Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Fully spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water soluble fertilizer containing high-concentration humic acid and preparation method thereof

ActiveCN103408373AImprove buffering effectReduce heavy metal contentFertilizer mixturesDipotassium hydrogen phosphateHigh concentration

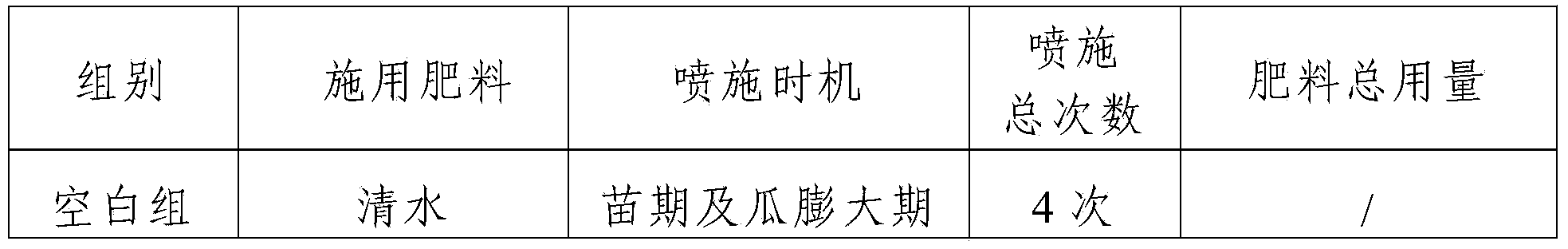

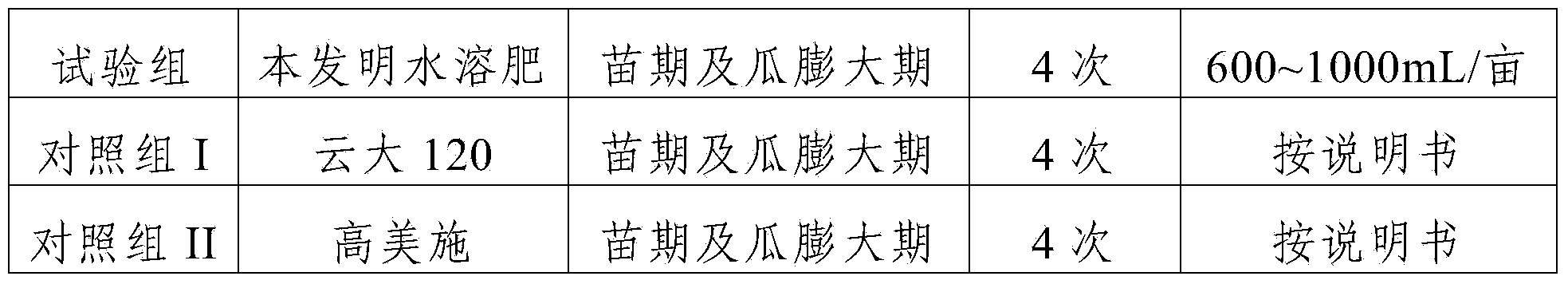

The invention provides a water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer comprises, by weight, 15-25 parts of a water soluble humic acid salt, 18-25 parts of urea, 9-15 parts of dipotassium hydrogen phosphate, 8-13 parts of potassium acetate, 0.5-2 parts of borax, 0.1-10 parts of polyglutamic acid, 1-5 parts of rhamnolipid, 5-10 parts of a hydroxymethyl cellulose aqueous solution and 30-40 parts of water. The water soluble fertilizer has humic acid content greater than or equal to 150g / L. The invention also provides a preparation method of the water soluble fertilizer containing high-concentration humic acid. The preparation method comprises the following steps of 1, carrying out heating stirring of the water soluble humic acid salt and water to obtain a humic acid salt solution, 2, adding dipotassium hydrogen phosphate, potassium acetate, borax, polyglutamic acid, rhamnolipid and urea into the humic acid salt solution, and carrying out heating stirring to obtain a mixed solution, and 3, carrying out emulsification of the hydroxymethyl cellulose aqueous solution and the mixed solution to obtain the water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer has obvious fertilizer efficiency, is environmentally friendly, stable and uniform and has a wide application range.

Owner:陕西鼎天济农腐殖酸制品有限公司

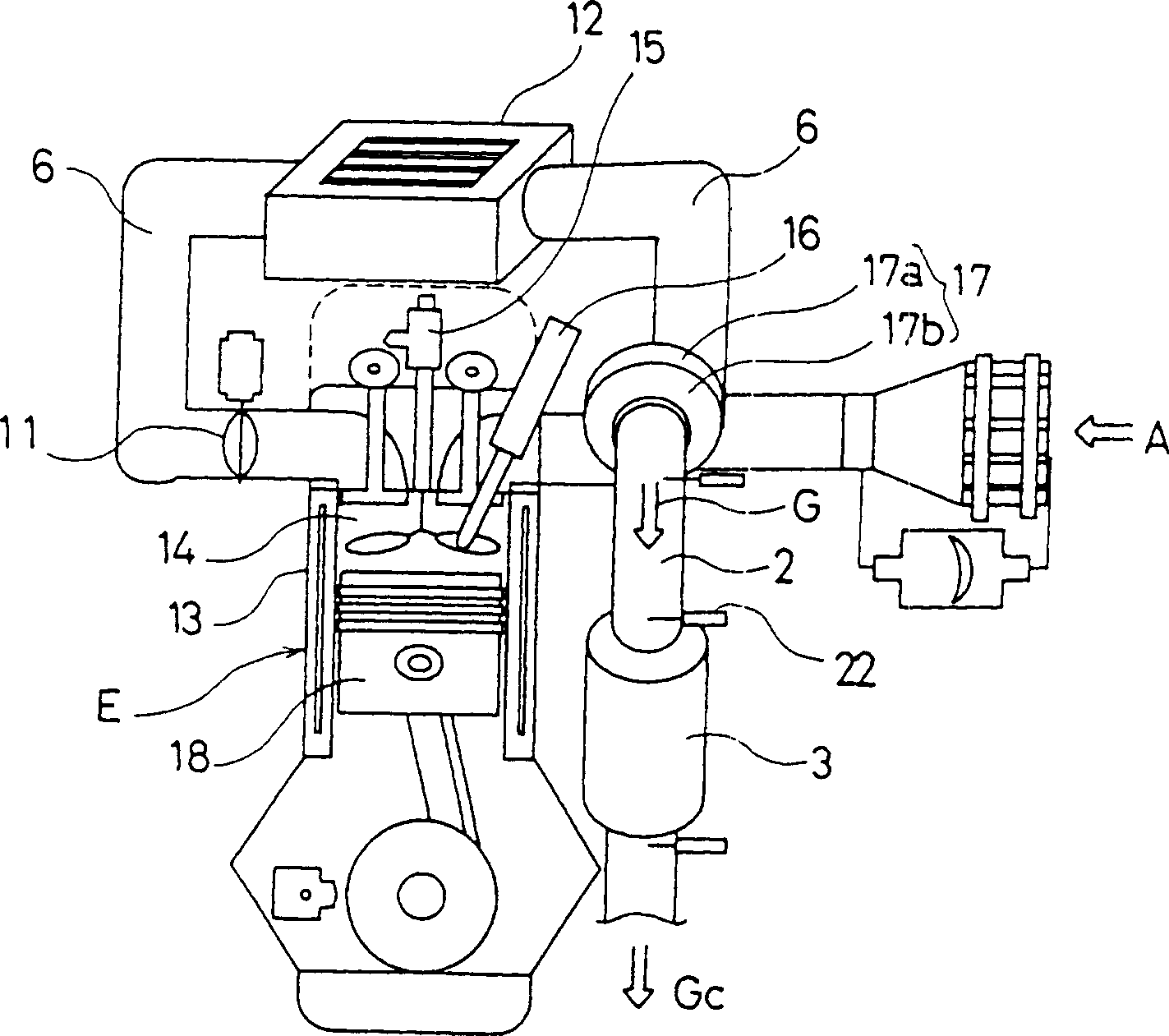

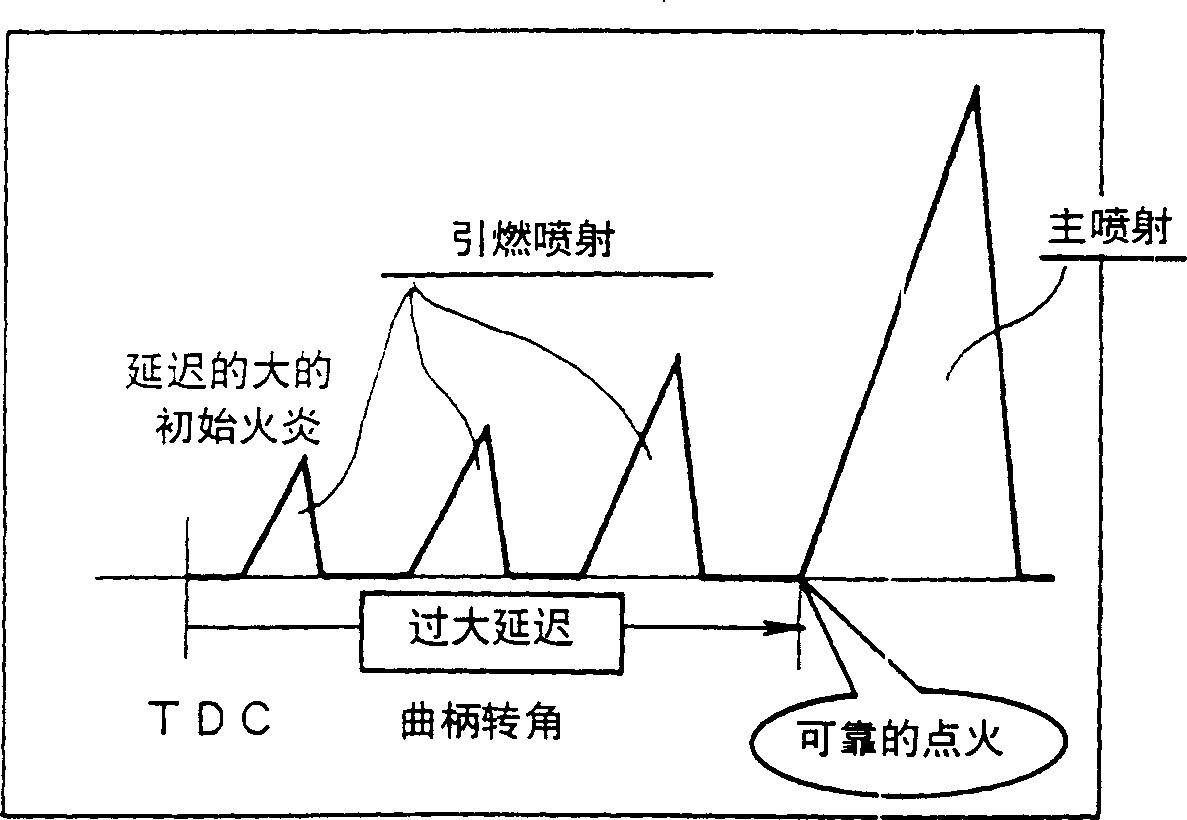

Waste gas purification system

InactiveCN1517526ALarge injection volumeDoes not affect the productionElectrical controlInternal combustion piston enginesExhaust fumesEngineering

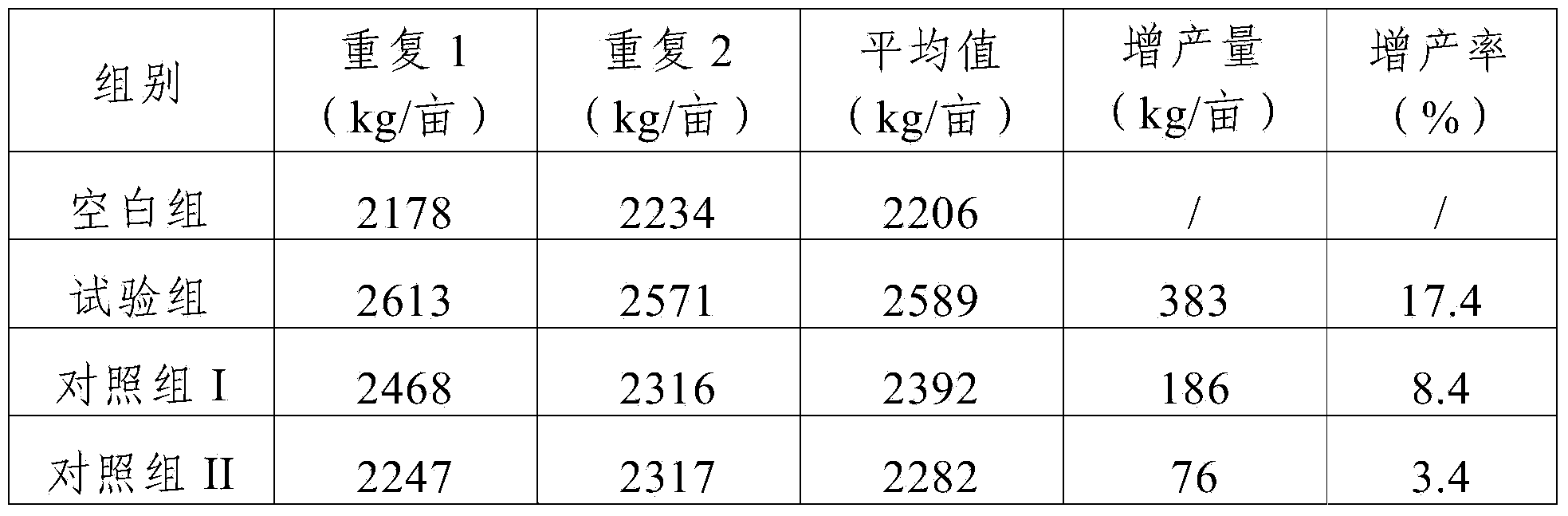

An exhaust gas purifying system (1) aving a continuous regeneration DPF (3) installed in the exhaust passage (2) of a diesel engine (E) provided with a glow plug (16) and a regeneration control means for regenerating the continuous regeneration DPF (3), is constituted so that the regeneration control means performs retarded injection or post-injection in the control of fuel injection into a cylinder (13) and heating the inside of the cylinder (13) by the glow plug (16) for regenerating the continuous regeneration DPF (3). Thereby, when raising the temperature of exhaust gas in the regeneration of the continuous regeneration DPF (3), it is possible to prevent the generation of white fumes and misfire and to raise the exhaust gas temperature efficiently and substantially. Therefore, it is possible to prevent the temperature of a catalyst and a DPF from being abnormal high and to prevent the deterioration and the melt down of the catalyst.

