Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174 results about "Hinge line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hinge line is an imaginary longitudinal line along the dorsal edge of the shell of a bivalve mollusk where the two valves hinge or articulate. The hinge line can easily be perceived in these images of a mussel shell and an ark shell.

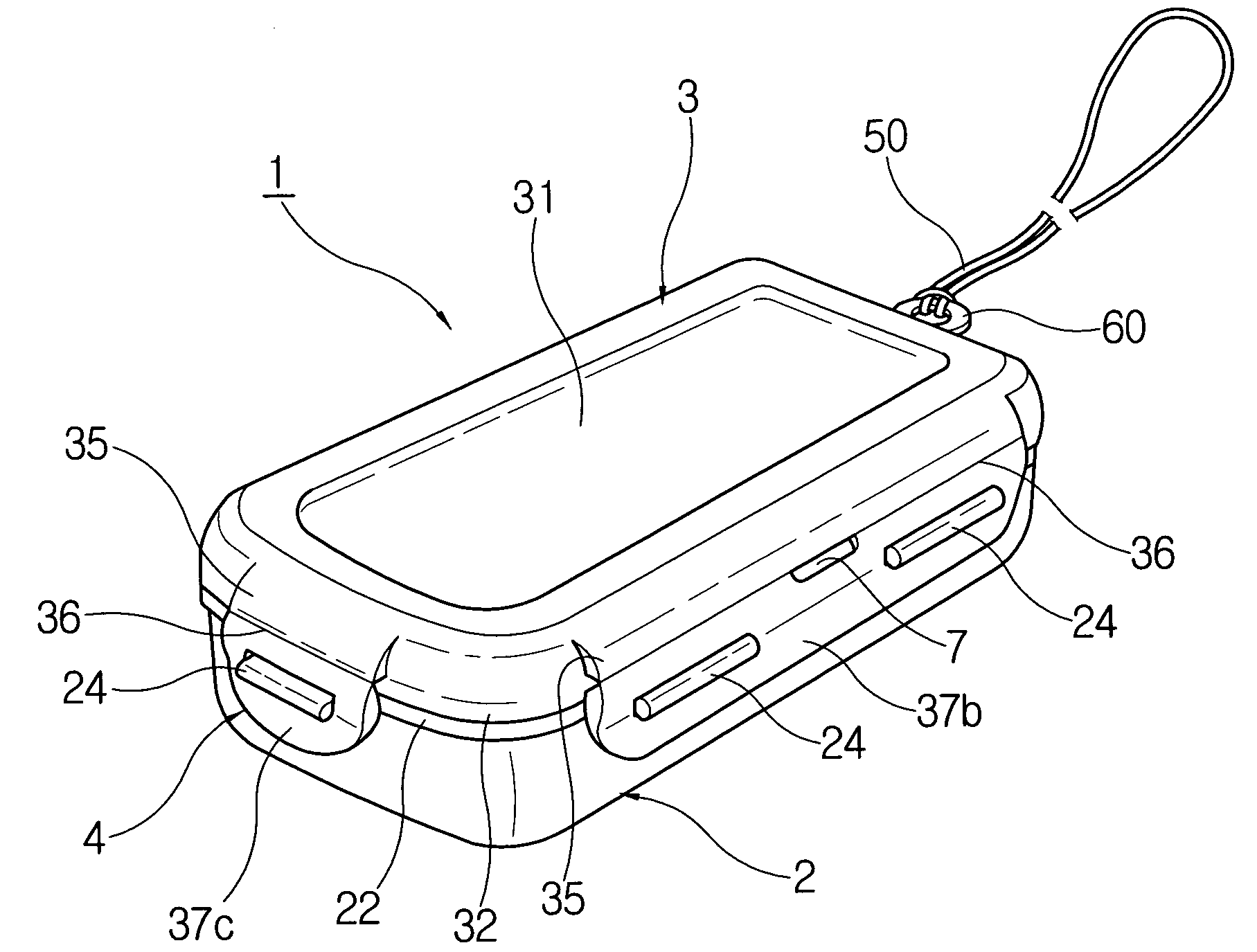

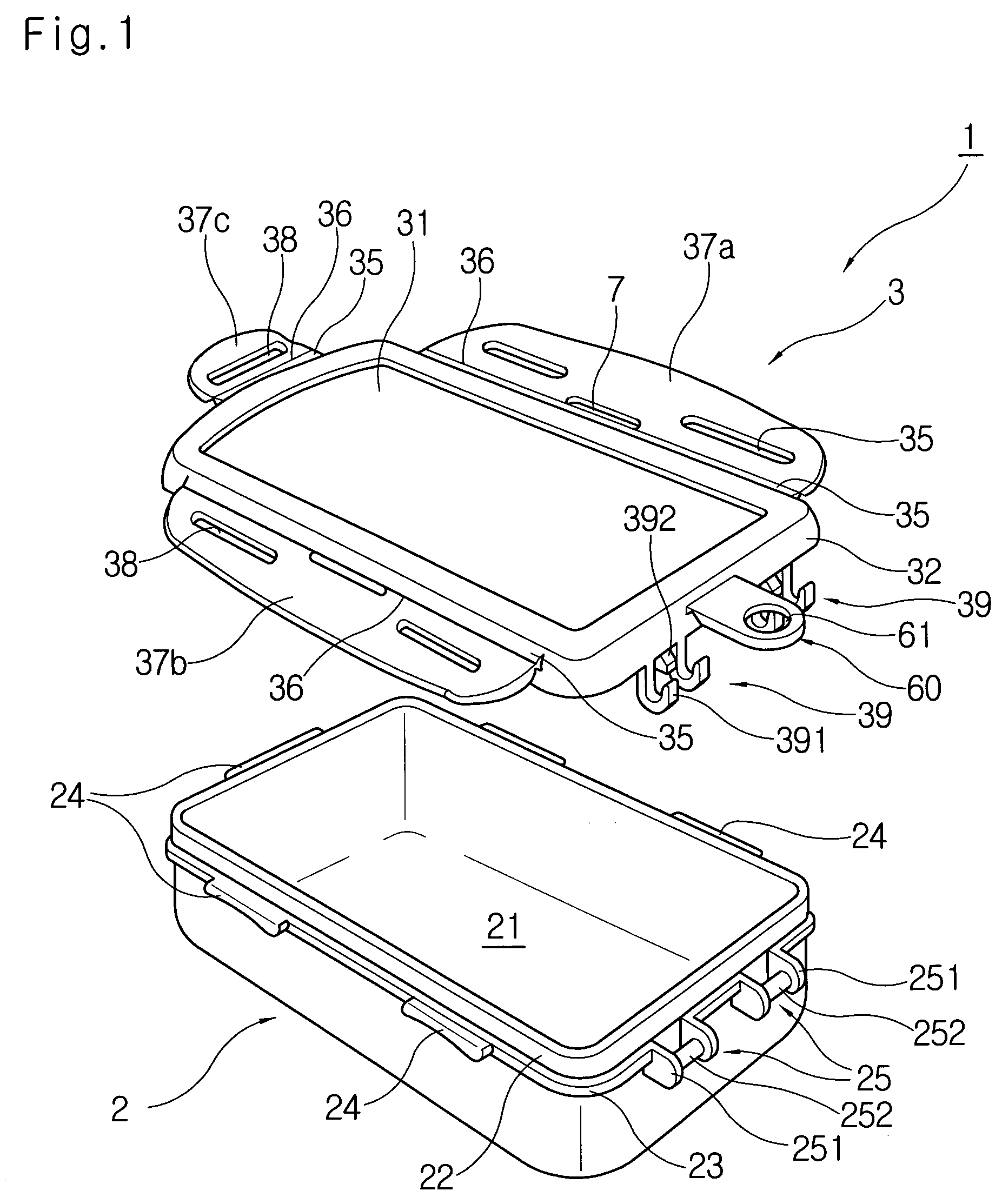

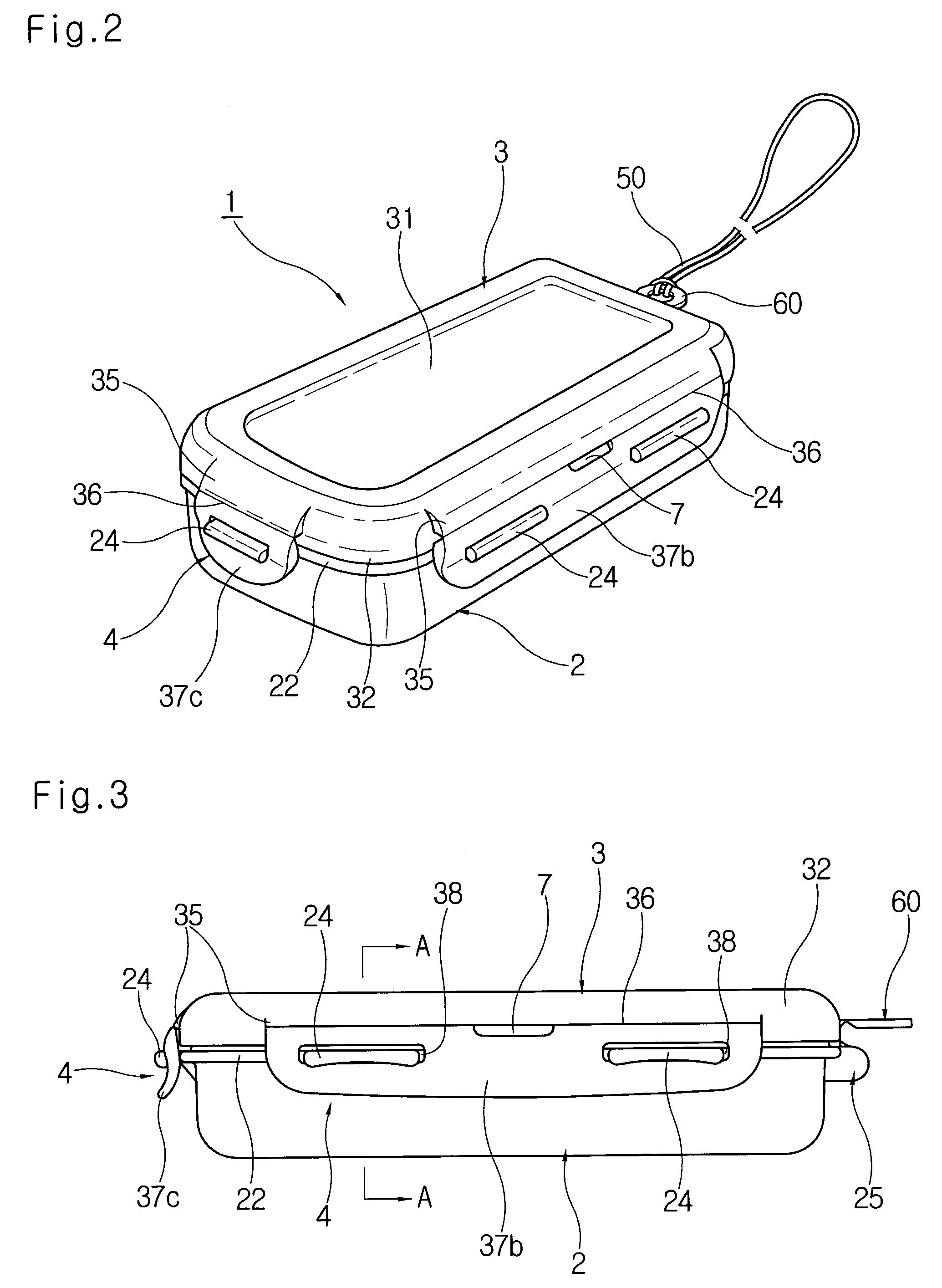

Cellular phone casing with melted liquid flow disconnection hole along hinge line

The present invention relates to an improved cellular phone casing capable of storing a cellular phone (a mobile phone) from an external impact when a cellular phone is stored in a bag and is carried and capable of preventing a cellular phone from moisture in rain or at a beach. The cellular phone storing casing comprises a casing body that has an inner storing space having a certain size and depth for storing a common cellular phone wherein an upper side of the same is opened for an easier storing and unloading of a cellular phone; a cover body that is fabricated in separation with the casing body and stores or unloads in a state that a cellular phone is sealed in the inner storing space of the casing body wherein the cover body is opened and closed with respect to the casing body; a hinge connection part that is designed so that the cover body is rotatable with respect to one surface of the casing body; and a locking part sealingly engages or opens the cover body with respect to the casing body.

