Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

555 results about "Toothpick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A toothpick is a small thin stick of wood, plastic, bamboo, metal, bone or other substance with at least one and sometimes two sharp ends to insert between teeth to remove detritus, usually after a meal. Toothpicks are also used for festive occasions to hold or spear small appetizers (like cheese cubes or olives) or as a cocktail stick, and can be decorated with plastic frills or small paper umbrellas or flags.

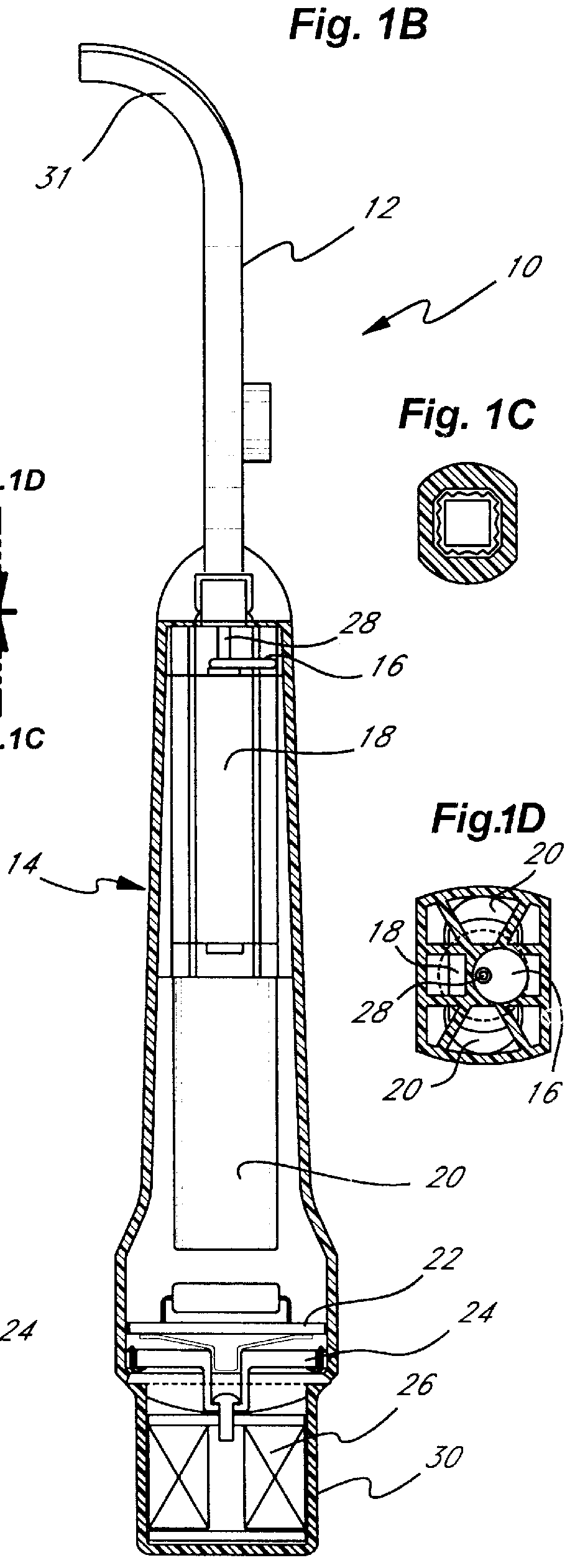

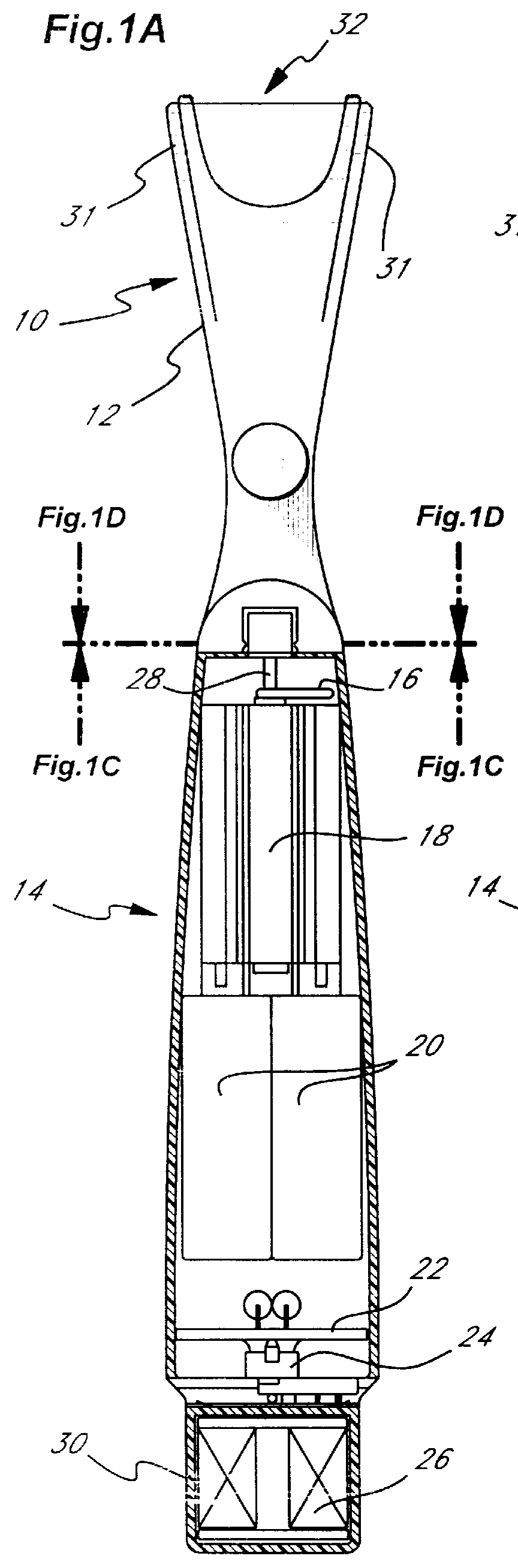

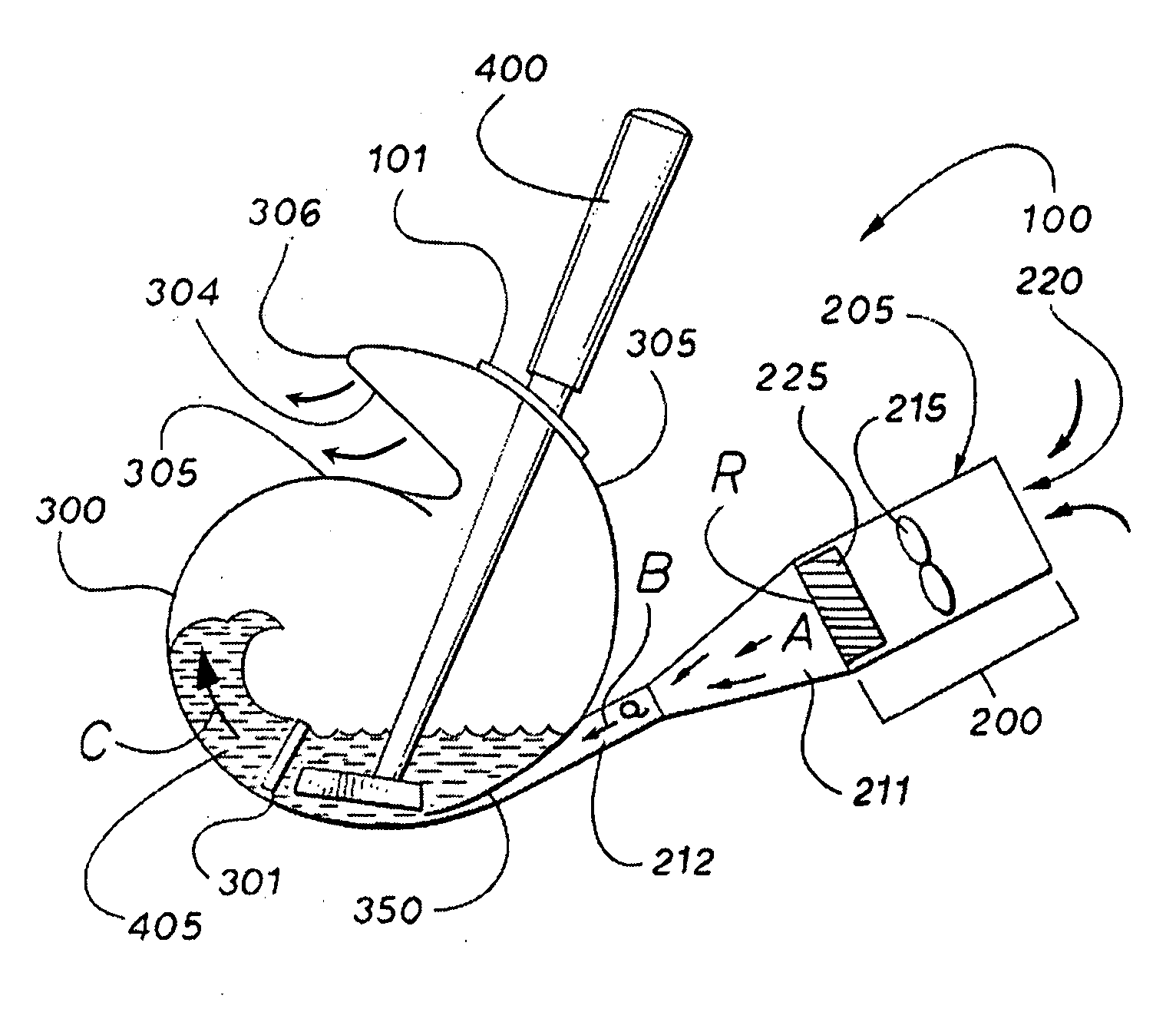

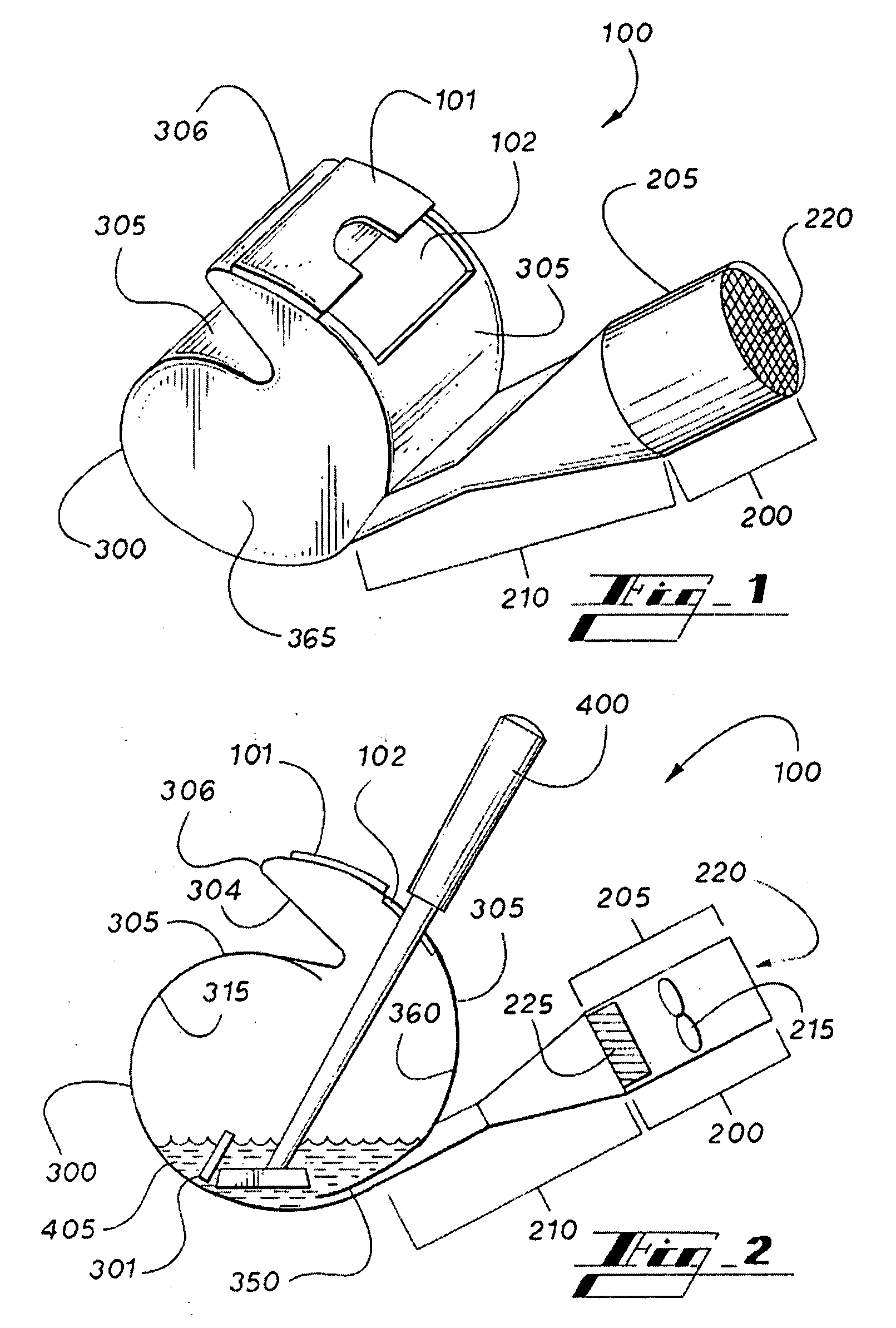

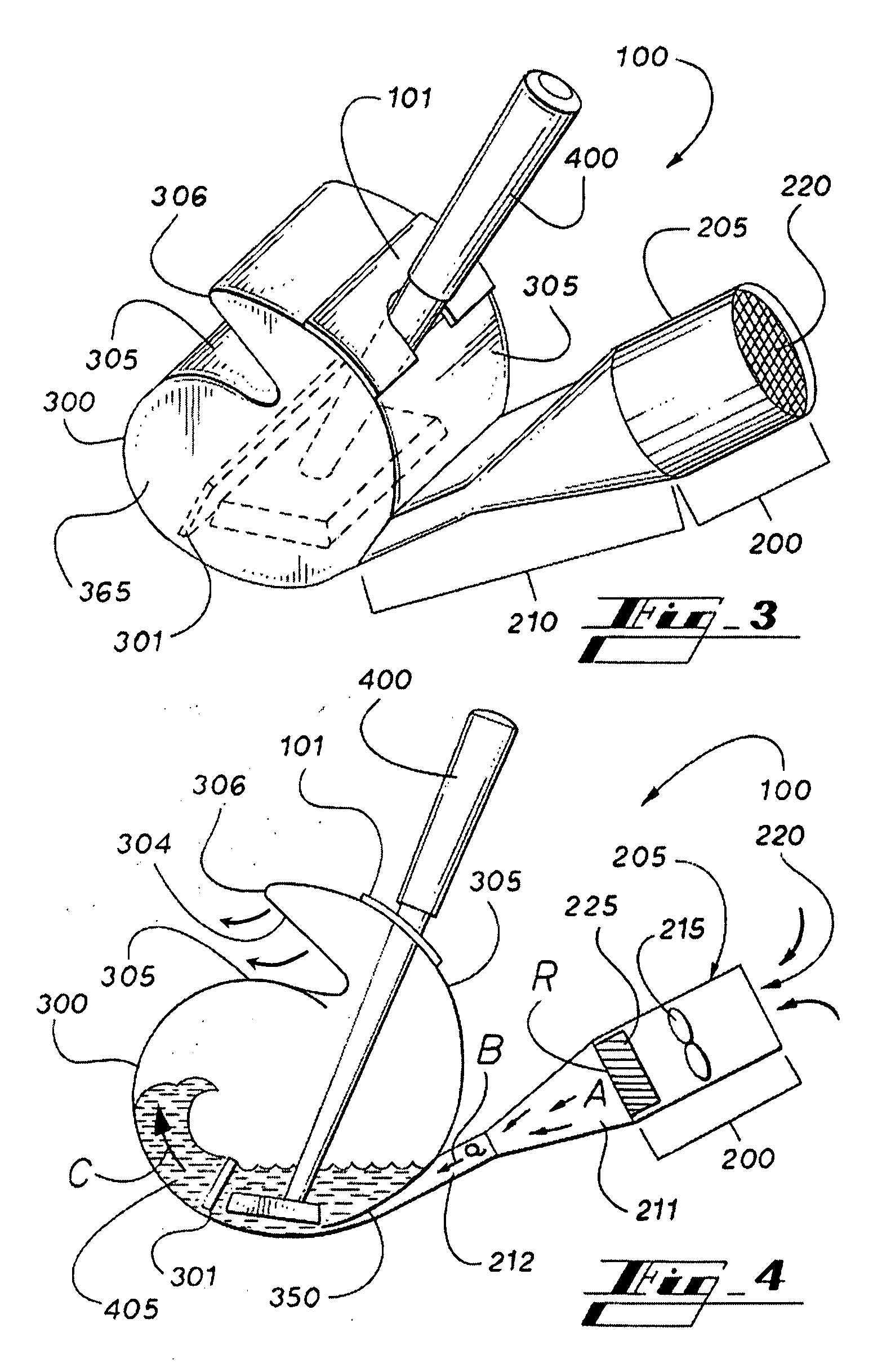

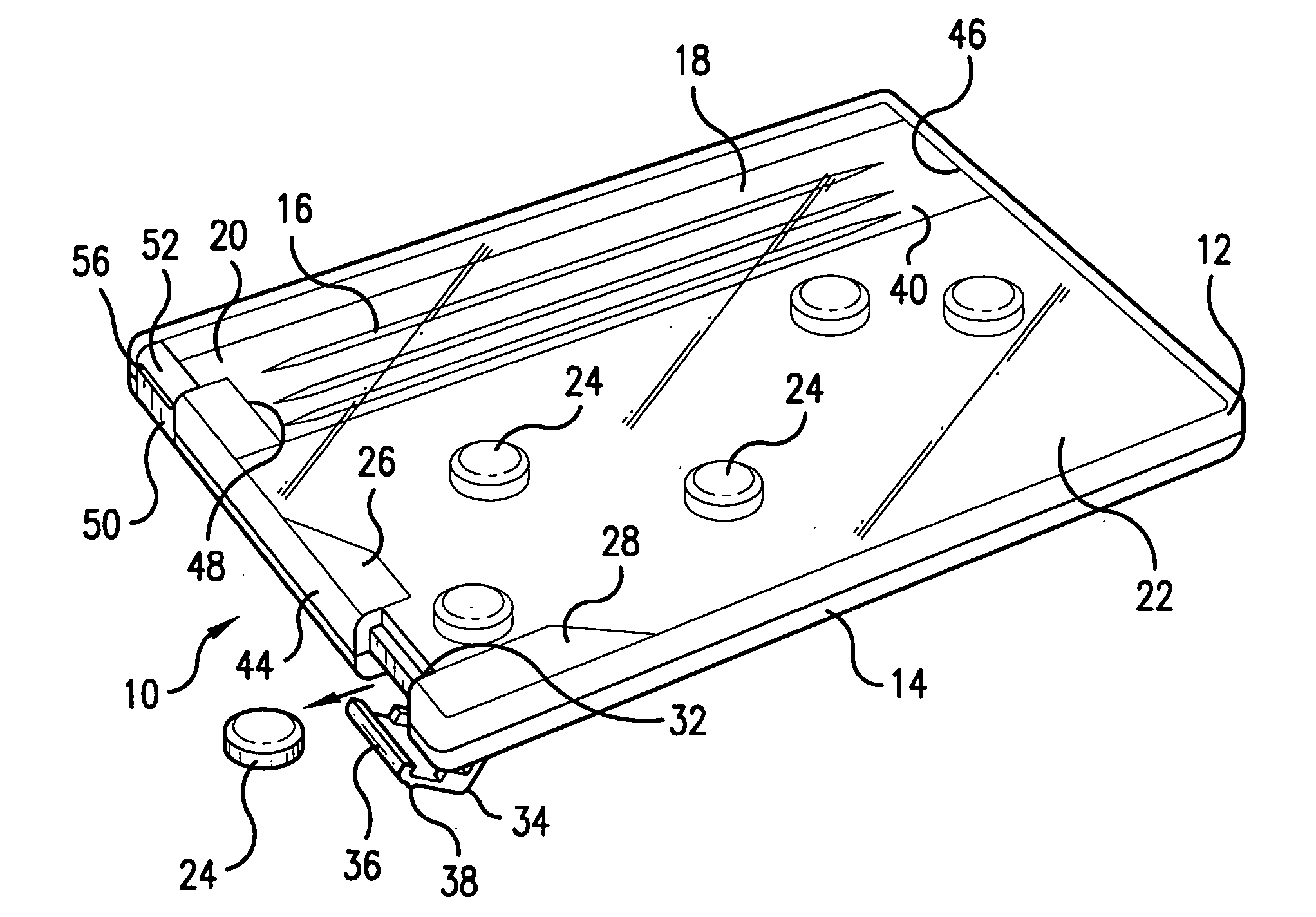

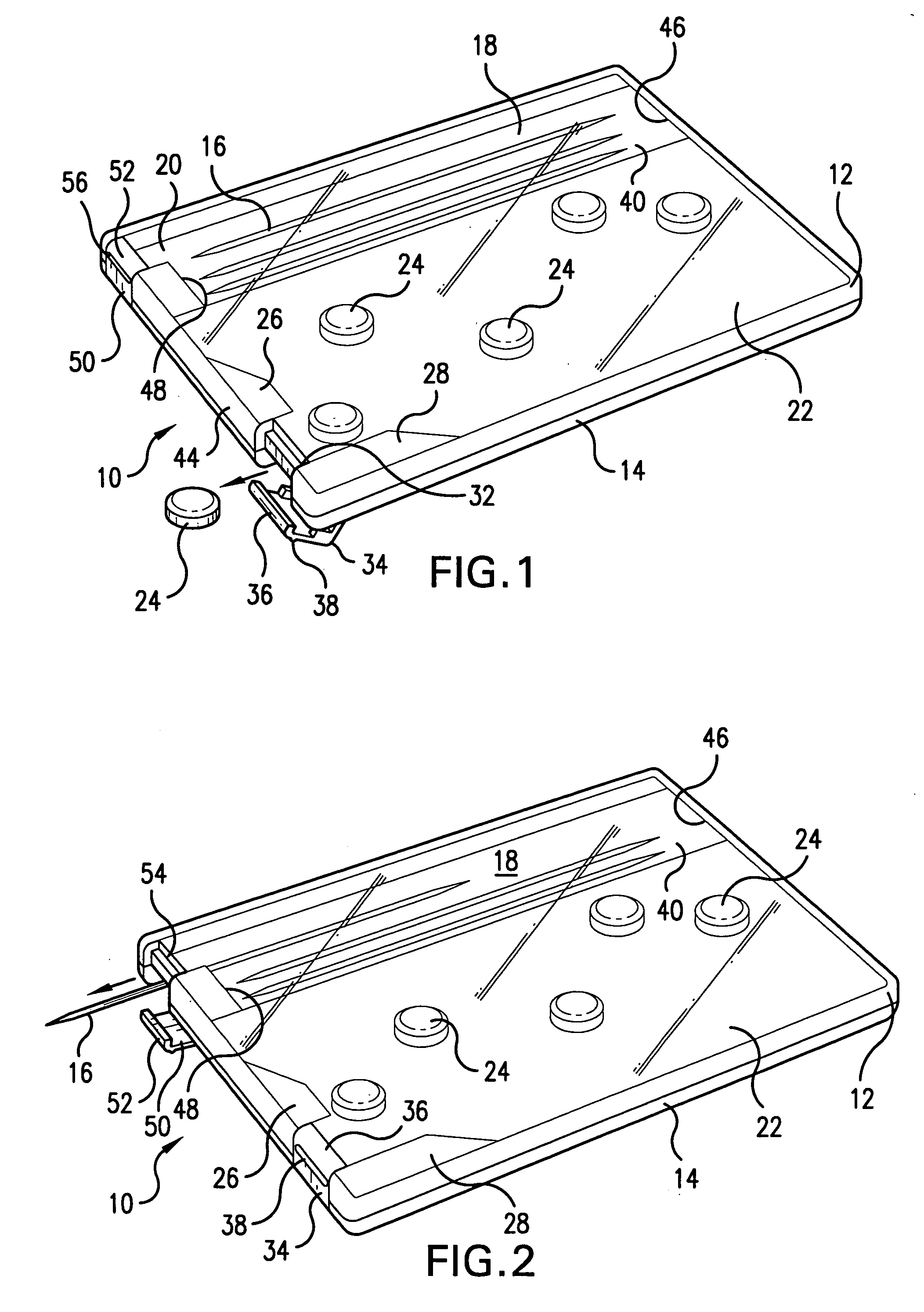

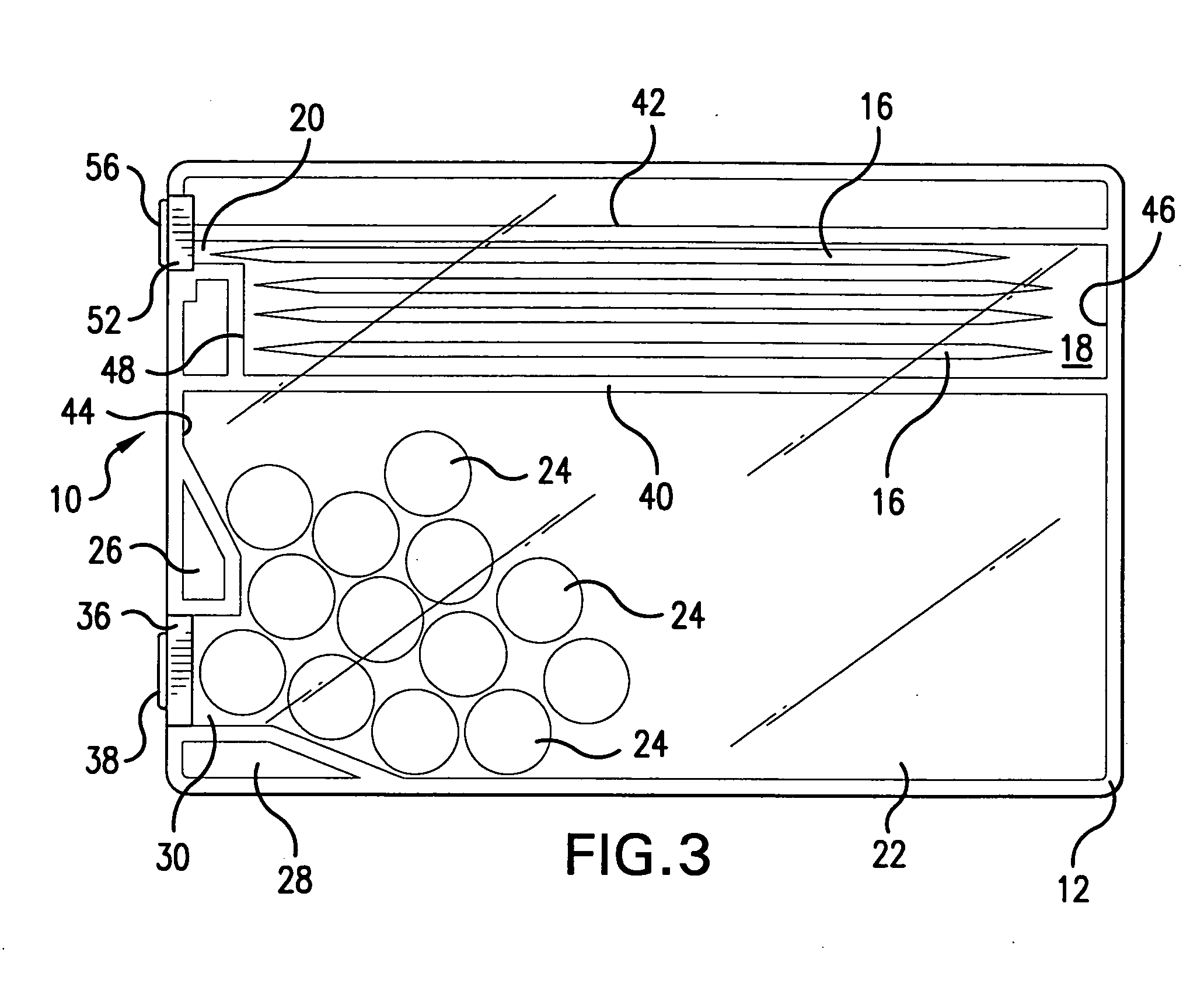

Sonic dental device

InactiveUSRE36699E1Improve easeImprove effectivenessGum massageTooth pluggers/hammersNatural resonanceDental floss

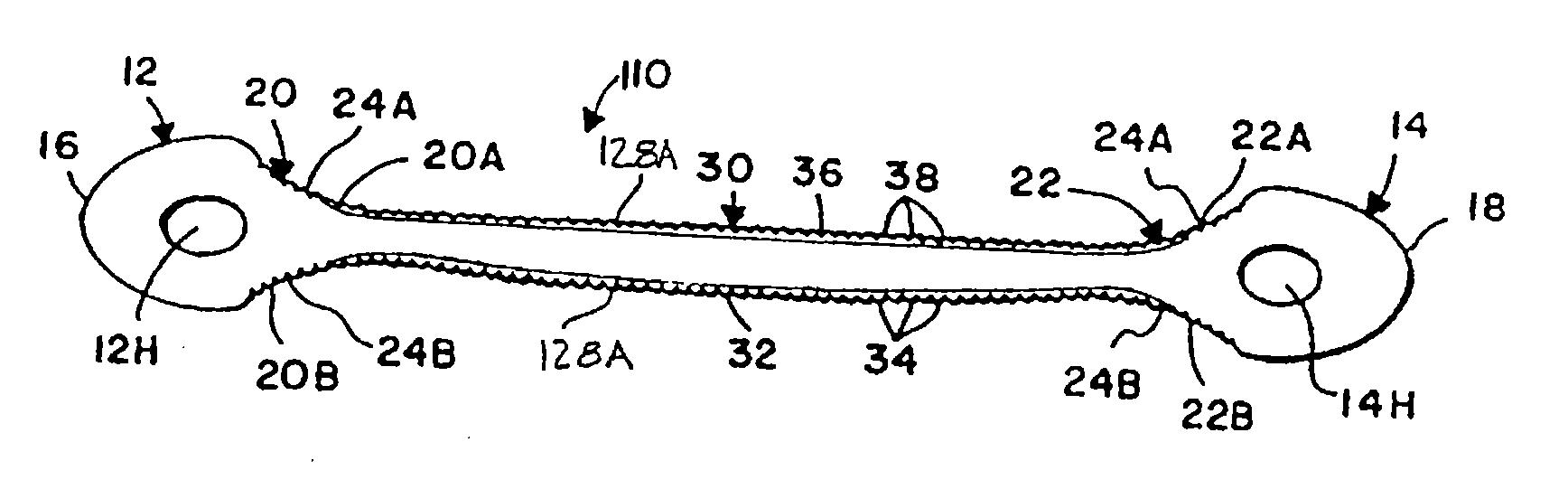

An electric device which removes supragingival and sub-gingival plaque and undesirable debris from the interproximal surfaces between teeth is described. This device utilizes a combination of sonic energy and dental floss which is secured between two tines, the tines being part of a flexible fork which is removable from a powered handle which contains batteries and an electric motor. The electric motor, which is coupled to an eccentrically mounted disc on an output shaft, revolves at sonic frequencies which in turn generates sonic energy that is transmitted to the flexible fork which holds the floss. The sonic energy is synchronized and in tune with the natural resonance frequencies of the fork thereby stimulating the resonance action of oscillating vertical and / or elliptical movement of the fork which in turn imparts cleaning energy to and enhances the cleaning properties of the floss. The flexible fork may be removed from the handle and replaced with other dental cleaning tools such as a brush, a pick, and / or a tray attachment.