Owner:ISUZU MOTORS LTD

Presoaking silver brazing method between diamond laminate sheet and carbon steel

InactiveCN101049647AImprove welding qualitySolve the problem of easy "off-chip"Soldering apparatusHeat treatment process controlAlloyPre treatment

A method for welding the composite diamond plate with carbon steel by use of pre-impregnation and Ag solder includes such steps as cleaning their surfaces to be welded, adding the chosen Ag solder and flux to the surface of hard alloy used as the substrate of composite diamond plate, heat treating at 650-700 deg.C for 5-10 s for impregnation and diffusion, adding the Ag solder to the surface of carbon steel, heat treating at 650-700 deg.C for 5-10 s, adding Ag solder and flux to the position between said composite diamond plate and carbon steel, and welding by oxyacetylene flame of HF induction.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

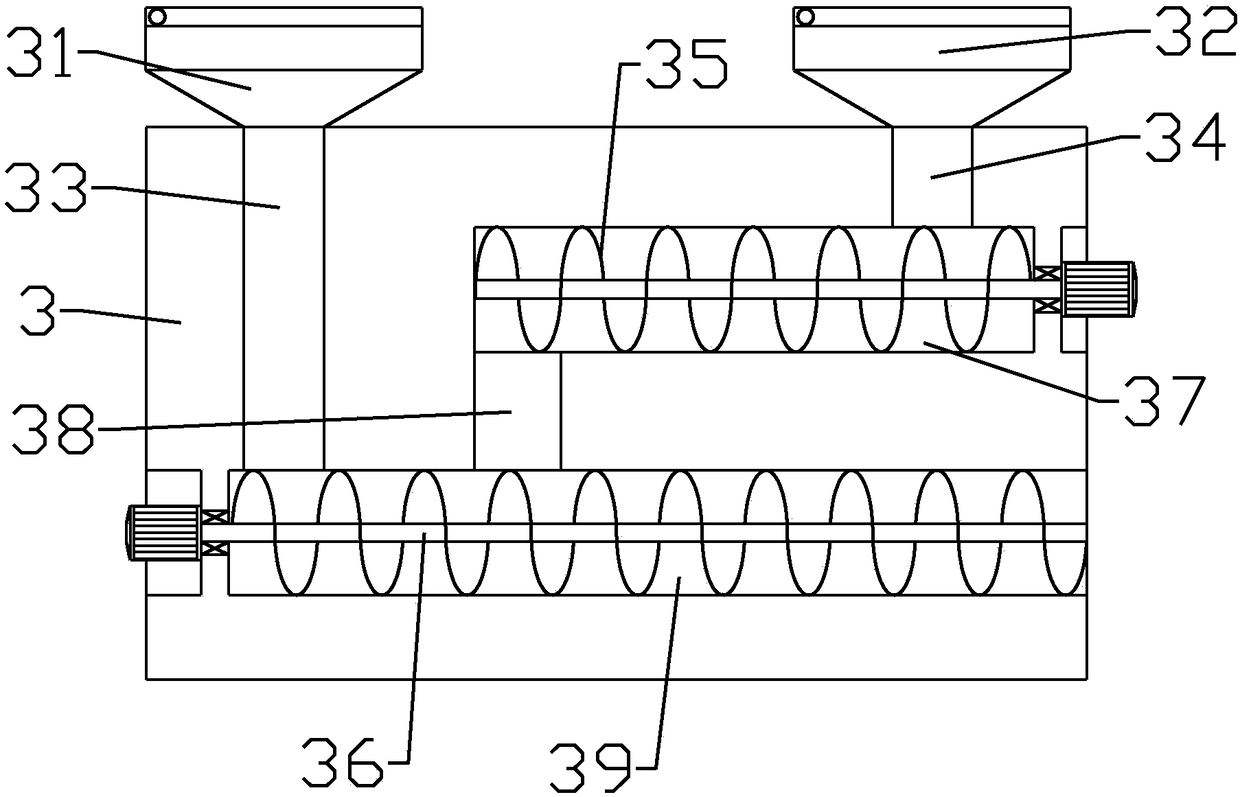

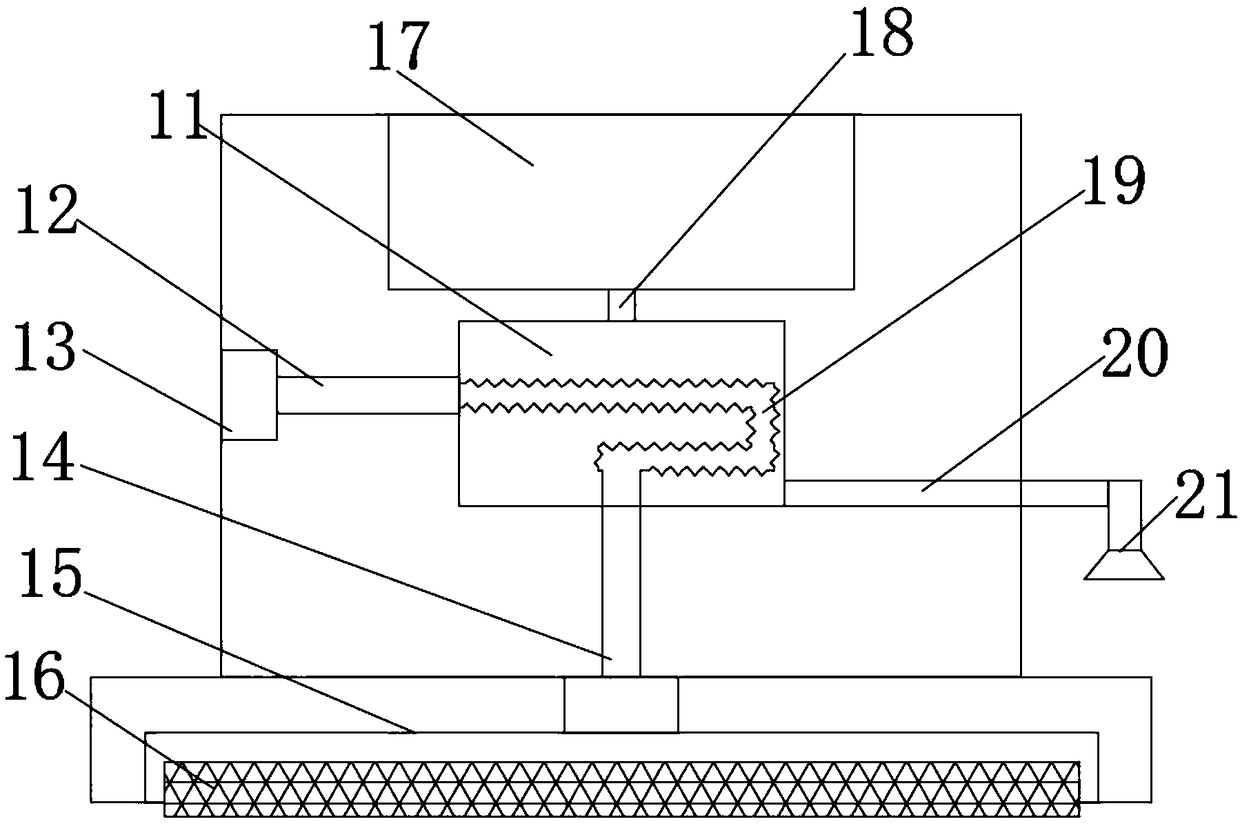

Feed scattering device for breeding industry laying hen feeding

InactiveCN108401943AFully spreadHelp farmingTransportation and packagingRotary stirring mixersEngineeringMechanical engineering

The invention discloses a feed scattering device for breeding industry laying hen feeding. The device comprises a base plate, a mixing box, a discharging box and a rotating box. A fixing base is fixedly installed on the upper surface of the middle of the base plate, the top of the fixing base is fixedly provided with a rotating motor for driving the rotating box to rotate, the side edge of the rotating box is communicated with a plurality of arc shunts arranged circumferentially, a supporting stand column is fixedly welded to the upper surface of the left end of the base plate, a mixing box fixing frame is arranged at the top end of the supporting stand column, a first feed conveying cavity and a second feed conveying cavity are formed inside the mixing box separately, the left end of thefirst feed conveying cavity is communicated with the middle of the second feed conveying cavity through a communicating pipe, and a discharging outlet in the bottom end of the discharging pipe is formed in an inner cavity of the rotating box. The device is simple and reasonable in structure, laying hen feed can be sufficiently mixed, laying hen feed can be conveniently and uniformly scattered, discharging is controllable, the laying he feed breeding effect is effectively improved, and the device is suitable for being used and popularized.

Owner:何锦国

Method for preparing lithium titanate cathode size

The invention relates to a method for preparing lithium titanate cathode size, belonging to the battery preparation method field. The method is characterized in that the lithium titanate cathode sizedis added with oxalic acid, wherein 1-6% of oxalic acid is added by taking the total weight of the cathode size as 100%. The method for adding oxalic acid includes: oxalic acid and lithium titanate are mixed in dry, fully mixed to be uniform and then added with other materials to be made into the lithium titanate cathode size; or materials except oxalic acid is firstly mixed into size, and then oxalic acid is added into the size and fully mixed to be uniform, so as to obtain the lithium titanate cathode size. The invention provides a method for preparing lithium titanate cathode size with highadhesive force with afflux surface and good bonding effect, thus being capable of effectively improving electrochemical performances of battery with lithium titanate as cathode such as capacity, cycle performance and the like.

Owner:SHENZHEN BAK BATTERY CO LTD

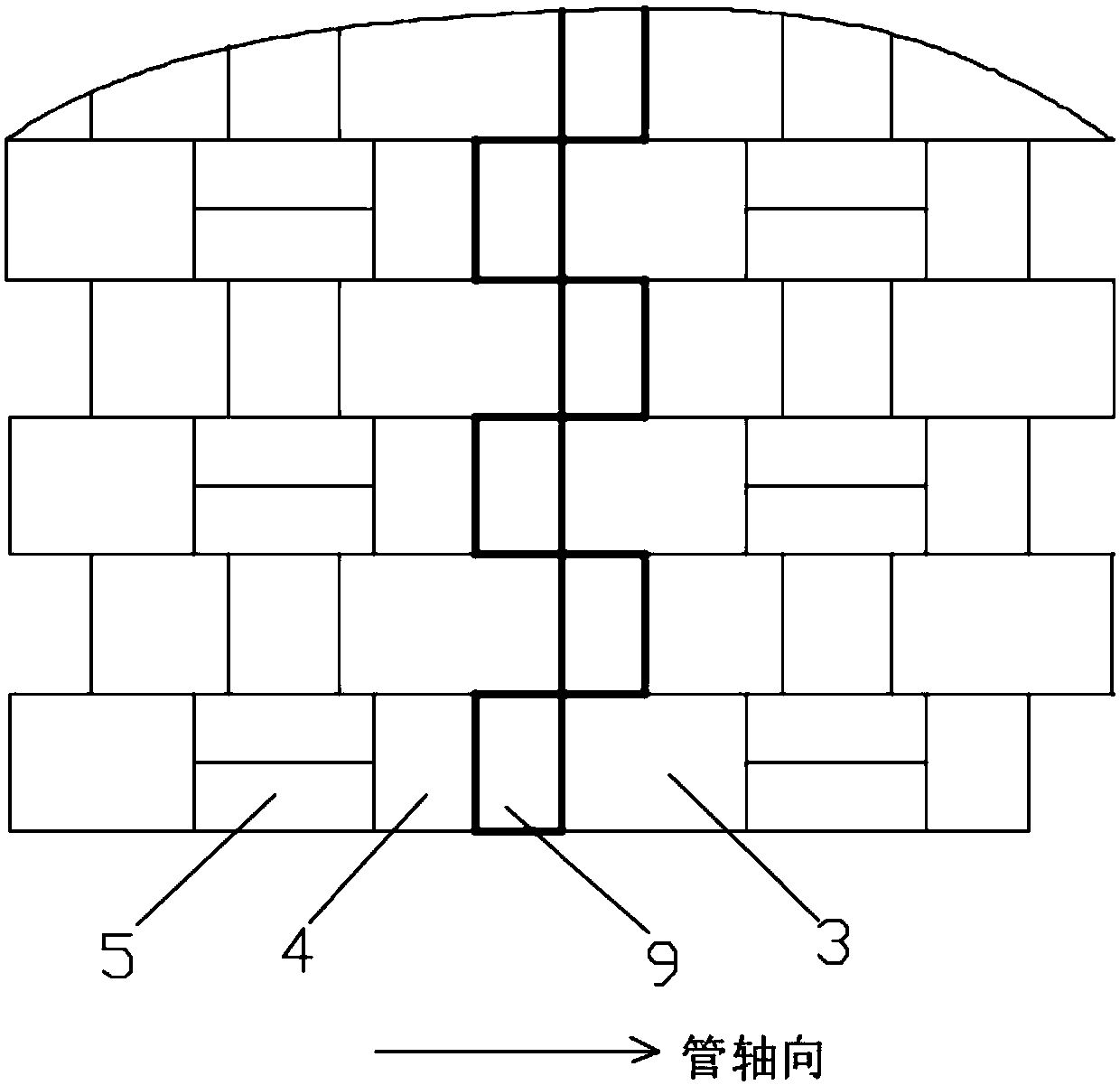

Internal and external finned tube inside evaporating and condensing dual-use ladder-shaped grid