Owner:HANA COBI PLASTIC

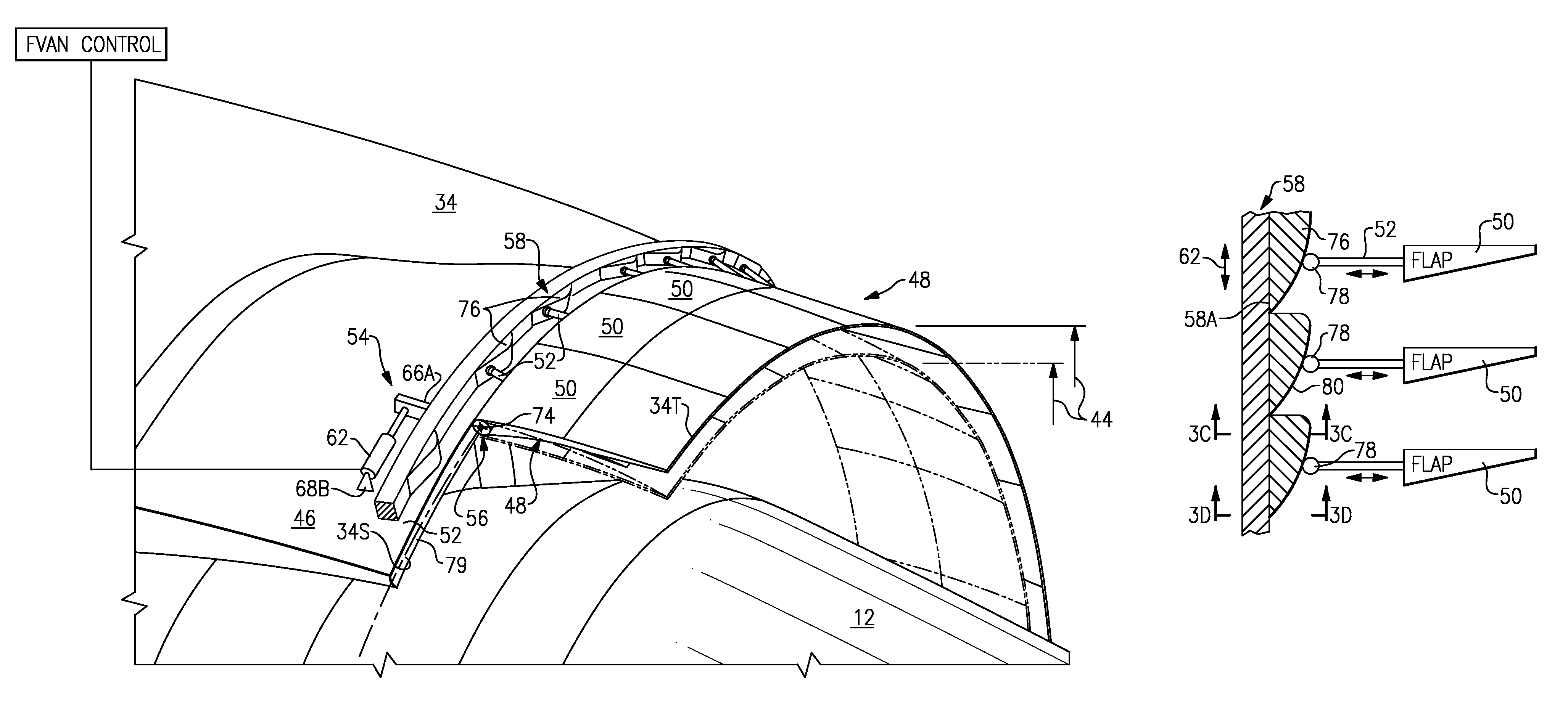

