Sonic dental device

a dental device and sonic technology, applied in the field of personal hygiene, can solve the problems of difficult cleaning of the interproximal area of teeth, difficult cleaning of teeth, time-consuming and laborious tasks, etc., and achieve the effect of increasing the ease and effectiveness of mechanical flossing and teeth cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

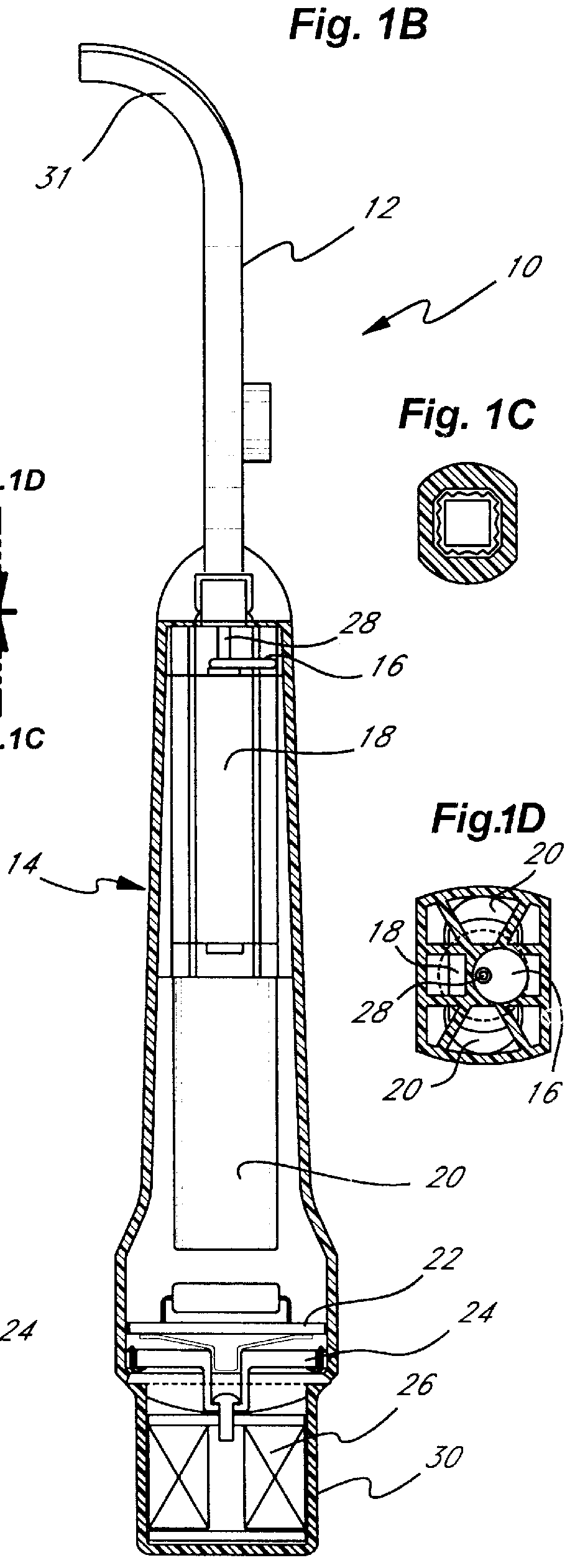

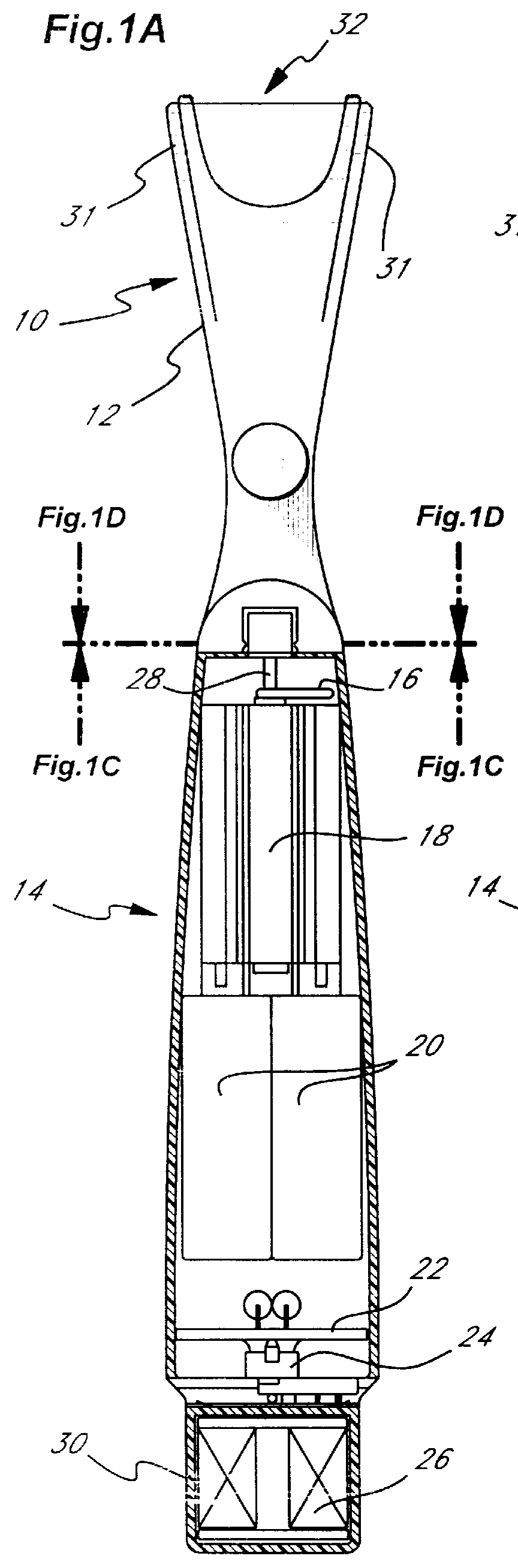

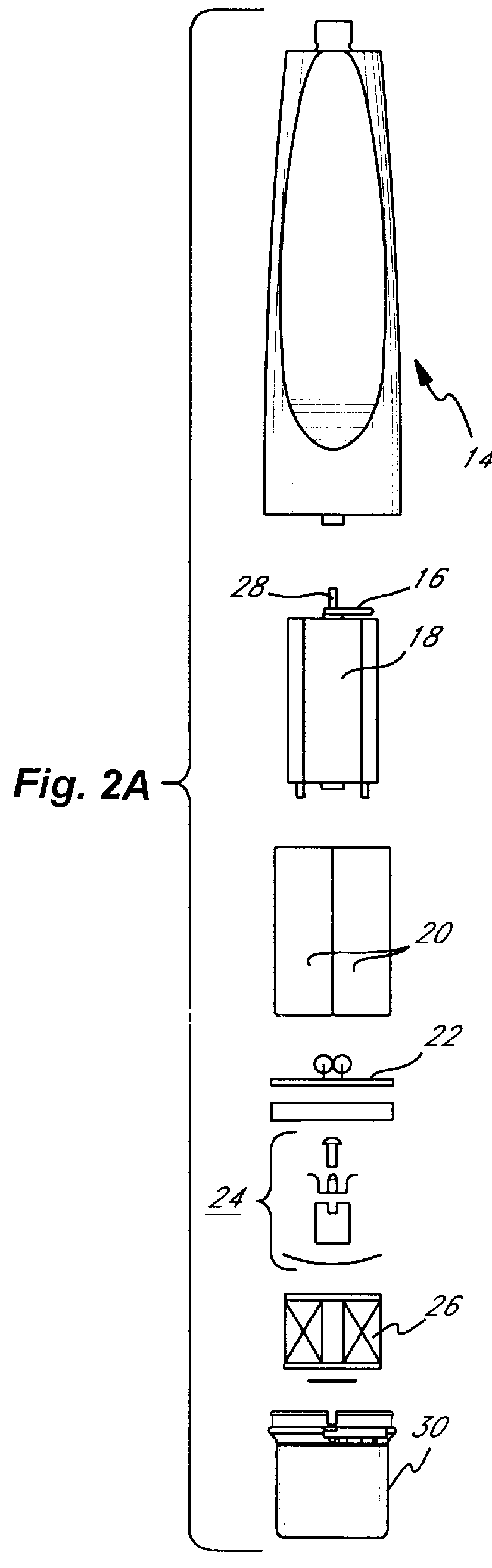

A sonic dental cleaning device 10 is described herein and shown in the Figures. The device 10, when assembled as a flossing device (FIGS. 1A and 1B), comprises two main pieces: (1) a hollow power driven handle 14 having two ends (also see FIGS. 2A and 2B); and (2) a detachable floss-holding fork 12 wherein one end of the fork 12 attaches to the handle 14 at one end and another end of the fork 12 forming a pair of tines 31 which hold floss 32. The handle 14 is preferably made of polymeric plastic and the fork 12 and tines 31 are preferably made of nylon or polymeric plastics. Located at another end of the handle 14, opposite the end attached to the fork 12, is a handle end piece 30 which holds a charging coil 26 which enables recharging the device 10 by induction in a conventional manner.

As shown in FIGS. 1A, 1B, 2A, and 2B, the handle 14 includes an electric motor 18 located therein which has an output shaft 28 and an eccentrically mounted disc 16 attached thereto. Power for the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com