PendingCN107782192AIncrease contact areaImprove evaporation performanceEvaporators/condensersTubular elementsEngineeringDistribution grid

The invention relates to an internal and external finned tube inside an evaporating and condensing dual-use ladder-shaped grid. The internal and external finned tube comprises a pipe base body, spiraljagged inner fins, spiral jagged outer fins, inter-groove double wedges, grid fins, ladder fins and triangular top teeth. The grid fins are located on both sides of the spiral jagged outer fins, thegrid fins on the two sides of the same spiral jagged outer fins are staggered, the ladder fins are located on both sides of the spiral jagged outer fins and on the outside of the grid fins, the ladderfins on the two sides of the same spiral jagged outer fins are staggered, the ladder fins on the same side are interleaved with the grid fins, the inner side of the grid fins, the spiral jagged outerfins, the pipe base body, and the inter-groove double wedges enclose an evaporation chamber, the outer side of the grid fins, the spiral jagged outer fins, and the ladder fins enclose an enhanced cavity, the evaporation chamber and the enhanced cavity communicate with each other through gaps. The internal and external finned tube can improve heat transfer efficiency of evaporation and condensation and belongs to the technical field of enhanced heat transfer tubes.

Owner:SOUTH CHINA UNIV OF TECH

Glass erosion liquid and preparation method thereof

The invention relates to a vitreous etching bath, which comprises 0.5%-8% microcosmic salt, 0.5%-8% pyrophosphate, 0.01%-0.5% inorganic alkaline, 5%-45% surface activator and 39%-93% water. The preparing method comprises the following steps: adding the microcosmic salt and the pyrophosphate in the water, heating in order to dissolve; adding inorganic alkaline and non-ionic surface activator and mixing. The invention can remove greasy dirt, fingerprint, particles and sio2 for buffed glass base plate, which can removes the impurity and Ceo2 on the glass, achieves the request of the environmental protection.

Owner:天津晶岭电子材料科技有限公司

Tissue box unit

A tissue box unit comprises a tissue box, an automatic toothpick box and an automatic chopstick box. The automatic toothpick box is parallelly connected with the automatic chopstick box. Both covers of the boxes are provided with wedged slots and connected with the rectangular advertisement tissue box. A cover of the advertisement tissue box is provided with an oval hollow, the bottom of the tissue box is provided with a wedged convex slot, and the tissue box is externally connected with an L-shaped box provided with an advertisement carrier. According to the arrangement, the chopstick box and the toothpick box are arranged under the tissue box, which is convenient for the customers to use without forward-backward moving, besides, space of the dinning table is saved, and wide promotion is achieved; an advertisement display device is arranged on the tissue box, allowing the customers to read the advertisements while waiting for dinner, in this way, advertisement is spread during off hours of customers, leading to obvious effect.

Owner:QINGDAO GREAT CONSTR INSTALLATION ENG

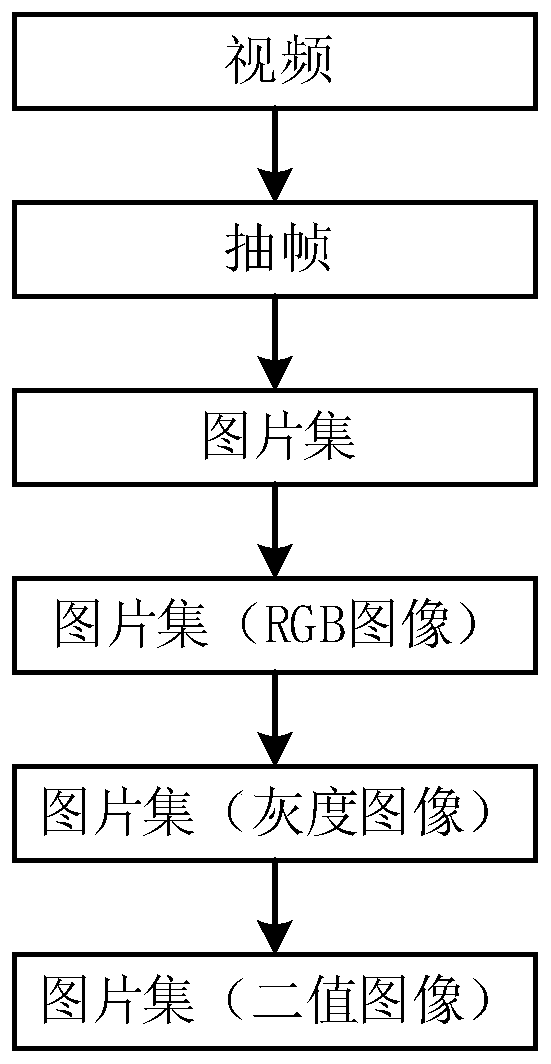

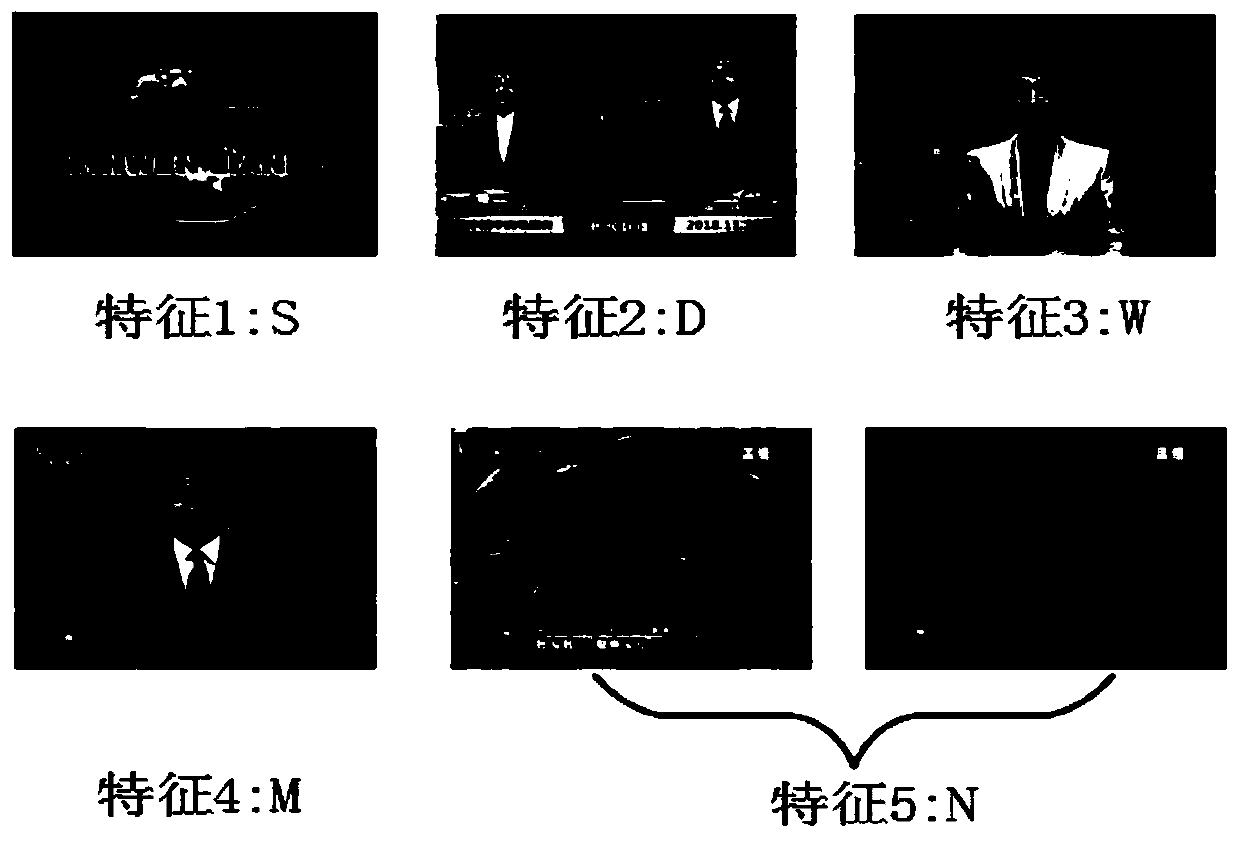

News video self-adaptive splitting method based on dynamic semantic features

InactiveCN110610500AFacilitates structured processingHigh splitting accuracyImage analysisDigital data information retrievalPattern recognitionKey frame

The invention provides a news video self-adaptive splitting method based on dynamic semantic features, which comprises the following steps: selecting a studio scene and a host as splitting features soas to search splitting time points of news content entries; the method specifically comprises the following steps: step 1, video frame extraction preprocessing; step 2, training a NewlicNet model; 3,determining a key frame picture time point; and 4, splitting the news video. The invention discloses a news video self-adaptive splitting method based on dynamic semantic features. News videos are split based on channel identifiers, studio scene information and host co-existing features.

Owner:BEIJING INFORMATION SCI & TECH UNIV

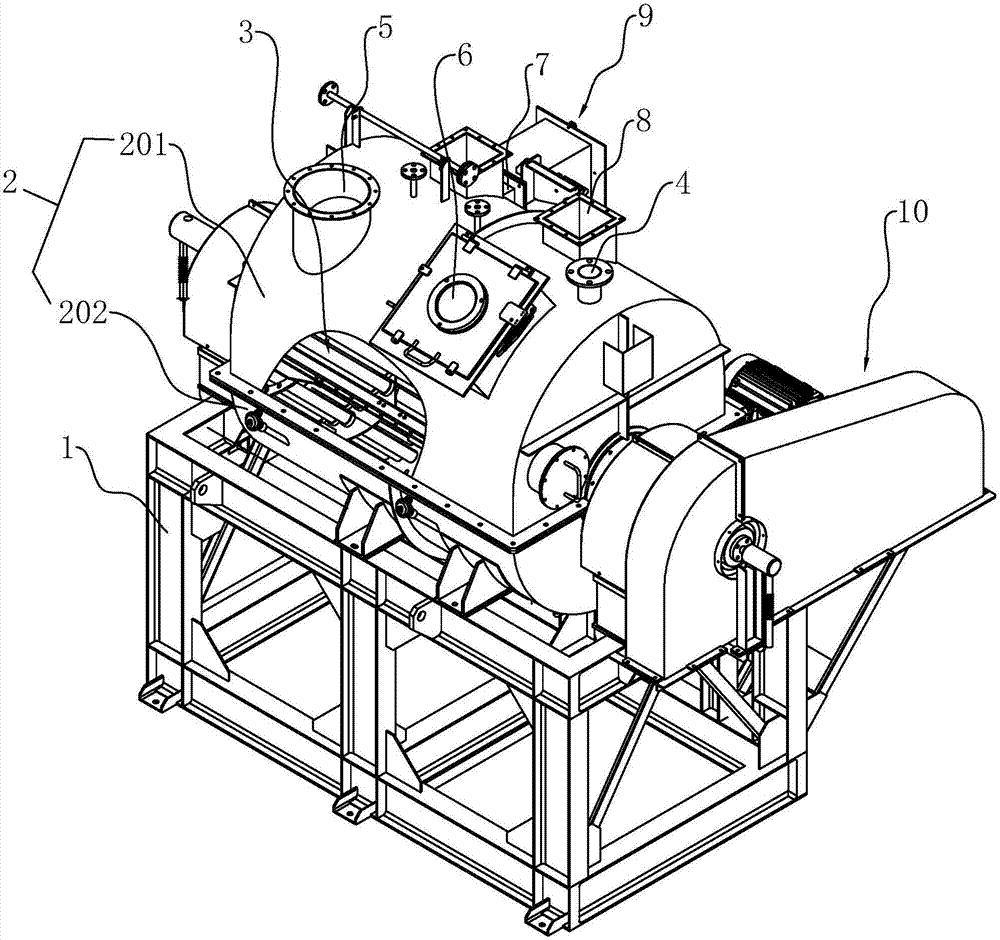

Steam-type sludge drying machine

InactiveCN107382014AAvoid accessEmission reductionSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a steam-type sludge drying machine, and belongs to the technical field of the sludge drying. The steam-type sludge drying machine comprises a machine frame, a driving device, a fixing cylinder and a heating component. The fixing cylinder is provided with a feeding port and a discharging port. The feeding port and the discharging port are provided with a feeding device and a discharging device. The heating component comprises a hollow shaft, a heat exchange pipe and a linkage component. Steam of which the temperature is 100 DEG C at least is conveyed in the hollow shaft. The driving device comprises a main motor, a reducer and a chain wheel mechanism. The feeding device comprises a first spiral conveying mechanism and a second spiral conveying mechanism. The discharging device comprises a discharging frame, a sealing door, a baffle and a driving mechanism. A plurality of lifting plates for lifting sludge is detachably fixed around the heating component. The steam-type sludge drying machine has the characteristics of high automation degree, energy conservation and emission reduction, good sludge drying effect and high sludge drying efficiency.

