Canister

A carbon canister and canister technology, which is applied in the field of engine fuel evaporation control accessories, can solve the problems of difficult emission standards, poor adsorption and desorption effects, and inability to fully and effectively utilize carbon powder adsorption and desorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

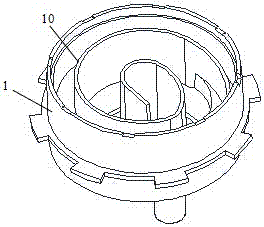

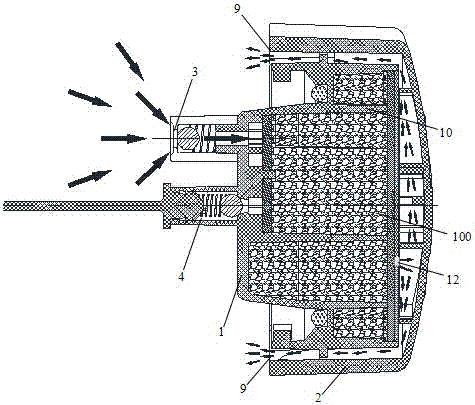

[0027] This embodiment provides a carbon tank, such as Figure 1-6 As shown, the tank body is composed of a body 1 and an upper cover 2 that are interlocked with each other. The adsorption port 3 and the desorption port 4 are located on the body 1 .

[0028] The adsorption port 3 is provided with a one-way valve for oil and gas to enter the tank, and the one-way valve includes a first spring 5 , a first steel ball 6 and a small cap 15 .

[0029] The desorption port 4 is provided with a one-way valve for discharging oil and gas in the tank, and the one-way valve includes a second spring 7 , a second steel ball 8 and a pull wire 16 .

[0030] The air opening 9 is a gap between the body 1 and the upper cover 2 .

[0031] A bent plate 10 is arranged in the body 1, and the bent plate 10 is arranged in a spiral shape with a gradually increasing bending radius. Carbon powder 100 is filled in the body 1 and distributed along the channel formed by the bent plate 10. . A partition 11...

Embodiment 2

[0038] Such as Figure 7 As shown, the spacer assembly includes a folded plate 800, and the folded plate is arranged in a spiral shape with a gradually increasing bending radius. The plate unit 800a is bent in the same direction, and the entire folded plate 800 is arranged in a spirally outwardly expanded form.

Embodiment 3

[0040] The spacer assembly includes at least two staggered spacer plates, such as Figure 8 As shown, there are four partitions in this embodiment, and the staggered arrangement means: the first partition 701 starts from the first side 790a of the inner wall of the tank body 790 and faces in the direction opposite to the first side 790a The second side 790b of the inner wall of the tank body 790 extends until close to the second side 790b, the second partition plate 702 is spaced apart from the first partition plate 701, and the second partition plate 702 starts from the first The two sides 790b extend toward the first side 790a until close to the first side 790a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com