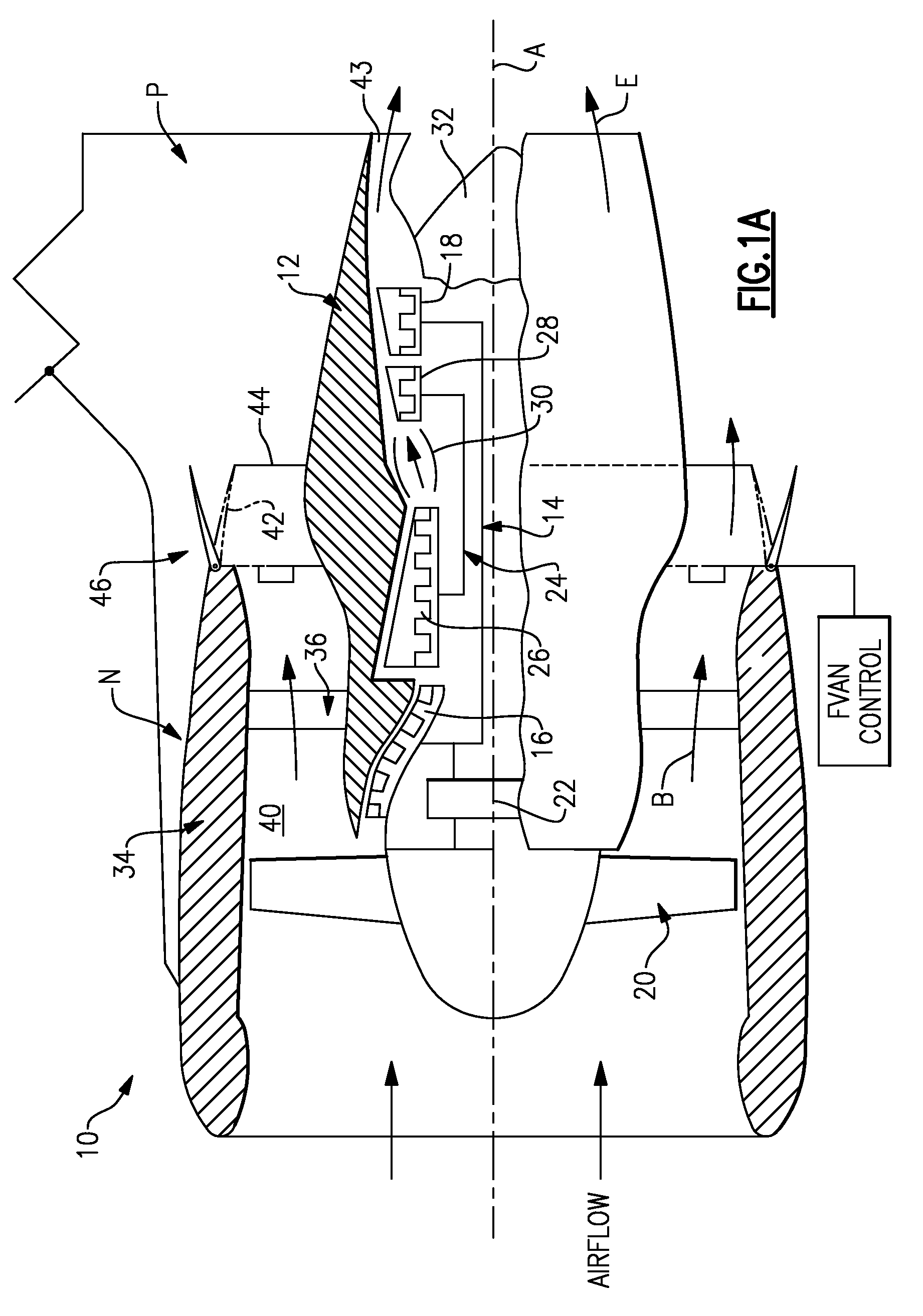

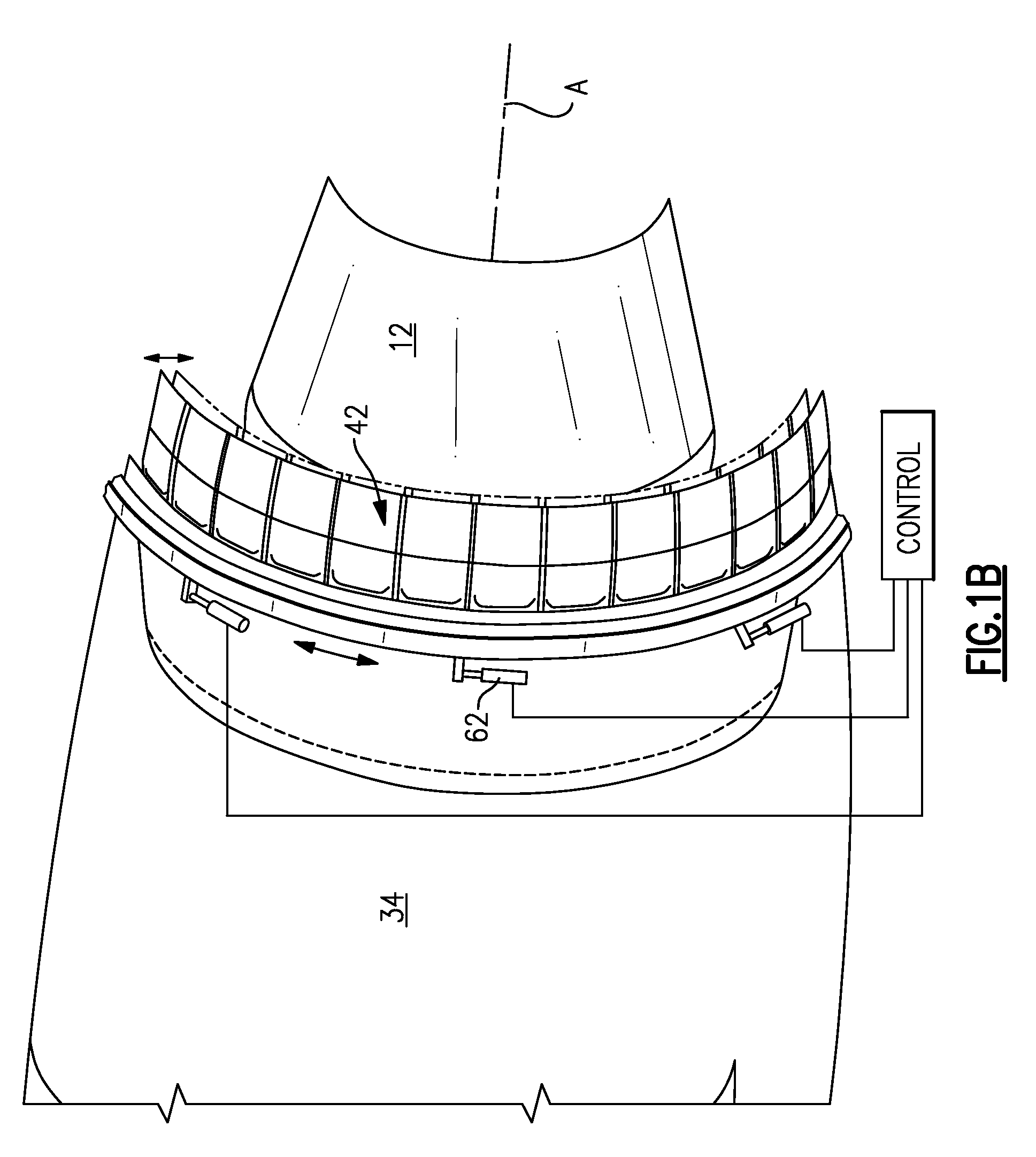