Owner:AMDEN

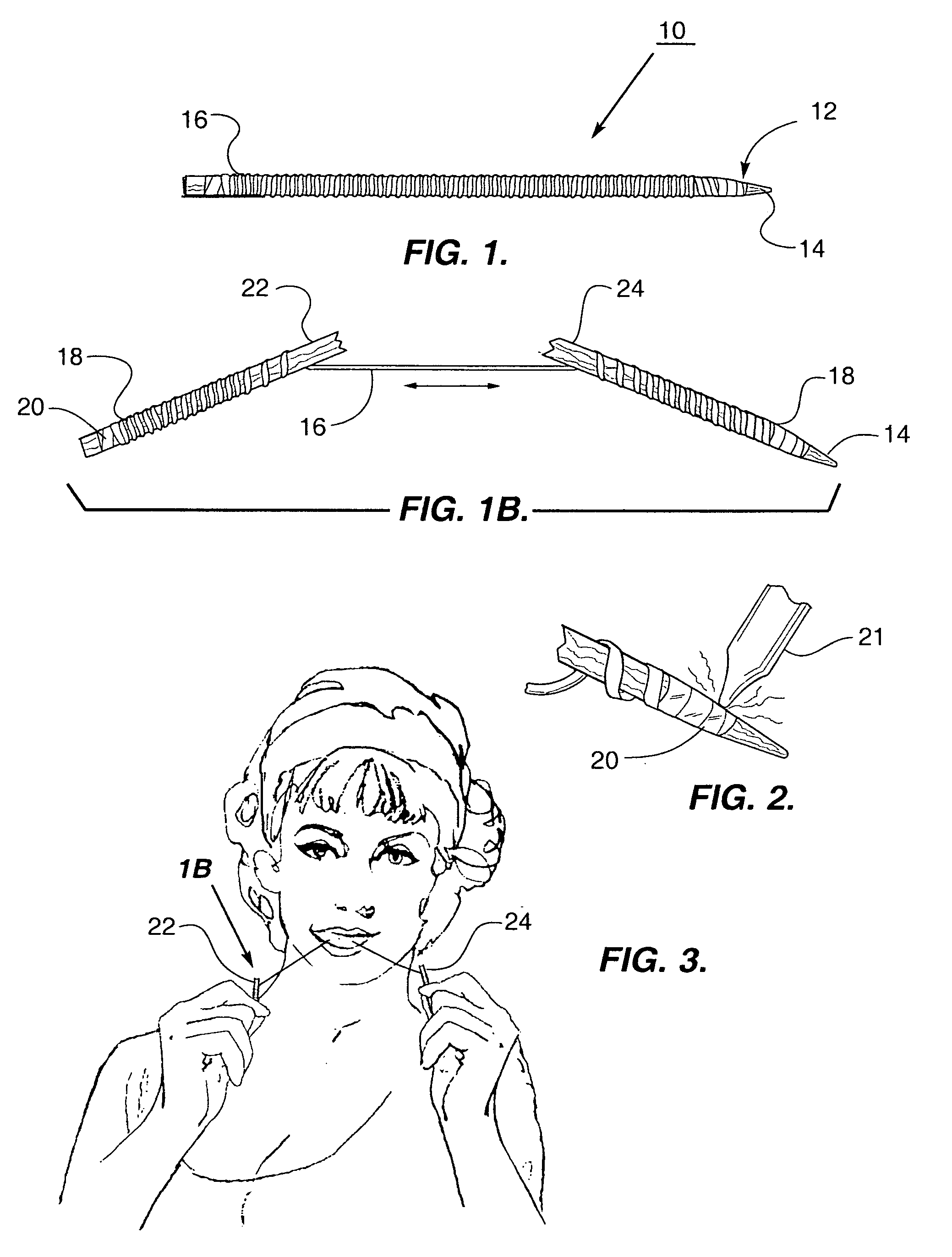

Method for making a nicotine toothpick

InactiveUS20060162732A1Satisfy fixationAvoid pollutionTobacco devicesTooth cleaningMedicineToothpaste

A method for making a nicotine-containing toothpick, includes creating a solution having a predetermined concentration of nicotine. A toothpick is exposed to the solution, and the amount of solution added to the toothpick is determined. The solution may be a liquid solution, or a saliva soluble powder solution. The concentration of the solution can be adjusted, or multiple solutions of varying concentrations of nicotine made, to create toothpicks of varying nicotine levels. Sweeteners, medicaments, breath fresheners, or dentifrices can be added to the toothpick.

Owner:WINN HALL

Medicated toothpick

InactiveUS20050058609A1Efficient deliveryEliminate effectiveCosmetic preparationsGum massageMedicineToothpick

A medicated toothpick for administering a selected dosage of medication including a toothpick shaped device impregnated with a selected quantity of medication. The medicated toothpick is particularly useful for the delivery of nicotine and provides a physical and mental nicotine delivery system that may effectively be substituted for smoking.

