Waste gas purification system

An exhaust gas purification system and exhaust channel technology, applied in exhaust treatment, electrical control, exhaust devices, etc., can solve the problems of easy natural ignition of fuel, etc., to eliminate engine flameout, prevent melting accidents, and suppress exhaust pressure the effect of rising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

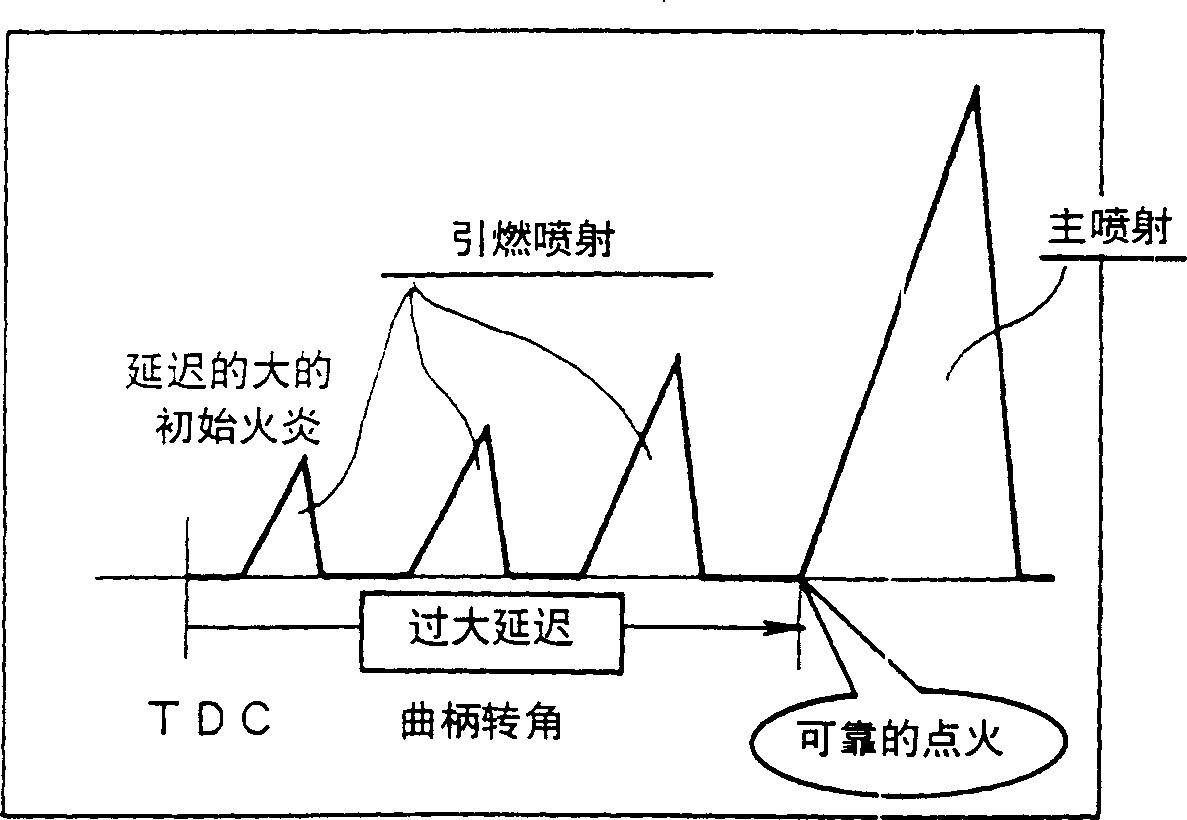

[0059] A multi-stage injection test accompanied by heating with a glow plug and a multi-stage injection test without heating with a glow plug were carried out below, and a comparative study was carried out. All the tests were three-stage multi-stage injection with pilot injection twice and main injection once.

[0060] As an example of exhaust gas temperature rise with multi-stage injection heated by the glow plug, in Figure 4 , shows the multi-stage injection in the case of heating with glow plugs at idling at an engine speed of 850 rpm. and, in Figure 5 A comparative example of exhaust gas temperature rise without concomitant heating with glow plugs is shown in .

[0061] according to Figure 4 with Figure 5 , it can be seen that the exhaust gas temperature immediately after starting, that is, the exhaust gas temperature at the turbine inlet, is greatly increased to about 500°C in the embodiment compared with about 300°C in the comparative example, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com