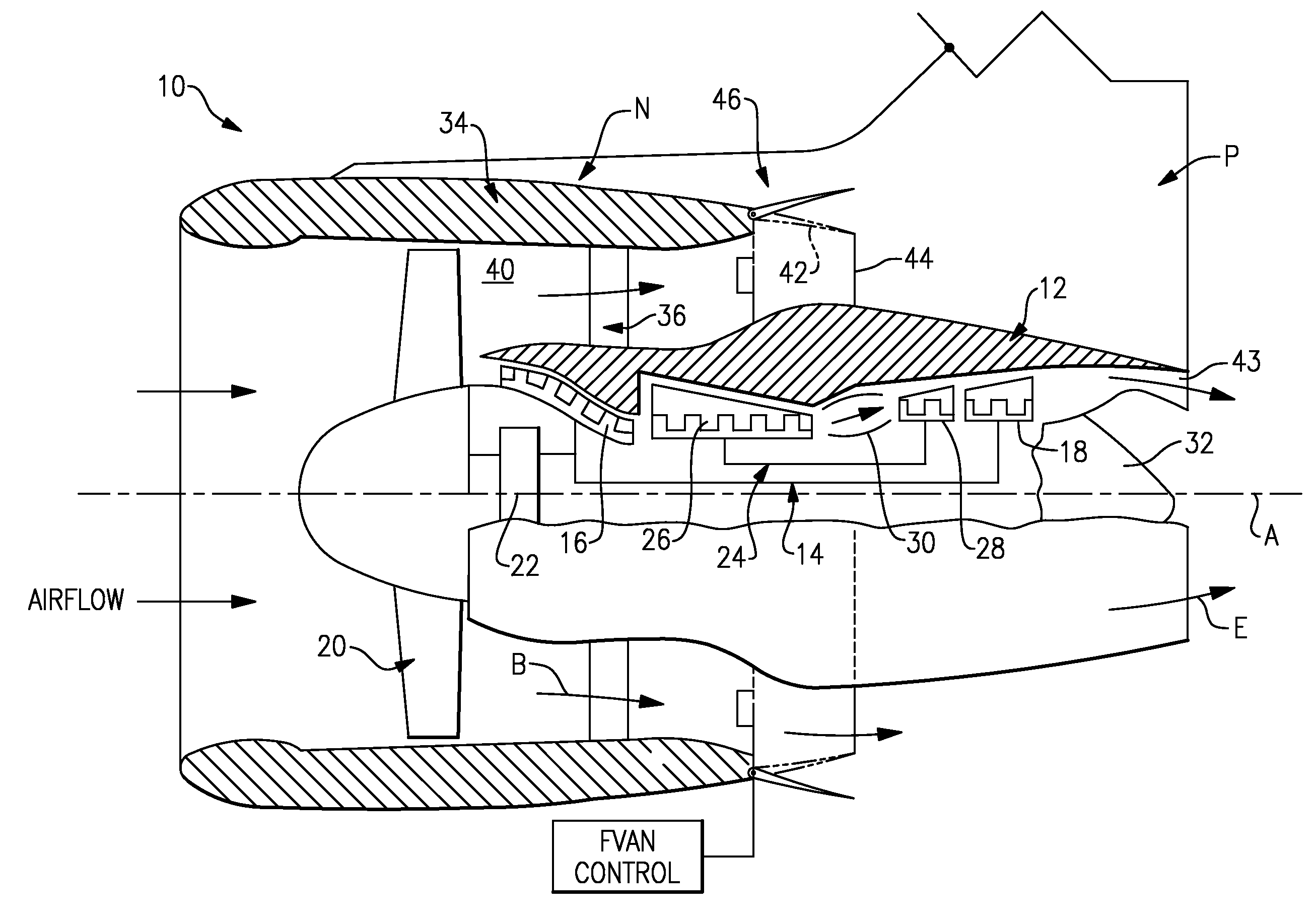

