Starch toothpick and its production process

A technology of starch toothpicks and toothpicks, applied in the field of toothpicks, can solve the problems of livestock injury, waste of bamboo and wood materials, consumption of large energy, etc., and achieve the effect of not destroying forest resources, not hurting teeth, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

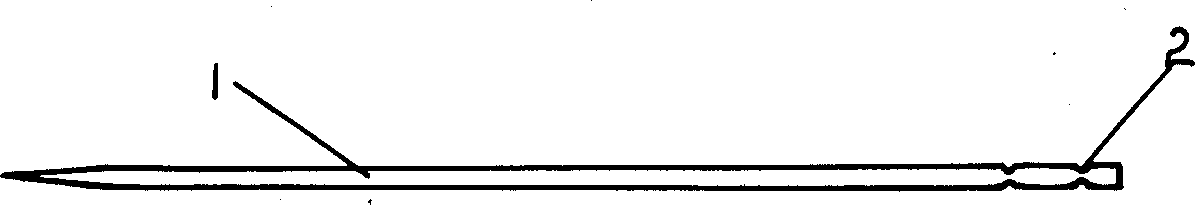

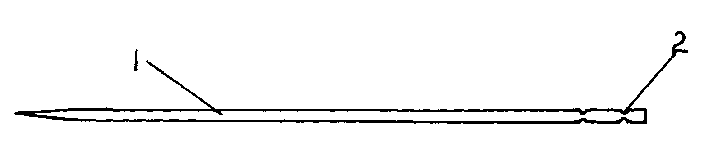

[0010] The starch toothpick is a cylindrical toothpick body 1 made of starch raw material, and the toothpick body 1 is a green toothpick body. One end of the toothpick body 1 is conical, and the other end is located on the periphery of the toothpick body 1 with two annular grooves 2 .

[0011] The starch toothpick is made of cornstarch, sweet potato starch, edible solid sorbitol, edible Mingfan, and edible green pigment; its proportioning is cornstarch 97.89%, sweet potato starch 1.96%, edible solid sorbitol 0.11%, edible Mingfan 0.03%, edible green pigment 0.01%.

[0012] The manufacture method of starch toothpick; be to get cornstarch 97.89%, sweet potato starch 1.96% and put into the noodle joint machine, then take edible solid sorbitol 0.11%, edible Mingfan 0.03%, edible green pigment 0.01%, and use comprising cornstarch, Sweet potato starch, edible solid sorbitol, edible Mingfan, and water with 30% of the total weight of edible green pigment are stirred evenly, put into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com