Toothpick filling machine

A filling machine, toothpick technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problems of difficult normal operation, low efficiency, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

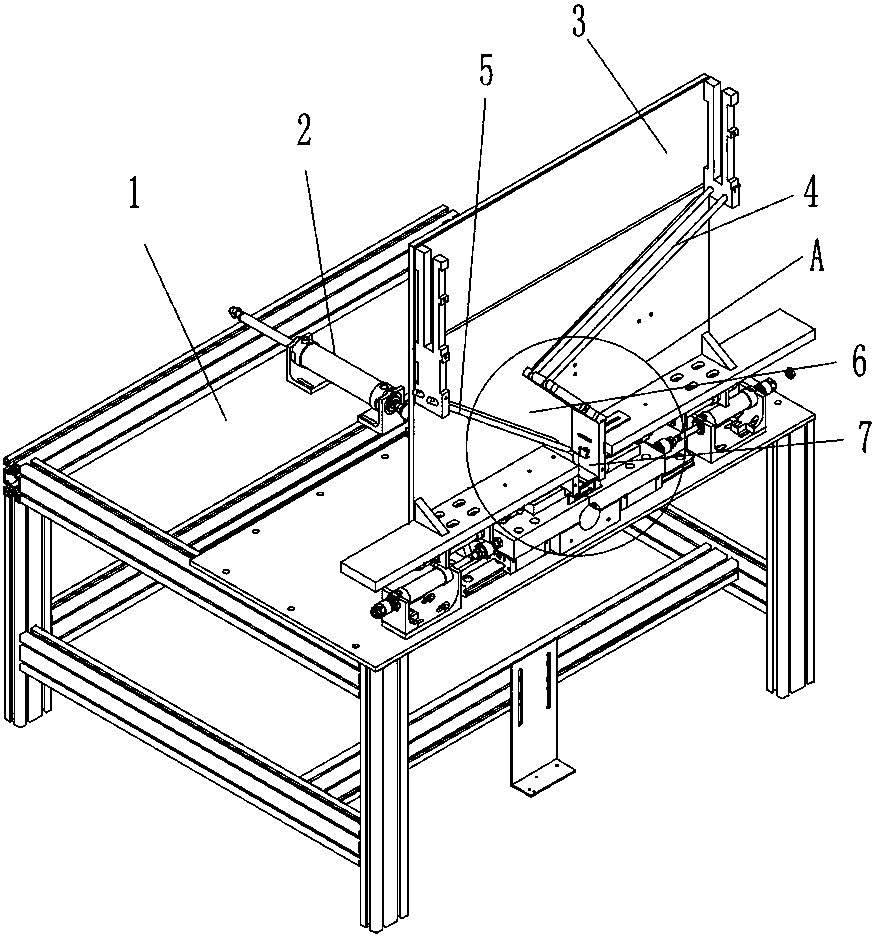

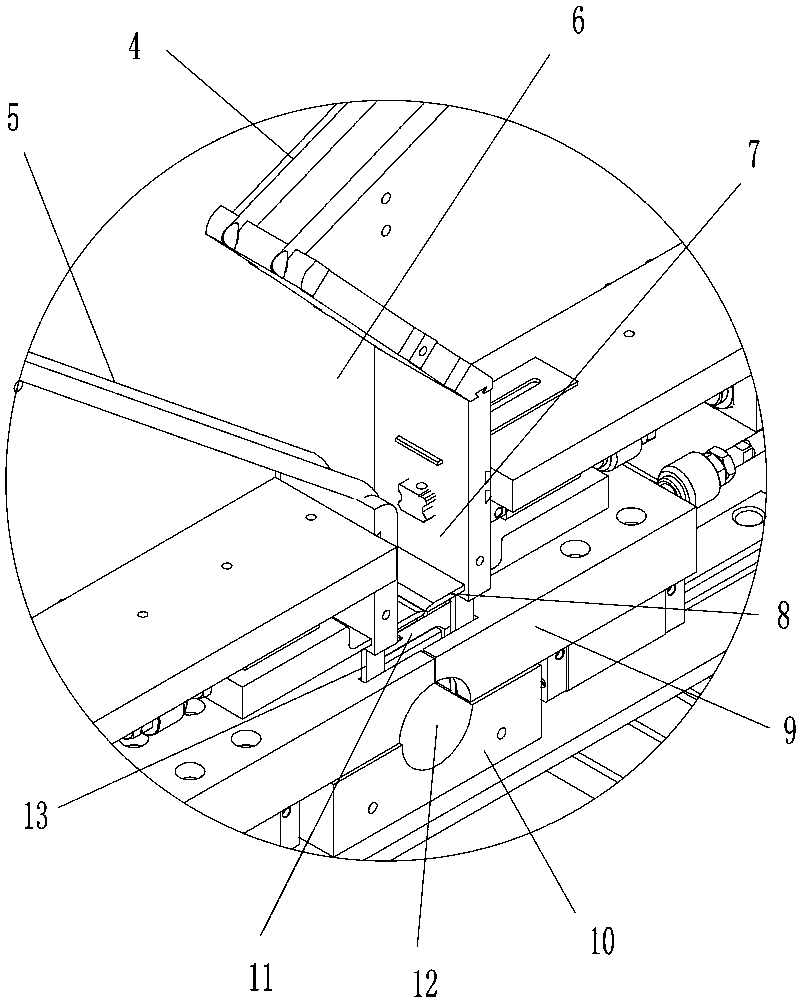

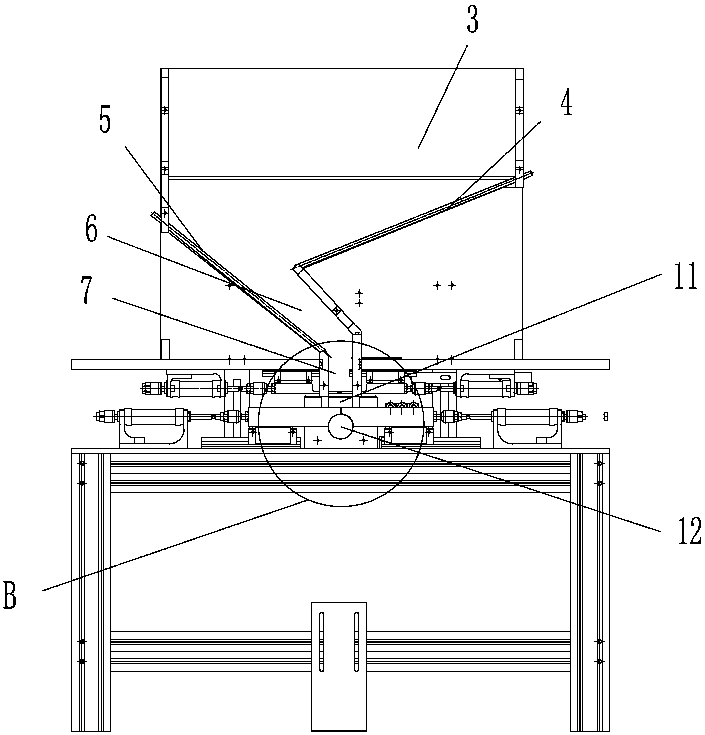

[0029] Embodiment: a kind of toothpick filling machine, as Figure 1-4 shown. The device comprises a frame 1, a hopper 3 is arranged on the top of the frame, and the bottom end of the hopper 3 is connected to a secondary silo 7 through a feeding passage 6. The secondary silo 7 is arranged below the center line of the hopper 3, while the discharge port of the hopper 3 is offset to the left, and the two are connected by an inclined discharge channel 6 . The discharge slope on the bottom surface of the hopper becomes smaller, which reduces the deflection of the toothpick during the downward falling process, and the capacity difference between the upper and lower ends of the discharge channel is small, reducing the flow change. The panels on the front of the hopper 3, the feeding channel 6 and the secondary feed bin 7 are transparent panels. The thickness of the hopper 3, the feeding channel 6 and the secondary silo 7 are adapted to the length of the toothpick. The bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com