Owner:NAZERI ALIREZA

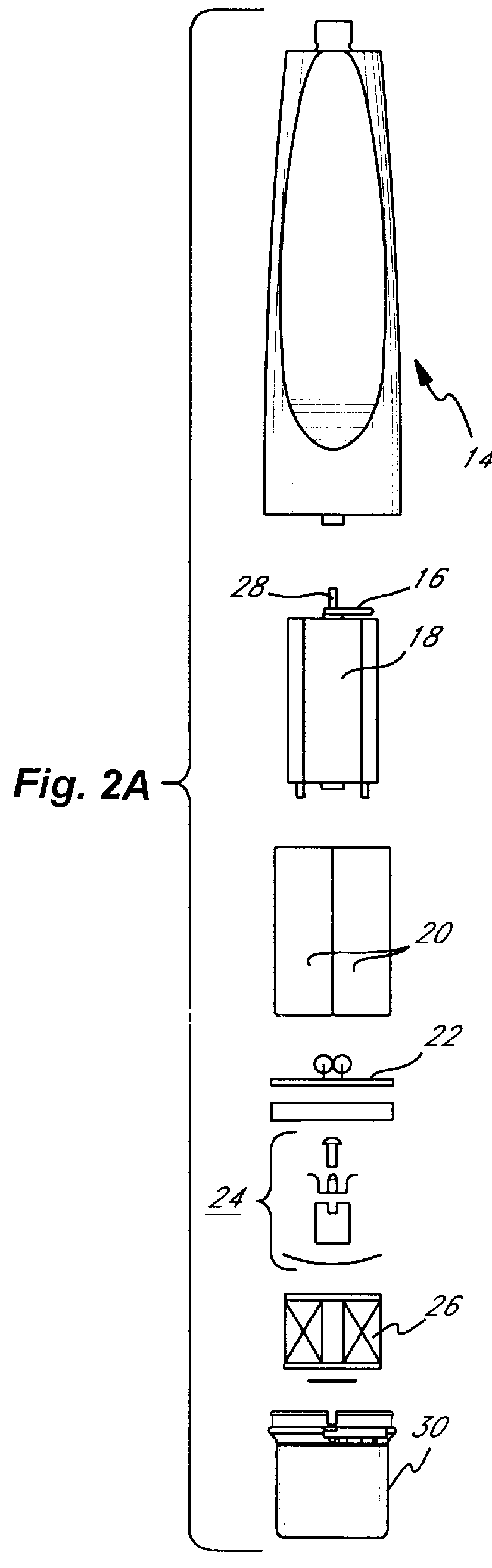

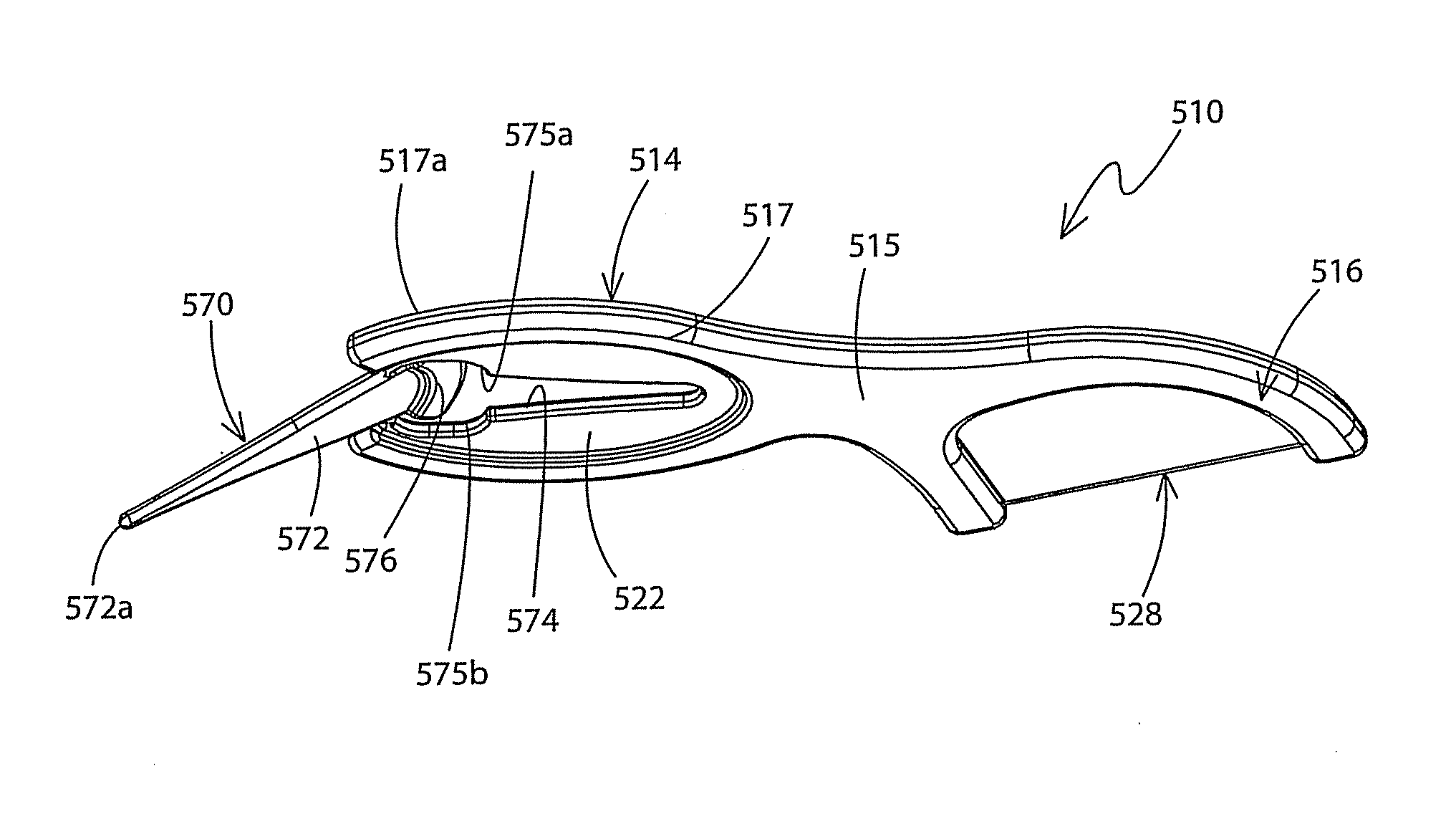

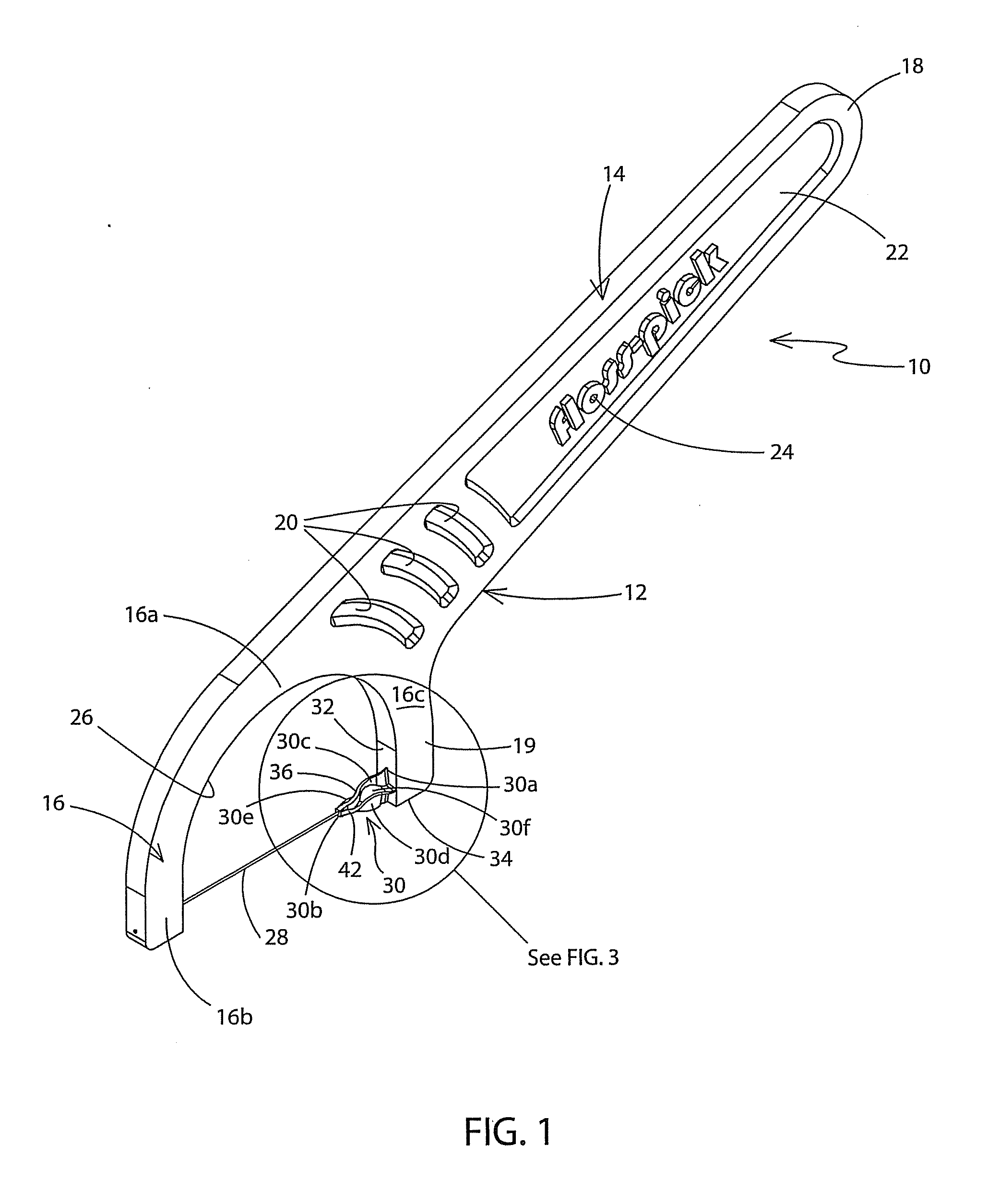

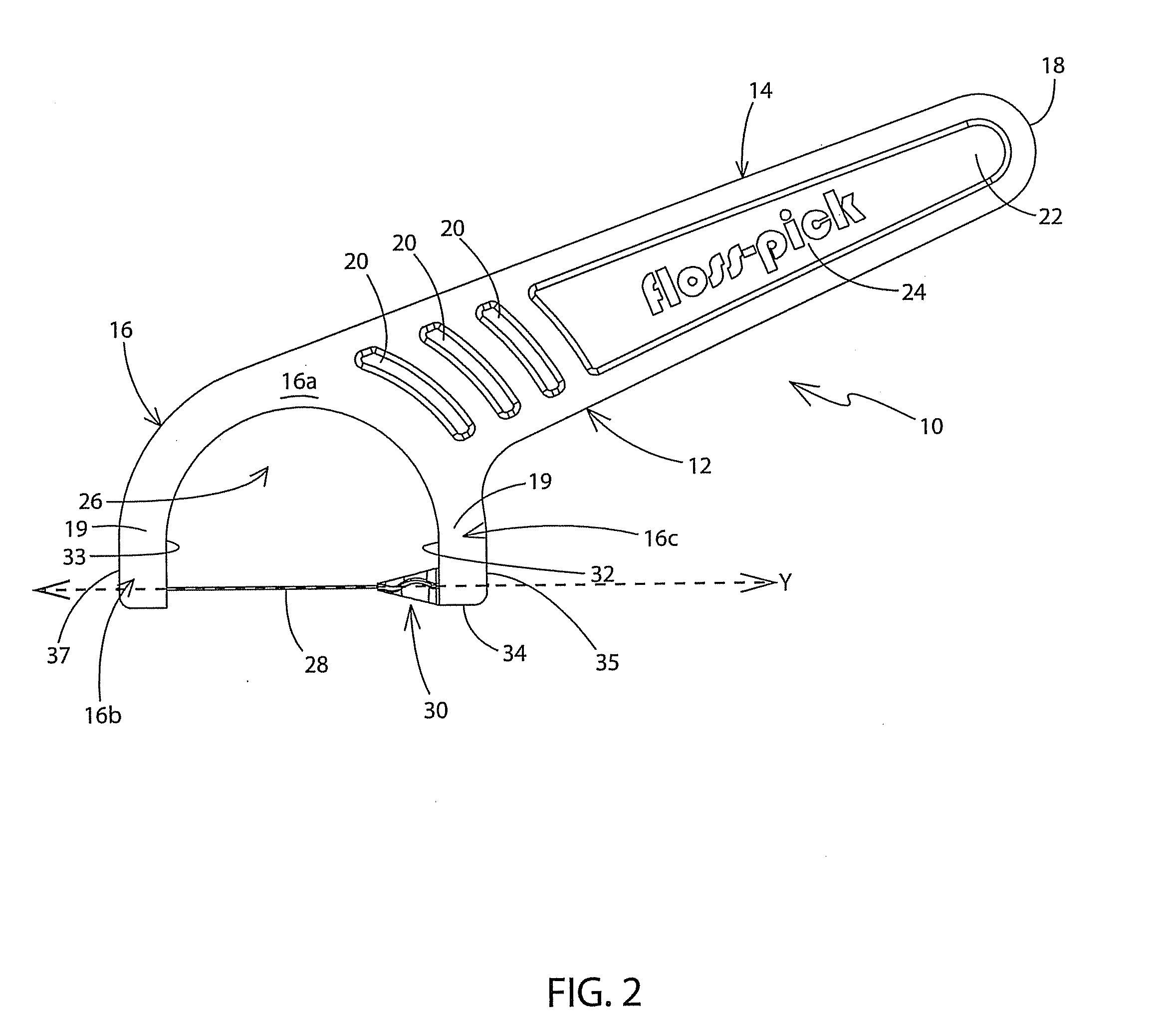

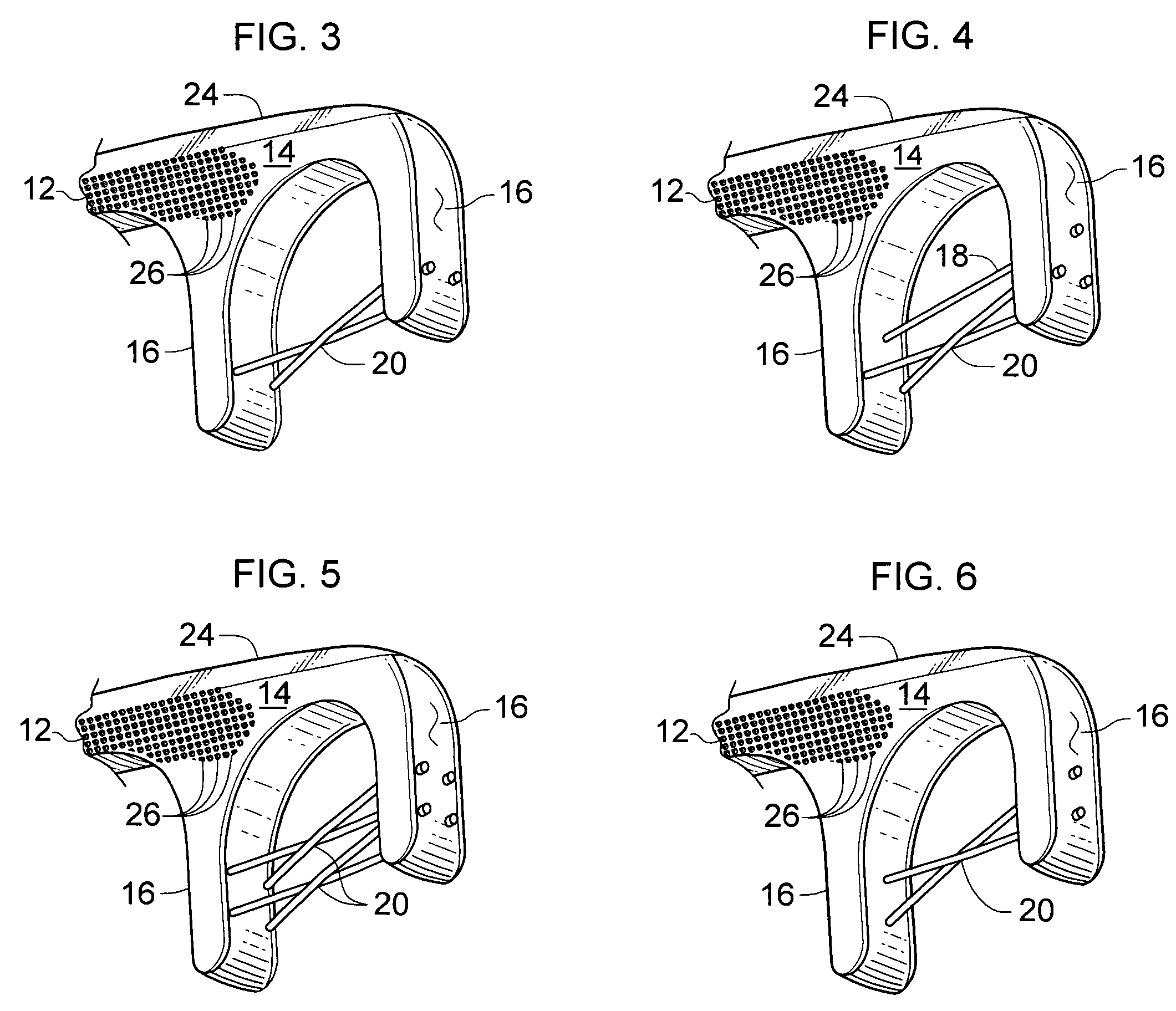

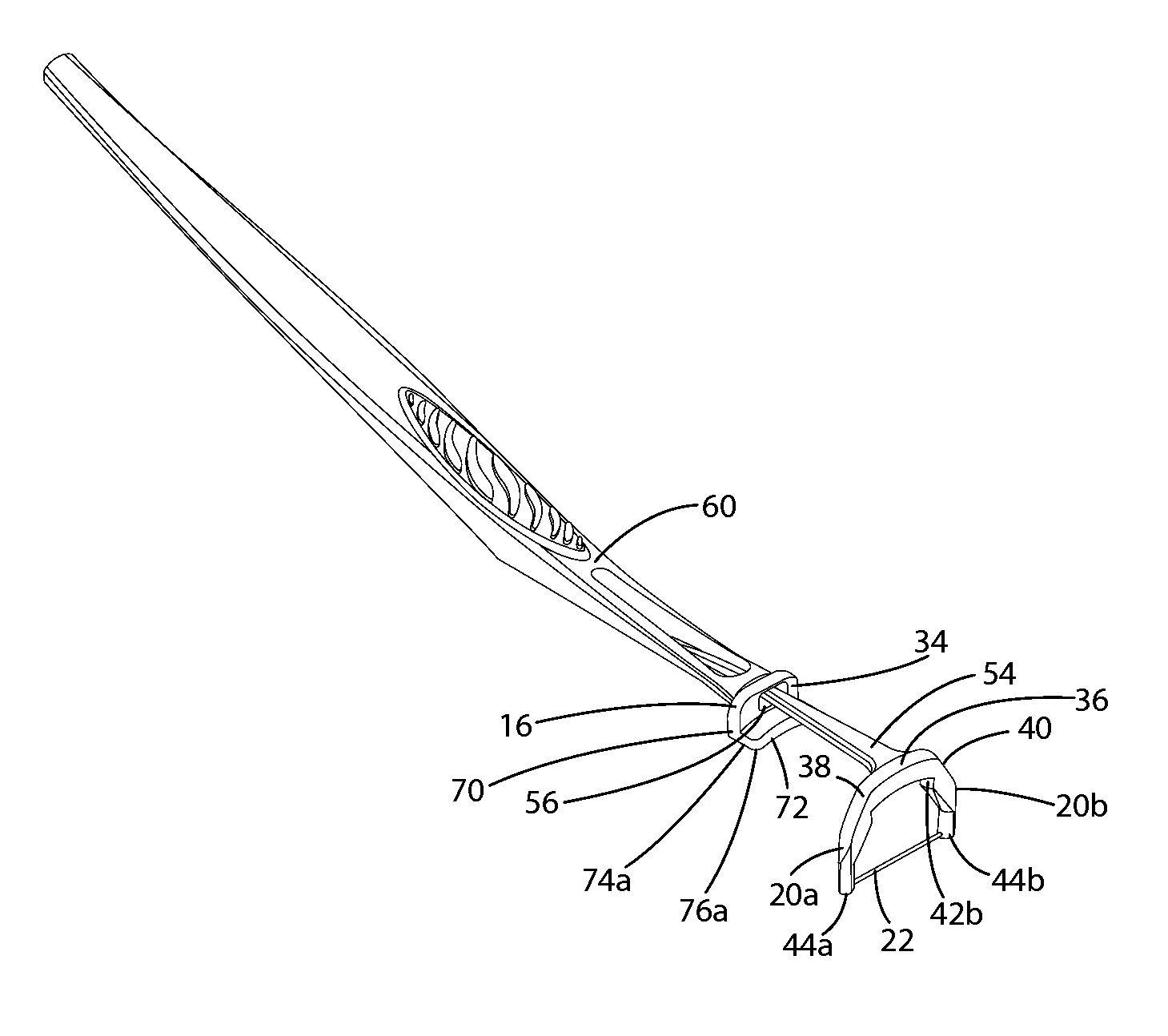

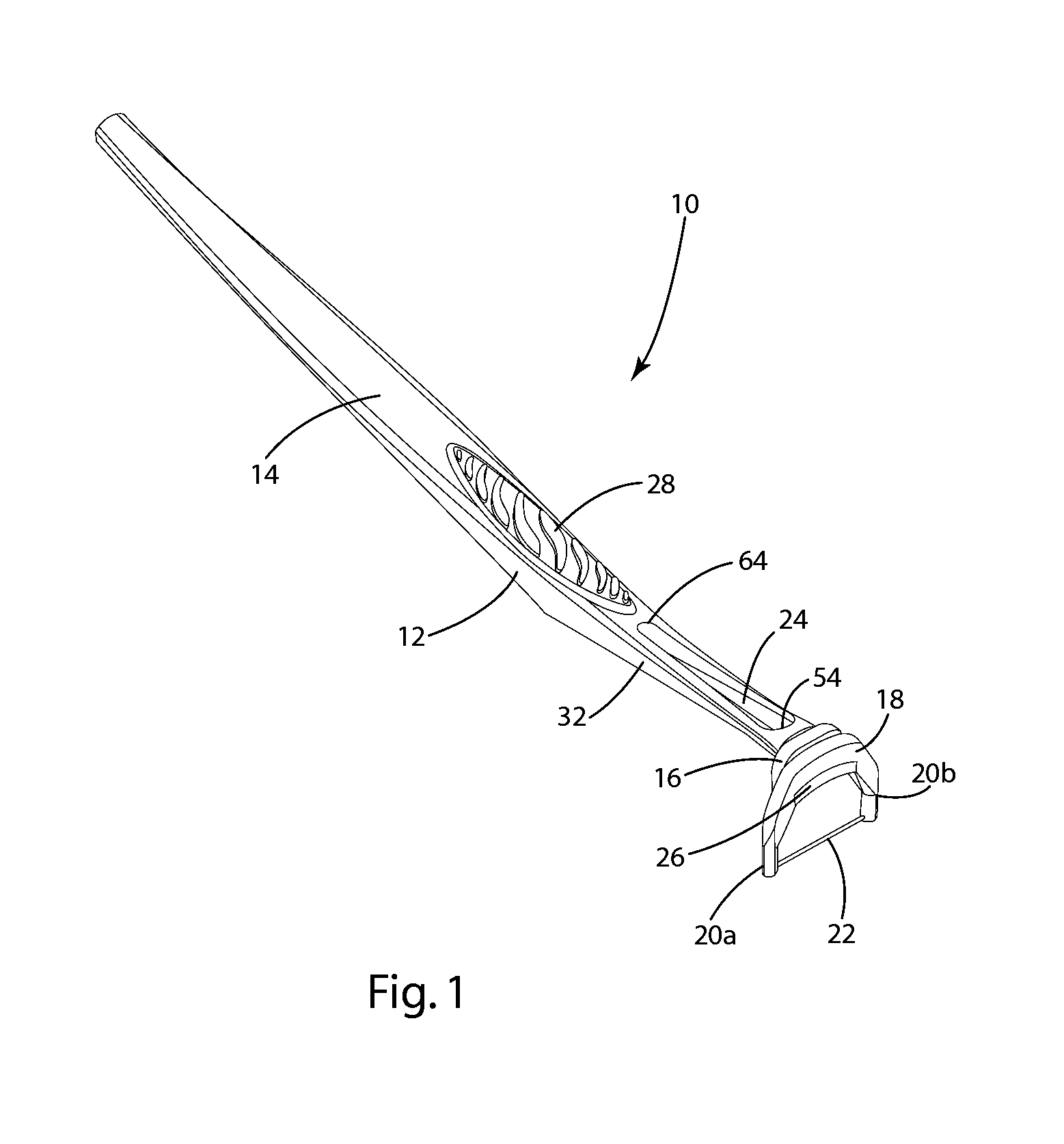

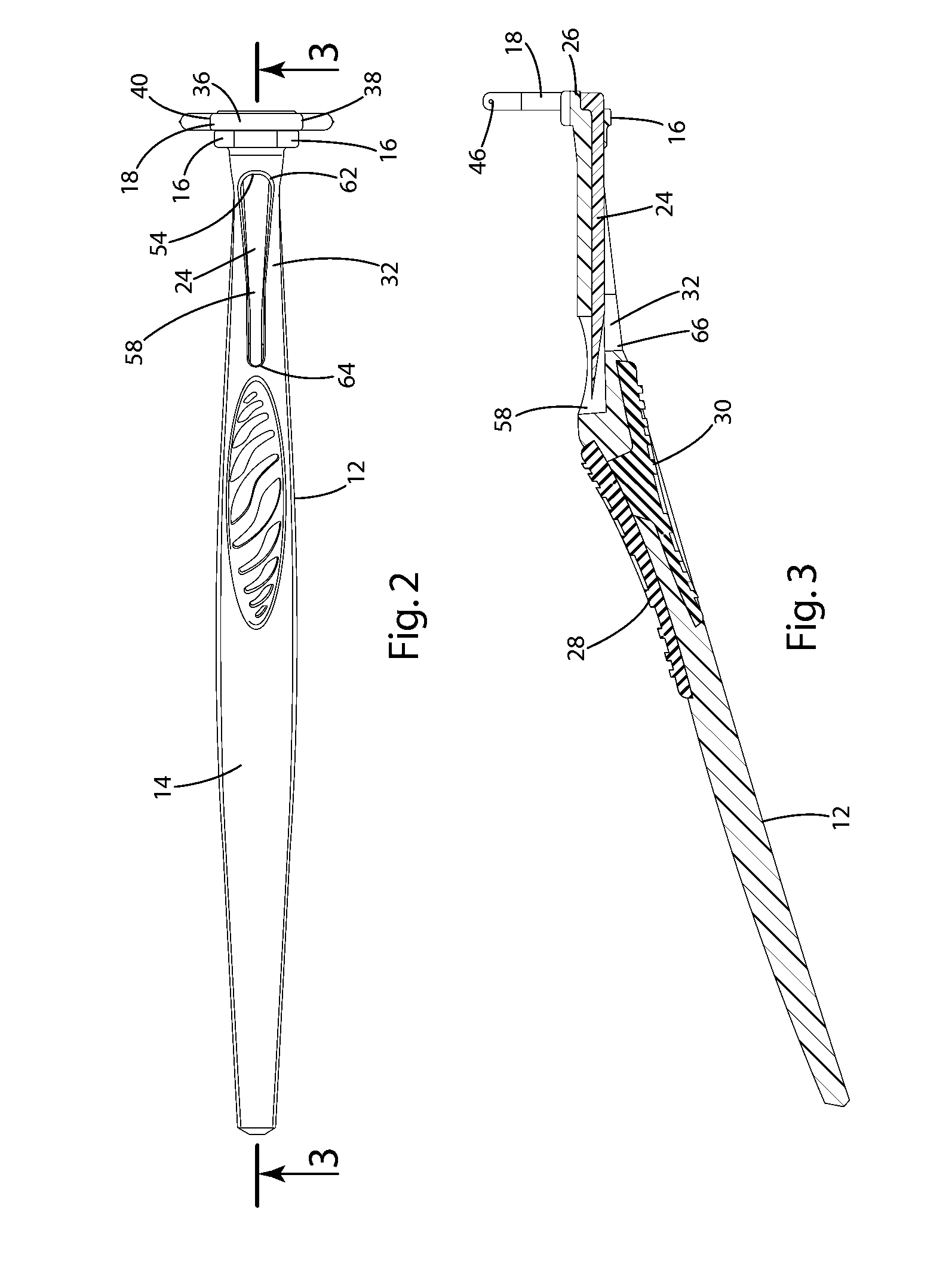

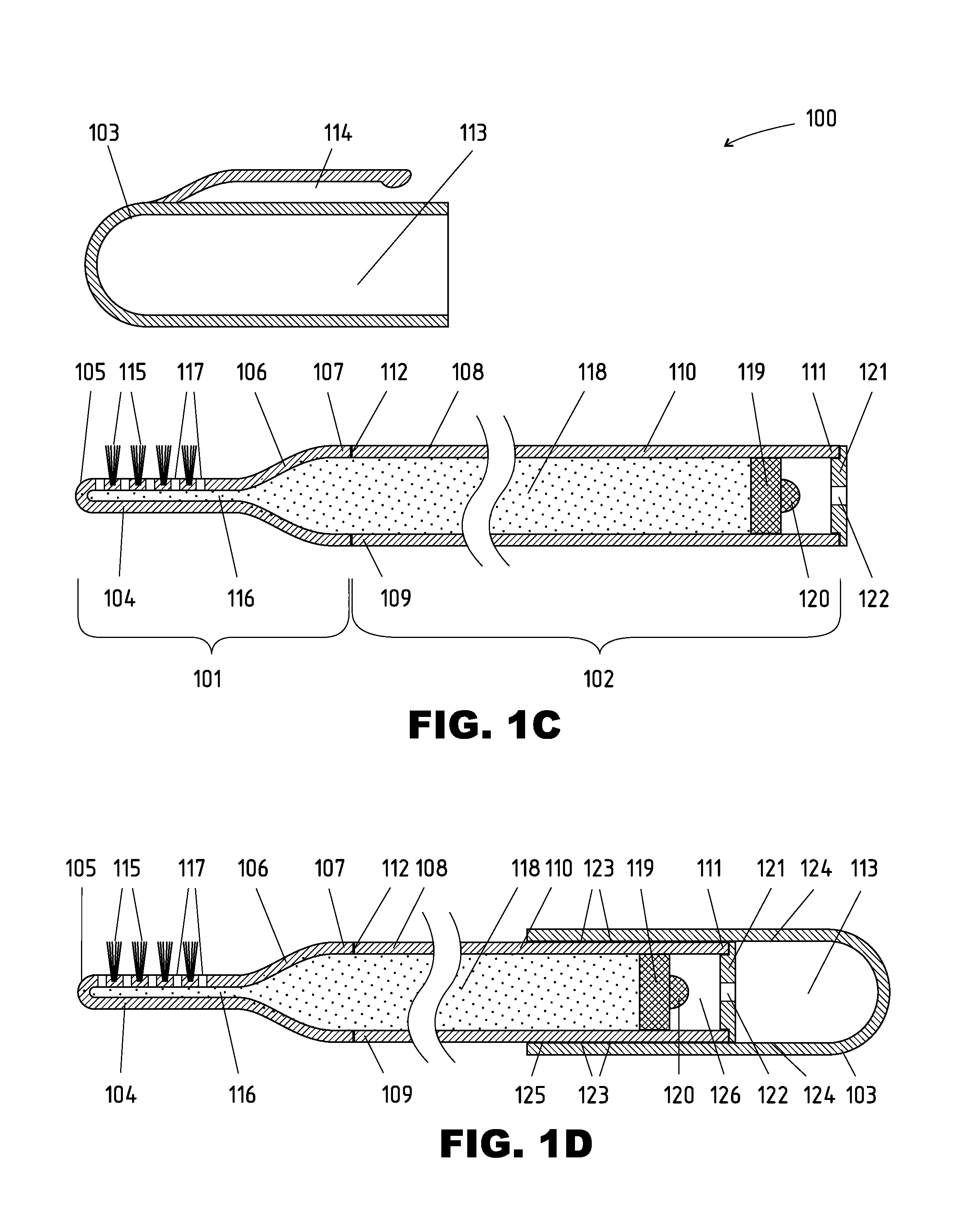

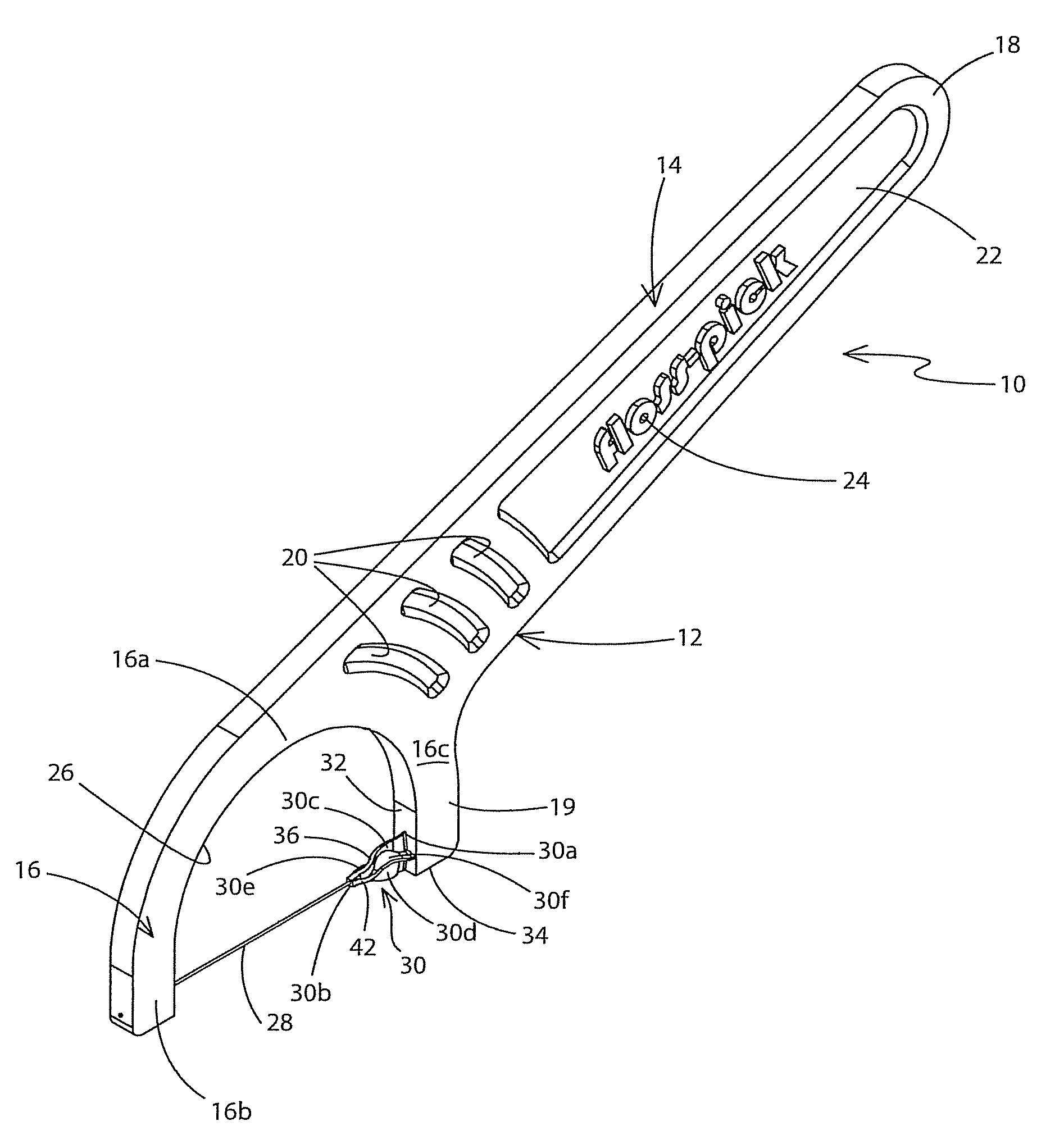

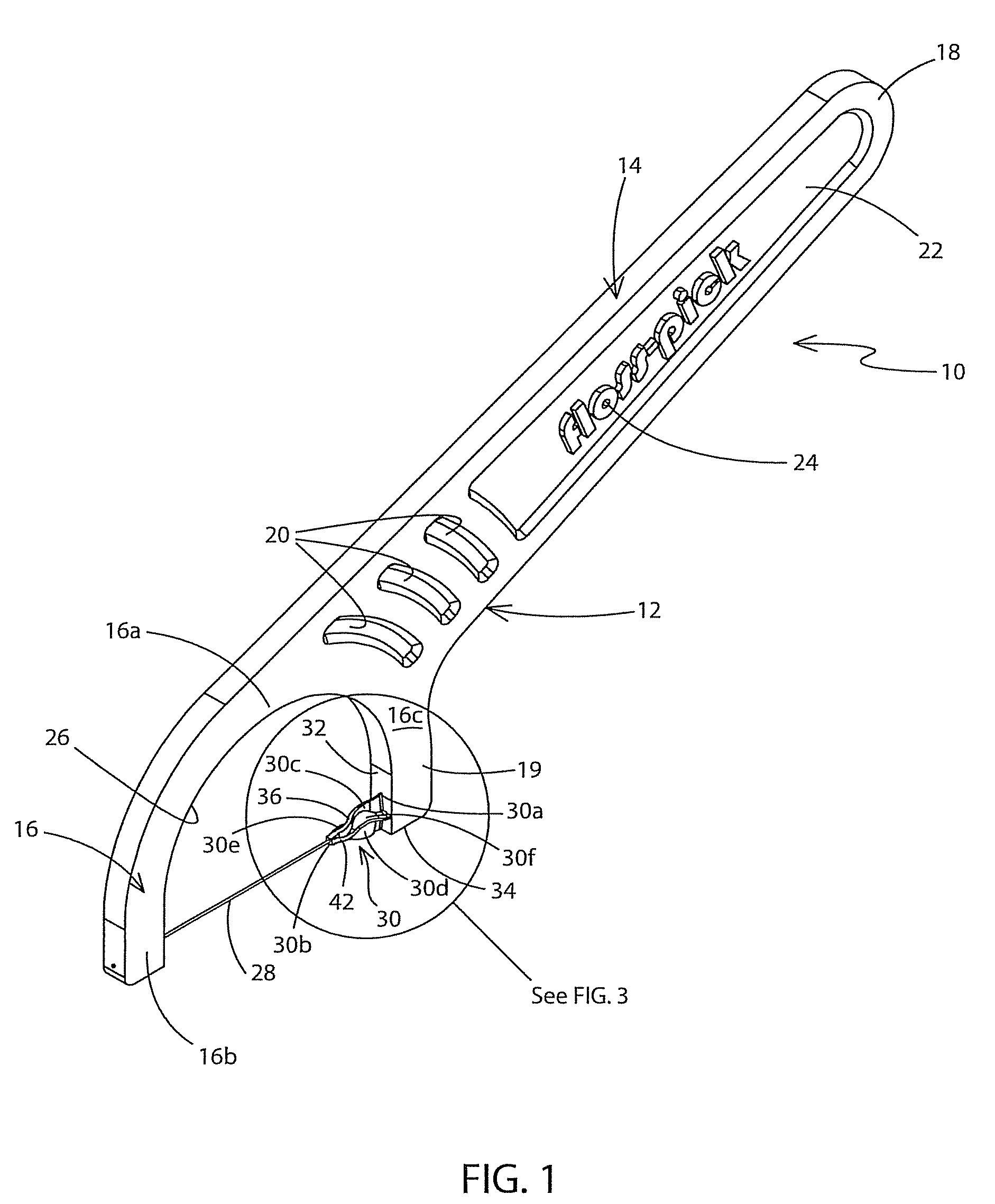

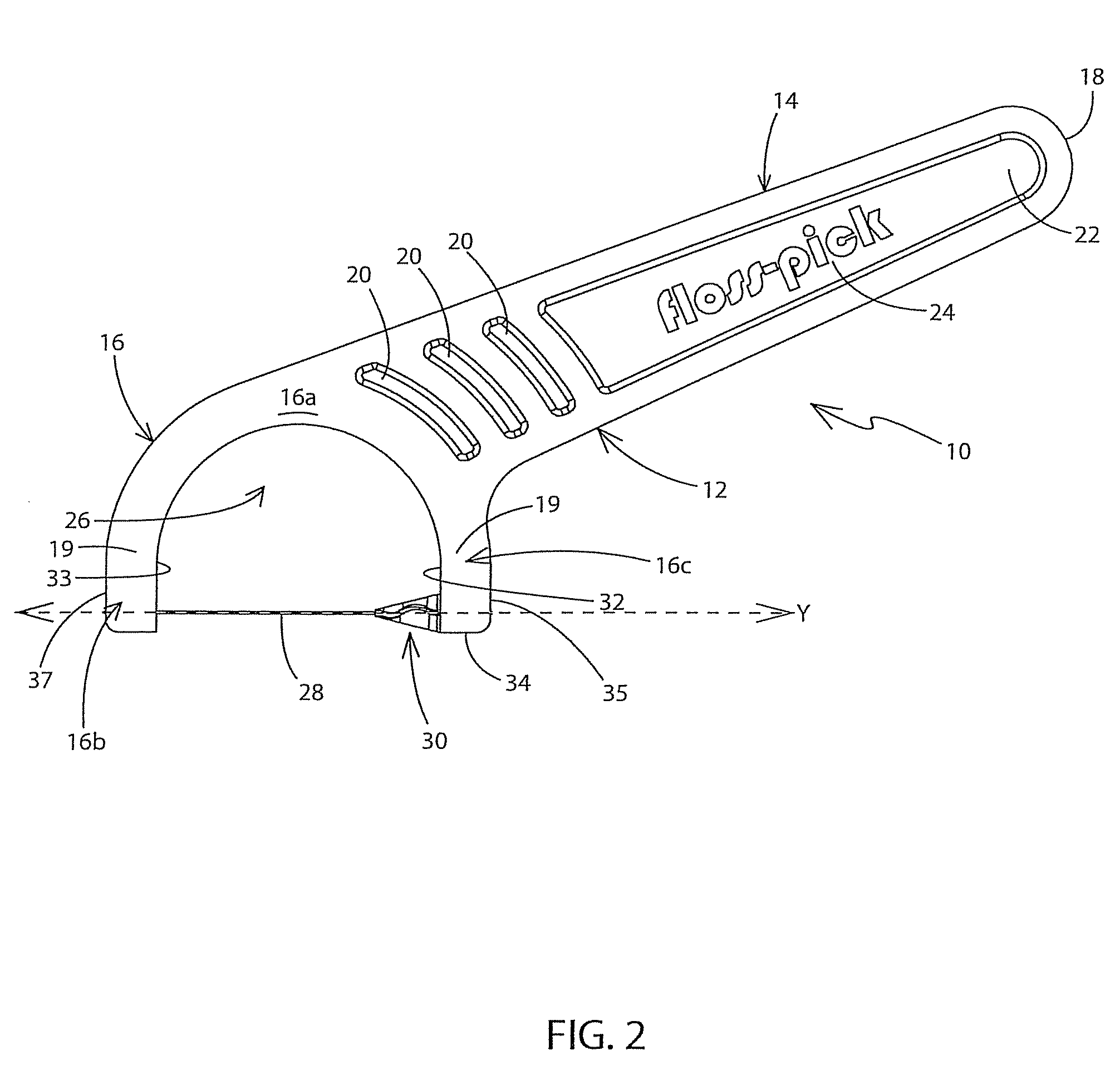

Floss pick

A floss pick including a body with a handle and a head having a length of floss therein. The handle defines an aperture with a toothpick member disposed therein. The toothpick member is connected to the handle by first and second bridge members. In a first instance, the bridge members are broken to detach the toothpick member. In a second instance, the bridge members are twisted to pivot the toothpick member from a non-use position to a use position where it is disposed at an angle relative to the body. The toothpick member is pivoted by engaging a terminal end thereof with an index finger of the hand in which the body is held. The angle of the toothpick member relative to the body is adjusted using the index finger to permit picking of the teeth in any region of the user's mouth without changing hands.

Owner:PROKOPCHUK WALTER +1

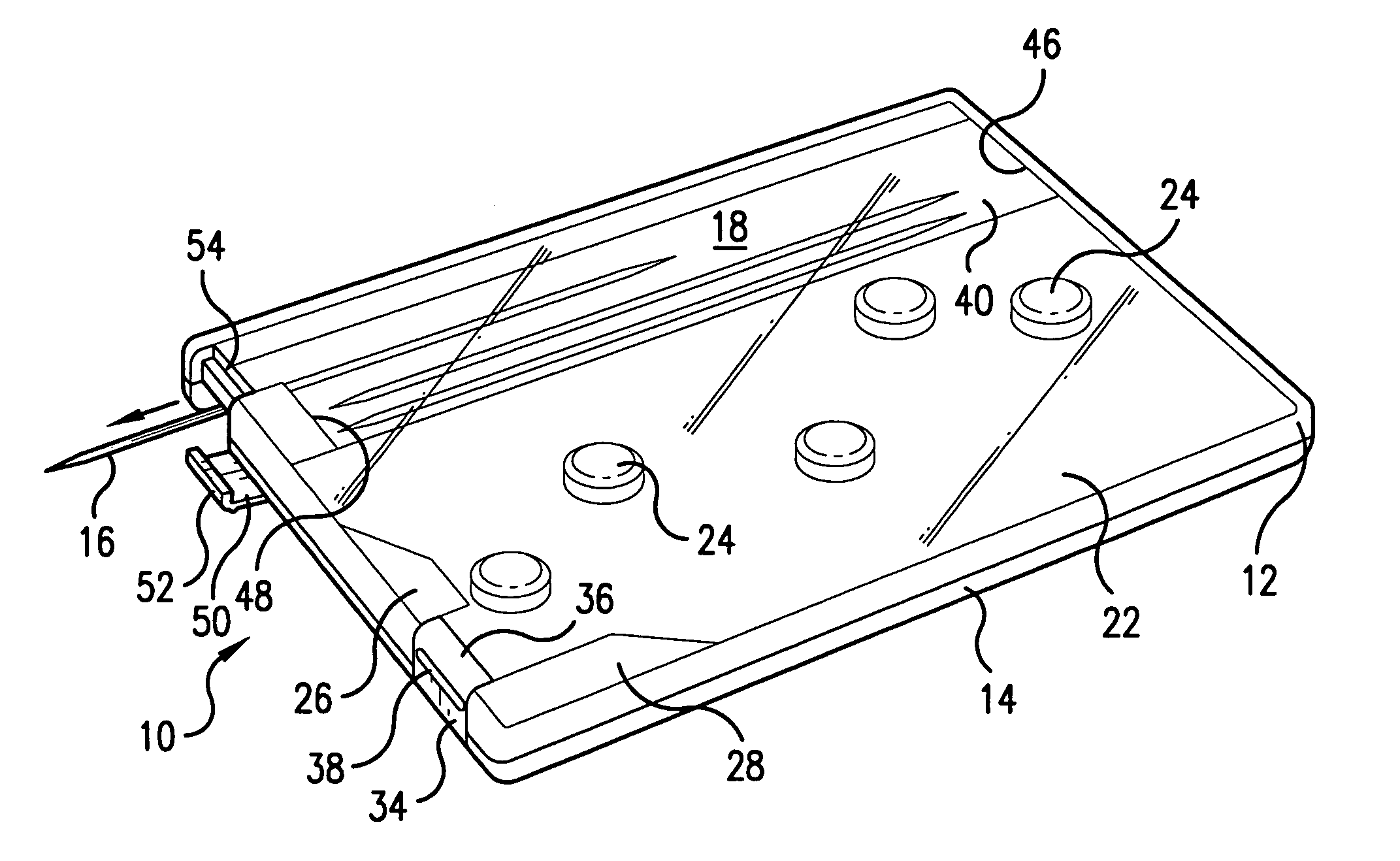

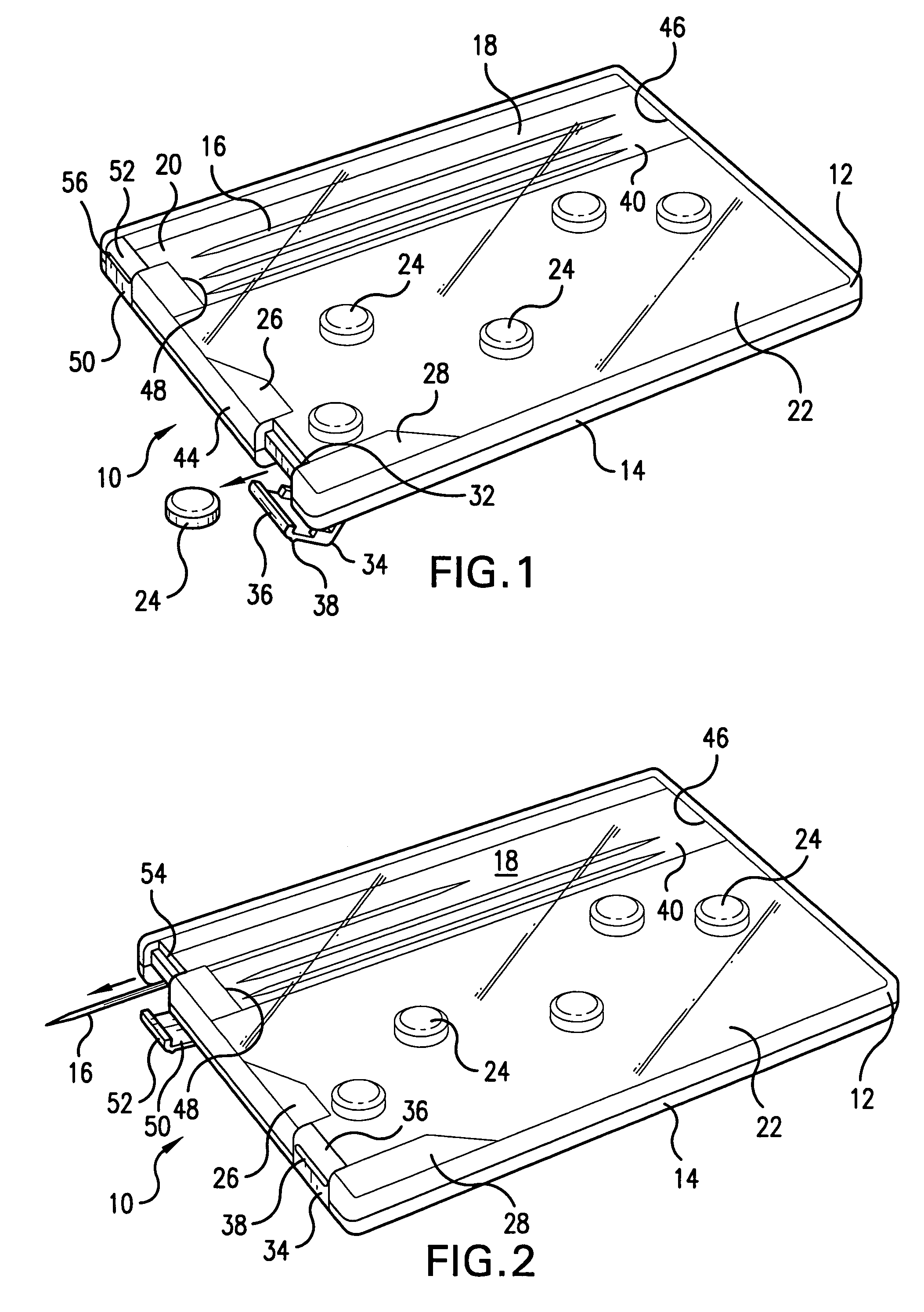

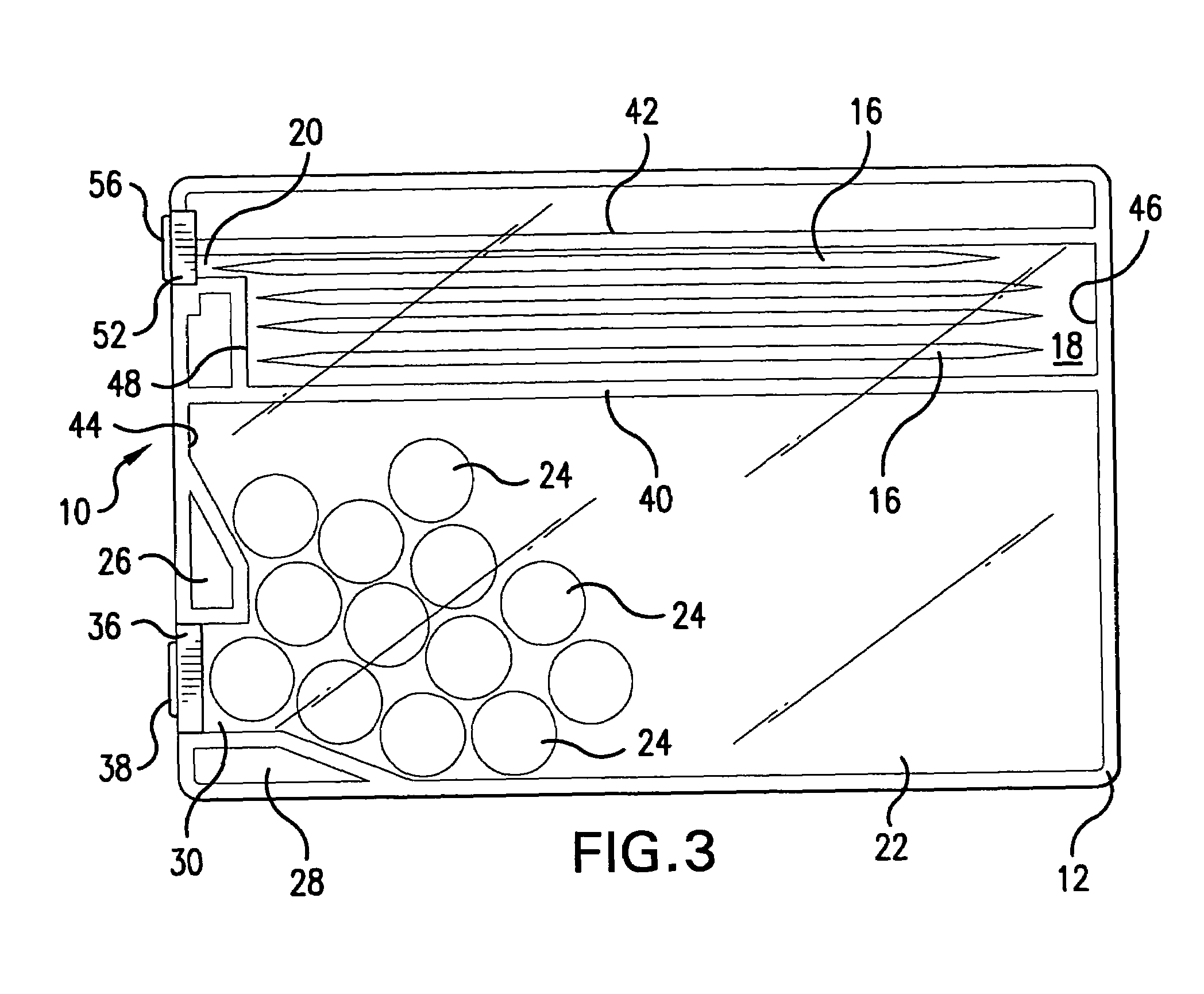

Disposable dental flosser

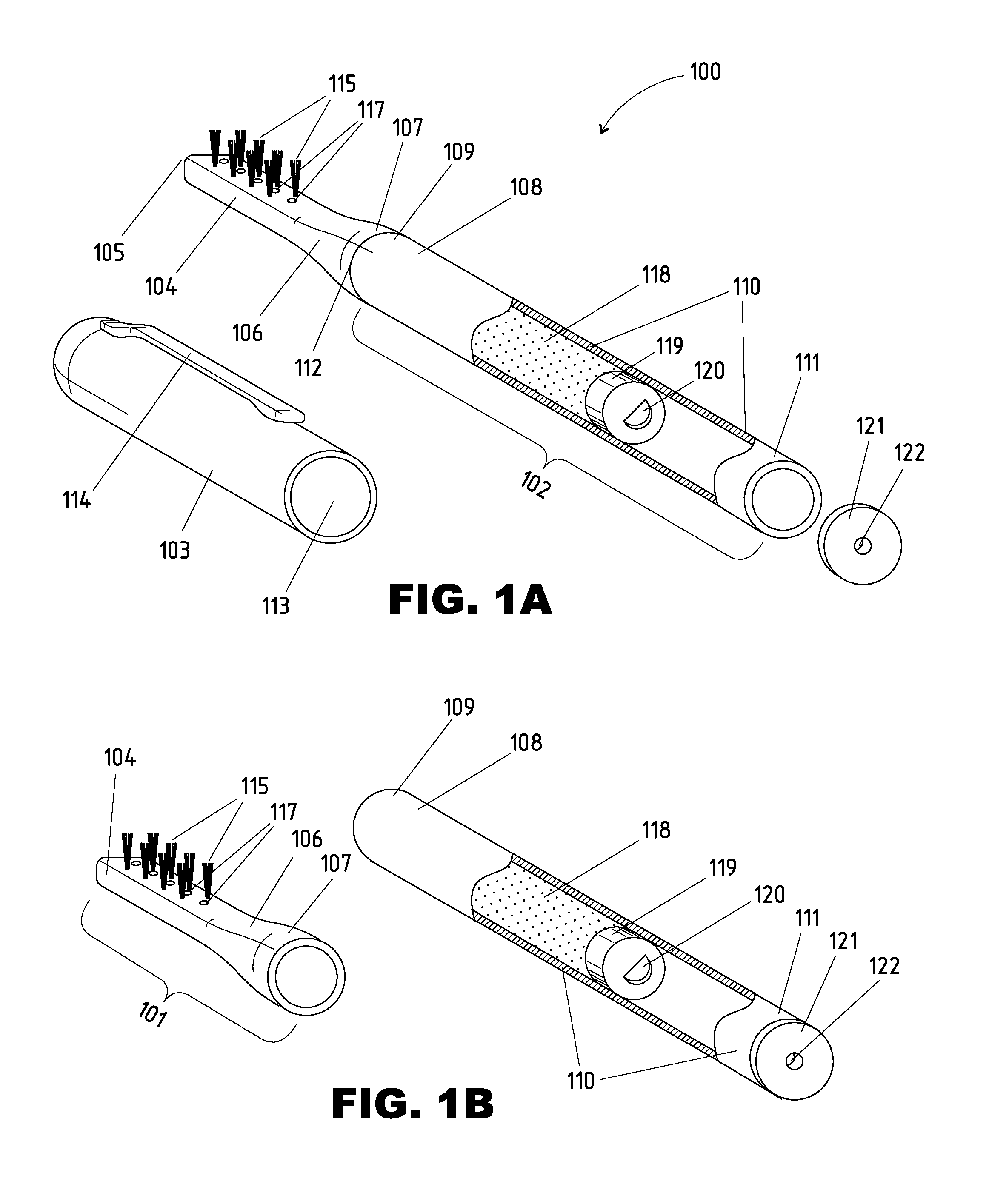

ActiveUS8069865B1Effective and efficient flossingLess timeGum massageDental flossTongue cleaningEngineering

A multi-strand disposable dental flosser with an improved floss strand pair arrangement. The dental flosser is an integral unit having an elongate gripping handle with a toothpick at one end, and a flosser head with two spaced apart arms at the opposite end. The floss strand pair is tautly stretched across the span between the arms and anchored securely near the tips thereof. The floss strand arrangement includes an X-configured floss strand pair, and can have at least one additional X-configured floss strand pair or at least one added single floss strand disposed slightly above the lower floss strand pair. The X-configured floss strand pair has two individual strands that are spaced apart at the ends thereof and cross together at the mid-lengths thereof. The flosser can have a tongue-cleaning edge and a tongue-cleaning surface area to enhance overall oral hygiene.