Owner:SHANGHAI TONGHUA STAINLESS STEEL PRESSURE VESSEL ENG

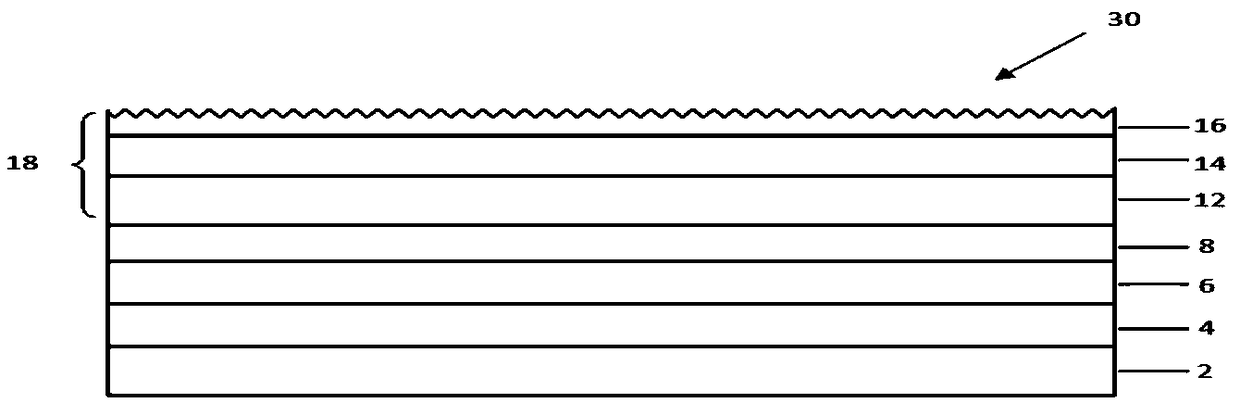

Preparation method of lithium ion battery and lithium ion battery

ActiveCN108039449AImprove adhesionFully spreadElectrode manufacturing processesFinal product manufactureElectrical batteryCyclodextrin

The invention discloses a preparation method of a lithium ion battery and the lithium ion battery and relates to the technical filed of lithium ion batteries. The preparation method of the lithium ionbattery comprises the following steps: pre-treatment of positive and negative current collectors, preparation of positive and negative pole pieces and assembly of batteries; the positive and negativecurrent collectors are wiped with an oxalic acid solution firstly and are then wiped with a potassium permanganate solution; the positive pole piece is coated with graphene-cyclodextrin cross-linkedpolymer slurry firstly and is then coated with positive material slurry, the coating surface density is 75-85 mg / cm<2>, and a positive active material occupies 98-99 percent of a positive material andcomprises 10-30 percent of lithium cobaltate, 10-30 percent of lithium nickelate, 50-70 percent of LiMnxFe(1-x)PO4 (x is more than 0.5 but less than 1). The preparation method of the lithium ion battery and the lithium ion battery, disclosed by the invention, have the benefits that the problem that the current battery energy density and the safety cannot be considered is solved; the lithium ion battery obtained by the preparation method disclosed by the invention not only is high in energy density, but also is good in safety.

Owner:福建荣华科技有限公司

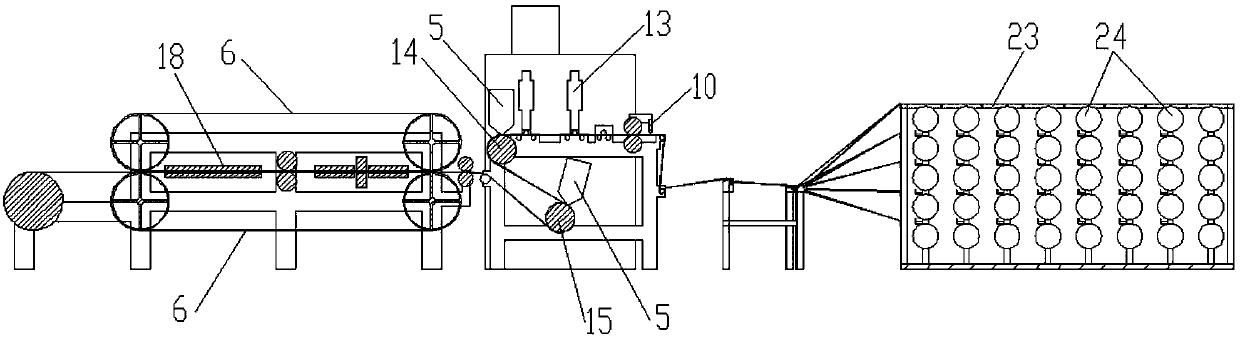

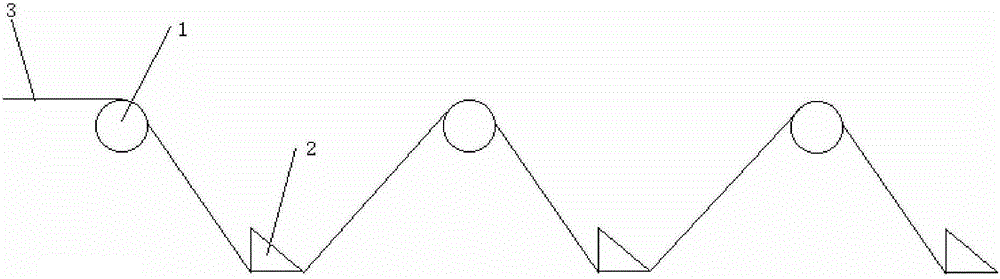

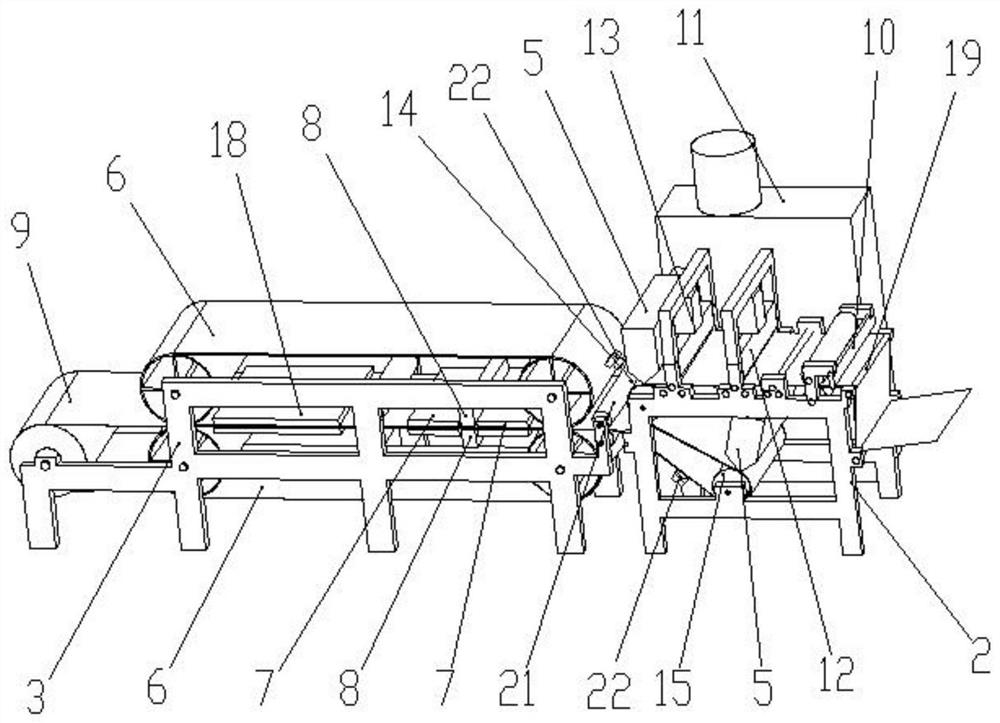

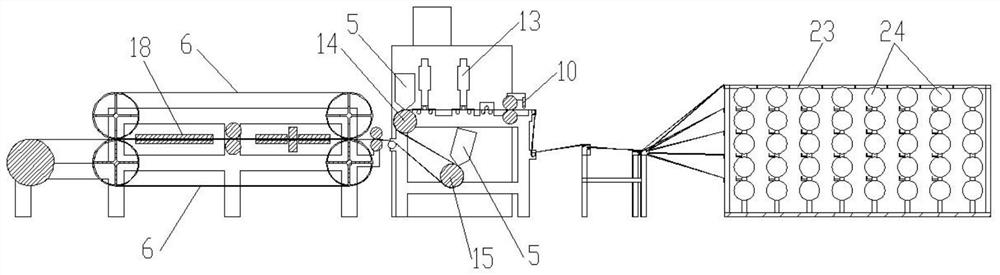

Thermoplastic casting vibration infiltration pre-impregnation machine for fiber

The invention discloses a thermoplastic casting vibration infiltration pre-impregnation machine for fibers. The pre-impregnation machine comprises a first machine frame, a second machine frame, a third machine frame, a feeding device, a driving mechanism, a preprocessing mechanism, a vibration yarn spreading mechanism, two casting heads, two pairs of steel belt sets, at least one set of heating assemblies, a pair of vibration generators and a containing device, wherein the first machine frame, the second machine frame and the third machine frame are arranged from back to front in sequence, thefeeding device is arranged on the rear side of the first machine frame and contains a material, the vibration yarn spreading mechanism carries out yarn spreading treatment on the material, the two casting heads carry out preliminary infiltration and yarn fixing treatment on the upper surface and the lower surface of the material, the two pairs of steel belt sets are arranged on the upper side andthe lower side of the materials in mirror symmetry and jointly extrude the upper surface and the lower surface of the material and drive the material to move forward, the heating assemblies are arranged in vertical mirror symmetry, are distributed on the upper surface and the lower surface of the material and carry out heating treatment on the material, the vibration generators are arranged on the upper side and the lower side of the material in mirror symmetry and are used for breaking molecular chains of the material, and the containing device is used for containing the processed material.According to the technical scheme of the pre-impregnation machine, the precision of a thermoplastic prepreg is high, the working efficiency is high, and fiber woven fabric and various unidirectional fibers can be impregnated.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

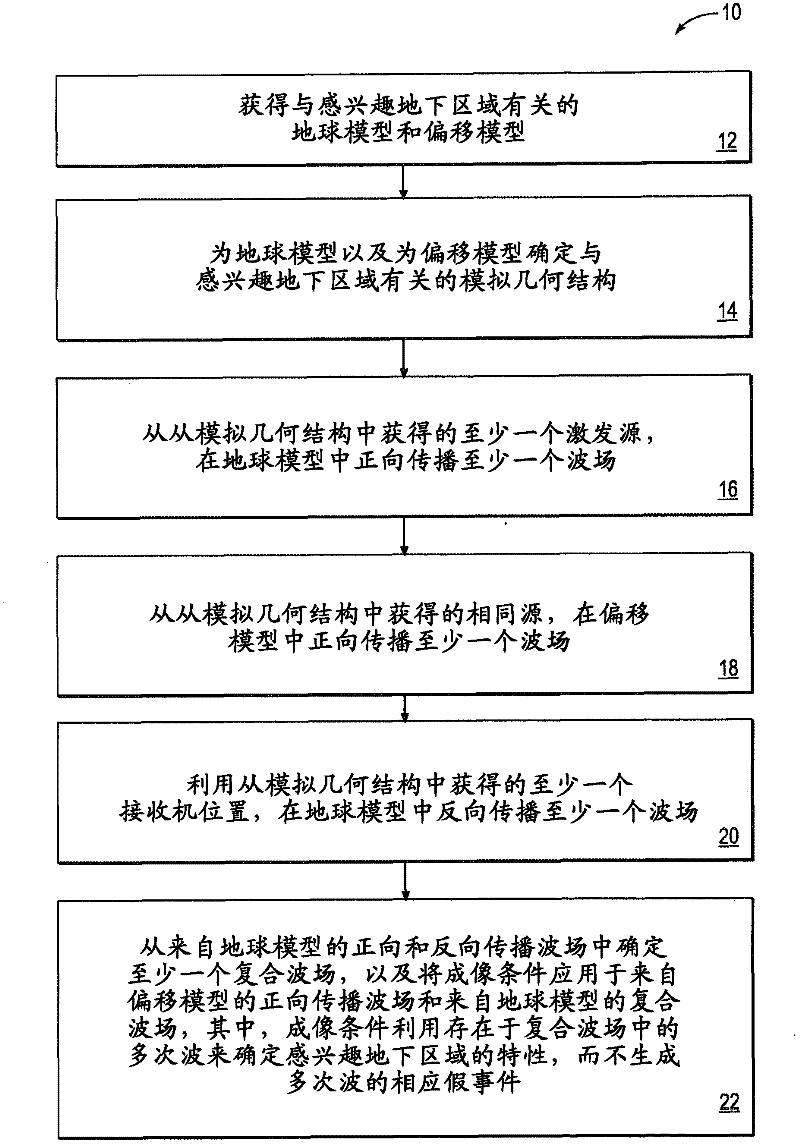

Method for wavefield-based data processing including utilizing multiples to determine subsurface characteristics of a subsurface region

