Water-based ultraviolet (UV) curing silk screening snowflake ink

A technology of snowflake ink and ultraviolet light, applied in the printing field, can solve problems such as polluting the environment, smelling bad, and affecting human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

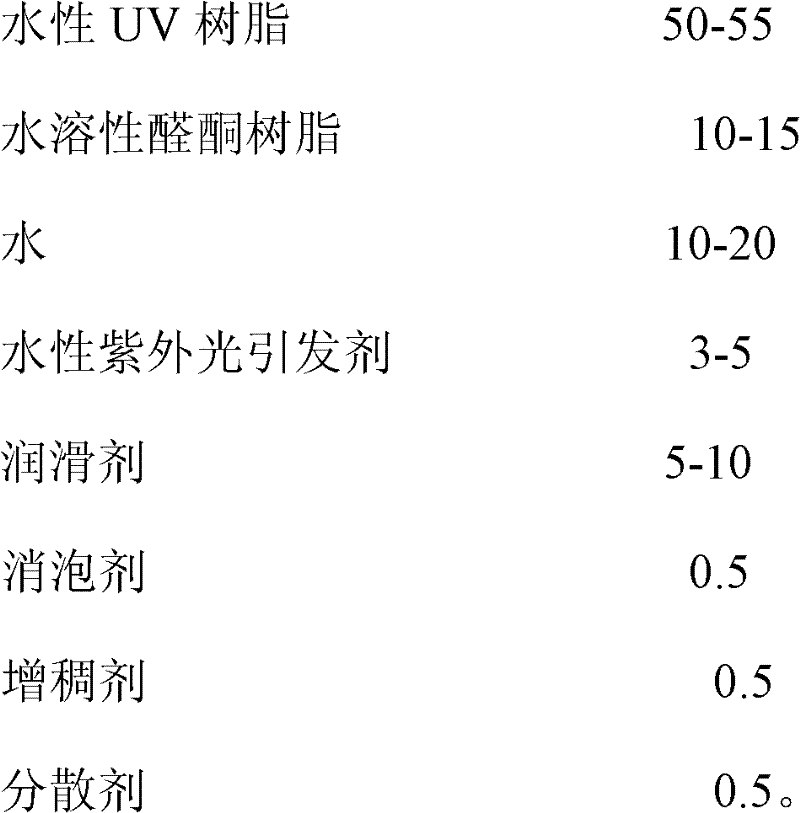

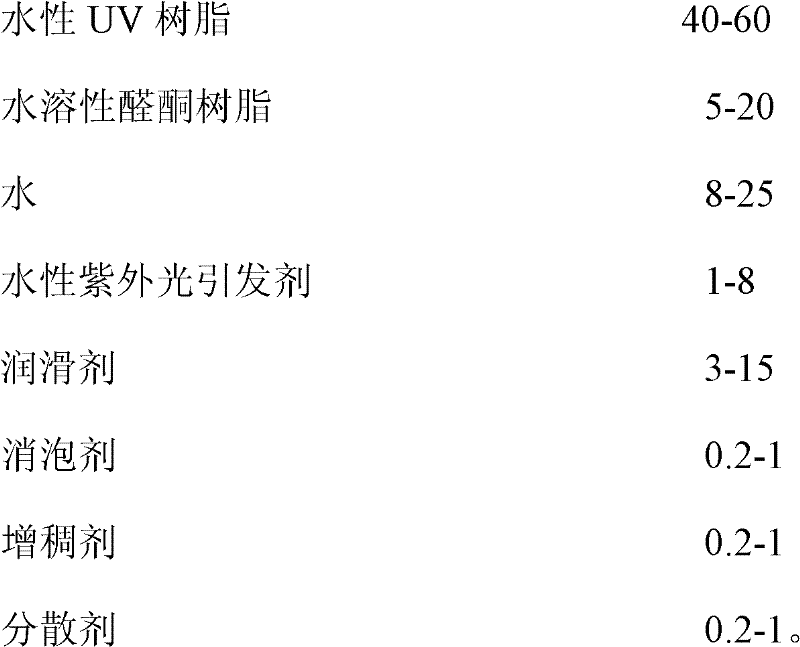

[0016] Embodiment 1, a kind of water-based UV-curable screen printing snowflake ink, is made of following raw materials in parts by weight: water-based acrylic UV resin 50, water-soluble aldehyde and ketone resin 10, water 10, water-based ultraviolet photoinitiator (trade name ciba 1173) 3. Polyethylene wax 5, defoamer (trade name dego 902) 0.5, thickener (trade name Lubrizol hv30) 0.5, dispersant Amp-95 0.5.

[0017] Preparation method: Mix the raw materials of water-based acrylic UV resin, water-soluble aldehyde and ketone resin, and water-based ultraviolet photoinitiator in the above parts by weight and put them into a high-speed mixer for stirring at a stirring speed of 3000 rpm for 1 hour, and wait for them to dissolve Finally, add other remaining raw materials, and then stir for 10 minutes to make water-based UV-curable screen printing snowflake ink.

Embodiment 2

[0018] Embodiment 2, a kind of water-based UV curing screen printing snowflake ink, is made of the following raw materials in parts by weight: water-based acrylic UV resin 55, water-based aldehyde ketone resin 15, water 20, water-based ultraviolet photoinitiator (trade name ciba 1173) 5 , polyethylene wax 10, defoamer (trade name dego 902) 0.5, thickener (trade name Lubrizol hv30) 0.5, dispersant Amp-95 0.5.

[0019] The preparation method is the same as in Example 1, and will not be repeated here.

Embodiment 3

[0020] Embodiment 3, a kind of water-based UV-curable screen printing snowflake ink, is made of the following raw materials in parts by weight: water-based acrylic UV resin 52, water-based aldehyde ketone resin 12, water 15, water-based ultraviolet photoinitiator (trade name ciba 1173) 4 , Klein 3620 8, defoamer (trade name dego 902) 0.5, thickener (trade name Lubrizol hv30) 0.5, dispersant Amp-95 0.5.

[0021] The preparation method is the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com