Owner:WINTER LYNN A

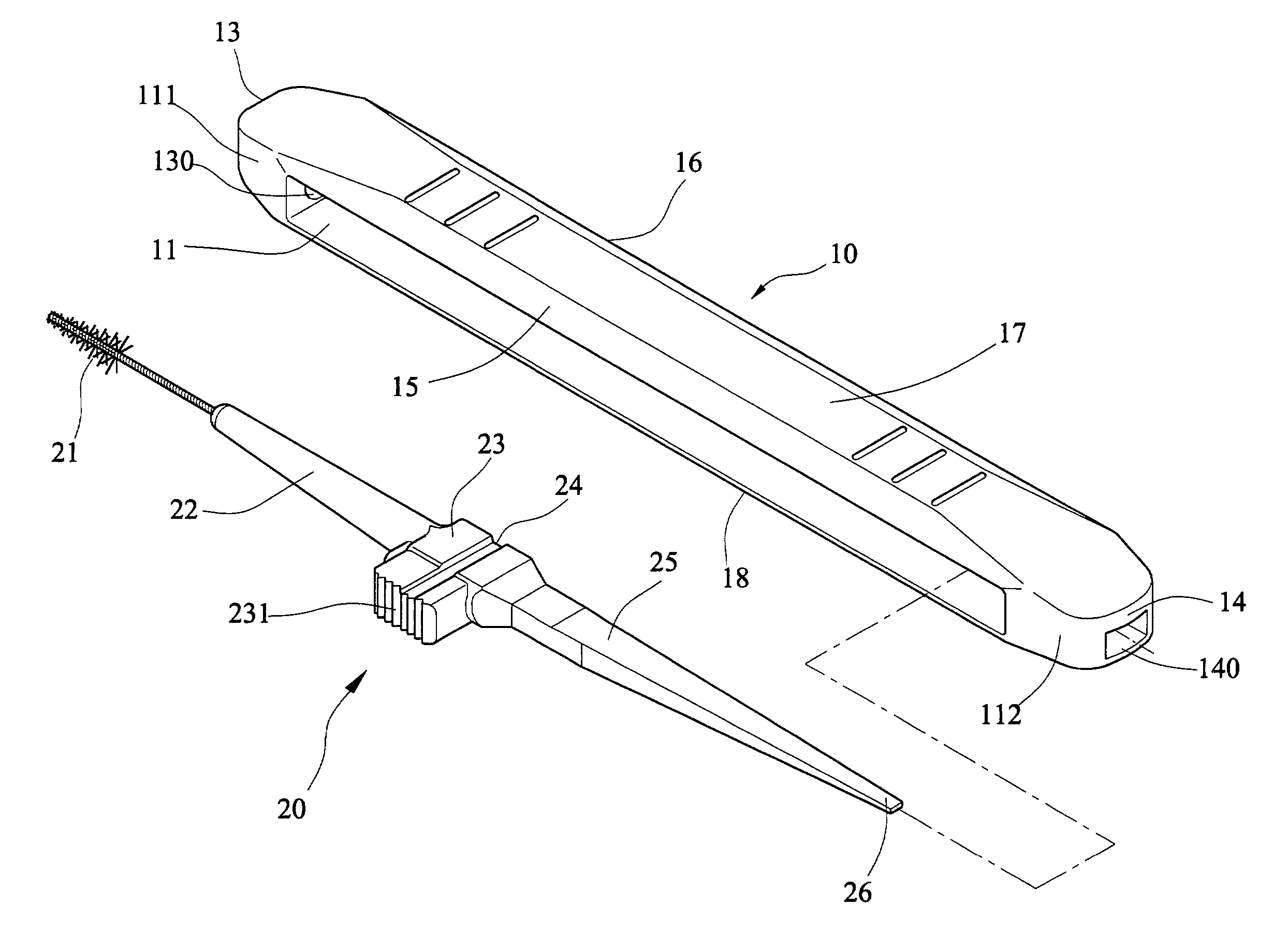

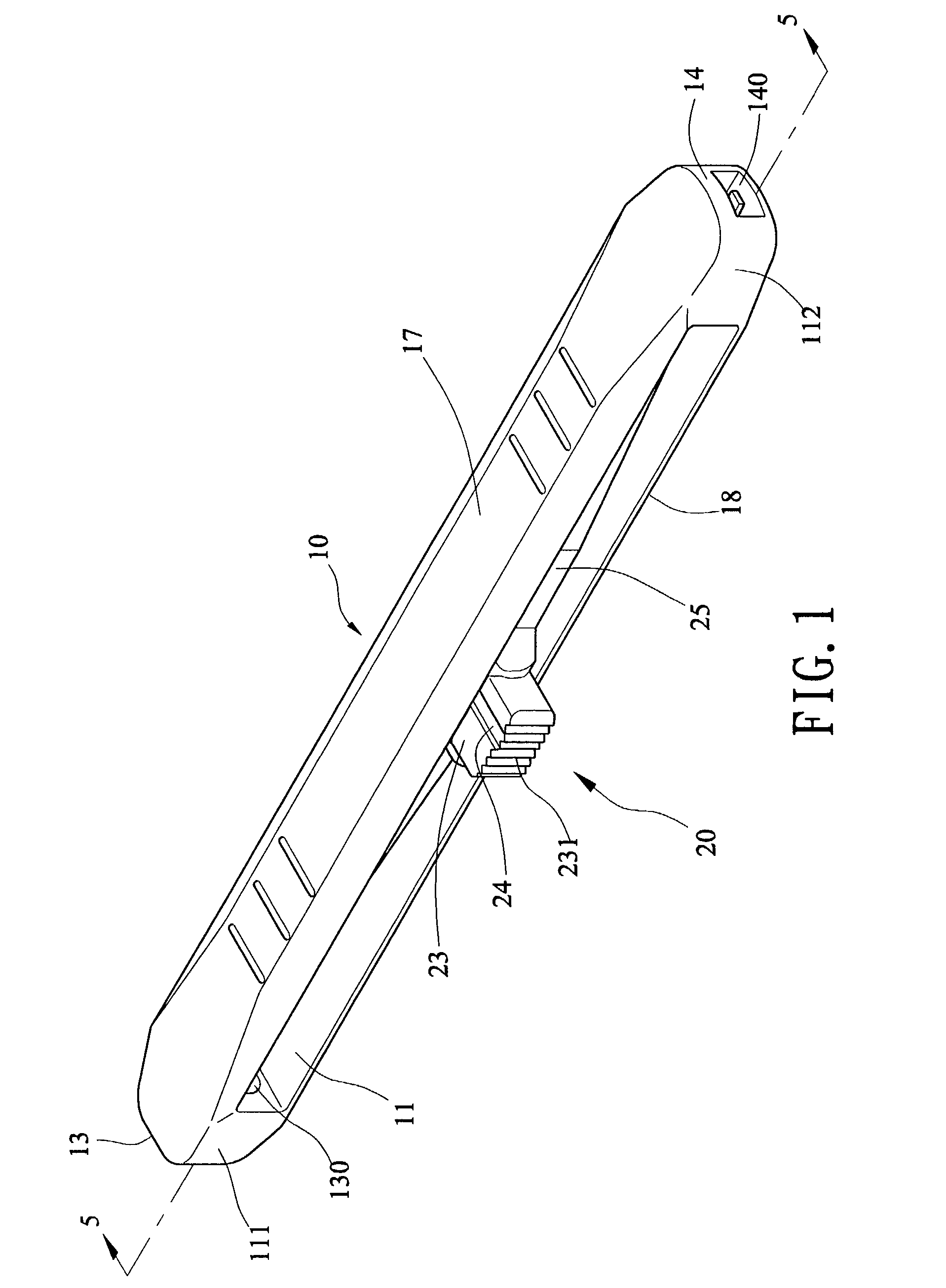

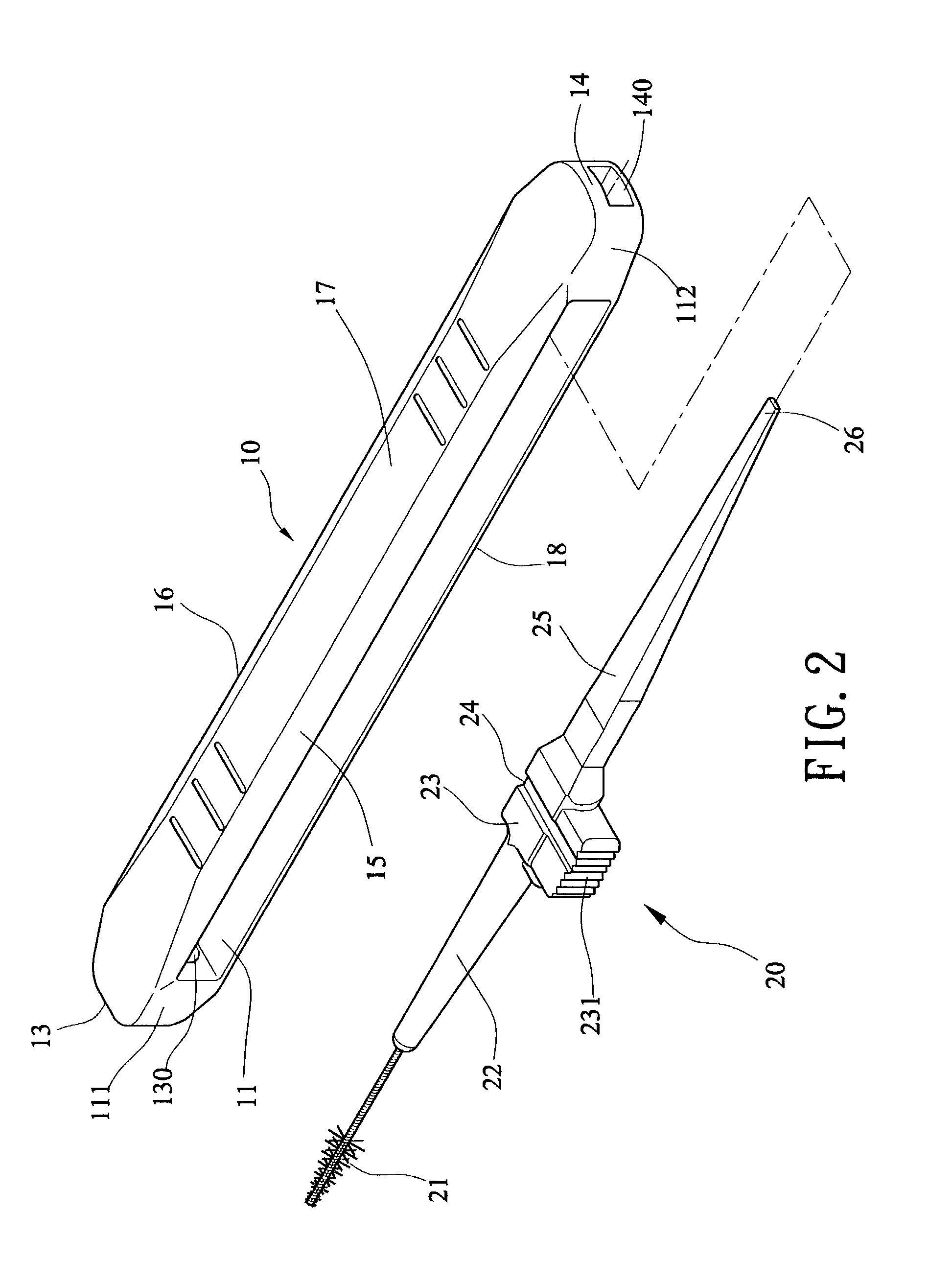

Toothpick and interdental brush combination

InactiveUS6973932B2Easy to carryEasy to cleanGum massageCarpet cleanersEngineeringMechanical engineering

A toothpick and interdental brush combination comprises a case comprising a lengthwise groove on a side, first and second end openings both in communication with the groove; and an assembly slidable in the case, the assembly comprising a projected trigger member, a first body member extended from the trigger member toward the first end, an interdental brush integrally formed with the first body member at first end, a second body member extended from the trigger member toward the second end, and a toothpick integrally formed with the second body member at the second end. In a storage state both the toothpick and the interdental brush are concealed in the case, or in a use state of the interdental brush or the toothpick a pushing of the trigger member toward the first or the second end causes the interdental brush or the toothpick to project from the first or the second opening respectively.

Owner:KO WEI CHU

Dental floss device

A dental flosser includes a handle and a dental floss holder releasably received by the handle. The dental floss holder includes a base, a pair of arms for holding a length of dental floss, and a toothpick extending from the base. The handle includes a receiver in which the toothpick on the dental floss holder is received. The handle and the dental floss holder cooperate to prevent transverse movement of the dental floss holder.

Owner:RANIR LLC

Refillable toothbrush and toothpaste cartridge

Disclosed herein is a refillable toothbrush with a refillable toothpaste chamber also adapted to contain a toothpaste cartridge. Thus the toothpaste chamber can be filled directly by toothpaste from different types of toothpaste tubes, or the consumer can use a toothpaste cartridge. An essential distinctive feature of the present invention is realization of two functions by means of the protective cap: its direct function—protecting the bristles in stowed position, and an additional function, namely—feeding toothpaste to the bristle section. The toothbrush is made of a small number of simple parts, is easy to manufacture, has the opportunity to be simply assembled-disassembled, and is easily cleaned. To facilitate cleaning of the toothbrush head conduit from the remnants of toothpaste before the next recharge of the toothbrush, it can be complete with a special removable rod having an ability to be let-in the conduit. A distinctive feature of the removable rod is that it fulfills additional useful functions: prevents paste hardening in conduit at long non-use of a brush; can serve as a toothpick; can serve as means for piercing membrane of a cartridge. The toothbrush can also be complete with a special clip for fixing it in the user's pocket. A special design of the clip provides it with an additional function that allows for the user to dose out more precisely supplied toothpaste to the bristles. A new kind of cartridge is also disclosed herein.

Owner:LUBINITSKY DANIEL

Throwaway toothpick containing a single dose of mouthwash

A throwaway toothpick containing a single dose of mouthwash. The throwaway toothpick containing a single dose of mouthwash includes a toothpick portion and a mouthwash portion. The toothpick portion is throwaway. The mouthwash portion extends axially from the toothpick portion, oppositely from the toothpick portion, is one-piece with the toothpick portion, and contains a single dose of mouthwash so as to allow a user to use the toothpick portion to pick the teeth thereof, thereafter turn the throwaway toothpick containing a single dose of mouthwash around and use the single dose of mouthwash of the mouthwash portion to wash the mouth thereof, and thereafter throw the throwaway toothpick containing a single dose of mouthwash away.

Owner:SALOFF AARON DANIEL +1

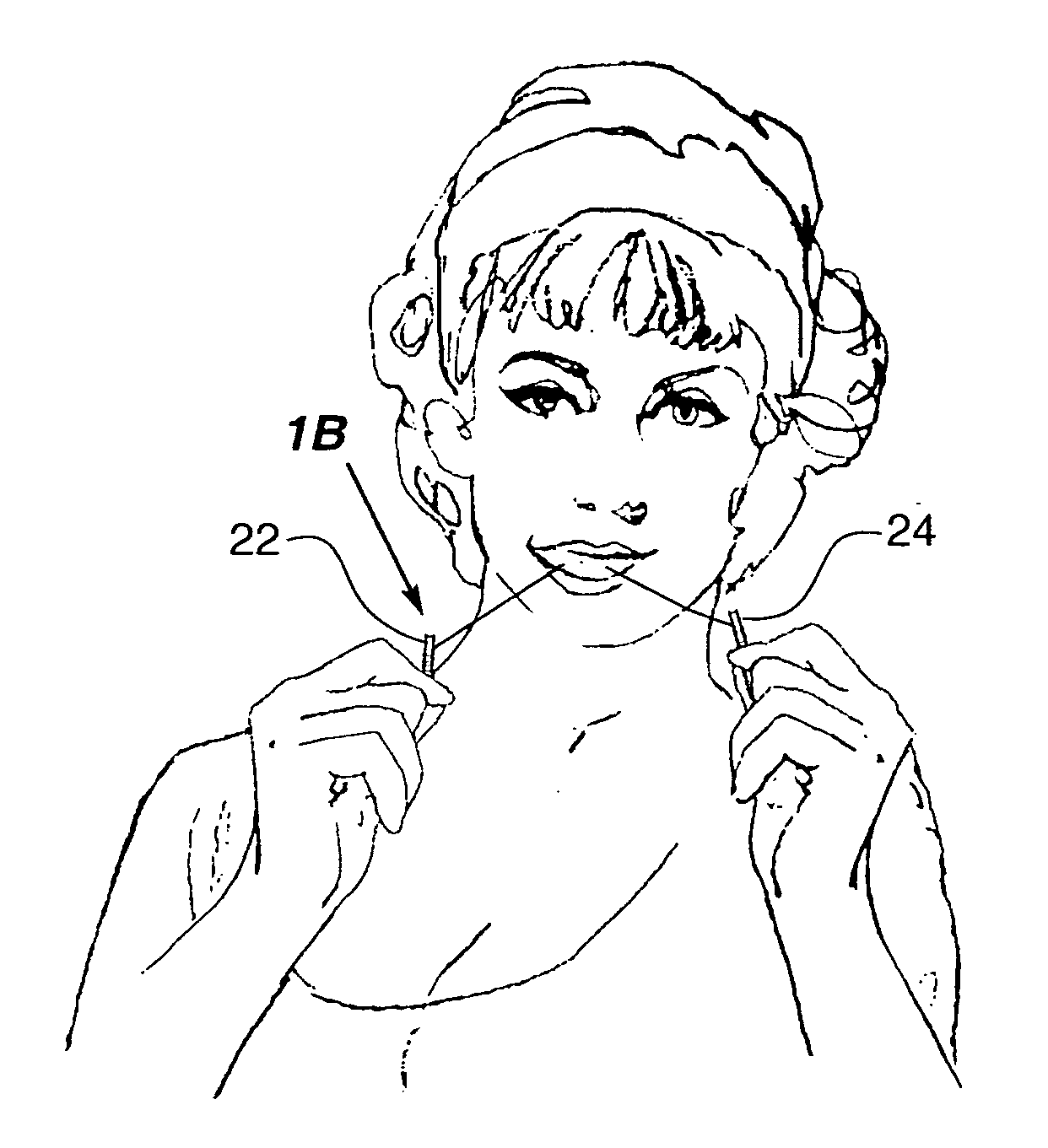

Disposable tongue scraper

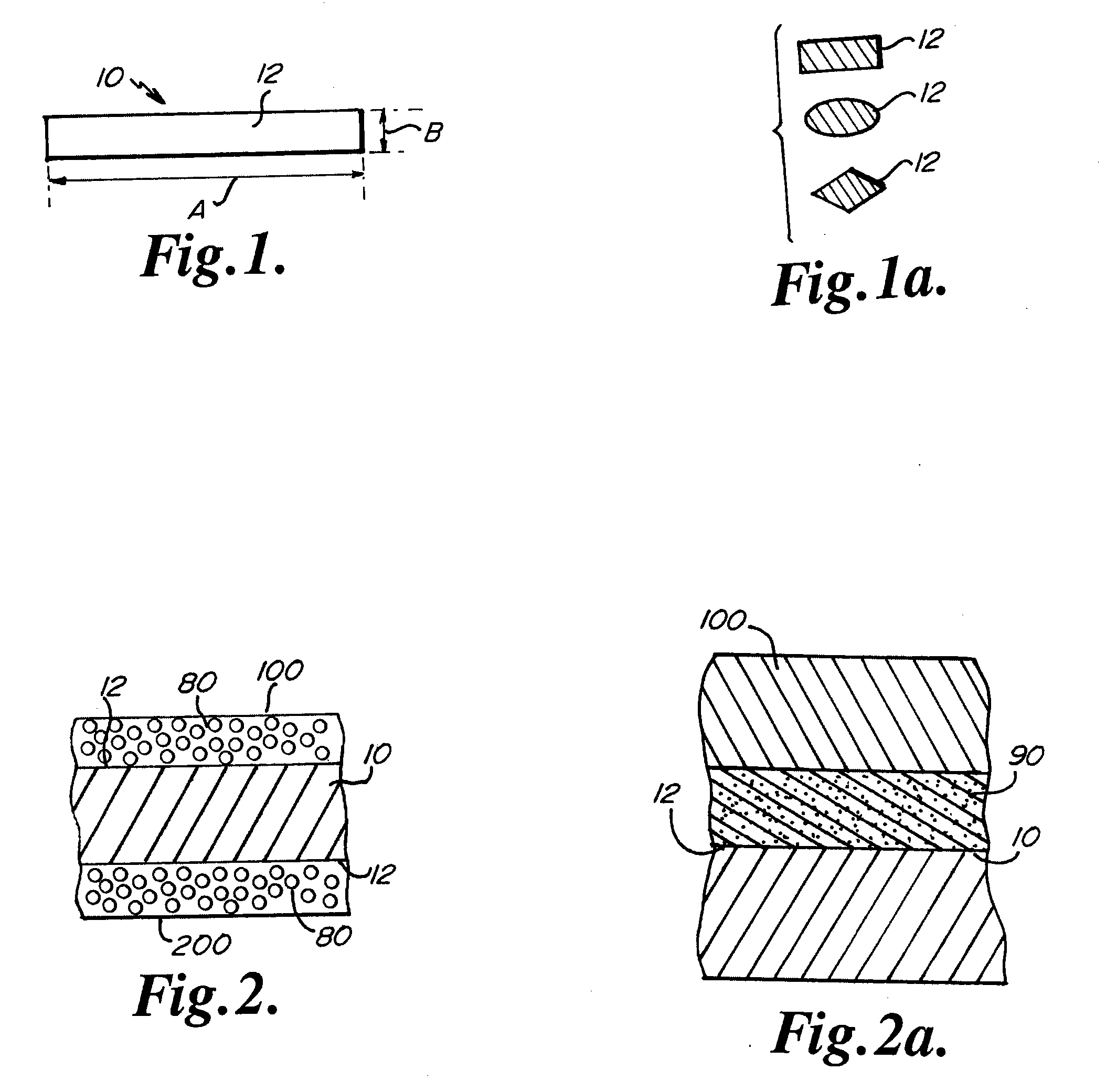

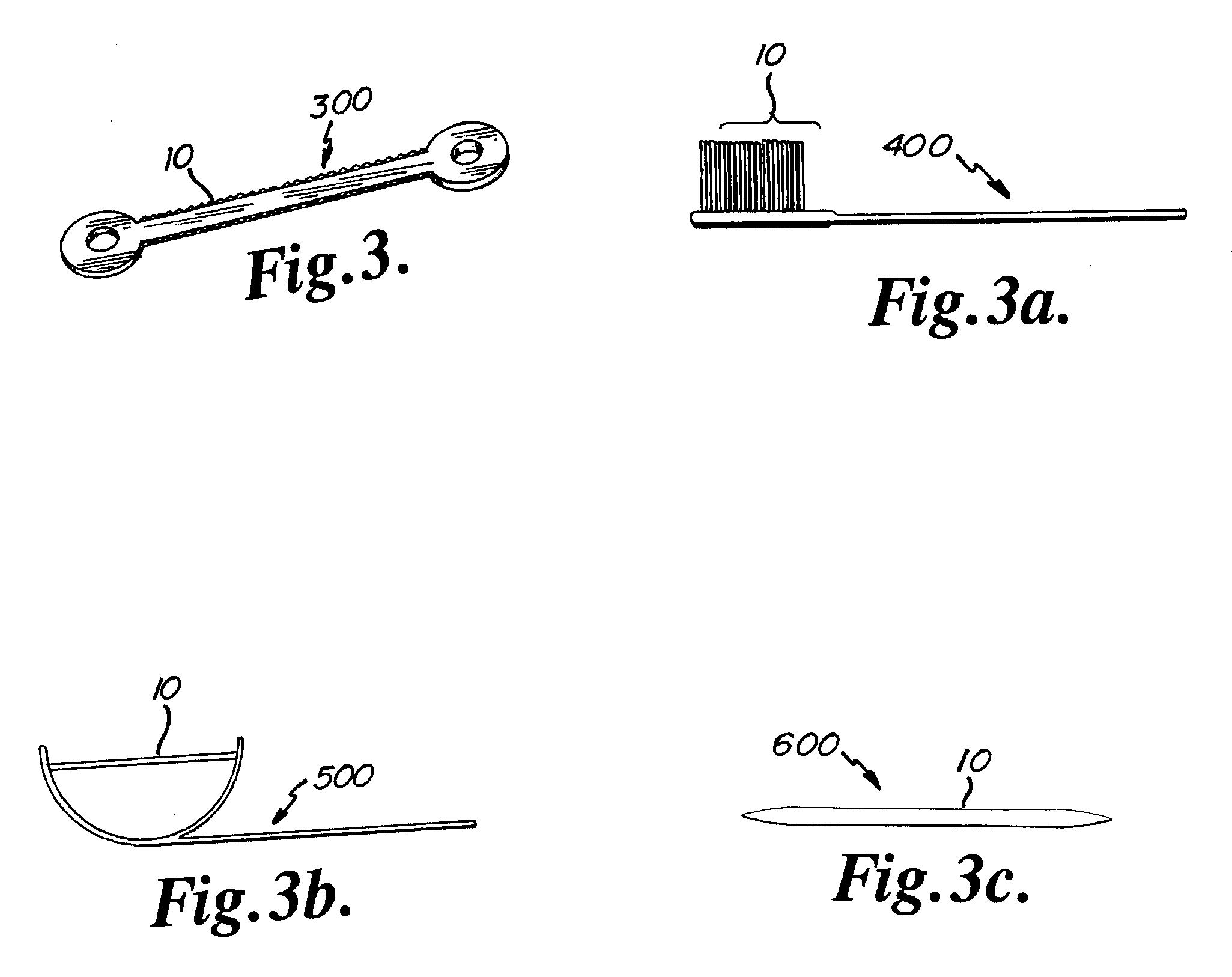

The present invention relates to a dental implement such as tongue scraper that is disposable and is adapted for prophylactic and / or therapeutic action for the oral cavity. The dental implement may include a tongue scraper, a dental floss, a toothpick, a toothbrush or combinations thereof. The dental implement may include a strip having a longitudinal dimension that is longer than its traverse dimension. The strip may be coated with a coating of a mixture including at least one medicament and a water soluble or erodible carrier. In one embodiment, the coating may be present on at least one of the longitudinal edges, for example, of a tongue scraper, toothpick or a dental floss. In another embodiment, the coating may be present on at least one of the traverse edges, for example, of a tooth pick or the bristles of a toothbrush. In a further embodiment, the coating may be present on a combination of edges. The integrity of the implement, such as a scraper and / or its edge or edges may be reinforced by the coating of substance or agent for sufficient integrity, and the scraper or its edge and / or the coating, for example, are adapted to degrade or break down as the substance or agent are released during use and / or upon contact with water and / or saliva. The dental implement may be exposed for use, and is appropriately stored prior to use.

