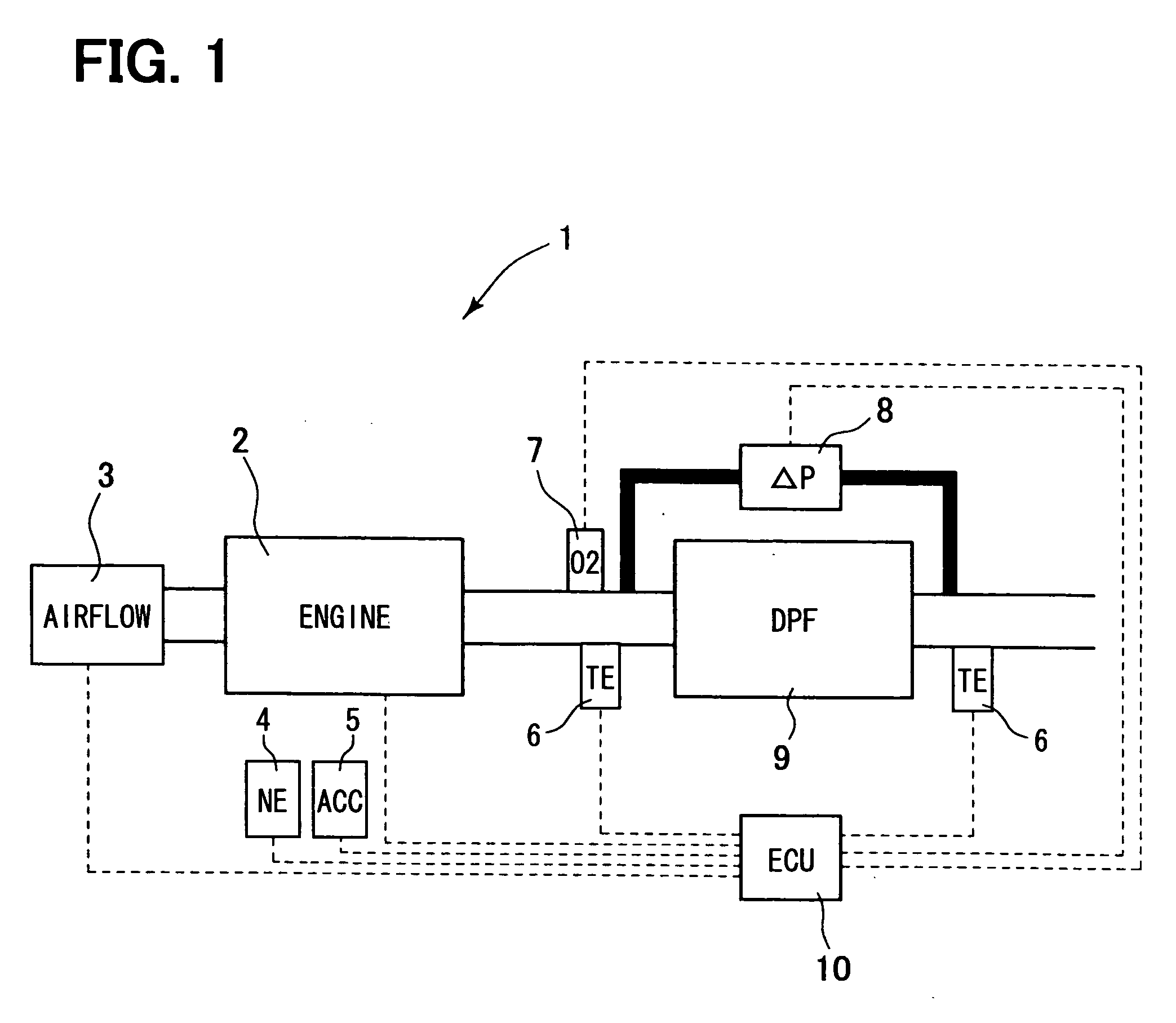

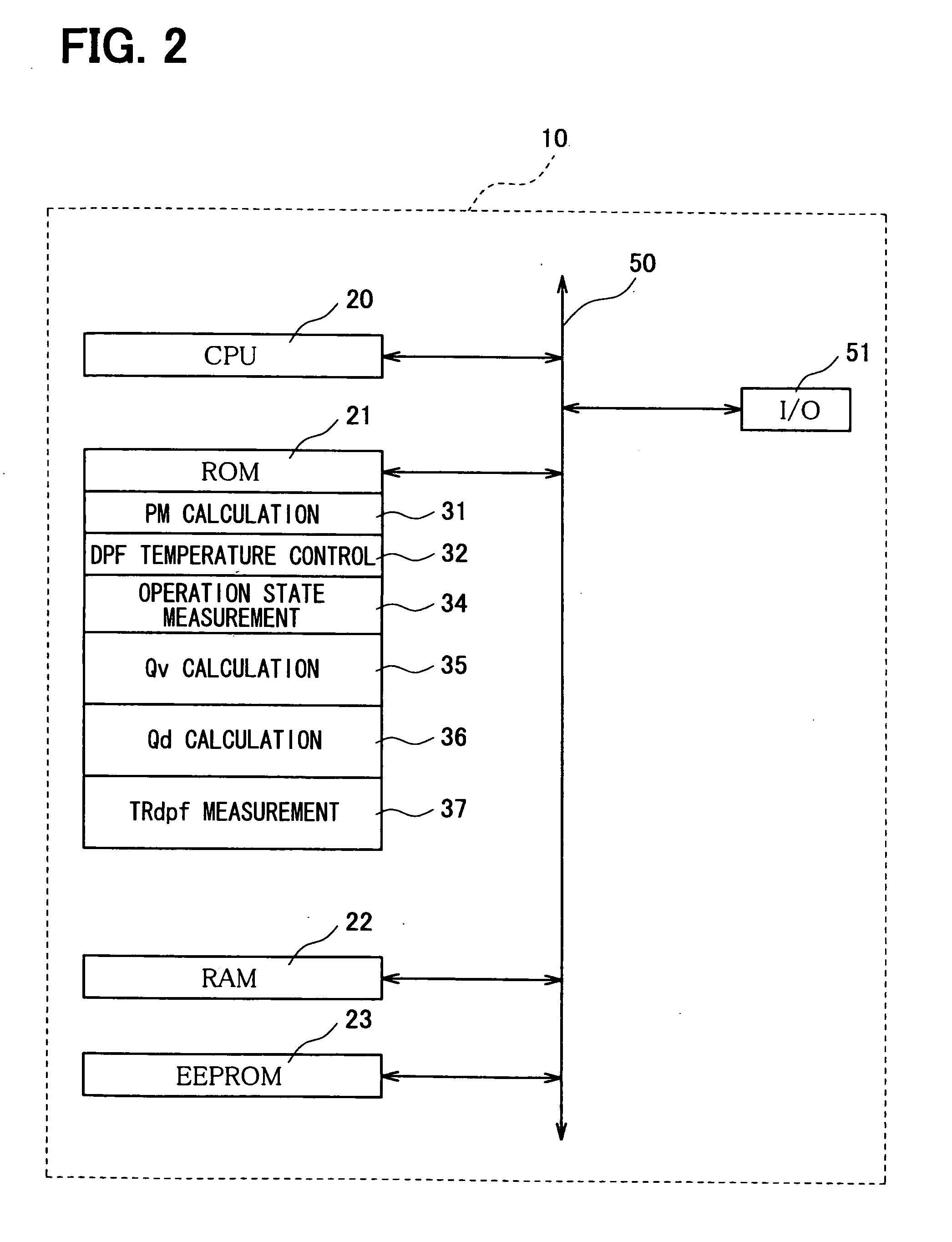

[0035]Now, a first embodiment of the present invention will be described with reference to drawings. FIG. 1 is a system diagram showing an exhaust gas purification device of an internal combustion engine 1 according to the present embodiment. A diesel engine 2 shown in FIG. 1 serves as a motor. An airflow meter 3 for measuring a flow rate of an air on an intake side of the diesel engine 2, an engine rotation sensor 4 for measuring rotation speed NE of the diesel engine 2, and an accelerator position sensor 5 for measuring a position ACC of an accelerator achieved by a driver are provided as sensors for determining a state of the diesel engine 2. The diesel engine 2 has an injector including a fuel injection valve for injecting fuel. The injector is electrically connected to an ECU 10 (engine control unit) as a control unit. The ECU 10 manages an opening degree and timing of the fuel injection valve of the injector for injecting the fuel. The airflow meter 3, the engine rotation sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com