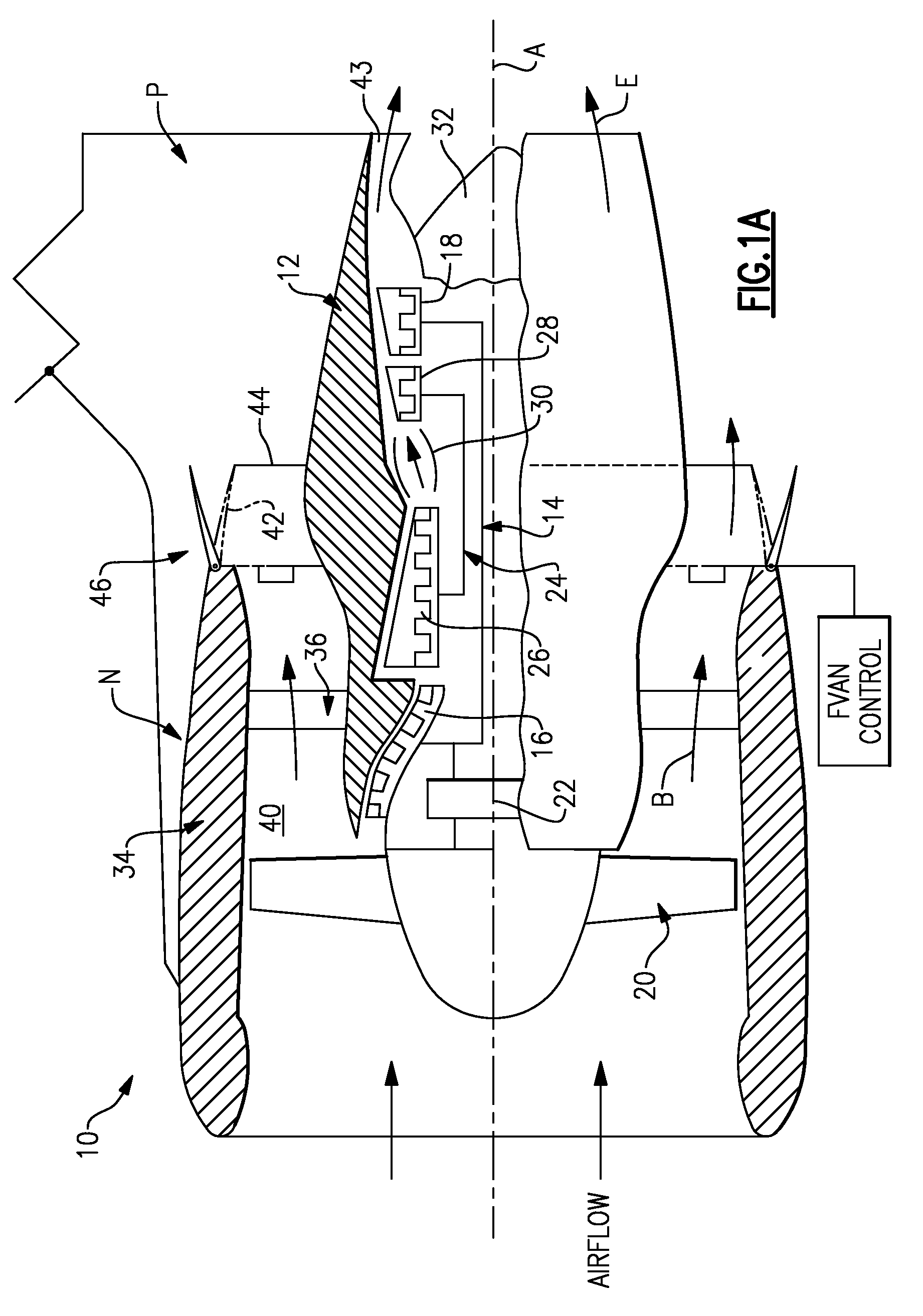

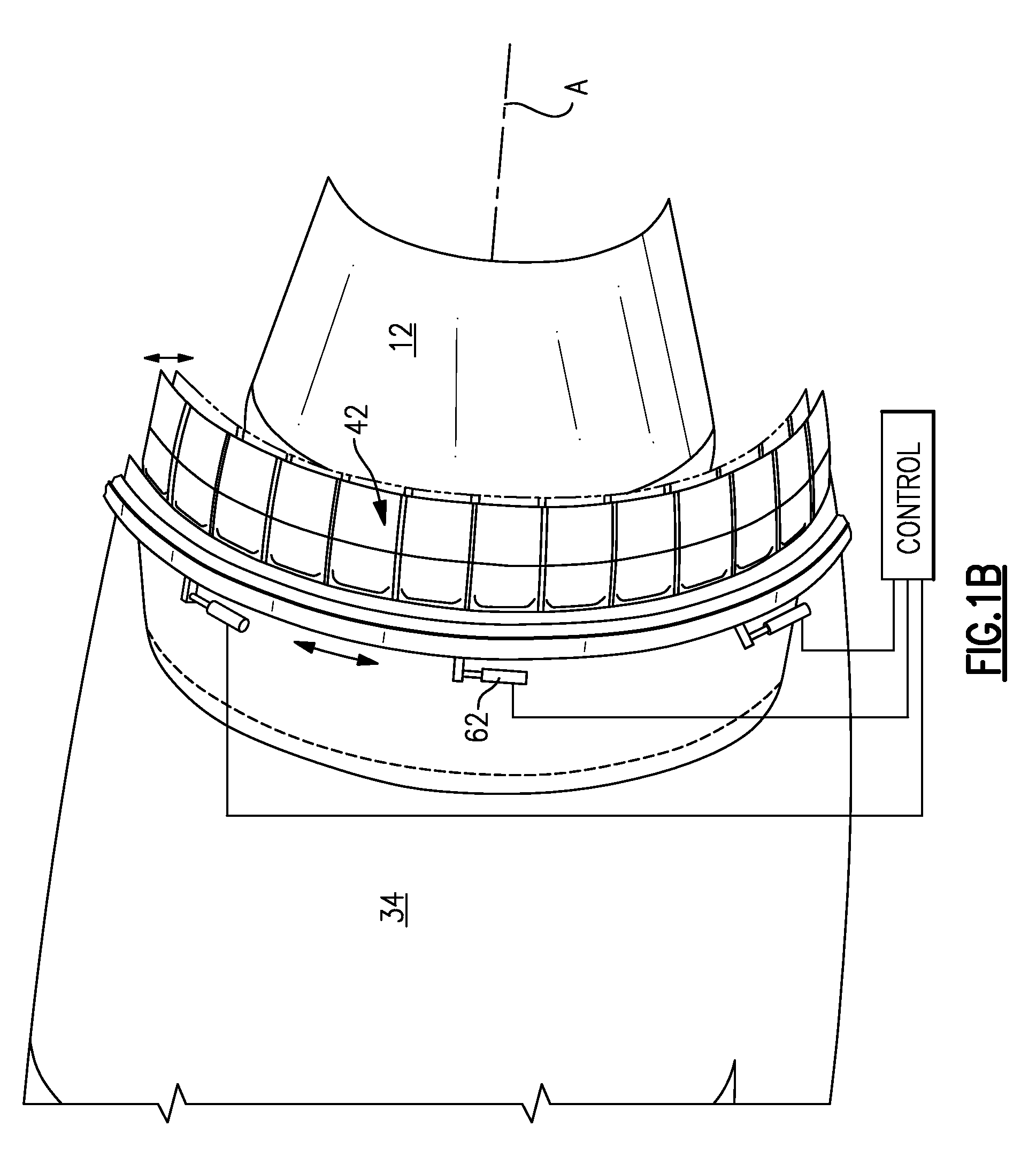