Owner:DISCUS DENTAL LLC

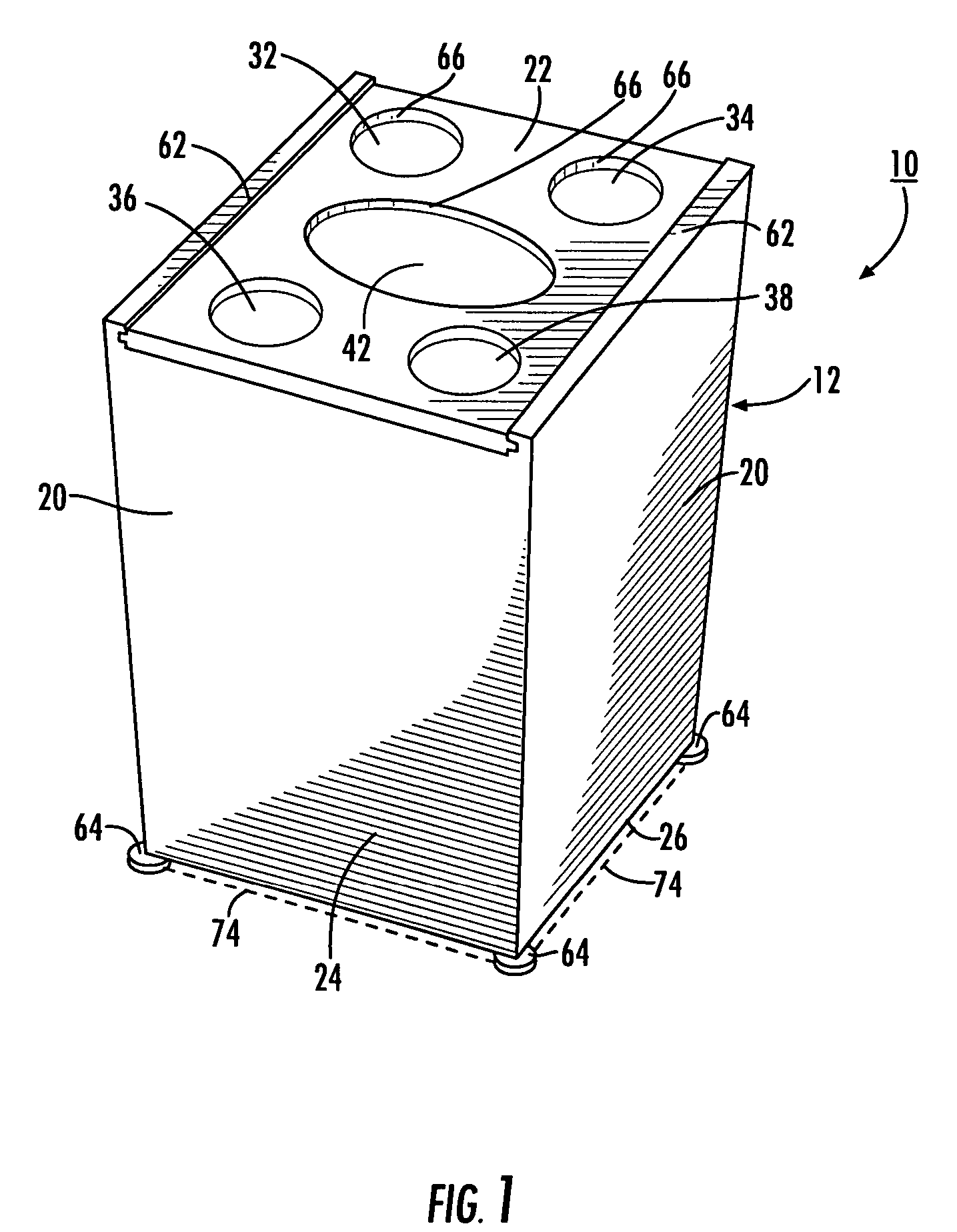

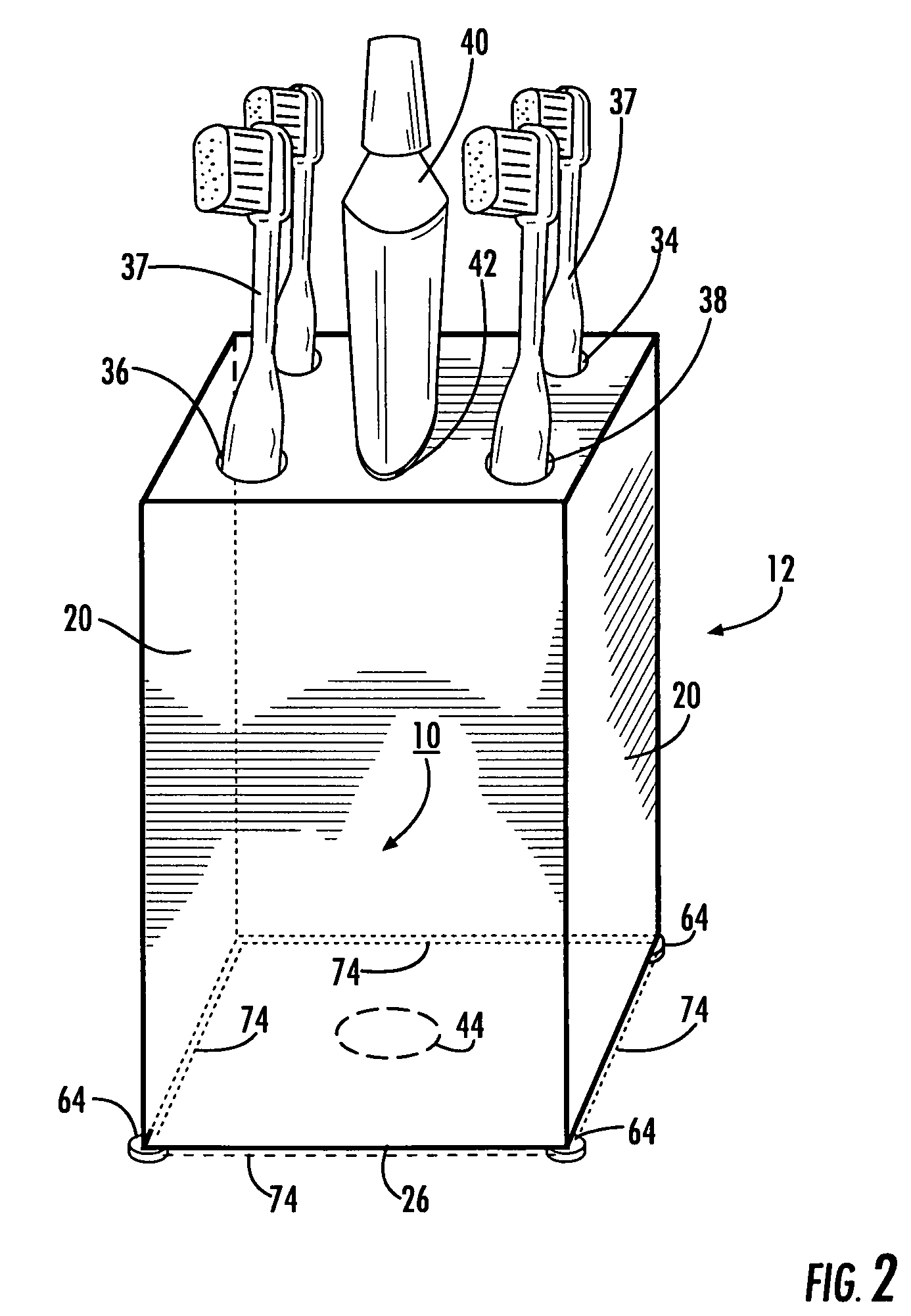

Decorative dentifrice holder

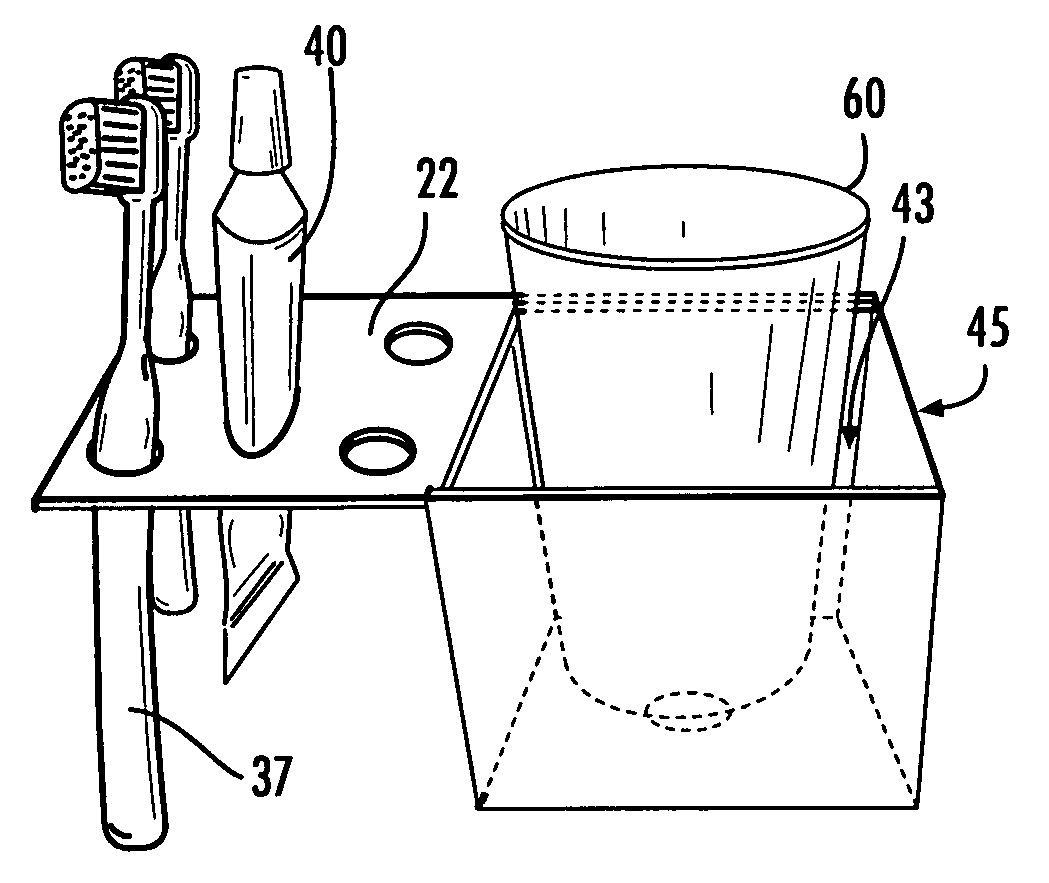

ActiveUS7299922B2Stable and durable designEasy to transportDispensing apparatusWash-standsTelecommunicationsToothpaste

The present invention is directed towards a dentifrice item holder; most particularly a holder capable of holding toothbrushes, toothpaste tubes and other various items, such as a rinse container, mouthwash, dental floss, toothpicks, and the like, all together.

Owner:CLEARY TAMERA

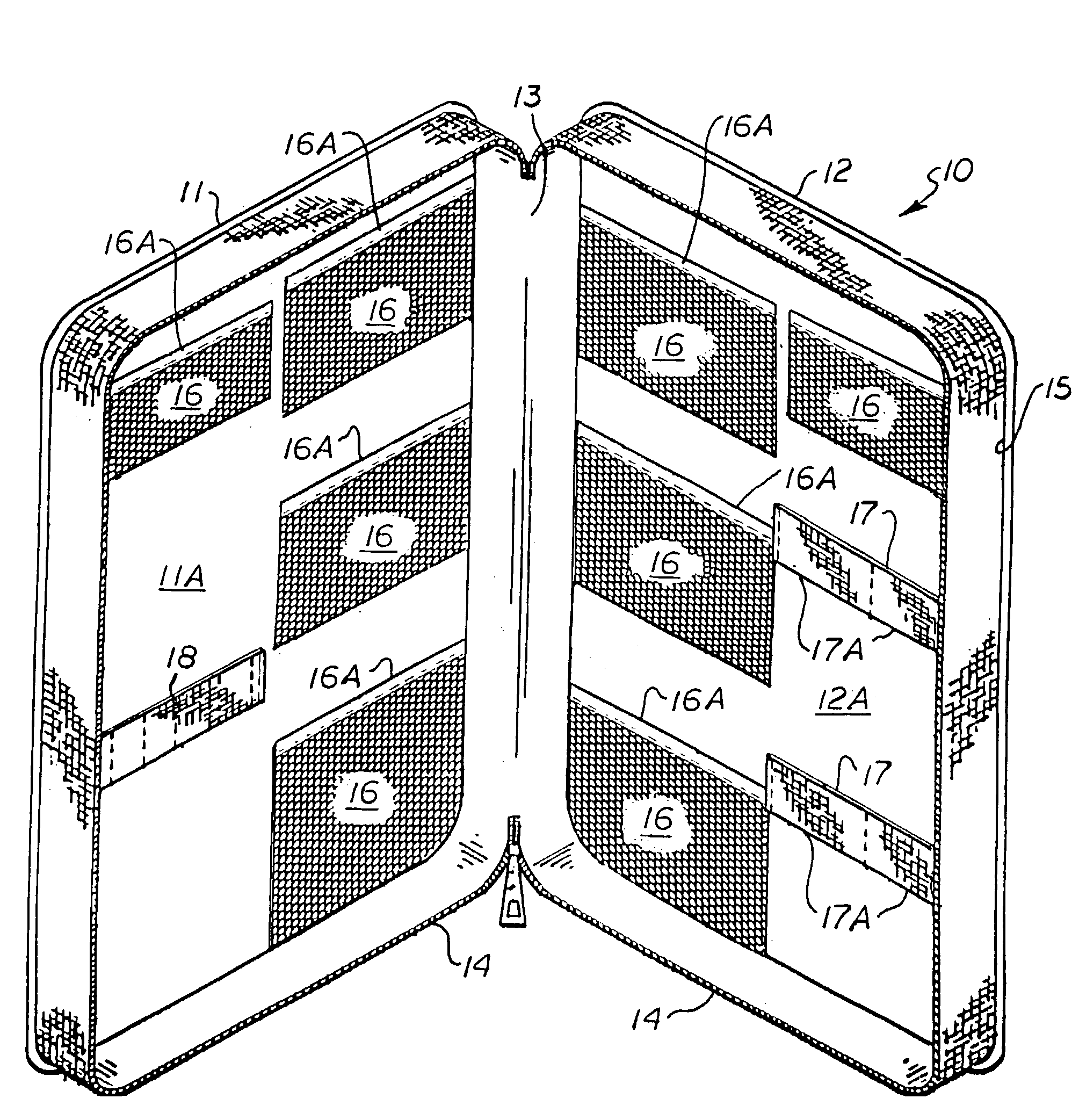

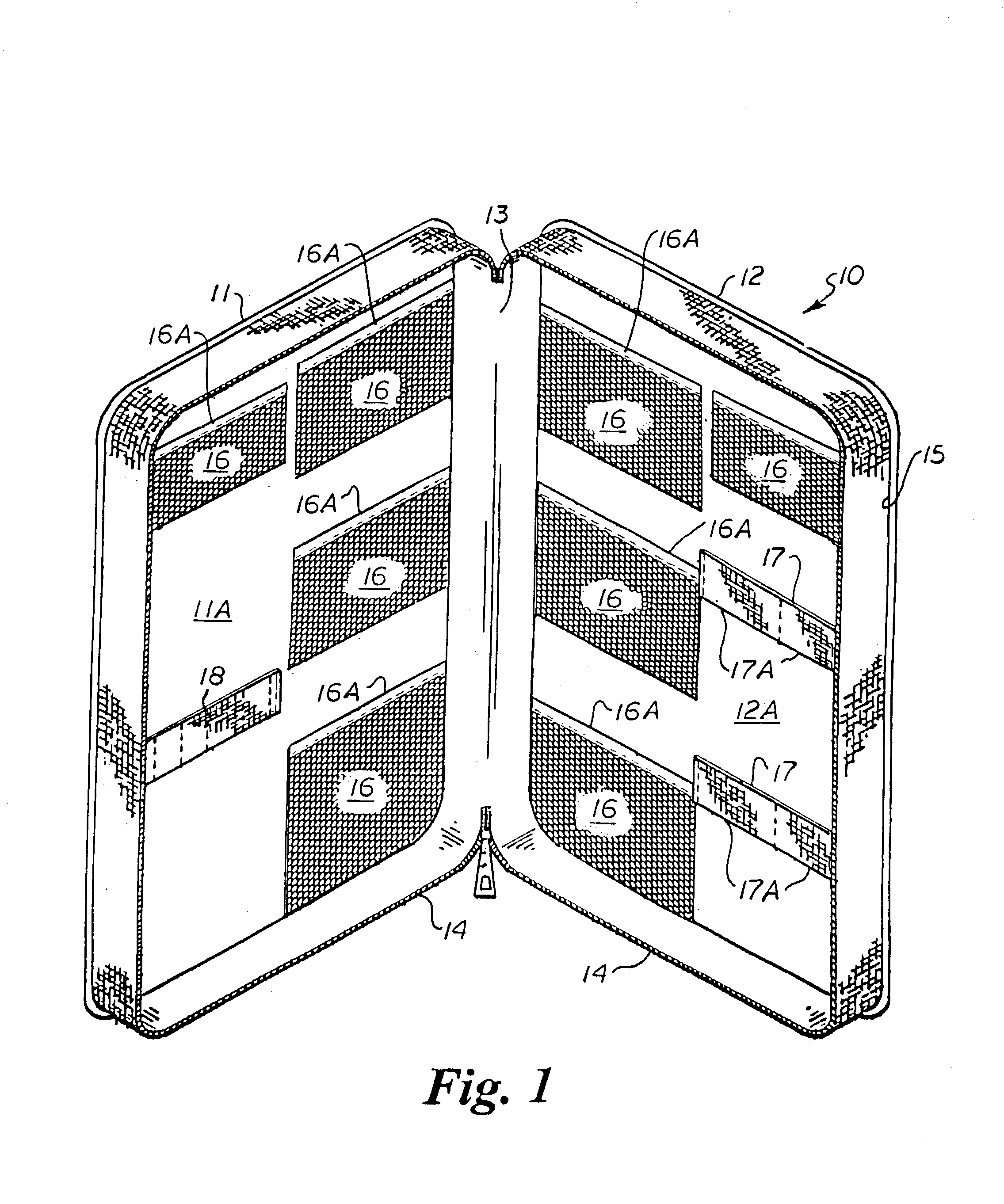

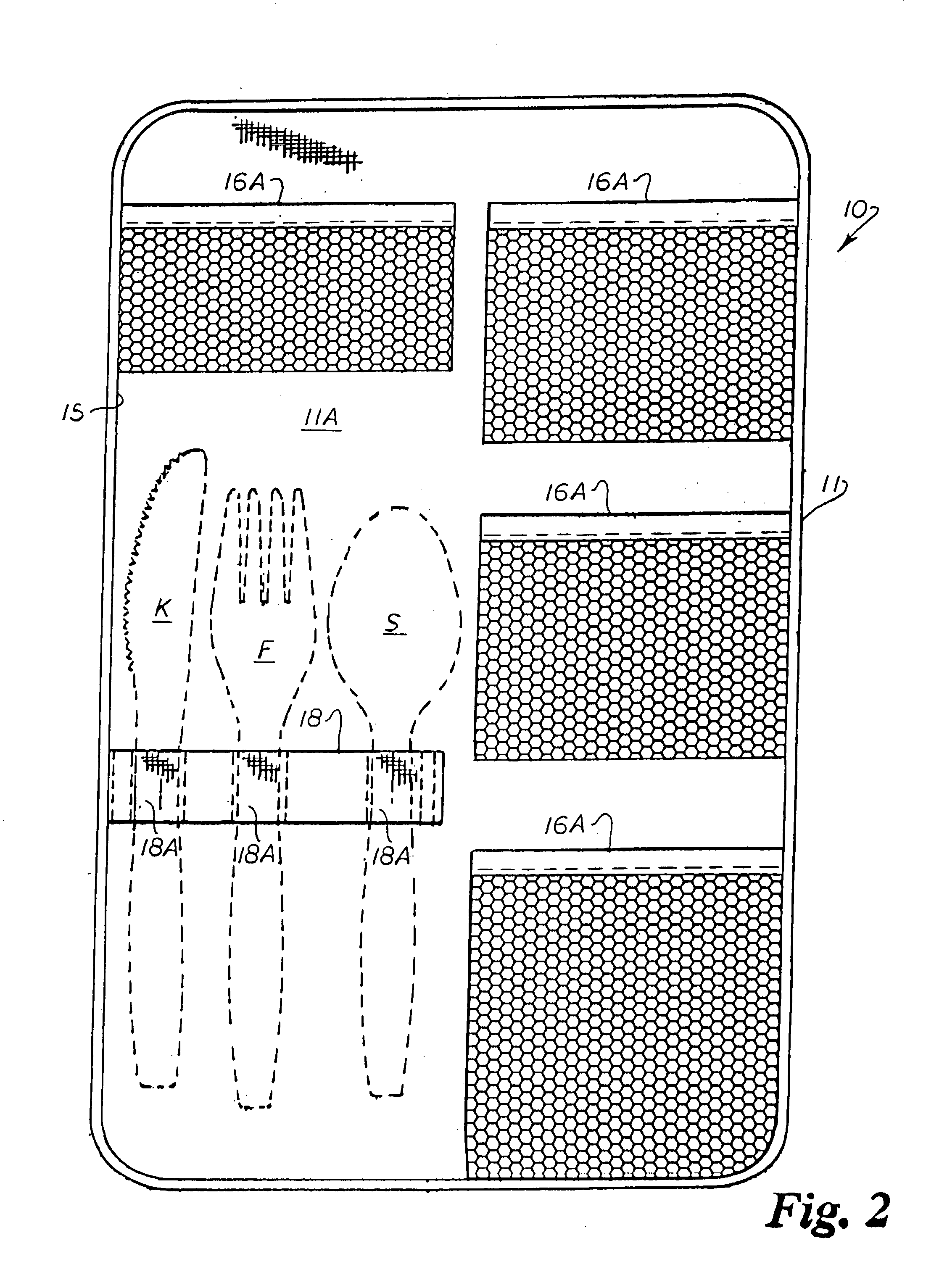

Portable condiment caddy

InactiveUS6910580B1Efficiently containing and organizing and transportingImprove organizationTravelling sacksHandbagsEating UtensilsEngineering

A portable soft-sided pocketed case or condiment caddy constructed particularly for containing, organizing, and transporting packets of food condiments, and other basic items such as napkins, straws and eating utensils, provides convenience and handy availability. The caddy includes a left and right panel flexibly joined together by a hinged portion and a zipper extends around three sides of the panels. A plurality of open mesh pockets and several elastic strips are attached to the interior surface of the left and right panels. The open mesh pockets are sized to accommodate small flexible condiment packets of condiments, such as catsup, mayonnaise, mustard, relish, various sauces, salad dressings, etc., of the type one receives from fast food restaurants, also salt and pepper packets, sugar or sweetener packets, and a quantity of toothpicks. The elastic strips hold additional condiment packets and one elastic strip is configured to hold knives, forks and spoons. An elongate pocket on the front cover holds straws and / or napkins. An optional transparent zippered money pocket on the front cover accommodates paper currency, coins, car keys, and other loose items. An elongate transparent zippered cargo pocket on the exterior of the right panel accommodates miscellaneous larger items.

Owner:FRUM SALLY MAY

Combined toothpick and mint dispenser

A thin, plastic dispenser for discharging toothpicks, and / or mints through distinct discharge passages in the dispenser. The dispenser has a body comprising a first housing and a second housing that are aligned and snapped together to form the body of the dispenser. A well is defined in the body for storing toothpicks, and a first discharge passage is provided in the well. A larger chamber is defined in the body for storing mints, and a second discharge passage is provided in the chamber. Locking levers, integrally formed with one of the housings, normally seal the discharge passages in the well and the chamber. When the user wishes to discharge a toothpick and / or mint, the manually engages a locking lever and pivots same about its hinge line to expose the adjacent discharge passage. The contents of the well and / or chamber can then be discharged, through the exposed discharge passages vacated by the movement of the locking lever. Guides, ramps, and abutments in the well and chamber limit the width of the discharge passages and insure that the toothpicks are mints are discharged, one at a time, when the dispenser is tilted.

Owner:COHEN HARRIS

Cleaning and drying system for a personal hygiene device

InactiveUS20080060671A1Remove debrisReduce corrosionInternal framesBrushesTweezersMechanical engineering

An apparatus, system and method to clean and dry a personal hygiene device, such as a razor, tweezers, a comb, a toothbrush or other dental apparatuses, such as a dental pick. Typically, the system includes dryer generally coupled to a curved-wall chamber. The dryer generally includes a housing coupled to a duct, which, in turn is coupled to the curved-wall chamber. The housing includes a fan for pulling intake air into a housing via an air-intake. The housing further may include a heating element for heating air before entry into the curved-wall chamber. Thus, a personal hygiene device placed into a curved-wall chamber having a cleaning fluid can advantageously be cleaned and dried via circulating heated air and fluid within the curved-wall chamber under the circulation force of air provided by the fan.

Owner:RUFFIN STEPHEN

Spoon, knife with toothpick combination

It is a dual-end function eating utensil with one end serving as a choice for the user whether to use it or not. This eating instrument negates the need for the knife eating utensils in the “take-out” food industry. Most consumers utilizes the spoon specifically for the liquid consumption of their “take-out” meal and the knife is used in cutting solid food portions into smaller bites. Most of the time the knife are used in conjunction with the forks. Dual end utensils that have a exposed serrated end posed a problems with most consumers. The serrated end of a exposed knife is associated with the potential of getting hurt and most people avoid picking up any serrated end no matter what it is made of.

Owner:WONG CHIN CHOON

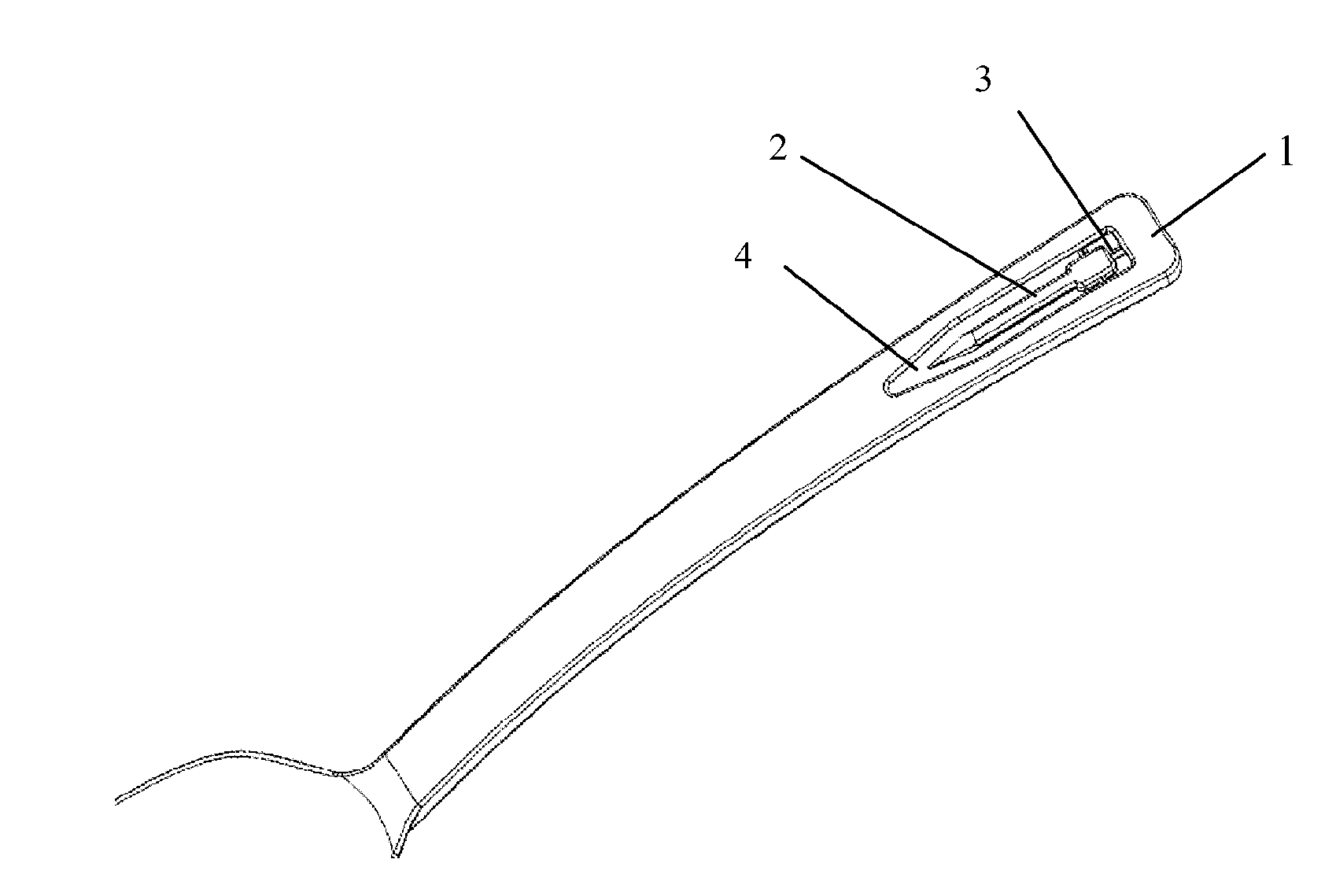

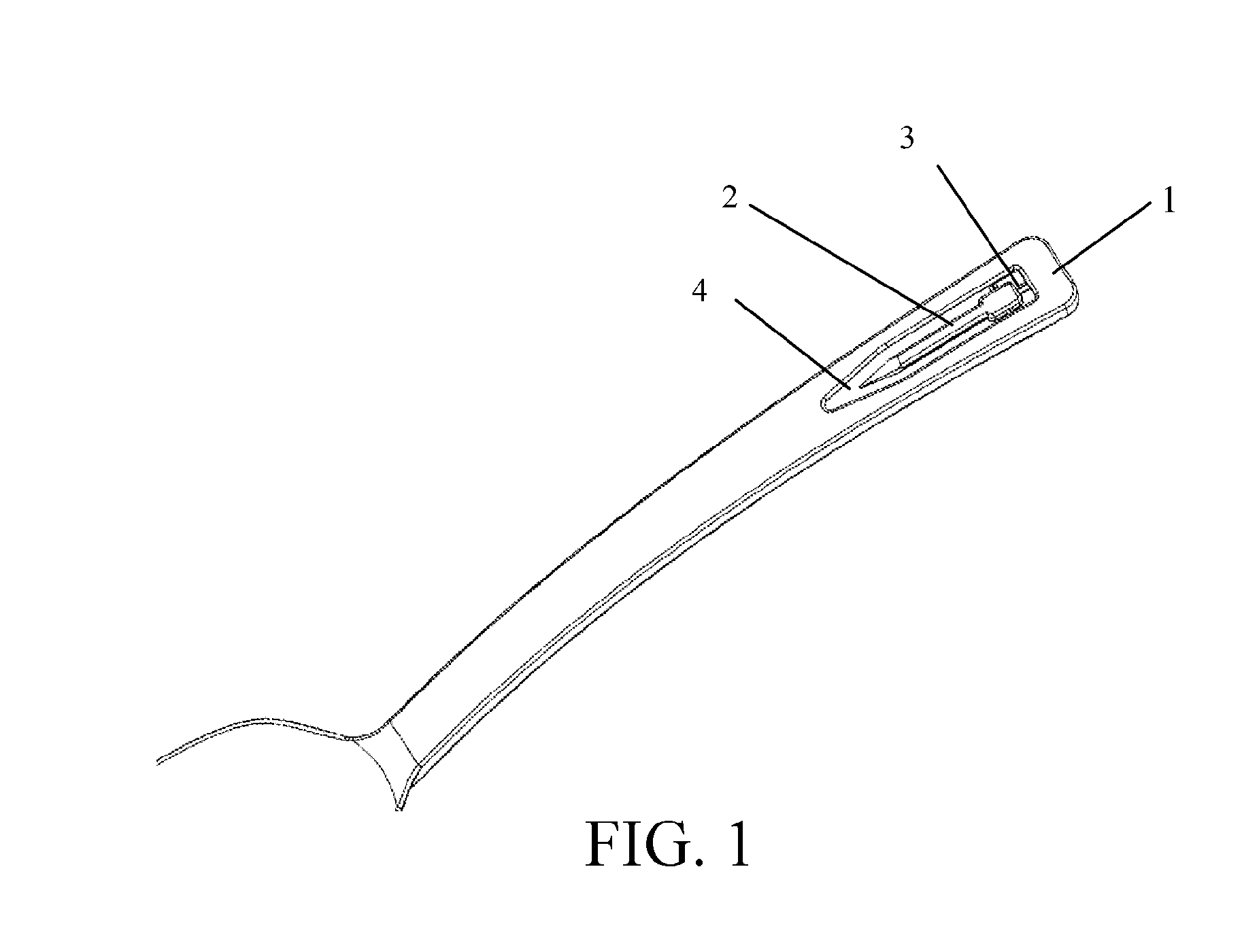

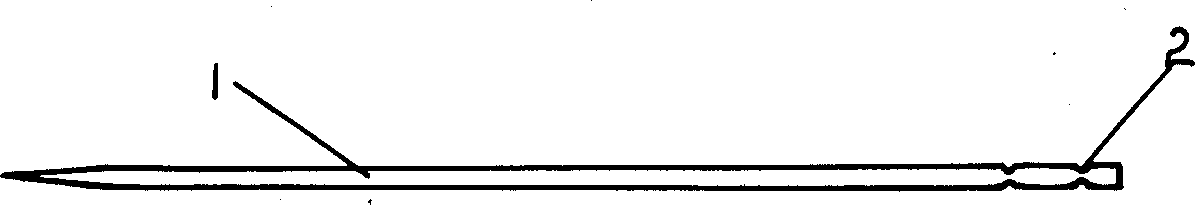

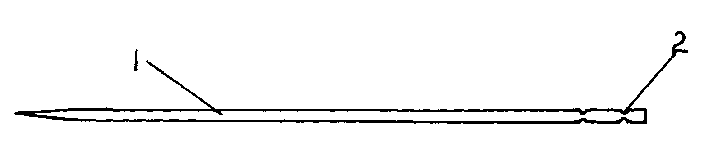

Tableware integrated with toothpick

InactiveUS20120222311A1Conveniently takenEnsure hygienePortable power-driven toolsMetal working apparatusBiomedical engineeringToothpick

A tableware integrated with a toothpick includes a handle (1). The handle is provided with a toothpick (2) integrated with the handle by a structure (3) which is easy to be broken off. By integrating the toothpick on the handle of the tableware, the tableware can not only be used in dinner, but also can provide the toothpick at any time. In addition, the toothpick is very convenient to take.