InactiveCN102414581AAvoid artifactsFully spreadSeismic signal processing3D modellingReverse timeImaging quality

Owner:CHEVROU USA INC

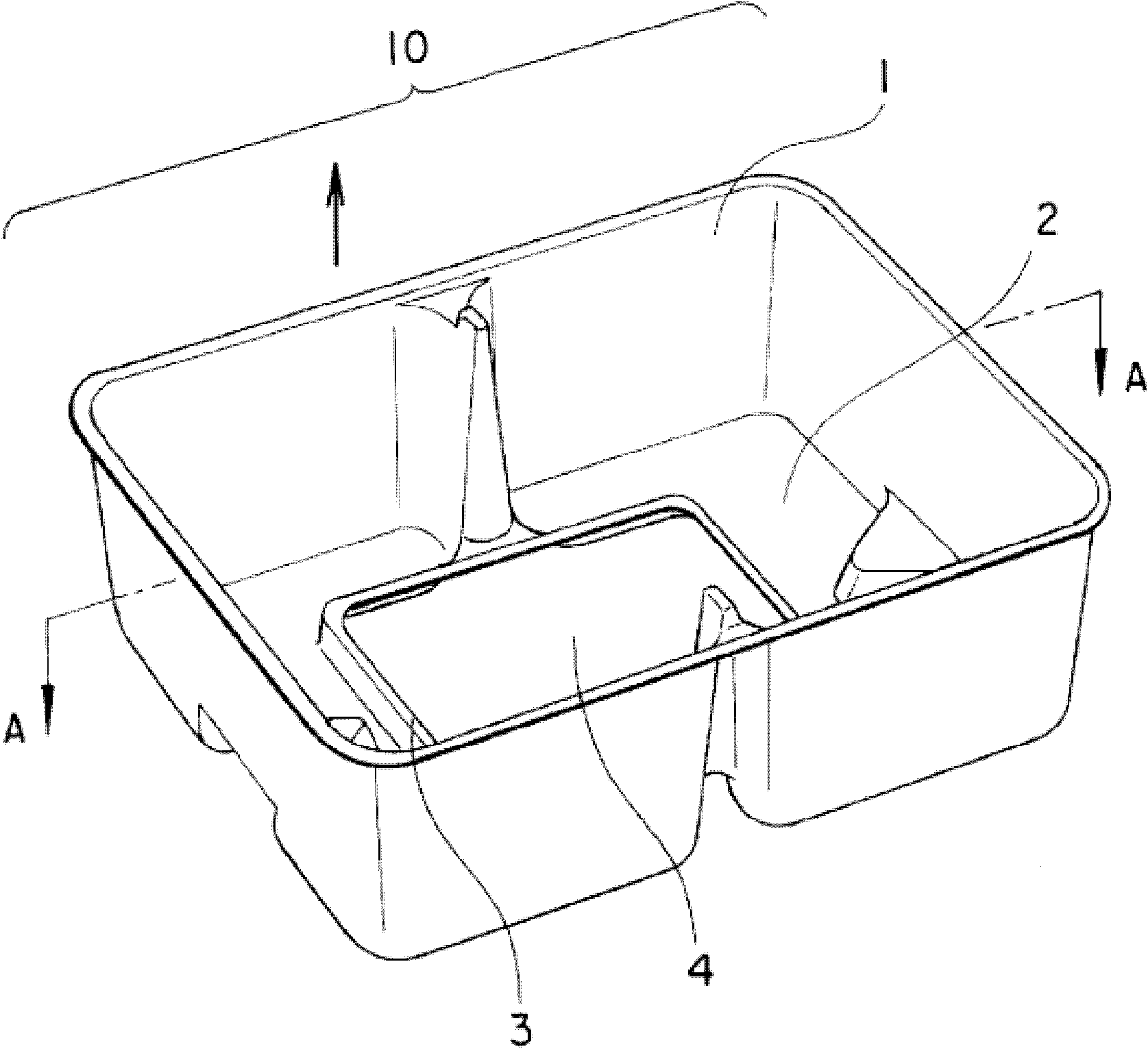

Wet sheet pillow package

ActiveCN102119109ASpeed up removalImprove stabilityBathroom accessoriesFlat article dispensingMechanical engineering

Provided is a wet sheet pillow package wherein a tray that individually arranges and contains individually-folded wet sheets is pillow-packaged, an opening that serves as a wet sheet removal opening is provided in the approximate center of the bottom of the tray, the opening is located on the flat part of the side opposite the butt seam of the pillow package, and a wet sheet removal opening is provided in said flat part. The wet sheet pillow package can adequately impregnate wet sheets economically using the minimum required amount of impregnating solution.

Owner:中村宪司 +1

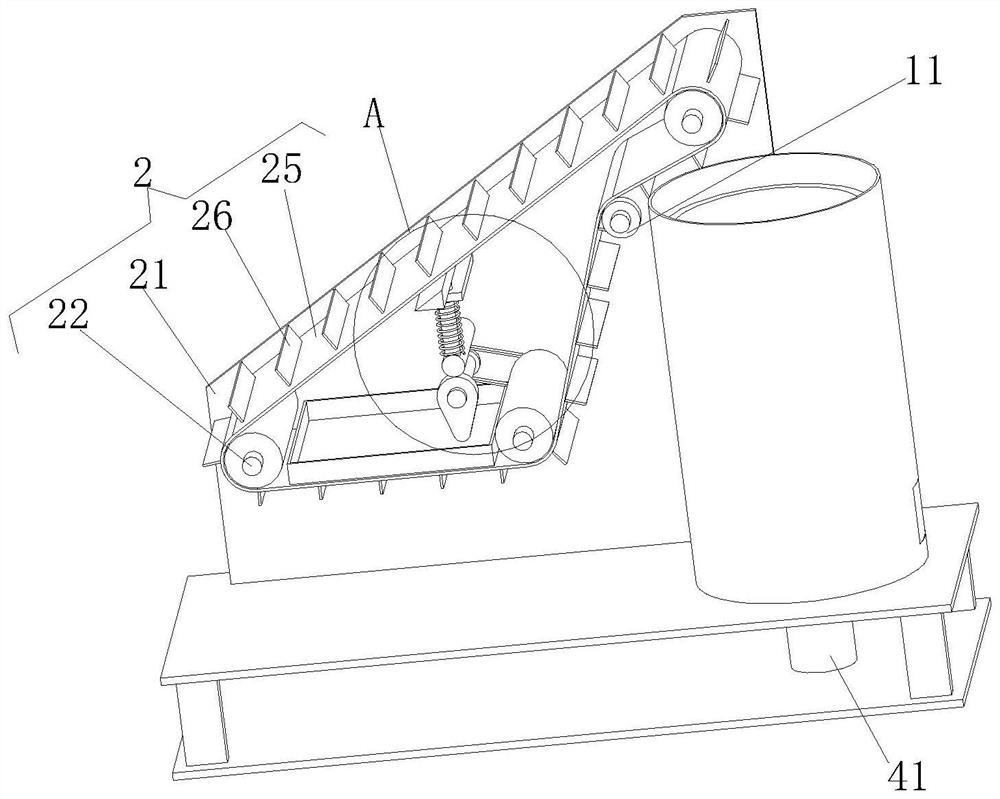

Lime powder preparation and processing treatment process

The invention relates to a lime powder preparation and processing treatment process, and calcining and crushing equipment is used. The calcining and crushing equipment comprises a supporting seat, a conveying device, a preheater and a material spreading device. The conveying device is used, a conveying motor is started, the conveying motor is started to drive a conveying shaft to rotate, the conveying shaft rotates to drive a conveying roller to rotate, the conveying roller rotates to drive a conveying belt to rotate so as to convey limestone, and light powder slag in the limestone on the conveying belt can be shaken and sieved to fall into a collecting box. The material spreading device is adopted, a material spreading motor is started, the output end of the material spreading motor drives a screw rotating rod to rotate repeatedly in the forward direction and the reverse direction, and the limestone can be spread and shaken. Lis fully spread and rapidly crushed in the preheater, and light powder slag is screened when the limestone is conveyed through an arranged pouring hopper, so that the raw limestone uniformly falling on the spreading elastic plate is calcined and crushed more rapidly.

Owner:陈荣健

Cosmetic additive with permanent anti-acne function and preparation method thereof

InactiveCN101574311AImprove securityGood effect on acneCosmetic preparationsToilet preparationsSolubilityGranularity

The invention discloses a cosmetic additive with the permanent anti-acne function and a preparation method thereof. The method comprises: dissolving 40 to 60 mass portions of active substances into 20 to 30 mass portions of deionized water, adding 30 to 50 mass portions of film-forming substances into the mixture, uniformly stirring the mixture, adding the mixture into a uniform base fluid containing 8 to 20 mass portions of auxiliary substances and 40 to 60 mass portions of deionized water, uniformly dispersing the obtained product in a viscolizer, hermetically standing the obtained product for 24 to 36 hours at the temperature of between 20 and 30 DEG C, and filtering the obtained product to obtain clear filtrate; and drying and crushing the clear filtrate to obtain powder with the granularity of between 60 and 1,000 meshes. The prepared powdery cosmetic additive has good water solubility and large solubility, is convenient to use, has good anti-acne efficacy in anti-acne water, anti-acne gel and anti-acne cream, and has good combination effect, large use range and long service life, wherein the service life of the powdery cosmetic additive is 1 to 2 times longer than that of the conventional additive with the anti-acne function.

Owner:SOUTH CHINA UNIV OF TECH

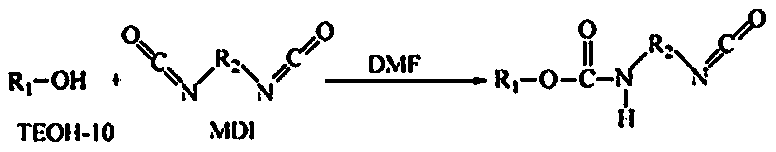

Preparation method of triazinyl fluorine-containing chain extender-modified polyurethane emulsion

ActiveCN110862508AFull coverage and protectionGood hydrophobicityPolyurea/polyurethane coatingsPrepolymerTriazine

The invention relates to the technical field of polyurethane coating layers, and in particular, relates to a preparation method of a triazinyl fluorine-containing chain extender-modified polyurethaneemulsion. The invention aims to solve the problem of how to modify waterborne polyurethane by utilizing organic fluorine, so as to make the waterborne polyurethane have excellent hydrophobic performance and reduce the preparation cost. The preparation method comprises the steps: 1) synthesis of a triazinyl fluorine-containing chain extender; 2) synthesis of an -NCO-terminated fluorine-containing polyurethane prepolymer; 3) preparation of triazinyl fluorine-containing chain extender-modified polyurethane; and 4) preparation of the triazinyl fluorine-containing chain extender-modified polyurethane emulsion.

Owner:SHAANXI UNIV OF SCI & TECH

Surface mechanical attrition treatment and ultrasonic wave collaborative assistance dissimilar metal TIG melting and brazing method

InactiveCN103934551AEasy to spreadImprove wettabilitySoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedMetal

The invention discloses a surface mechanical attrition treatment and ultrasonic wave collaborative assistance dissimilar metal TIG melting and brazing method. The method includes the step B that TIG melting and brazing is achieved through assistance of ultrasonic waves in the welding process. The method is characterized by further including the step A that surface mechanical attrition treatment is performed on low-melting-point parent metal. The method has the advantages that operation is easy to perform, the welding quality can be improved, it is prevented that welded joint structures are thick and large, brittle intermetallic compounds are prevented from being generated, the welding performance is improved, and the method is particularly applicable to connection of dissimilar metal under the condition that metal oxide can be easily generated on the surface of the low-melting-point parent metal in two types of parent metal.