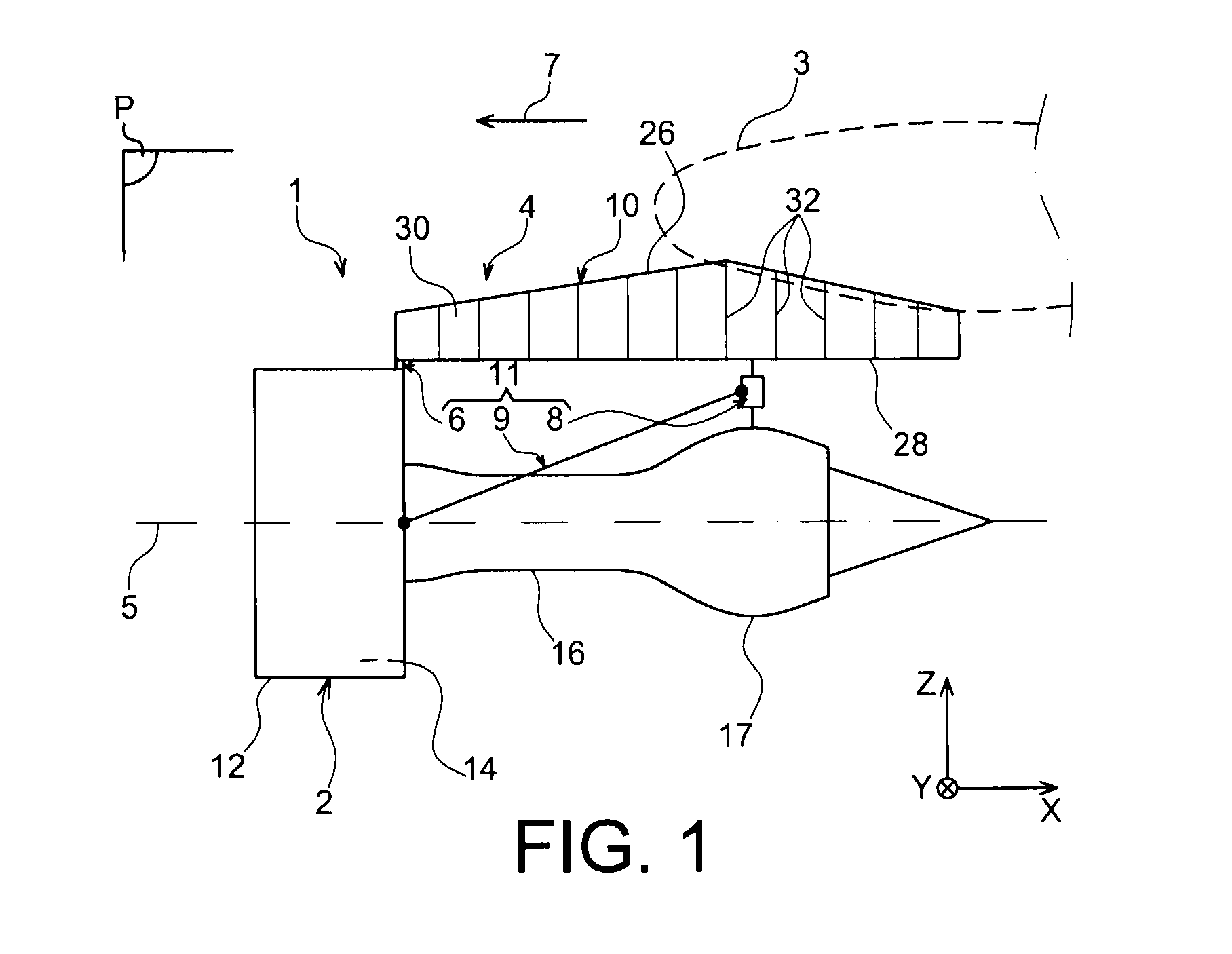