Owner:AMBULANC (SHENZHEN) TECH CO LTD

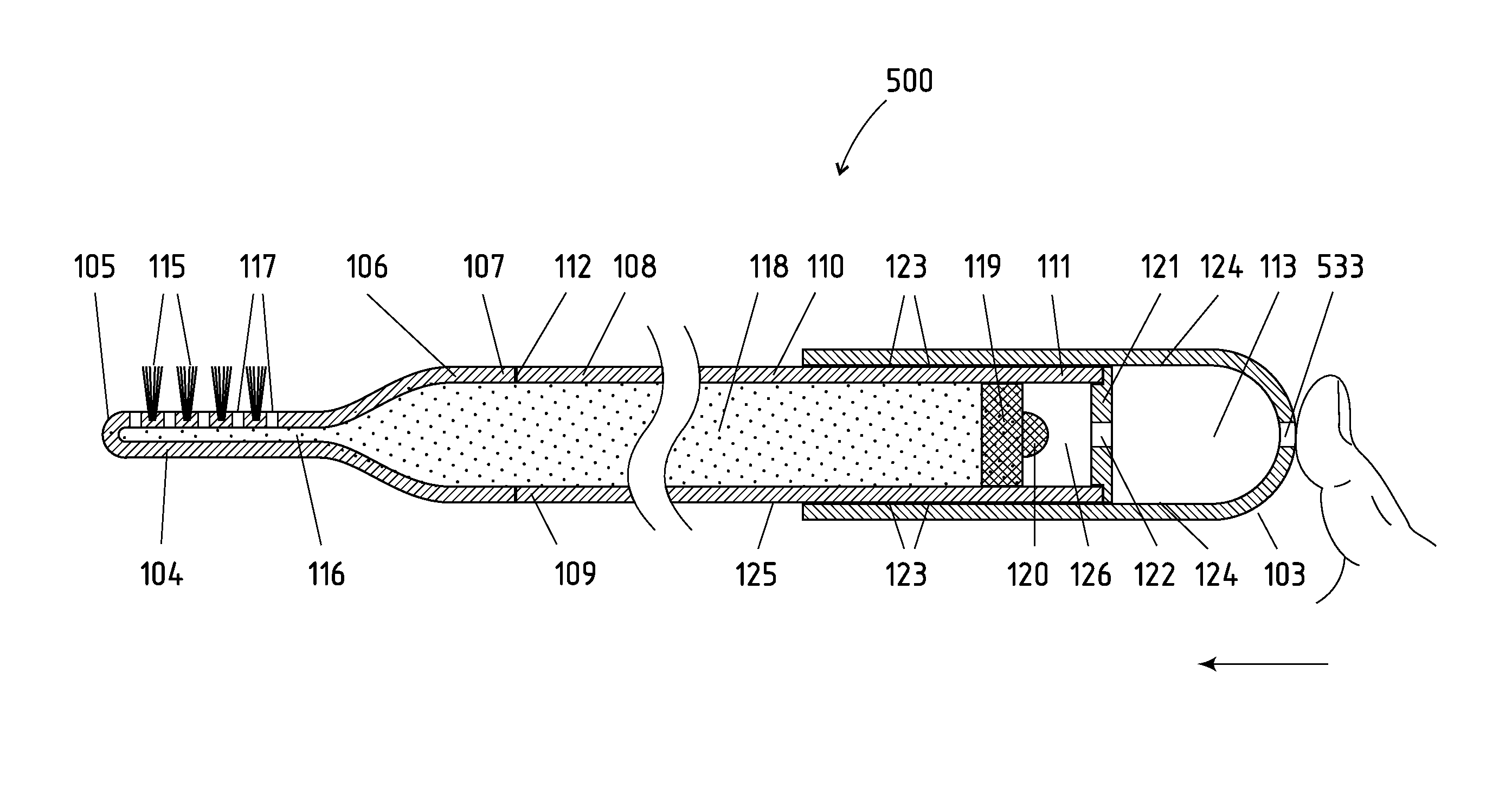

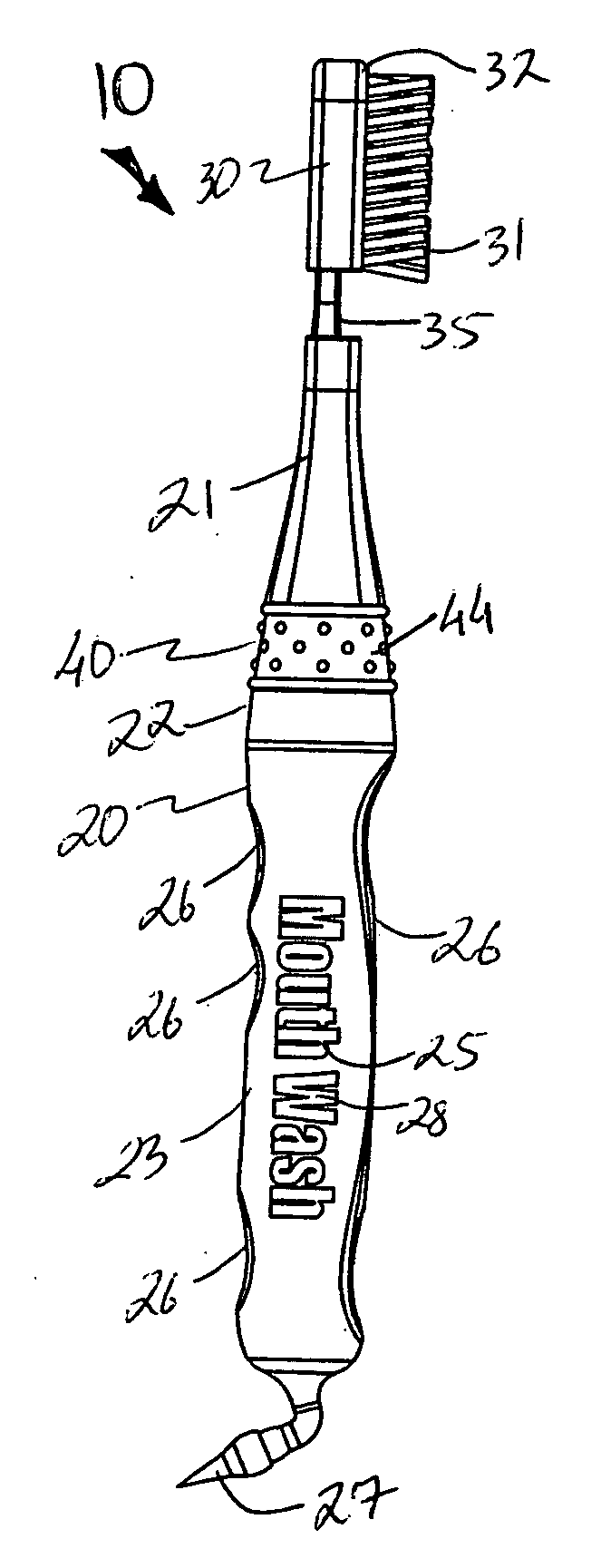

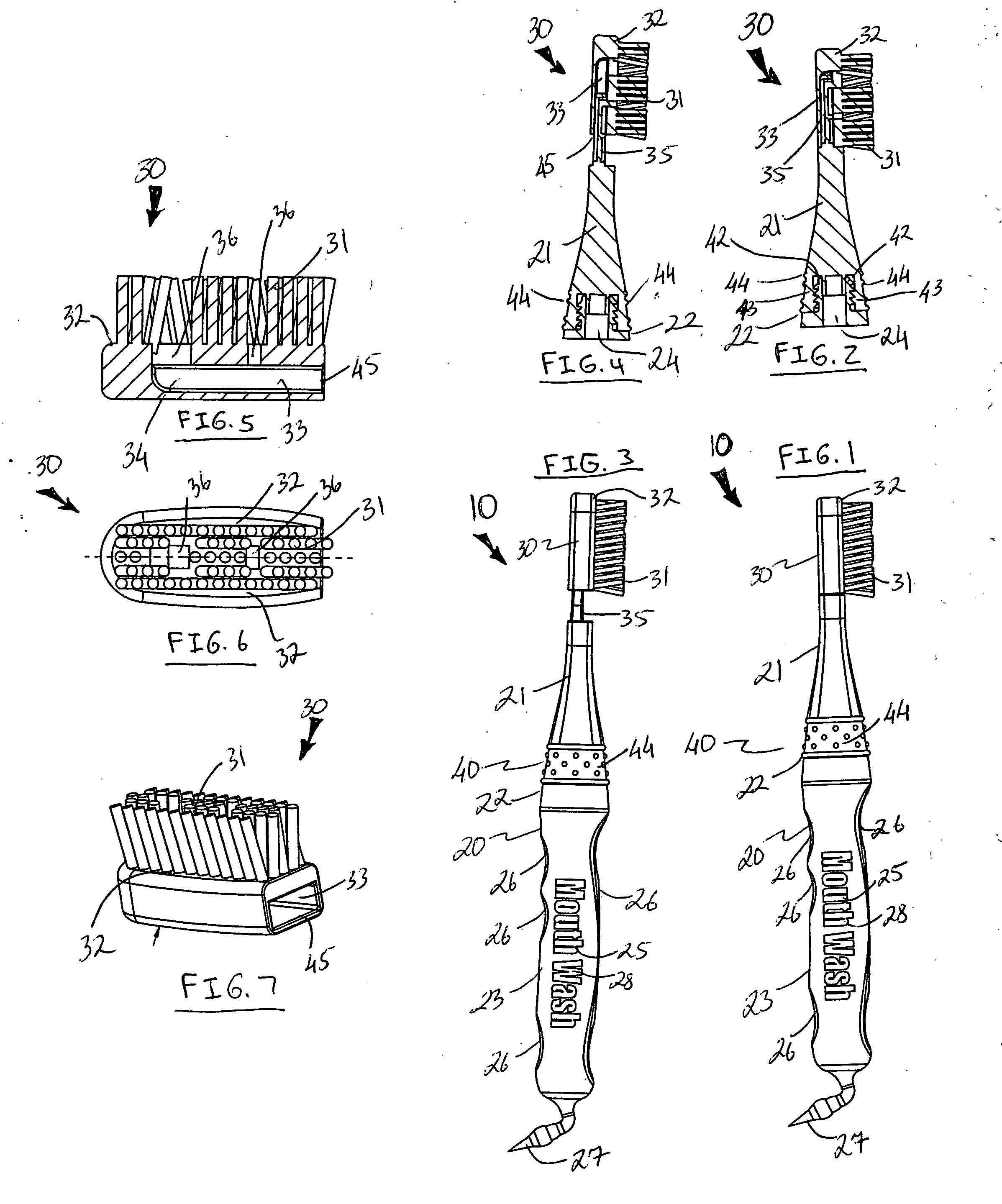

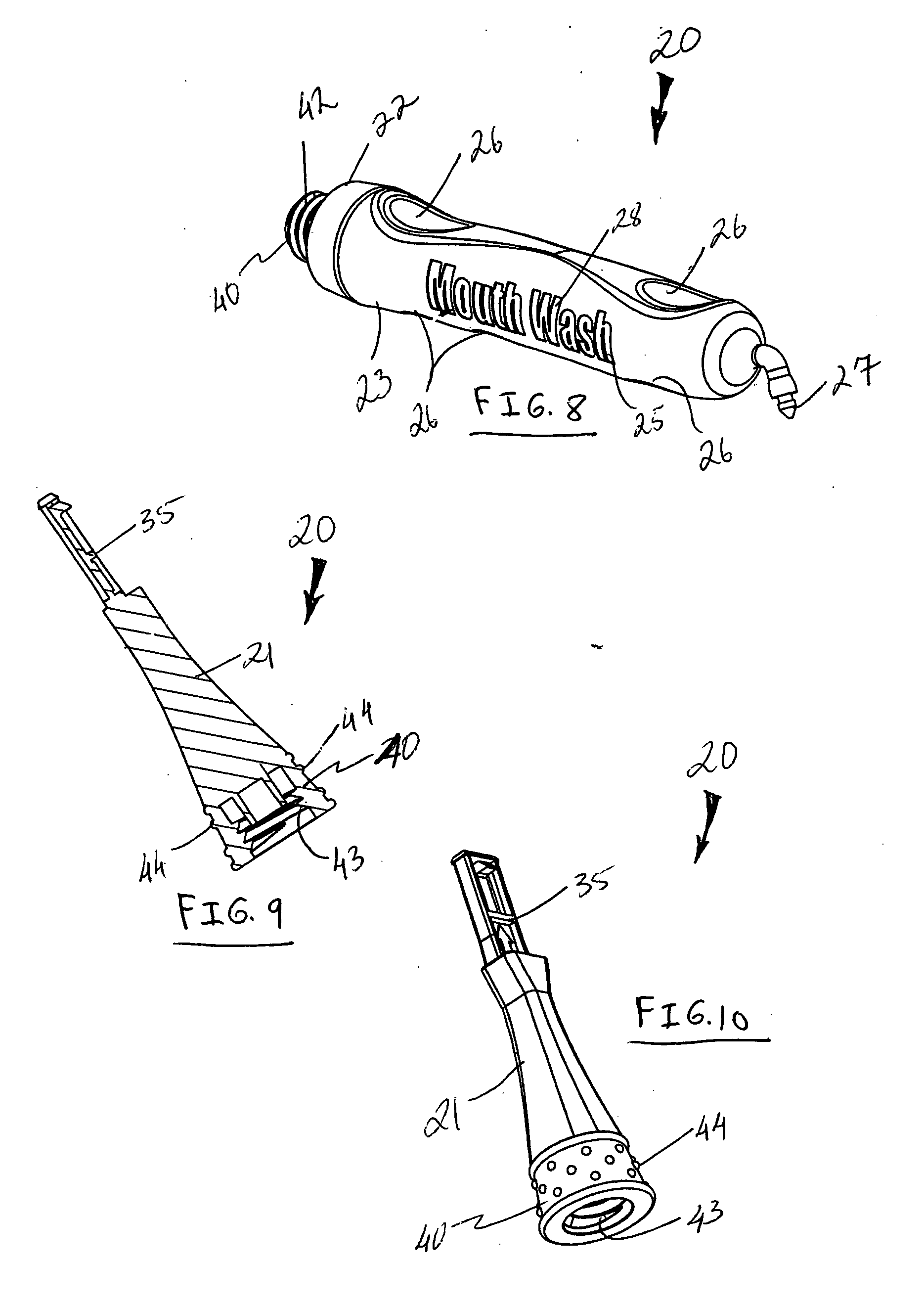

Combined toothbrush, toothpaste and mouthwash device

A disposable toothbrush containing a small amount of toothpaste disposed within an internal cavity in the head of the toothbrush and a small amount of mouthwash disposed within an internal cavity in the grip of the toothbrush, where the toothpaste is expelled onto the bristles of the toothbrush by pressing the head onto the handle shaft, and where the mouthwash is accessed by removing the head from the handle. The toothbrush further includes a tooth pick connected to the handle assisting a user to further clean their teeth.

Owner:FRISON EDWIN

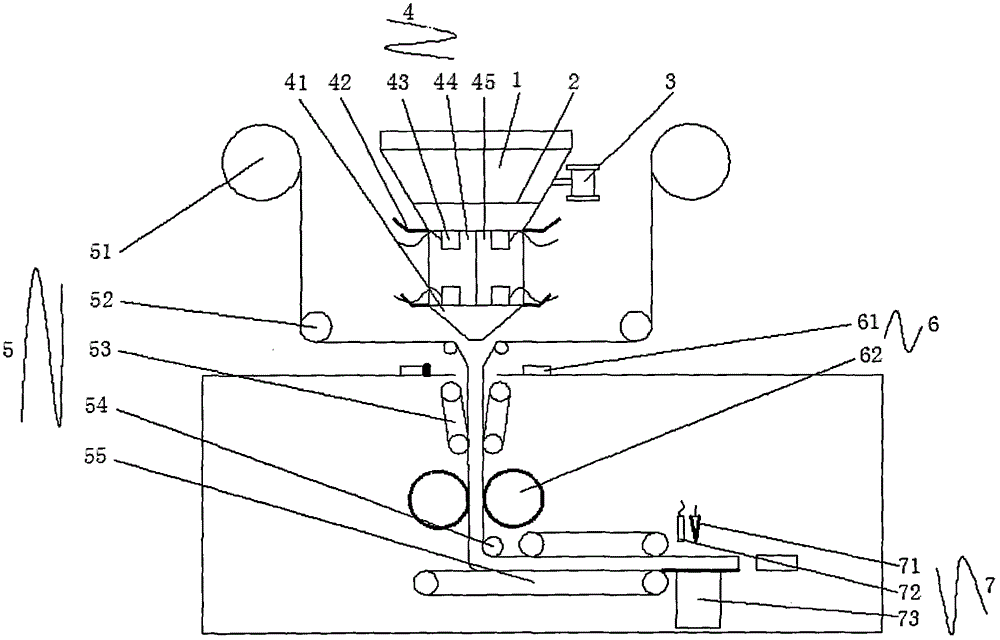

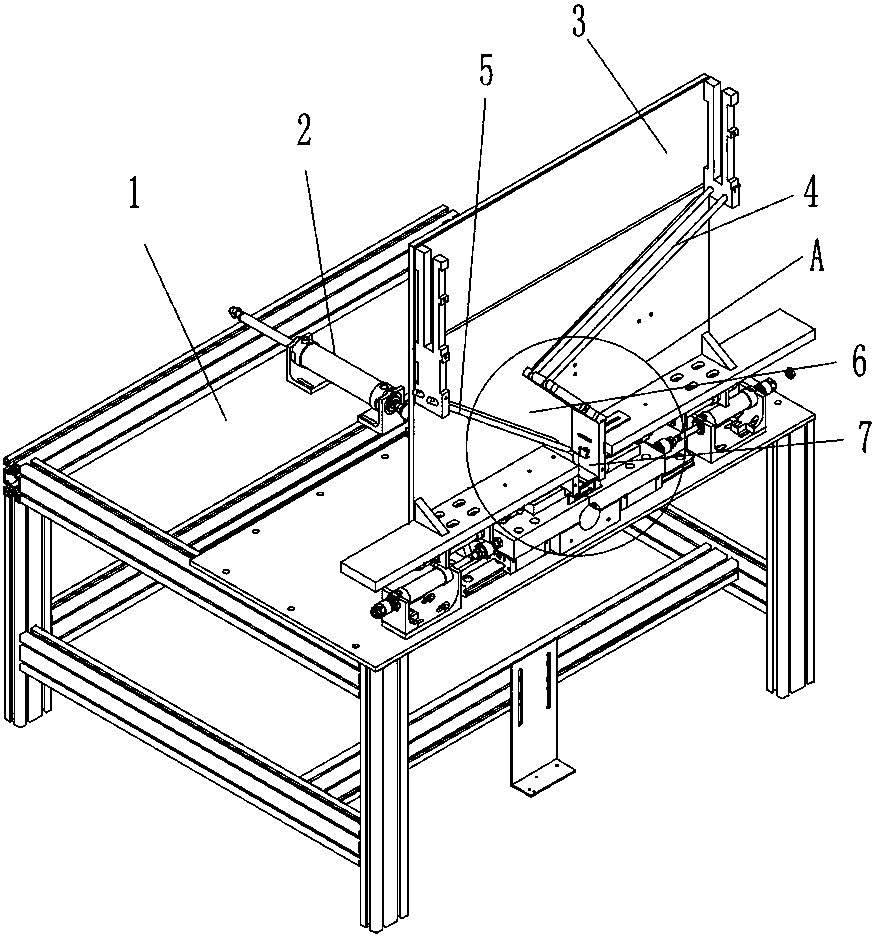

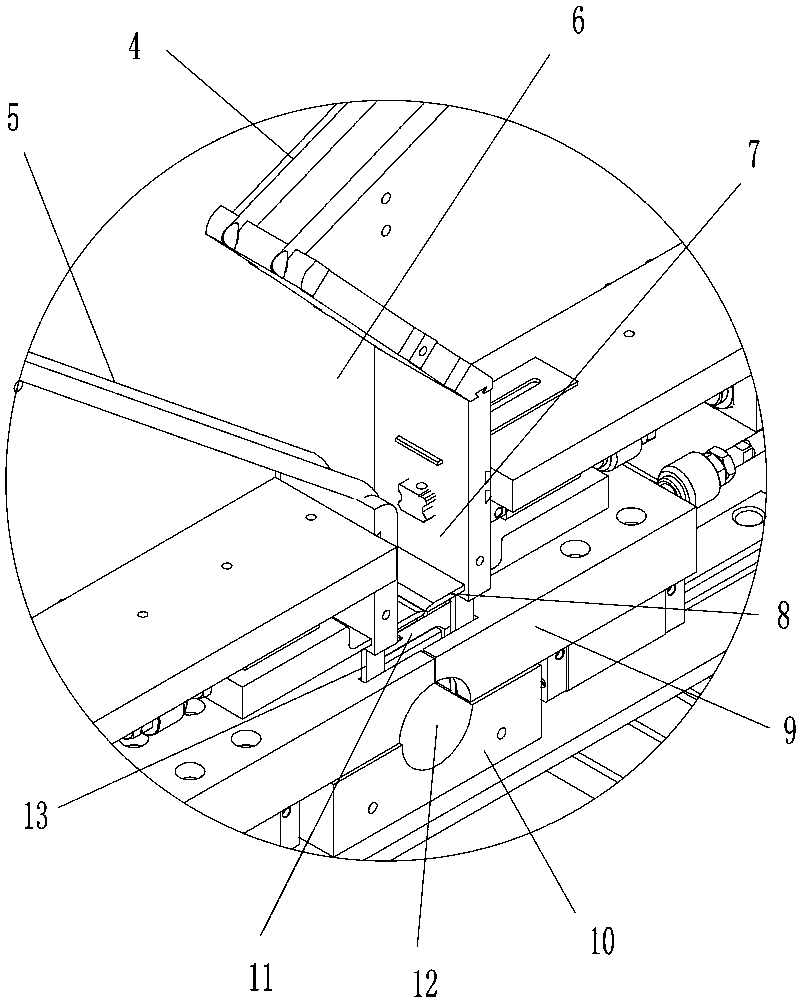

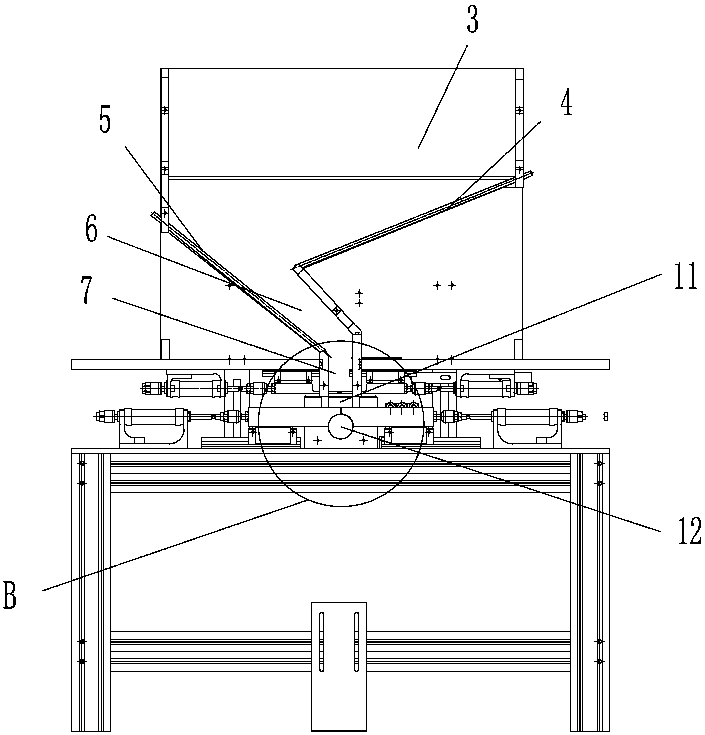

Automatic packing machine for toothpicks

InactiveCN104648706AControl the amount of packagingGuaranteed relative continuitySuccessive articlesGratingEngineering

The invention discloses an automatic packing machine for toothpicks. The automatic packing machine comprises a rack, a trapezoidal hopper, an arrangement grating, a vibrator, a toothpick metering mechanism, a plastic thin film feeding mechanism, a thin film bag sealing mechanism and a thin film bag cutting mechanism. According to the machine, the toothpicks are only required to be manually placed in the trapezoidal hopper, the toothpick packing quantity filled in each bag is controlled through the toothpick metering mechanism, and a thin film is automatically conveyed by the plastic thin film feeding mechanism, is automatically sealed by the thin film bag sealing mechanism and is automatically cut by the thin film cutting mechanism, so that automatic packing of the toothpicks can be automatically finished, the degree of automation is high, and the hygiene level of toothpick packing can be effectively improved.