Owner:CHONGQING UNIV

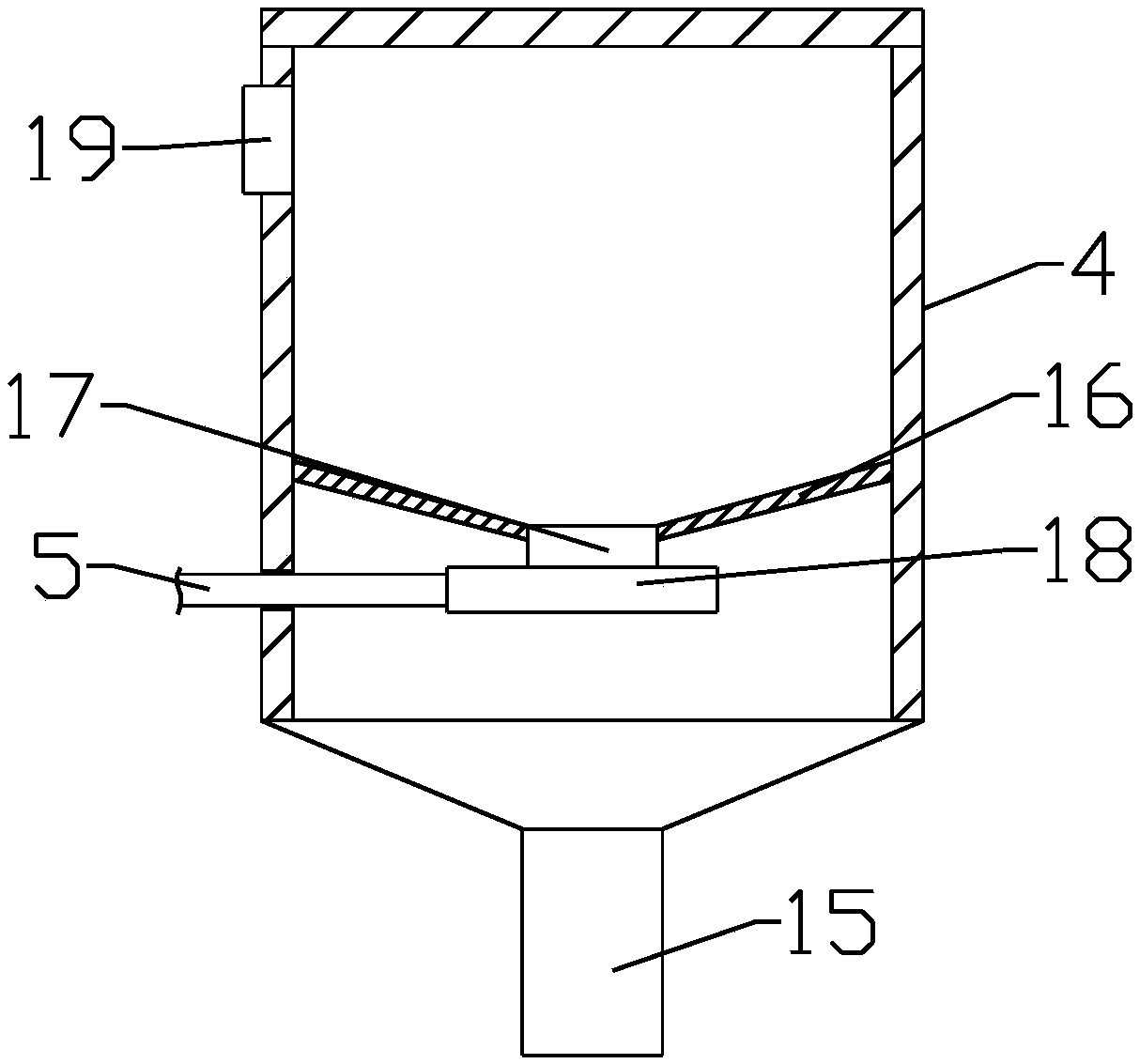

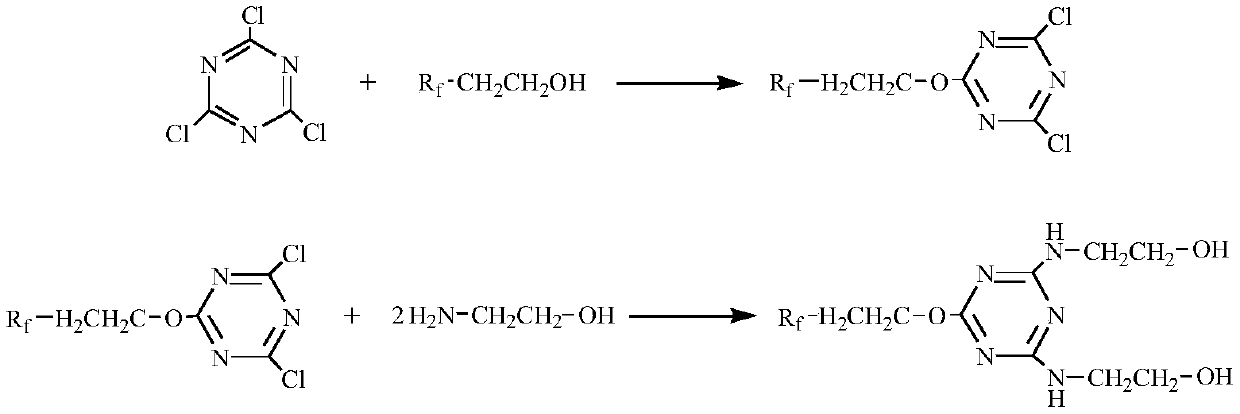

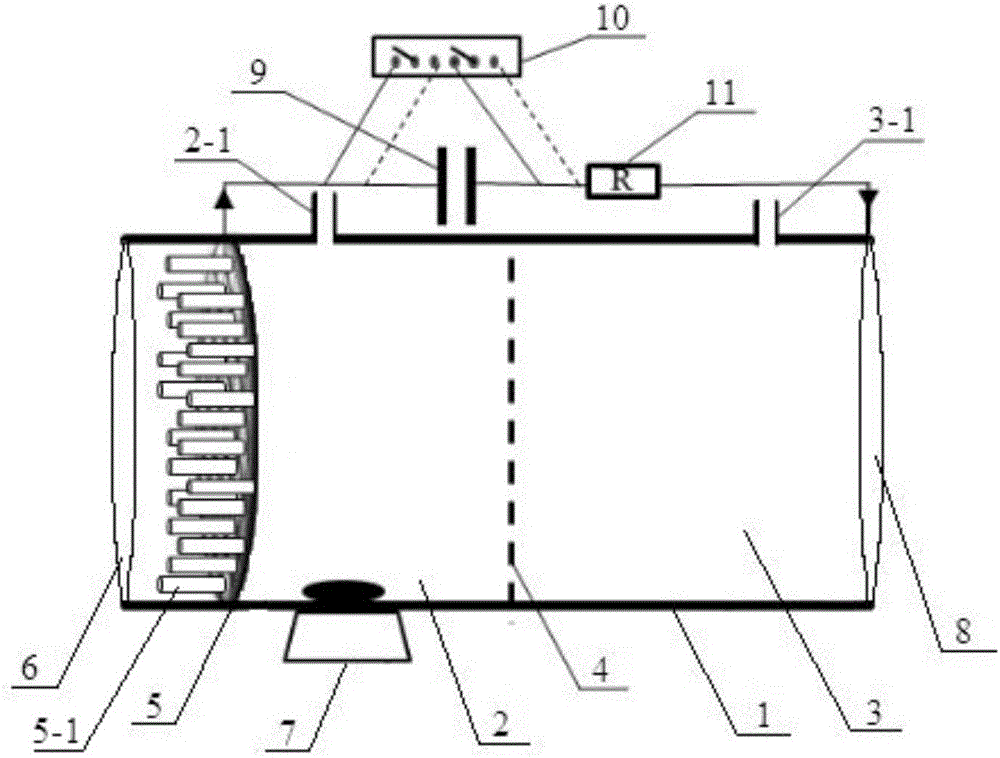

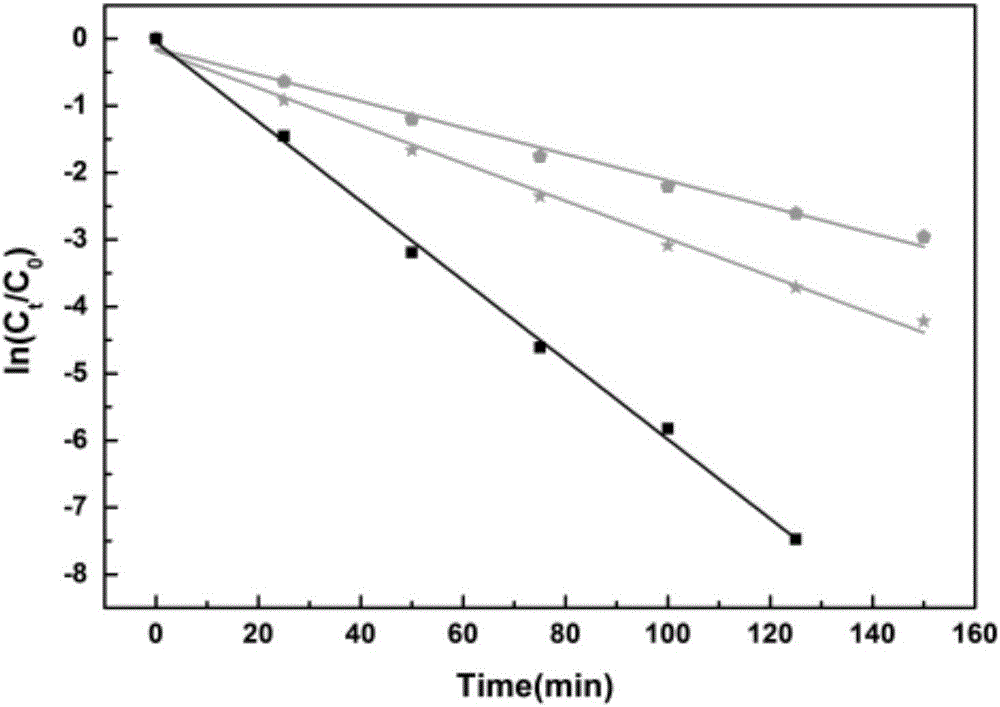

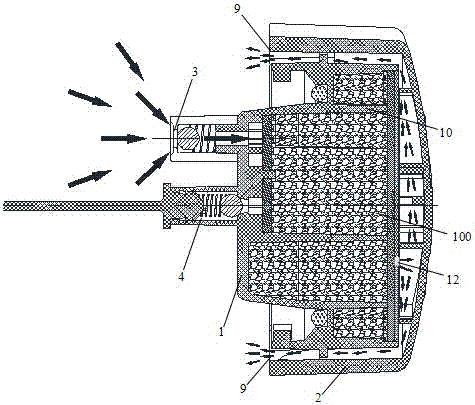

Batch type photocatalytic energy collection reactor and method for wastewater treatment by same

ActiveCN105836842ASimple structureLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionProton

The invention relates to a photocatalytic reactor and a method for wastewater treatment by the photocatalytic reactor, in particular to a batch type photocatalytic energy collection reactor and a method for wastewater treatment by the batch type photocatalytic energy collection reactor and aims to solve the problem of low photocatalytic organism degradation efficiency of existing photocatalytic wastewater treatment methods. The reactor comprises a shell, an anode chamber, a cathode chamber, a proton exchange membrane, a photoanode, guartz glass, a stirring device, a counter electrode, a capacitor and a converter. The proton exchange membrane is arranged in the middle of the shell, the shell is provided with the photoanode at one end of the anode chamber and provided with the counter electrode at one end of the cathode chamber, and the photoanode and the counter electrode are connected through an external circuit. The method includes: feeding wastewater into the reactor through a water inlet of the anode chamber, starting the stirring device, subjecting the photoanode to ultraviolet irradiation, and discharging the treated water through a water inlet hole of the anode chamber. The batch type photocatalytic energy collection reactor and the method for wastewater treatment by the batch type photocatalytic energy collection reactor are applied to the field of wastewater treatment, improve efficiency in separation of photogenerated holes and electrons and effectively and synchronously improve system production capacity and efficiency in degradation and mineralization of refractory organics in wastewater.

Owner:HARBIN INST OF TECH

UHMWPE sheet material manufacturing method

InactiveCN106480600AFully spreadImproved ballistic resistanceNon-woven fabricsFiber bundleEngineering

The invention discloses a UHMWPE sheet material manufacturing method comprising steps of unwinding, clustering, laying out, spreading, gluing and drying fiber bundles. A filament spreading device is employed in the spreading step; the filament spreading device comprises a plurality of filament spreading units; each filament spreading unit has a first filament spreading member horizontally arranged and a second filament spreading member horizontally arranged; the first filament spreading member is provided with an arc-shaped curved surface; the second filament spreading member is provided a corner angle; and the fiber beam is spread via contacting the arc-shaped curved surface of the first filament spreading member and the corner angle of the second filament spreading member. Elastoresistance performance can be improved by at least 10% for a single-oriented pre-dip belt manufactured by the method at the same areal density.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP +1

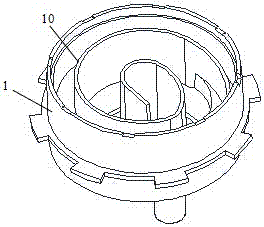

Canister

ActiveCN104806387BFully adsorbedFully spreadNon-fuel substance addition to fuelMachines/enginesDesorptionBody positions

The invention discloses a carbon tank, which comprises a tank body, an adsorption port, a desorption port and an air port located on the tank body. The tank body is provided with an accommodating cavity, and the accommodating cavity is separated into a continuous channel by a spacer assembly. Carbon powder is arranged in the channel, the adsorption port and the desorption port are located at one end of the channel, and the atmospheric port is located at the other end of the channel. With the above technical solution, oil and gas will gradually spread along the channel after entering the accommodation cavity, and dividing the accommodation cavity into channels can increase the path of oil and gas spreading as much as possible under the condition of constant volume, so that it can be absorbed by the channels in the channel. The carbon powder is fully adsorbed to achieve good adsorption and desorption effects.