Owner:GUANGDONG UNIV OF TECH

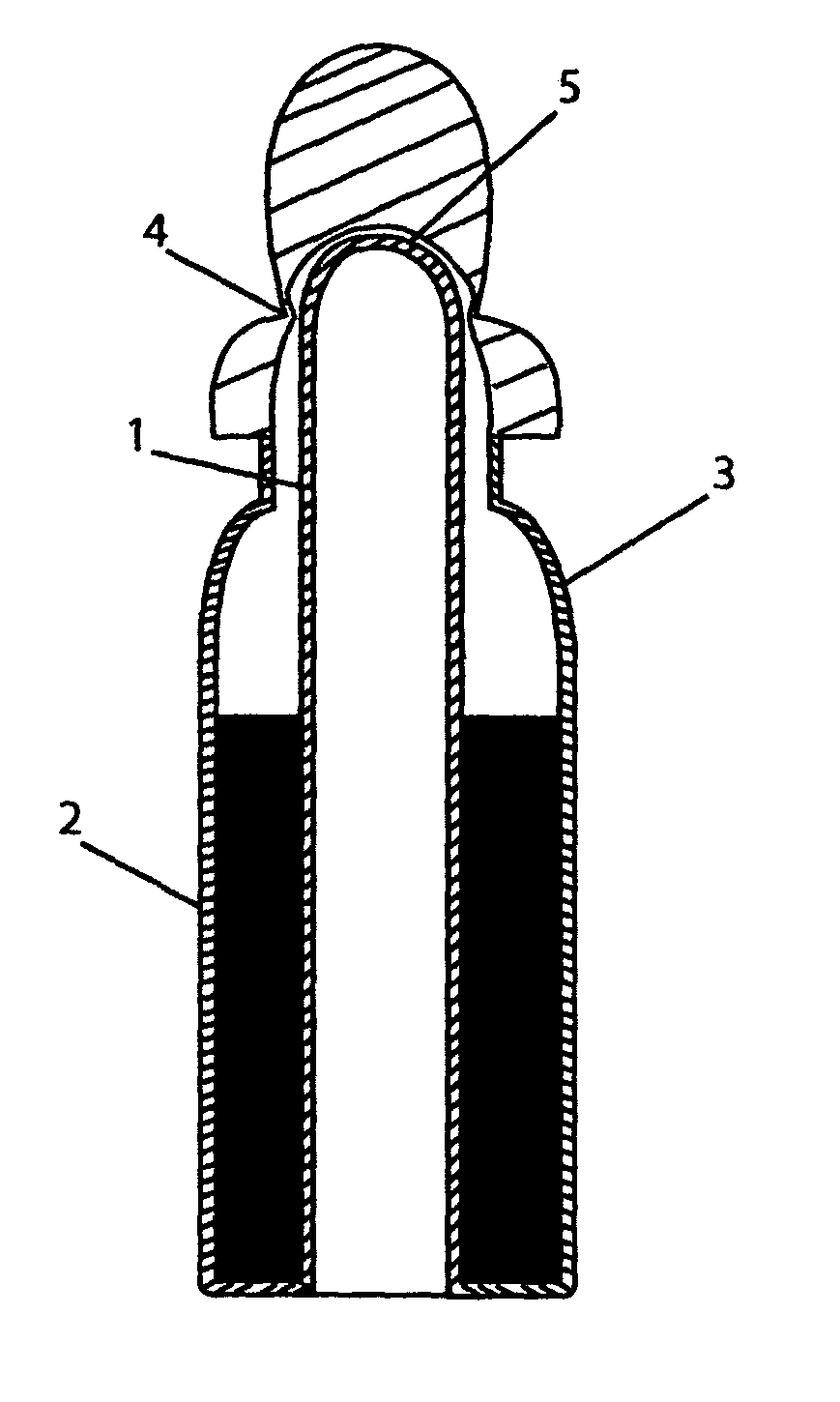

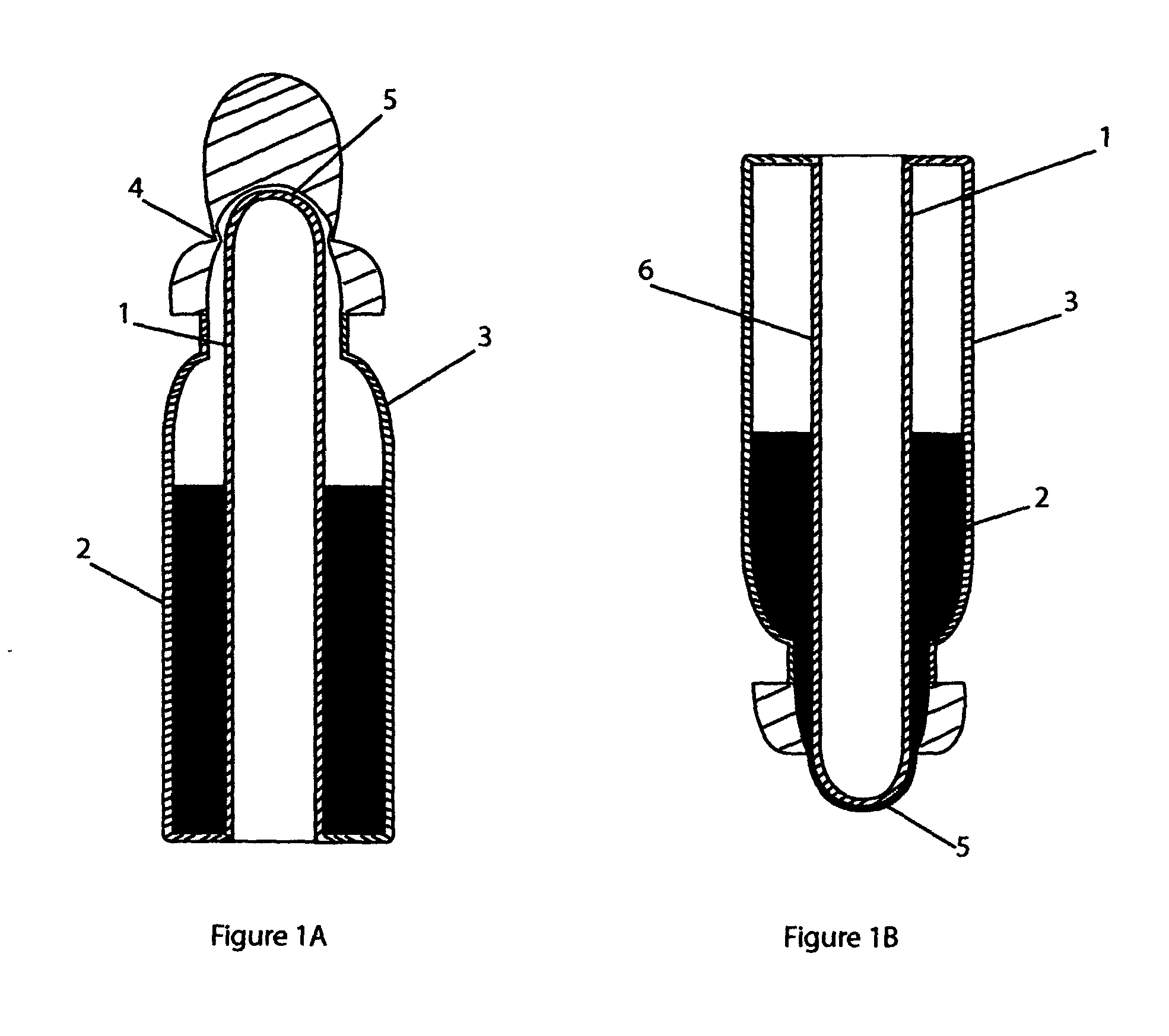

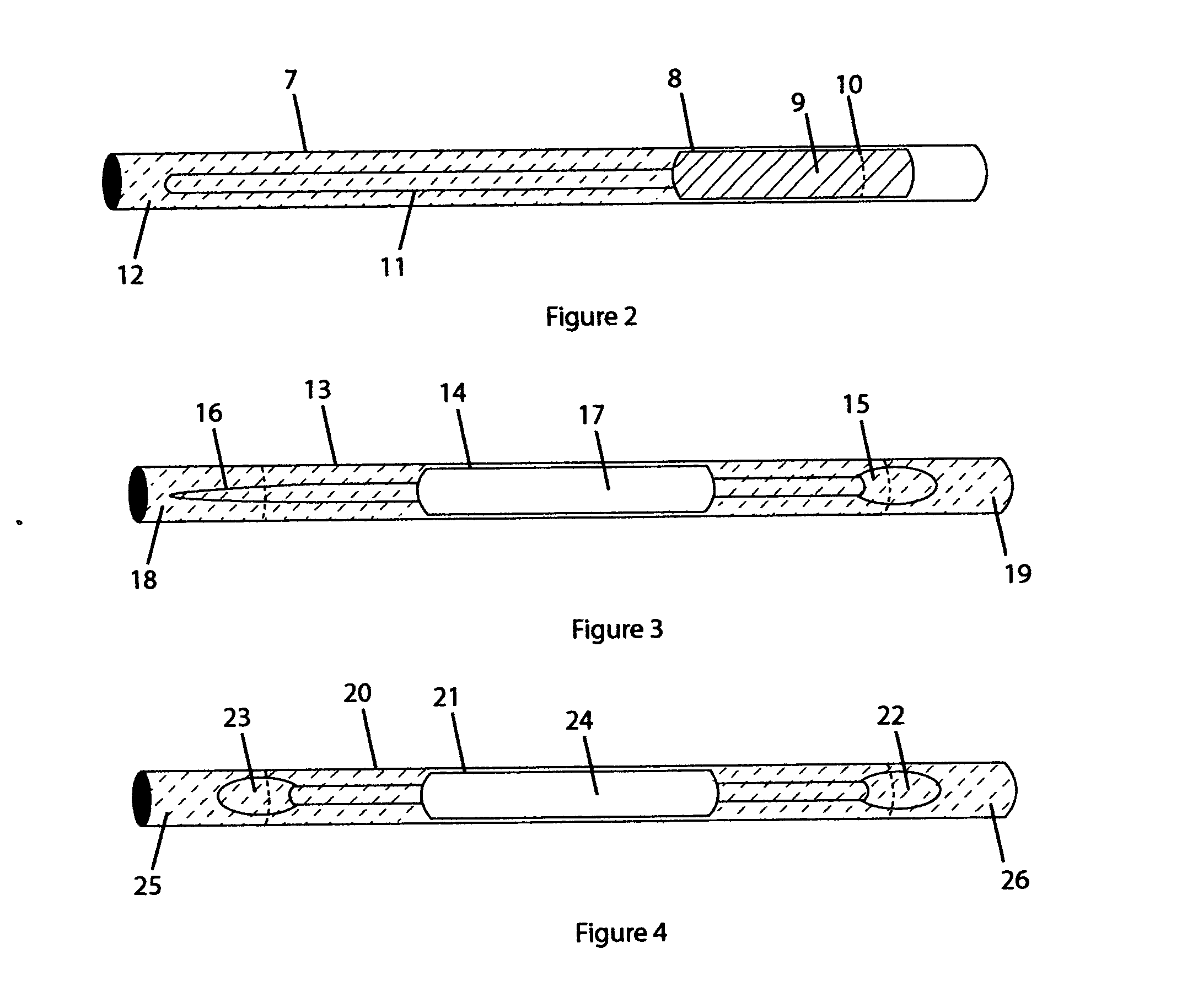

Enclosed applicator

An applicator fully sealed along with fluids such as perfume, disinfectant, or other medications within an elongated housing with one or more opening means is disclosed. The applicator may be a swab or an elongated member such as a toothpick. The applicator may also have two ends with the same or different applicator tips, and the two ends may be sealed in the elongated housing with the same fluid or different fluids at each end. When the applicator is exposed through the opening means, the fluid in the elongated housing may be applied through the applicator tip.

Owner:TSAUR GARRY

Process for preparing health-care starch toothpick

InactiveCN1356095AThere will be no phenomenon of bifurcation and breakageHard textureGum massageTooth cleaningPotato starchHigh pressure

A health-care starch toothpick is made up of corn starch, sweet potato starch, mint, imperate rhizome, dehurian angelica root, alum sorbitol, water and edible pigment through pretreating the mint, imperate rhizome and dahurian angelica root, boiling water, mixing with other, high-temp high-pressure extruding out to obtain bar, wash with clean water, freezing at -21 deg.C for 24 hrs, washing with clean water, drying at 35-40 deg.c for 24-30 hrs, cutting and sharpening. Its advantages include high hardness, health-care action to tooth, and no environmental pollution.

Owner:赵方培 +1

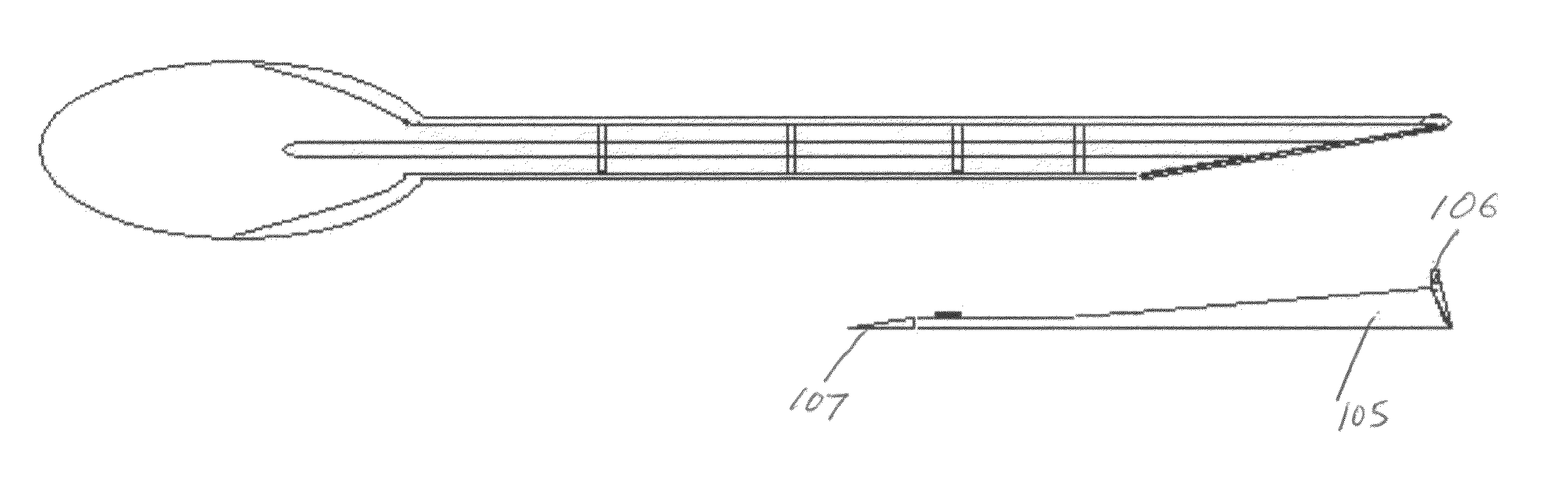

Toothpick device

A toothpick device for cleaning teeth includes a toothpick. The toothpick is comprised of two separable portions and has at least one pointed end. A length of dental floss is provided with each end of the dental floss being secured to one of the two portions of the toothpick by melted wax. The dental floss is wound for storage between said two portions whereby separating the two portions unwinds the dental floss for use.

Owner:PETERS JR CASSIE

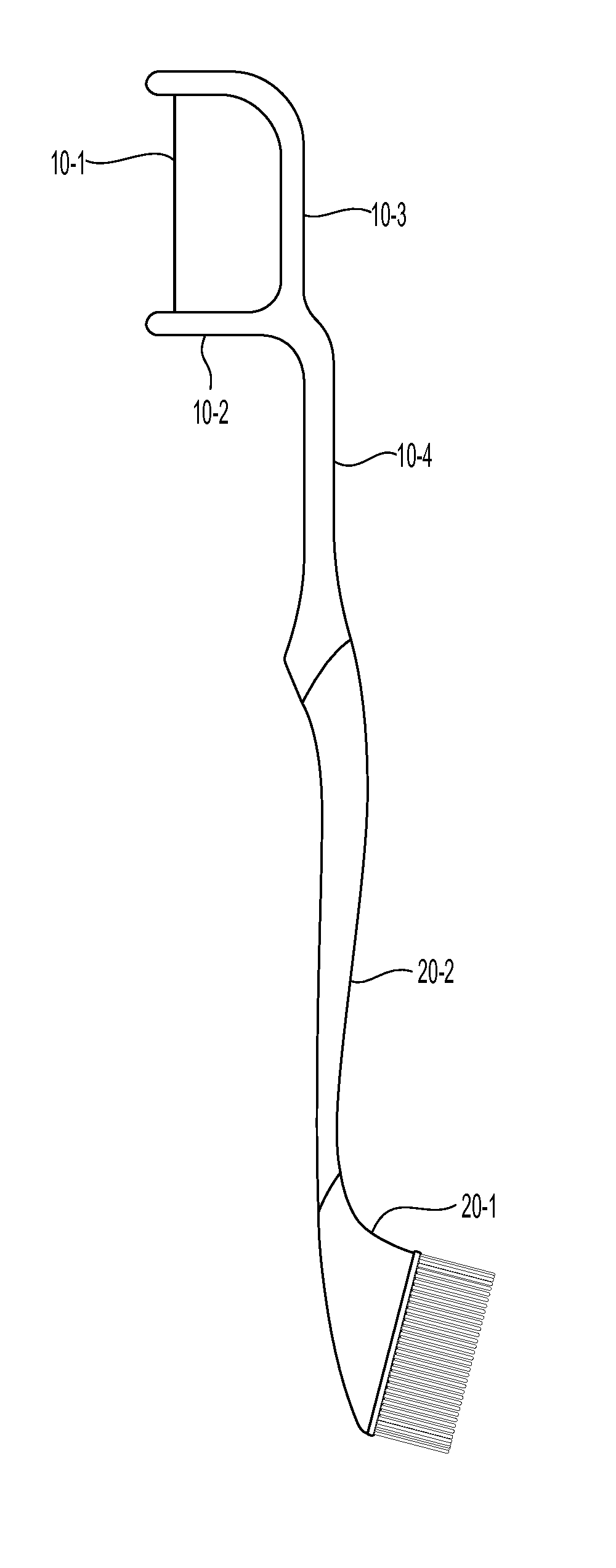

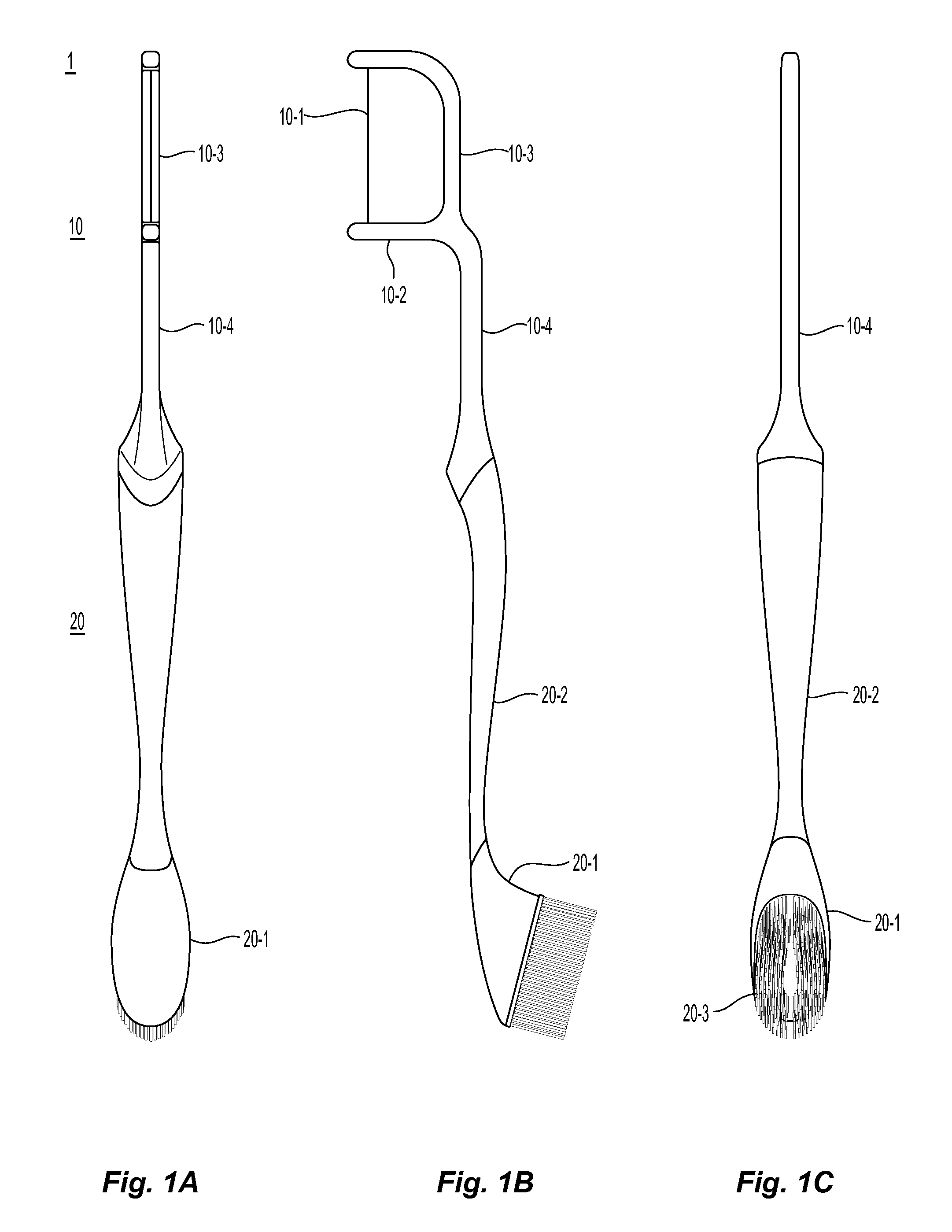

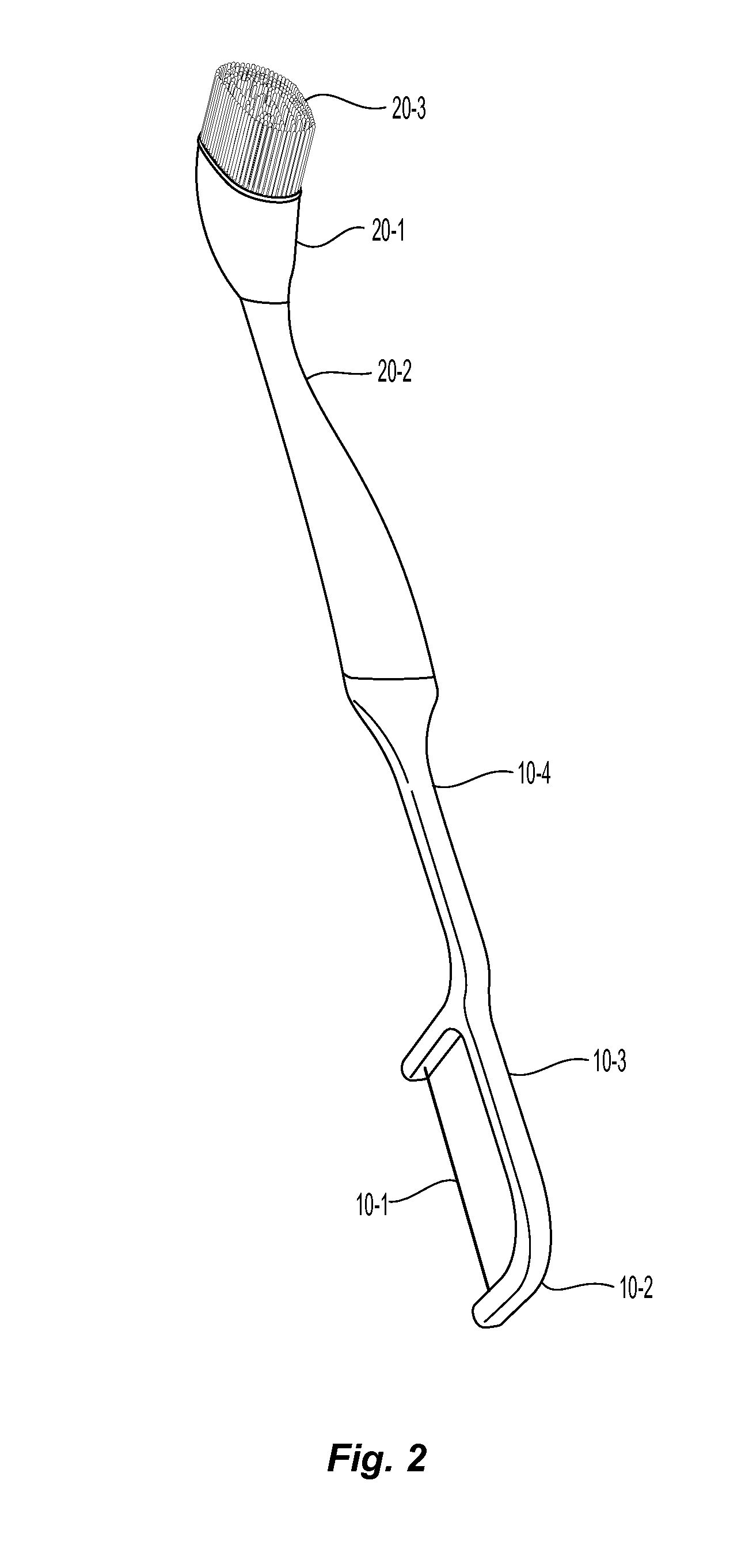

Circular tubular toothbrush

A circular tubular toothbrush having bristles implanted with an appropriate implant density distribution in the direction of the axis of a handle. The structure allows a user to comfortably use the toothbrush and provides the toothbrush with excellent massage performance in addition to excellent brushing performance. A circular tubular brush head (20) provided to the front end of a handle (10) has a hybrid structure in which hard round brush elements (20A) and soft round brush elements (20B) are arranged in the axial direction in a mixed state. The hard round brush elements (20A) each consist of a large number of nylon threads used for the bristles of toothbrushes and are each formed as a thin radial blade in which the nylon threads project radially outward. The soft round brush elements (20B) are each formed as an integral part consisting of an SEBS resin used for toothpicks etc. and each have a petaline shape in which tongue-shaped planar projections project radially outward.

Owner:NARUTOYA

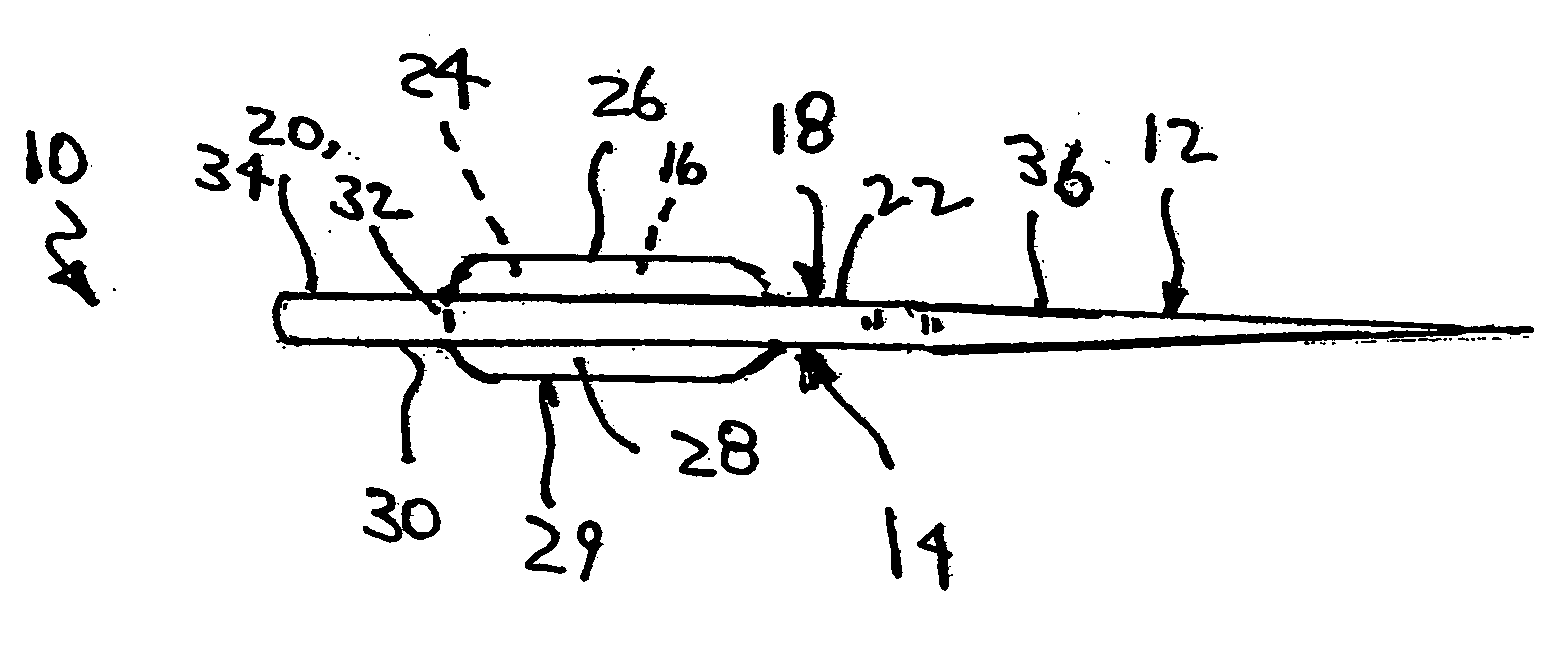

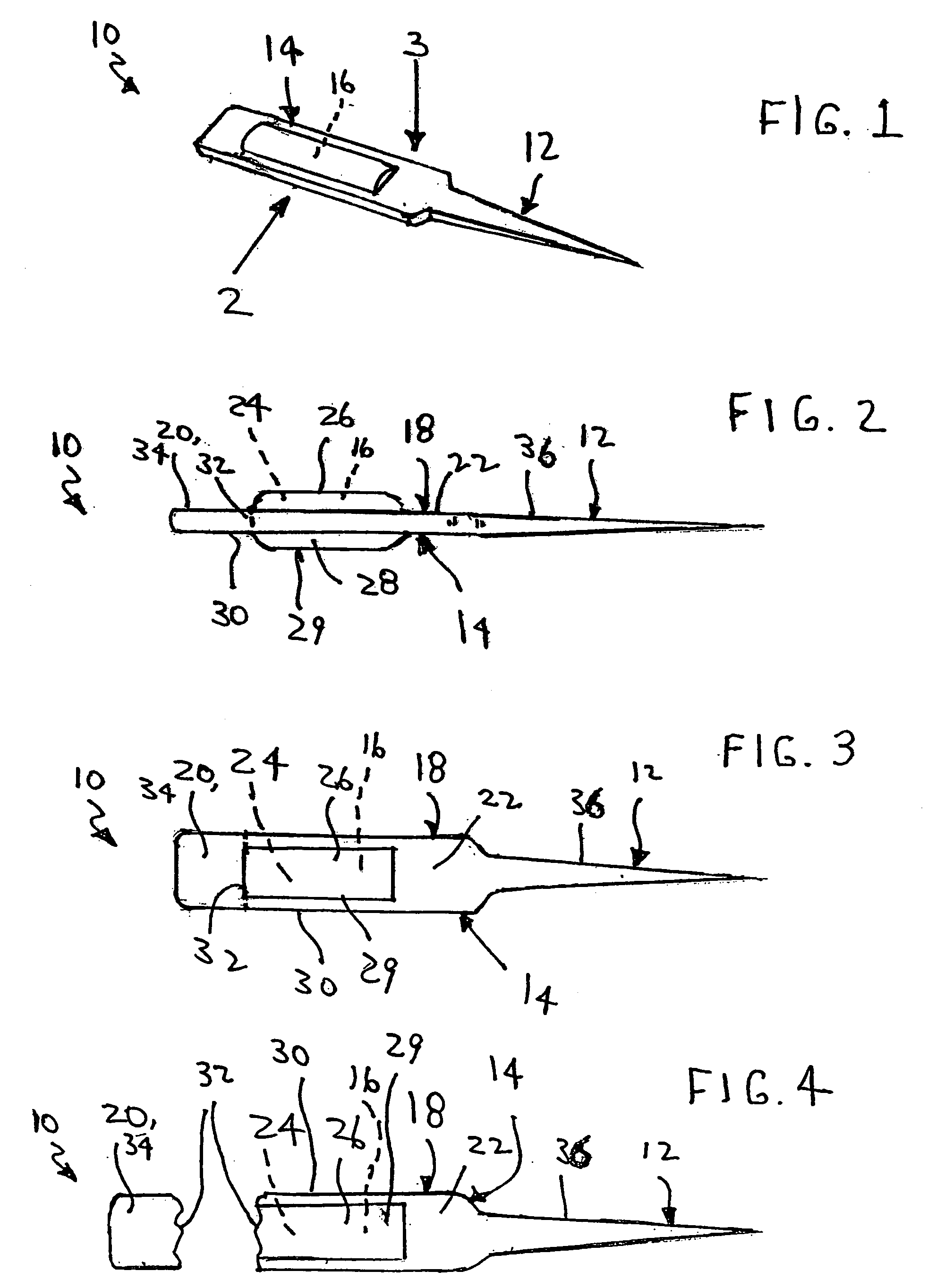

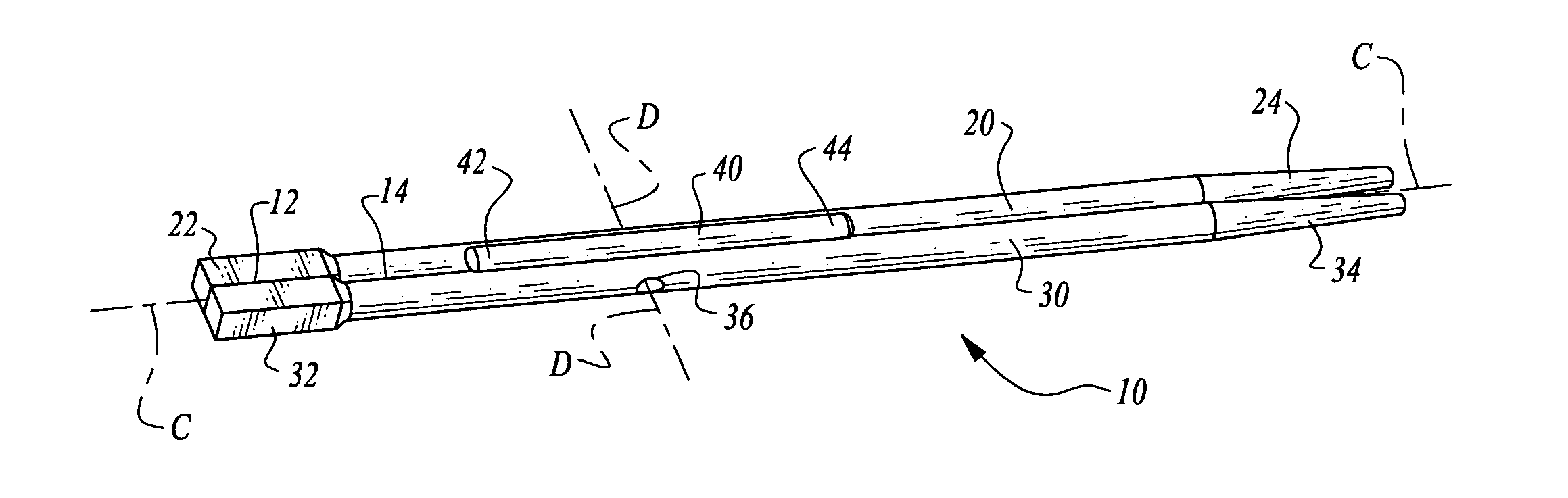

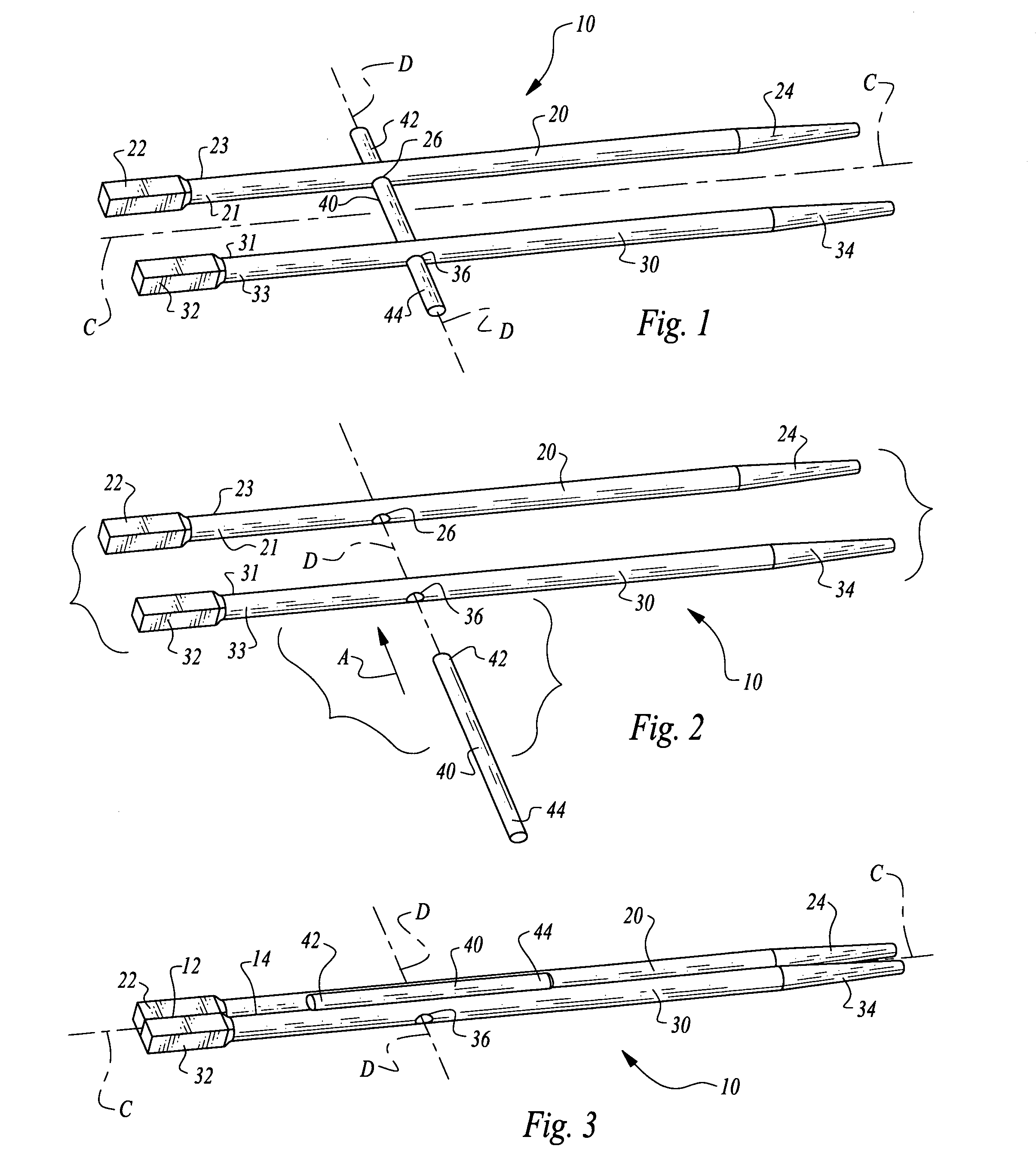

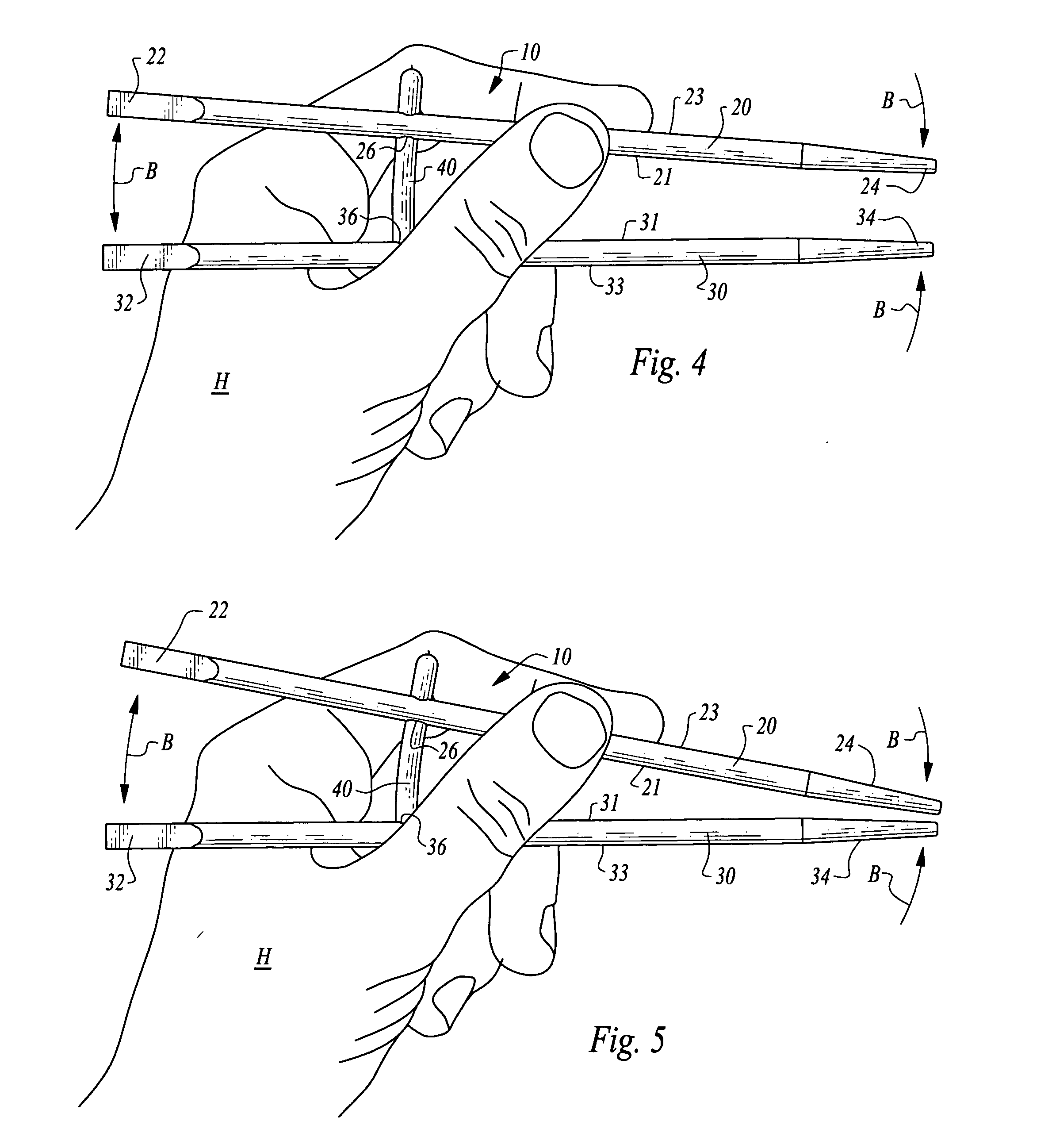

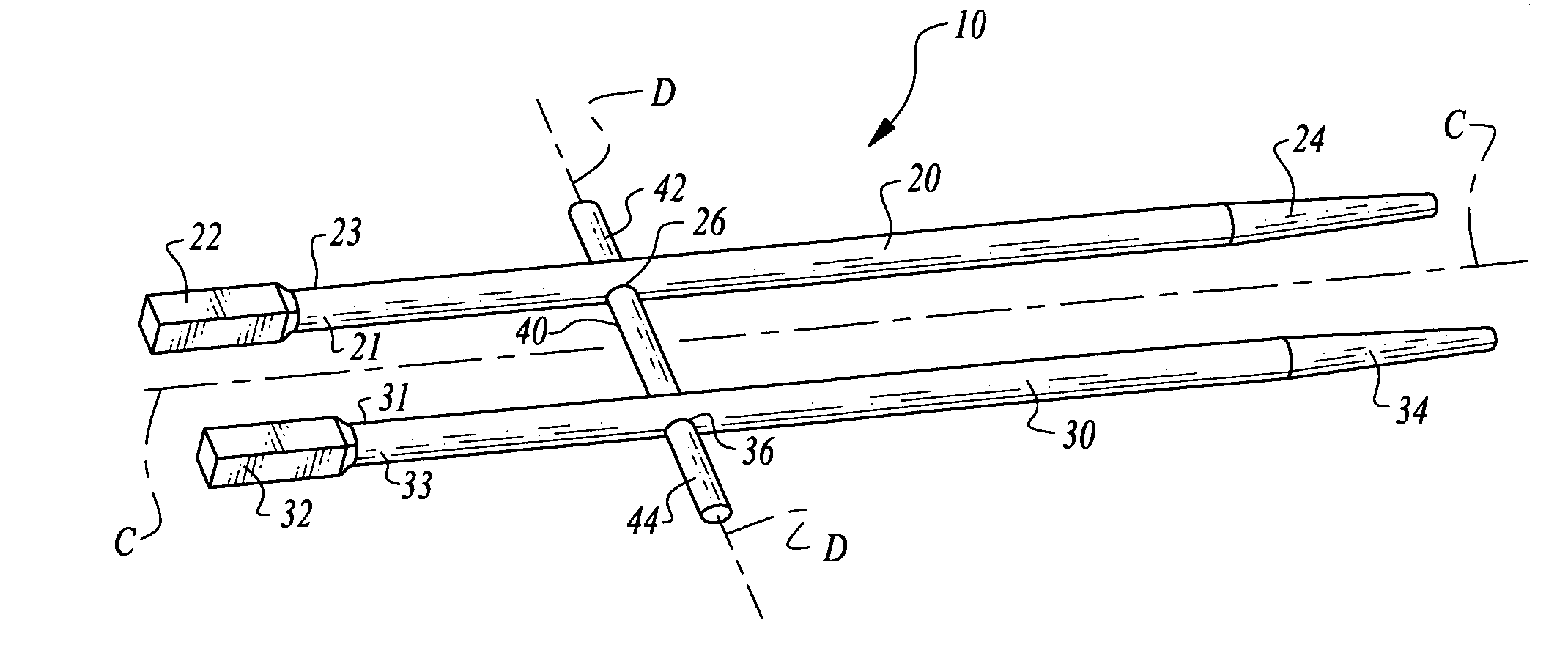

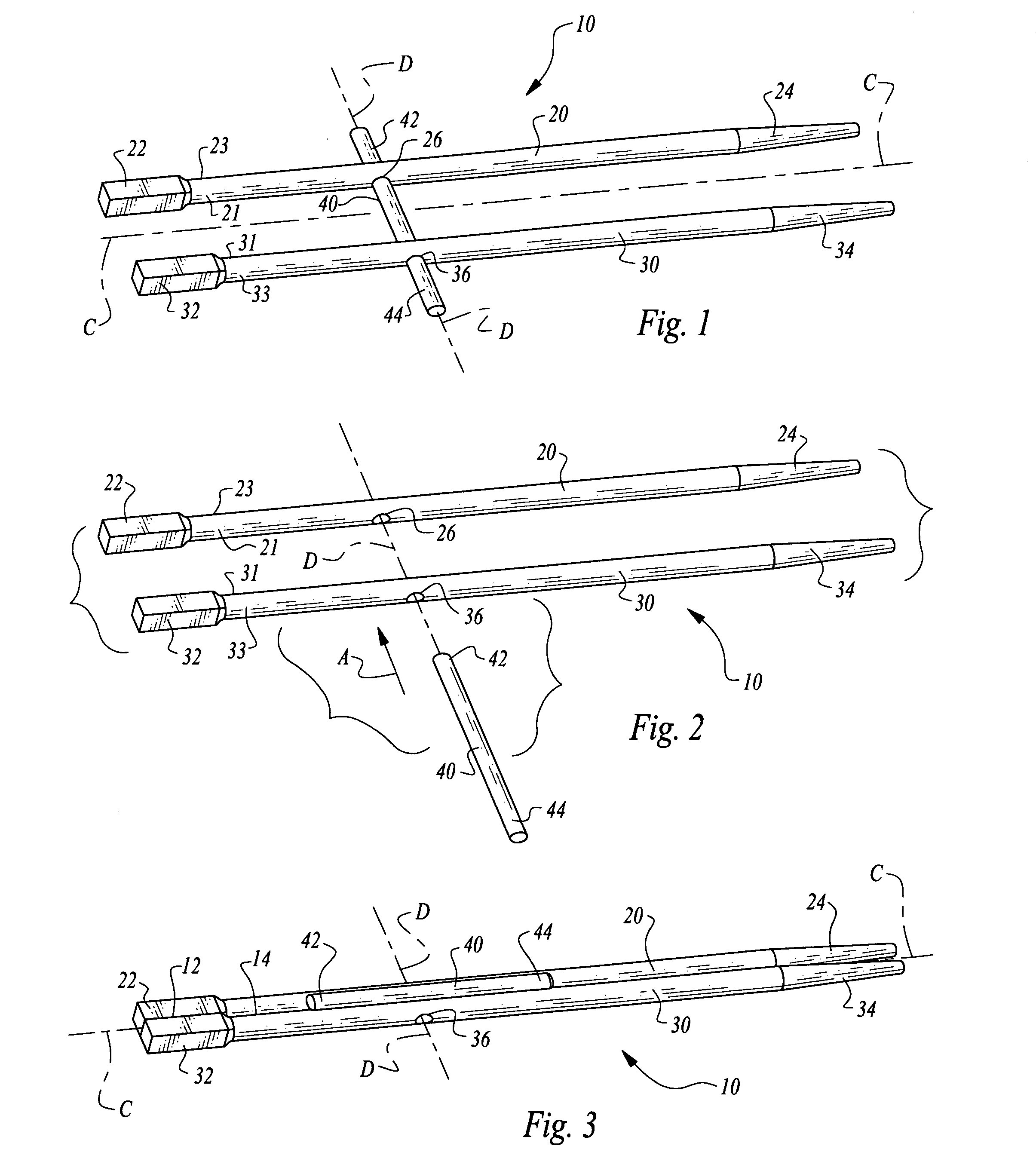

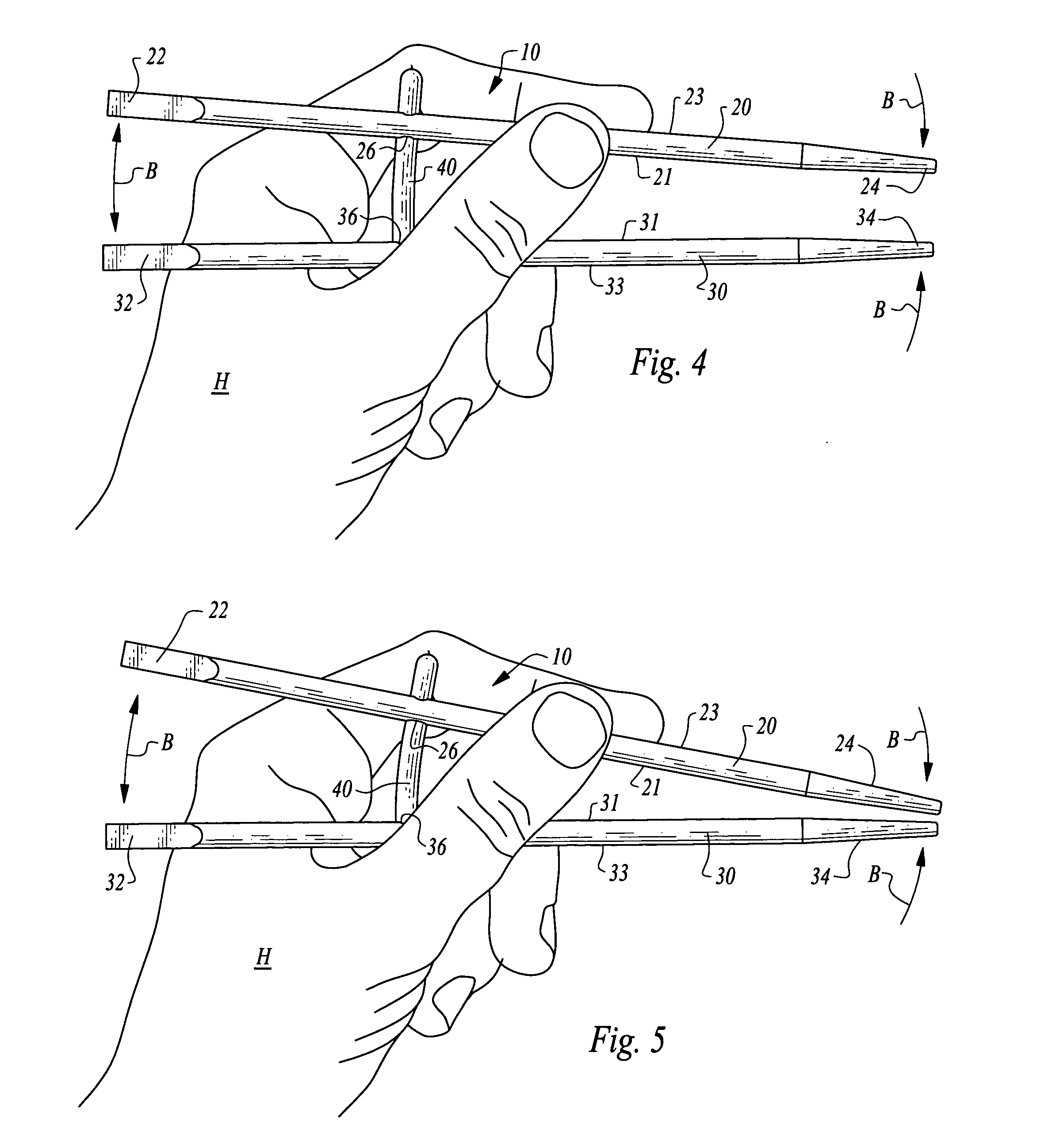

Training chopsticks

ActiveUS20110298236A1Easy to manufactureReliable and low-cost fashionPliersLifting devicesBiomedical engineeringToothpick

Chopsticks are provided including a first chopstick and a second chopstick which have been modified to be readily coupled together. Bores are formed in each of the chopsticks. A pin is supplied which passes through each of the bores. The pin has a friction fit within the bores such that the chopsticks are held together. The pin resiliently flexes when distal ends of the chopsticks are brought together, so that the pin provides a return force to the chopsticks. The bores and pin preferably have a non-circular cross-section so that the chopsticks are held within a common plane. The pin can have at least one tip that is pointed so that the pin can double as a toothpick.

Owner:KELLER ROBIN O

Combined toothpick and mint dispenser

A thin, plastic dispenser for discharging toothpicks, and / or mints through distinct discharge passages in the dispenser. The dispenser has a body comprising a first housing and a second housing that are aligned and snapped together to form the body of the dispenser. A well is defined in the body for storing toothpicks, and a first discharge passage is provided in the well. A larger chamber is defined in the body for storing mints, and a second discharge passage is provided in the chamber. Locking levers, integrally formed with one of the housings, normally seal the discharge passages in the well and the chamber. When the user wishes to discharge a toothpick and / or mint, the manually engages a locking lever and pivots same about its hinge line to expose the adjacent discharge passage. The contents of the well and / or chamber can then be discharged, through the exposed discharge passages vacated by the movement of the locking lever. Guides, ramps, and abutments in the well and chamber limit the width of the discharge passages and insure that the toothpicks are mints are discharged, one at a time, when the dispenser is tilted.

Owner:COHEN HARRIS

Starch toothpick and its production process

Starch toothpick is cylindrical toothpick made of starch and with conic point in one end and two ring notches in the other end. It is produced by using the material including corn starch in 97.89 wt%, sweet potato 1.96 wt%, edible solid sorbic alcohol 0.11 wt%, edible alum 0.03 wt% and edible pigment 0.01 wt% as well as water in 30 wt% of the said material and through mixing, extrusion to form and freezing at -22 deg.c for 12 hr, drying in a water heating drying room at 45 deg.c for 24 hr, cutting into sections and grinding and formation in a toothpick grinding machine. it is degradable and no environmental pollution and no damage to teeth.

Owner:吴兴录

Disposable dental device with removable floss and toothpick combination

A combination toothbrush, flossing device, and toothpick are provided in a single dental device. A first part of the dental device comprises a toothbrush connected to a stem of the first part, and a second part of the dental device comprises a toothpick attached to a first end and a flossing device connected to a second end. The first part and the second part are detachably attached to each other.

Owner:EDWARD ARTHUR INT

Training chopsticks

ActiveUS8562054B2Optimal performance characteristicEasy to manufacturePliersLifting devicesEngineeringBiomedical engineering

Chopsticks are provided including a first chopstick and a second chopstick which have been modified to be readily coupled together. Bores are formed in each of the chopsticks. A pin is supplied which passes through each of the bores. The pin has a friction fit within the bores such that the chopsticks are held together. The pin resiliently flexes when distal ends of the chopsticks are brought together, so that the pin provides a return force to the chopsticks. The bores and pin preferably have a non-circular cross-section so that the chopsticks are held within a common plane. The pin can have at least one tip that is pointed so that the pin can double as a toothpick.

Owner:KELLER ROBIN O

Toothpick filling machine

PendingCN108502233ASlow down the feeding flow rateAvoid jammingSolid materialRod-shaped articlesEngineeringBottle

The invention relates to a toothpick filling machine, and the problems that manual packaging is commonly adopted in existing bottled toothpicks, efficiency is low, sanitation hidden danger exists, automatic bottled toothpick packaging machine equipment difficultly normally runs for a long time, and the production efficiency is not high are solved. According to the scheme, the toothpick filling machine comprises a rack, a hopper is arranged at the upper portion of the rack, the bottom end of the hopper is connected with a second-level bin through a discharging channel, a metering bin is arranged below the second-level bin, a metering partition plate capable of being telescopically opened and closed is arranged between the second-level bin and the metering bin, a shaping bin is arranged below the metering bin, movable push blocks capable of being telescopically opened and closed are arranged between the metering bin and the shaping bin, the shaping bin and the section of a toothpick bottle body are matched in shape, and a piston push rod is arranged on the part, on the rear side of the shaping bin, of the rack. According to the toothpick filling machine, toothpick discharging can becombed through guiding rods, and tidiness and orderliness in the discharging process are guaranteed. The movable push blocks above the shaping bin are in comb meshing, and the situation that in the process of toothpick inward extruding, folding and shaping, the toothpicks are pressed and bounce, and jamming is caused is avoided.

Owner:廖小全

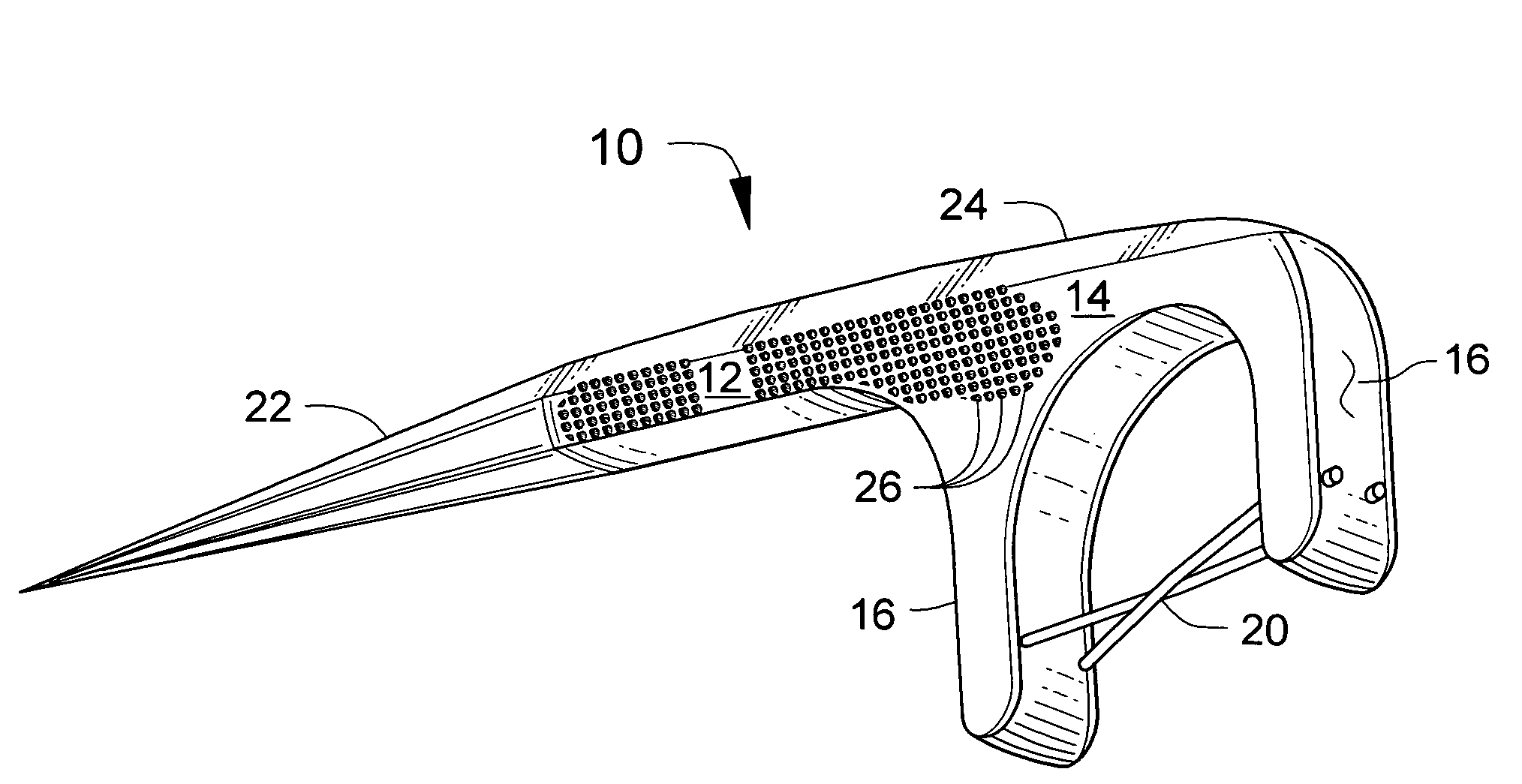

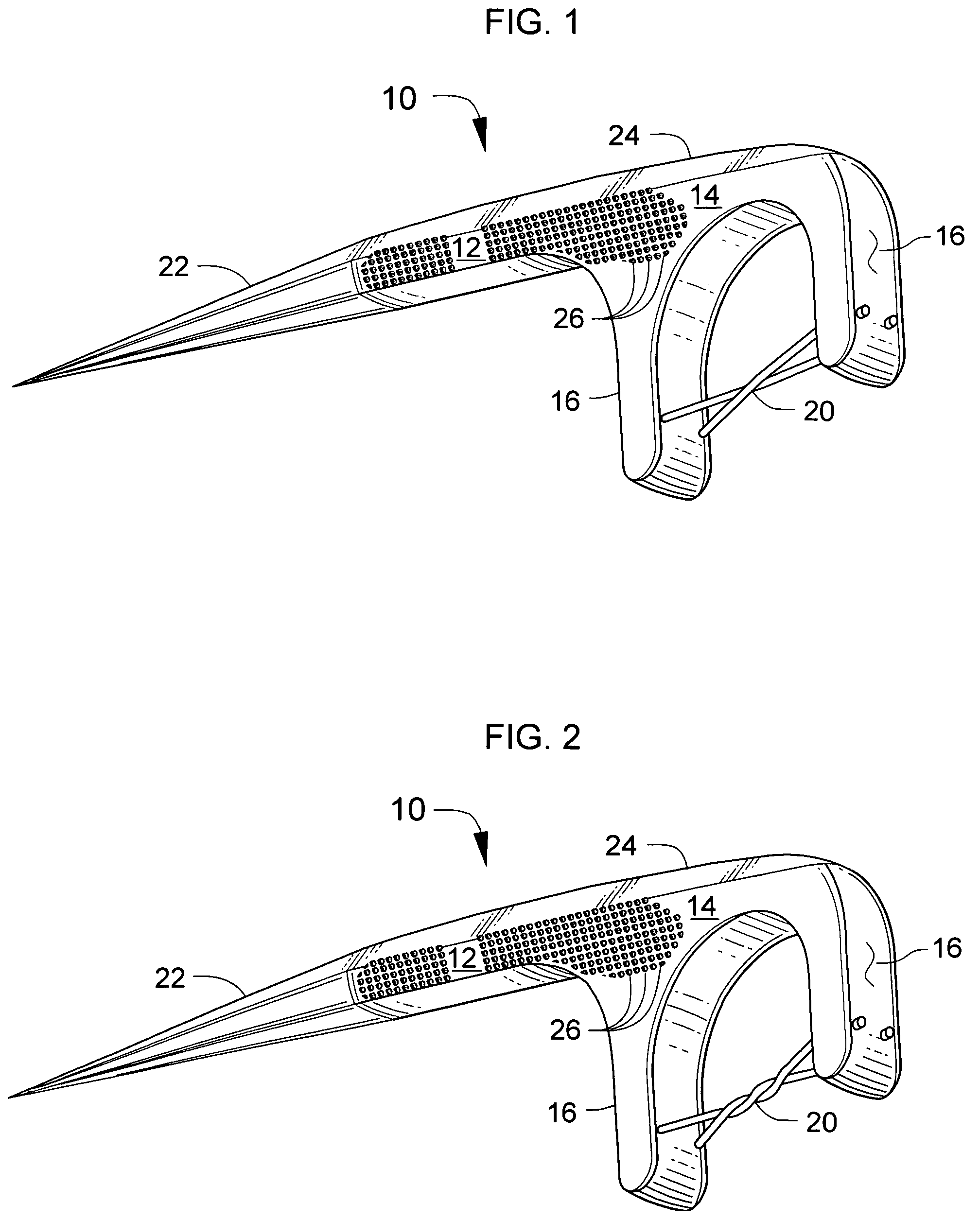

Floss pick

A floss pick including a body with a handle and a head. The head has first and second arms defining a cavity between them, and a length of dental floss extending between the arms and across the cavity. Preferably, the handle is oval in shape for easier grasping by the user. The body includes a toothpick member that preferably is disposed on the head and extends outwardly from one of the first and second arms into the cavity. The floss extends between the other of the first and second arms and the toothpick member and during use guides the toothpick member into interproximal spaces between teeth. Alternatively, a toothpick member may be provided in a recessed region of the handle and extend forwardly toward the head. The latter toothpick member is able to be detached from the handle for separate use.

Owner:PROKOPCHUK WALTER +1

Convenient chopsticks made from Conyza canadensis and processing technique

InactiveCN101323122AEasy to manufactureHigh surface finishWooden sticks manufactureWood treatment detailsCuticleHigh surface

The invention discloses a convenient chopstick made from conyza japonica and a production process, which is characterized in that, the stem of the mature conyza japonica is adopted; branches are cut off; epidermis is skinned in water and xylem is presented; the material is cut into the normal size of common chopsticks; the integral shape is straightened, dried, disinfected and made into chopsticks; or the material can be steamed and boiled in sticky slurry made from boiled glutinous rice, and then extrusion, formation, drying, cutting and packaging are carried out. The production process of the invention can also be applied to the production of ice cream sticks, toothpicks, medical tongue depressor, cotton swab sticks and other products. The convenient chopsticks and the tooth picks made from the conyza japonica have the advantages of high surface smoothness, low cost, convenient manufacture, large cultivation acreage, high productivity and strong reproducibility; the conyza japonica can be used for replacing precious forest wood resources.

Owner:王玉华 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com