Owner:金华市合发科技有限公司

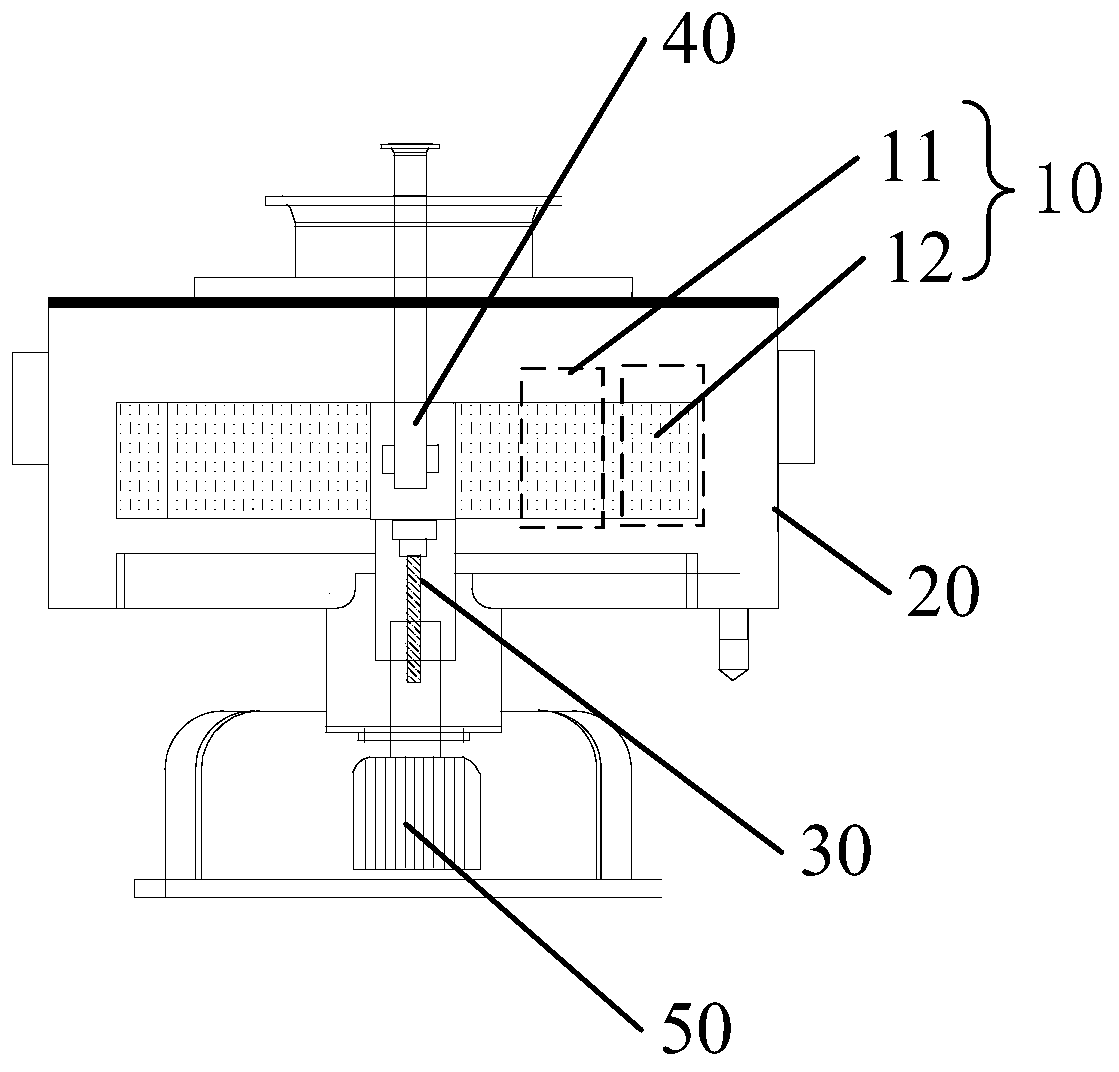

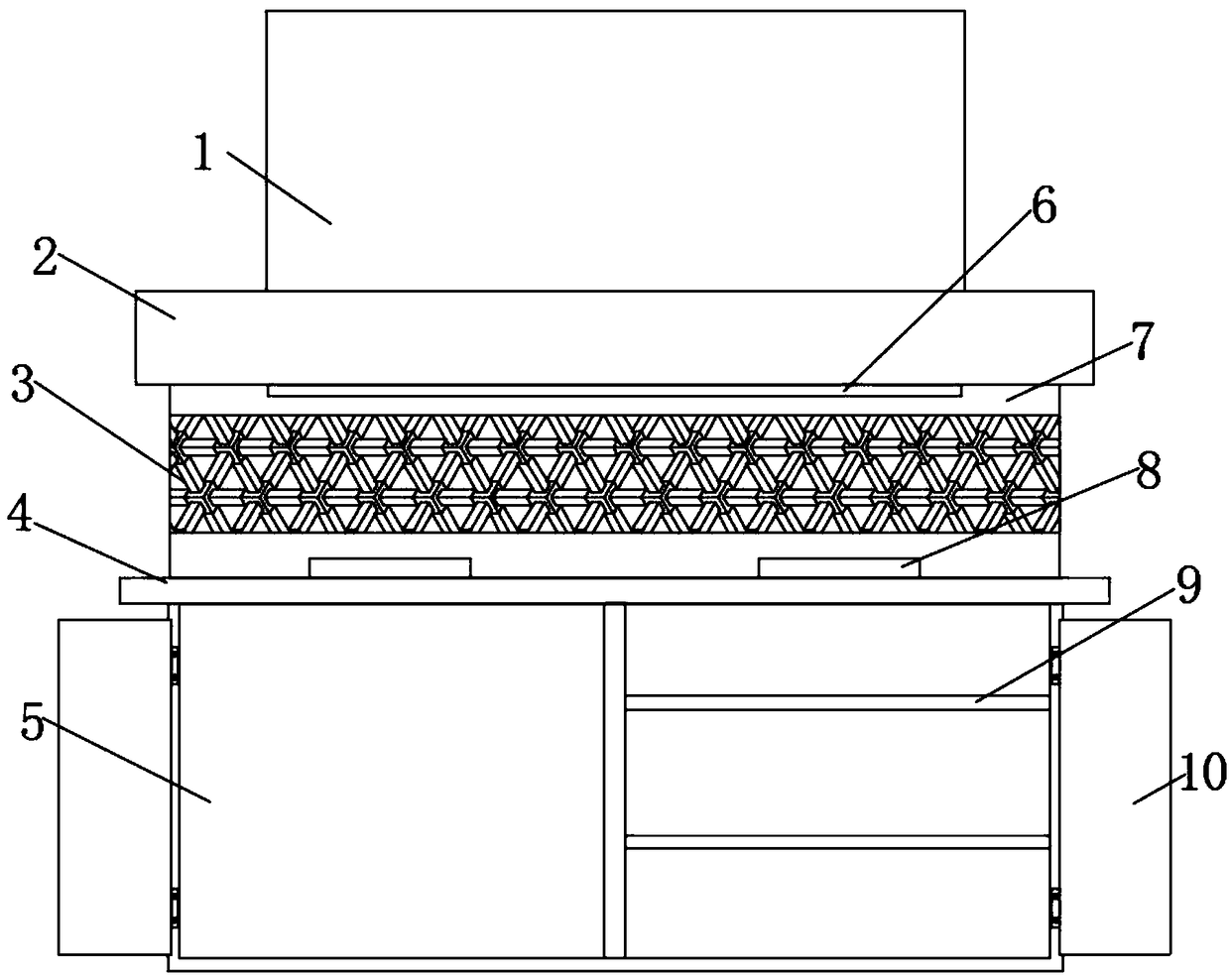

Rotary filling bed based on hydrophilic-hydrophobic combined filler, and system

ActiveCN110252238AIncrease wettabilityReduce turbulenceGas treatmentDispersed particle separationHydrophilic hydrophobicMixing effect

The invention provides a rotary filling bed based on a hydrophilic-hydrophobic combined filler, and a system. According to the present invention, a hydrophobic filler and a hydrophilic filler are combined into a combined filler, and when a liquid is cut by the filler, the hydrophobic filler can fully disperse the liquid to uniformly disperse the liquid in the filler region, and the wettability of the hydrophilic filler can make the liquid spread sufficiently so as to increase the wetting fraction of the filler, such that different mixing effects can be achieved through the reasonable combination; the numbers of the hydrophilic filler layers and the hydrophobic filler layers in the combined filler are limited, such that the liquid droplet coalescence phenomenon generated by the liquid in the single hydrophobic filler region and the liquid turbulence reduction phenomenon generated by the liquid in the single hydrophilic filler region can be avoided; and the negative effect caused by the hydrophilicity can be alleviated or offset by the hydrophobicity while the negative effect caused by the hydrophobicity can be alleviated or offset by the hydrophilicity, such that the mass transfer and mixing performance of the hydrophilic-hydrophobic combined filler can be further improved by applying the hydrophilic-hydrophobic combined filler in the rotary filling bed.

Owner:BEIJING UNIV OF CHEM TECH

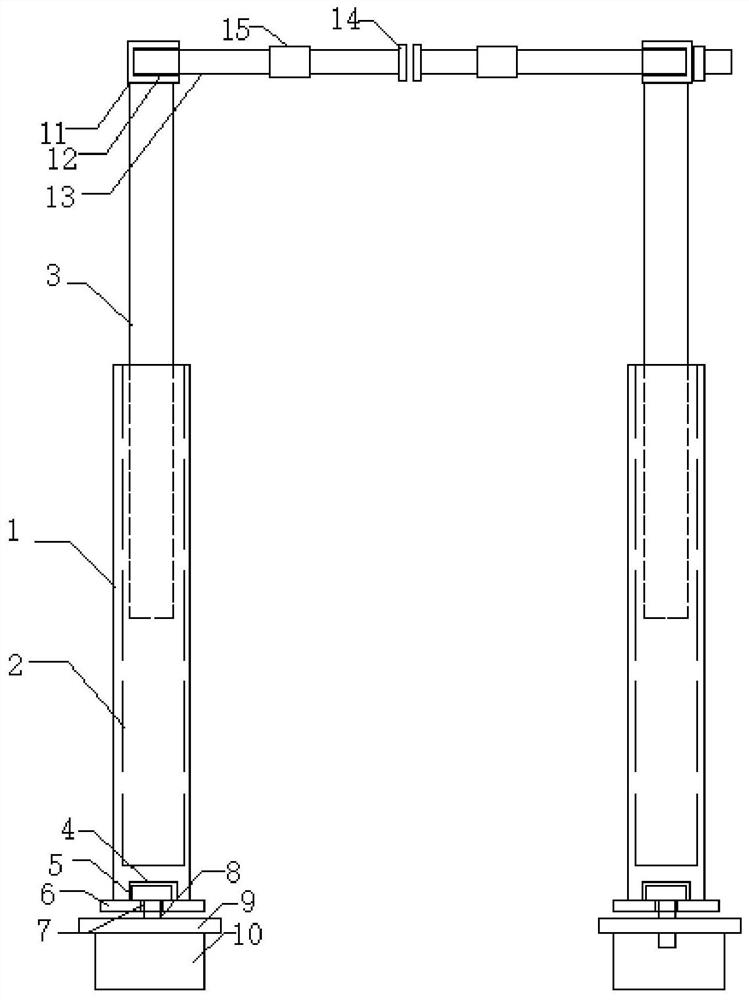

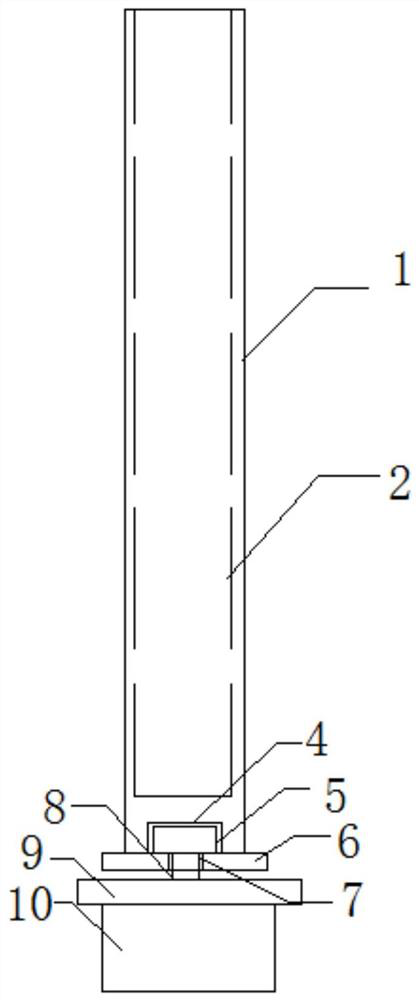

Sun-shading equipment suitable for agricultural machinery

InactiveCN112009211AAdjustable combined lengthFull sunshade and rain shelterAntiglare equipmentAgricultural scienceAgricultural engineering

The invention discloses sun-shading equipment suitable for agricultural machinery. The sun-shading equipment comprises a first supporting rod, a fixed channel is formed in the middle position of the top surface of the first supporting rod; the surface of the fixed channel is in threaded connection with a second supporting rod; a fixed clamping groove is formed in the middle position of the bottomsurface of the first supporting rod; and a first limiting block is fixedly clamped to the surface of the fixed clamping groove, a first fixing supporting plate is fixedly connected to the bottom end of the first supporting rod, and a fixing rotating hole is formed in the middle of the surface of the top and the middle of the surface of the bottom of the first fixing supporting plate in a penetrating mode. The invention relates to the technical field of architectural decoration engineering equipment. According to the sun-shading equipment suitable for the agricultural machinery, the purpose ofeffectively protecting the agricultural machine and an operator of the agricultural machine is achieved; the sun-shading equipment is adjustable in area, wide in application range, beneficial to improving the use comfort of agricultural machinery of outdoor workers, beneficial to body health of the outdoor workers, capable of effectively preventing the agricultural machinery from rusting and corroding to be rotten and beneficial to prolonging the service life of the agricultural machinery.

Owner:张静雯

Energy-saving and environment-friendly stove device capable of being used conveniently

InactiveCN109297059AIncrease profitRelieve pressureDomestic stoves or rangesCooking fumes removalScrapWater pipe

The invention discloses an energy-saving and environment-friendly stove device capable of being used conveniently. A water storage tank is fixedly installed at the top of a soot waste heat utilizationdevice, and a hot water release pipe connected by a flange is installed on one side of a water heating tank. A hot water faucet is fixedly installed at one end of the hot water release pipe. A gas diluting tank can mix gas and air before an energy-saving and environment-friendly stove is used, so that the gas utilization rate can be greatly improved. A soot particle adsorption plate can absorb soot particles in combustion emissions to reduce the pressure of a gas flue, and at the same time, the accumulation of soot in a coil cooling pipe is prevented from affecting the utilization rate of waste heat. When flue gas enters the coil cooling pipe, part of water in the water heating tank is subjected to heat treatment, and water in the water storage tank is added into the water heating tank through a water adding pipe to maintain the full utilization of the waste heat. The energy-saving and environment-friendly stove can fully burn the gas, and at the same time, the energy-saving and environment-friendly stove can clean solid waste and soot in the flue gas in time, and brings great convenience to the life of people.

Owner:赖友行

Water-based ink for film printing and preparation method of ink

The invention discloses a water-based ink for film printing, and belongs to the technical field of printing. The water-based ink for film printing comprises the following components: a water-based polyurethane-acrylic resin emulsion, deionized water, a pigment, ammonia water, calcium carbonate, kaolin clay, a defoaming agent, sodium alkyl sulfate, polyacrylamide and monoalkoxytitanate, wherein thewater-based polyurethane-acrylic resin emulsion takes butyl acrylate, methyl methacrylate and methacrylic acid as monomers, adopts an emulsion polymerization method to prepare the water-based acrylicresin emulsion, and then modifies the water-based polyurethane to prepare the water-based polyurethane-acrylic resin emulsion. A reinforcing system consisting of sodium alkyl sulfate, polyacrylamideand monoalkoxytitanate is adopted to improve the tinting strength and adhesion strength of the water-based ink.

Owner:长沙浩然医疗科技有限公司

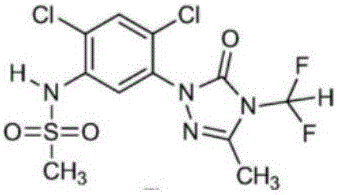

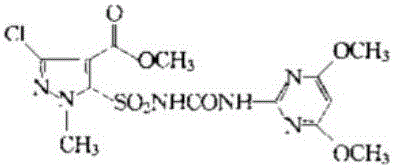

Weeding composition and application thereof

ActiveCN106106508AReduce surface tensionPromote wettingBiocideDead animal preservationHalosulfuron methylSuspending Agents

Owner:LIER CROPSCIENCE CO LTD

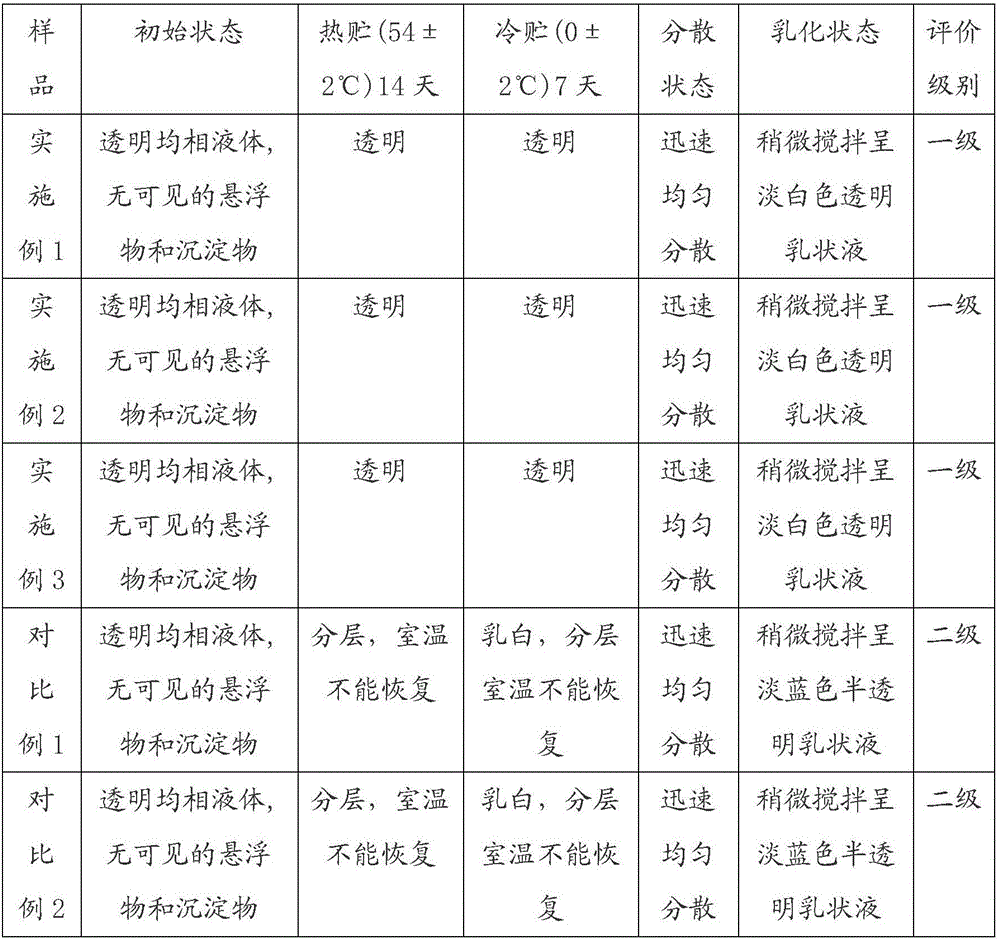

Pixel defining unit, pixel defining structure, display structure and display device

ActiveCN110416433AAchieve thinningFully spreadSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThinning

The embodiment of the invention provides a pixel defining unit, a pixel defining structure, a display structure and a display device. The pixel defining unit is provided with a pixel hole and first guide slot sections, wherein the pixel hole is used for arranging a sub-pixel, and the first guide slot sections are communicated with the pixel hole and extend beyond the pixel defining unit. Accordingto the embodiment of the invention, the pixel defining structure of a flexible display screen is transformed, and the guide slots communicated with the pixel hole are additionally arranged, so that the encapsulation operation can be carried out in the pixel hole and the guide slots, the leveling height is reduced under the premise of ensuring the sufficient spreading and leveling of a liquid membrane material for forming TFE (Thin-Film Encapsulation), thereby realizing the thinning of the TFE, and thus thinning the flexible display screen. In addition, the liquid membrane material is guide bythe guide slots for leveling, so that the leveling direction is clear, the leveling efficiency is improved, the consumption of the liquid membrane material is also reduced, and the material and costare reduced.

Owner:BOE TECH GRP CO LTD

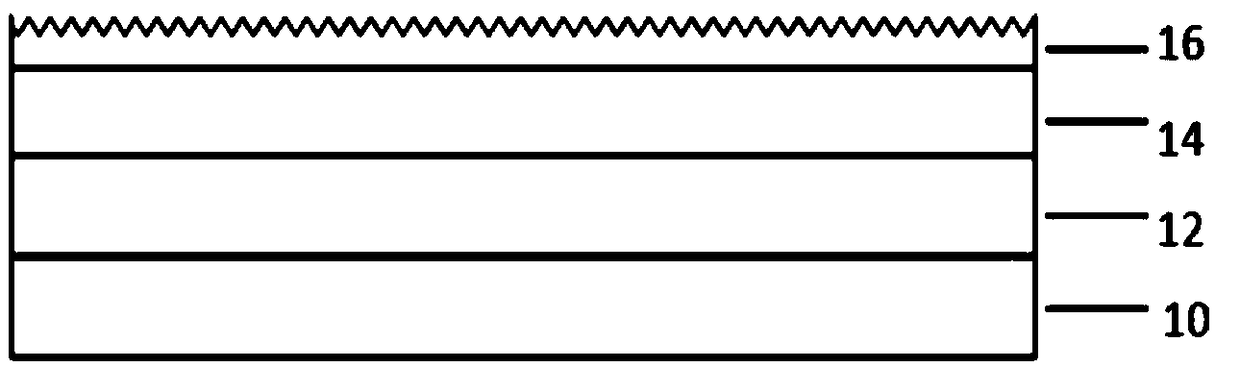

Solar cell back membrane and preparation method thereof

InactiveCN107819055AReduce manufacturing costIncrease surface tensionPhotovoltaic energy generationSemiconductor devicesChemistrySolar cell

The invention provides a preparation method of a solar cell back membrane. The method comprises the steps of sequentially carrying out electric corona, dip coating and heating treatments on a base membrane. By adopting the preparation method of the solar cell back membrane, the solar cell back membrane can be prepared without modifying the resin. Therefore, the problem in the prior art that the fluorine-containing resin needs to be subjected to blow molding modification or the high-viscosity fluorocarbon resin needs to be prepared is solved. Meanwhile, the production cost is reduced. The invention provides a solar cell back membrane prepared by the above method. The peeling strength average value of the solar cell back membrane and EVA (ethylene-vinyl acetate) reaches 104.5N / cm, and the adhesive force of the coating reaches the zero level. The breakdown voltage reaches 19 kV. Meanwhile, the results of the solar cell back membrane in the neutral salt fog experiment and the boiling waterexperiment are qualified. Moreover, the results of the solar cell back membrane in the wet-heat experiment, the ultraviolet experiment, the thermal cycling experiment and the wet-freezing experimentcan all reach the level A.

Owner:马继

Light extraction film for OLED illumination device and manufacturing method thereof

InactiveCN108899435AFacilitates changing the direction of transmissionReduce glare effectsMaterial nanotechnologySolid-state devicesTectorial membraneNanoparticle

The present invention relates to a light extraction film for an OLED illumination device. The light extraction film is composed of a supporter; a low-refractive-index adhesive layer and a protective film which are disposed on a side of the supporter; and a high-refractive-index uneven coating disposed on the other side of the supporter. The main components of the low-refractive-index adhesive layer comprise 60 to 70 parts of resin, 17 to 27 parts of first diluent, 10 to 15 parts of nanoparticles, and 2 to 5 parts of bridging agent and curing agent. The main components of the uneven coating comprise 50 to 55 parts of film-forming resin, 10 to 14 parts of the second diluent, 15 to 20 parts of nanoparticle material, 8 to 15 parts of polymer microspheres, and 2 to 5 parts of curing agent. Thelight extraction film can be directly attached to the light-emitting surface of the OLED illumination device, and increases a light extraction rate to about 80%. The light extraction film also has ananti-dazzle effect and a function of equalizing the light of a light-emitting device. The light extraction film can be manufactured by a roller-to-roller wet coating method, and is convenient to produce and low in cost.

Owner:CHINA LUCKY FILM CORP

A Fiber Thermoplastic Casting Vibration Immersion Prepreg Machine

The invention discloses a thermoplastic casting vibration infiltration pre-impregnation machine for fibers. The pre-impregnation machine comprises a first machine frame, a second machine frame, a third machine frame, a feeding device, a driving mechanism, a preprocessing mechanism, a vibration yarn spreading mechanism, two casting heads, two pairs of steel belt sets, at least one set of heating assemblies, a pair of vibration generators and a containing device, wherein the first machine frame, the second machine frame and the third machine frame are arranged from back to front in sequence, thefeeding device is arranged on the rear side of the first machine frame and contains a material, the vibration yarn spreading mechanism carries out yarn spreading treatment on the material, the two casting heads carry out preliminary infiltration and yarn fixing treatment on the upper surface and the lower surface of the material, the two pairs of steel belt sets are arranged on the upper side andthe lower side of the materials in mirror symmetry and jointly extrude the upper surface and the lower surface of the material and drive the material to move forward, the heating assemblies are arranged in vertical mirror symmetry, are distributed on the upper surface and the lower surface of the material and carry out heating treatment on the material, the vibration generators are arranged on the upper side and the lower side of the material in mirror symmetry and are used for breaking molecular chains of the material, and the containing device is used for containing the processed material.According to the technical scheme of the pre-impregnation machine, the precision of a thermoplastic prepreg is high, the working efficiency is high, and fiber woven fabric and various unidirectional fibers can be impregnated.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com