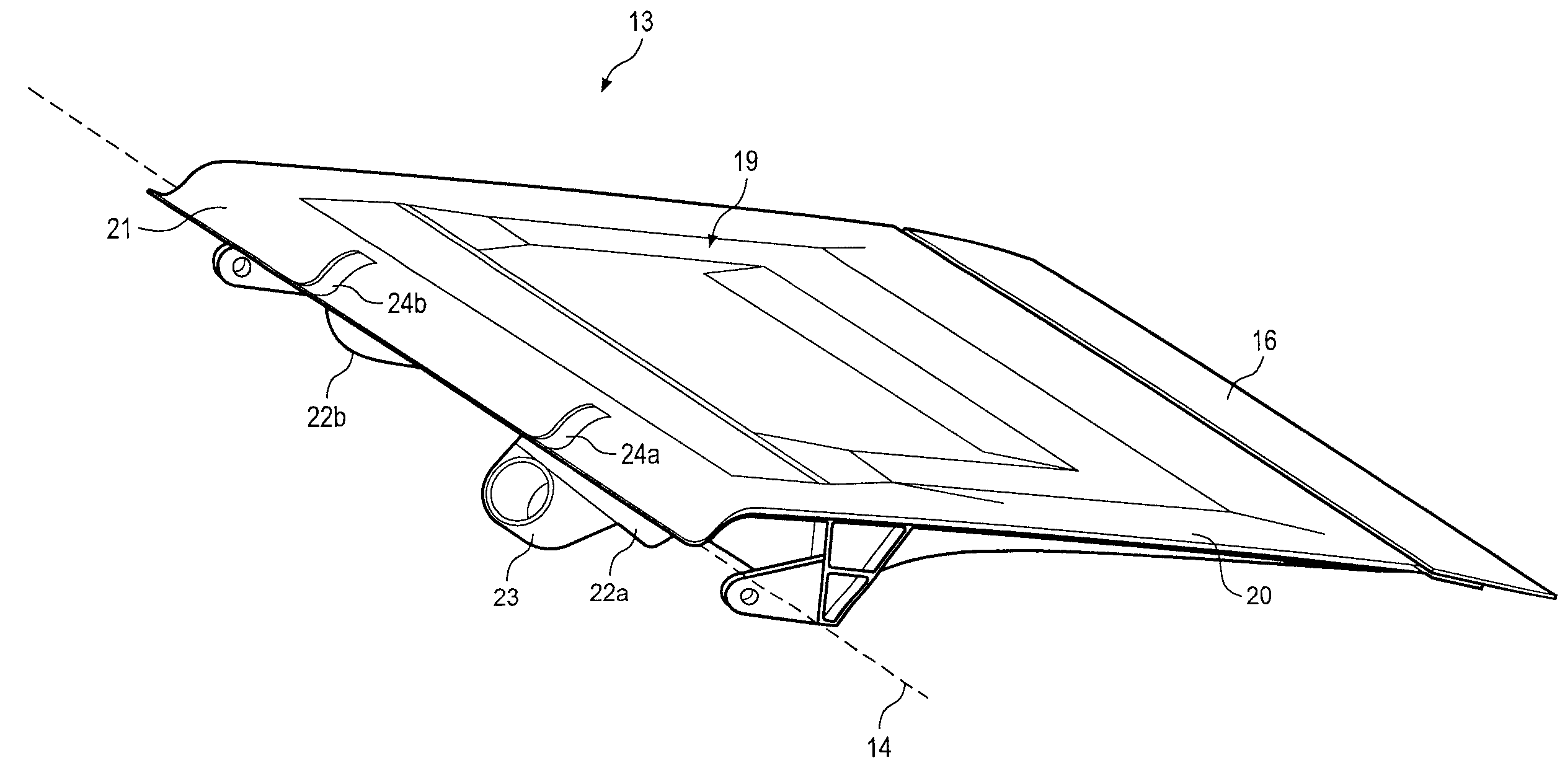

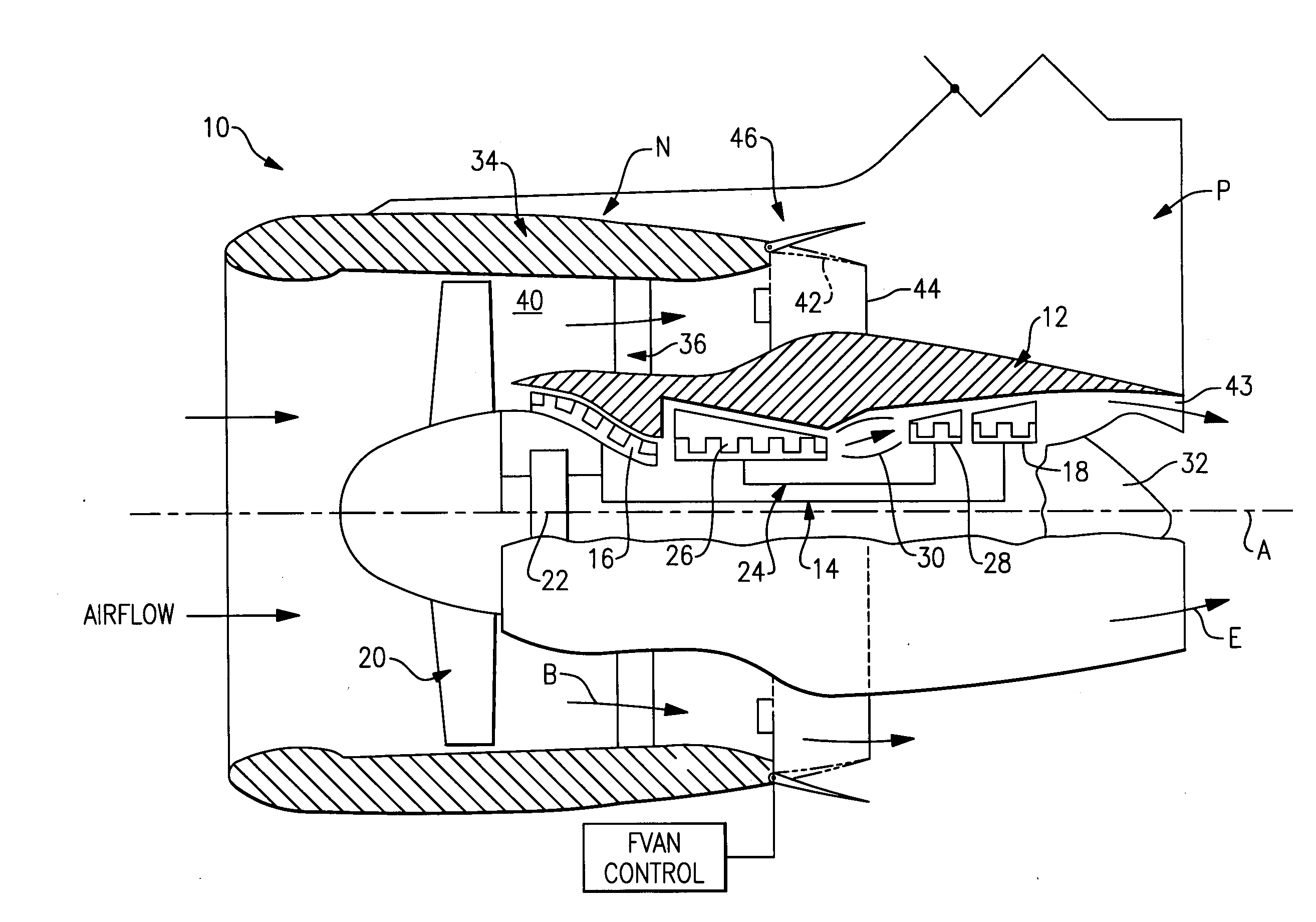

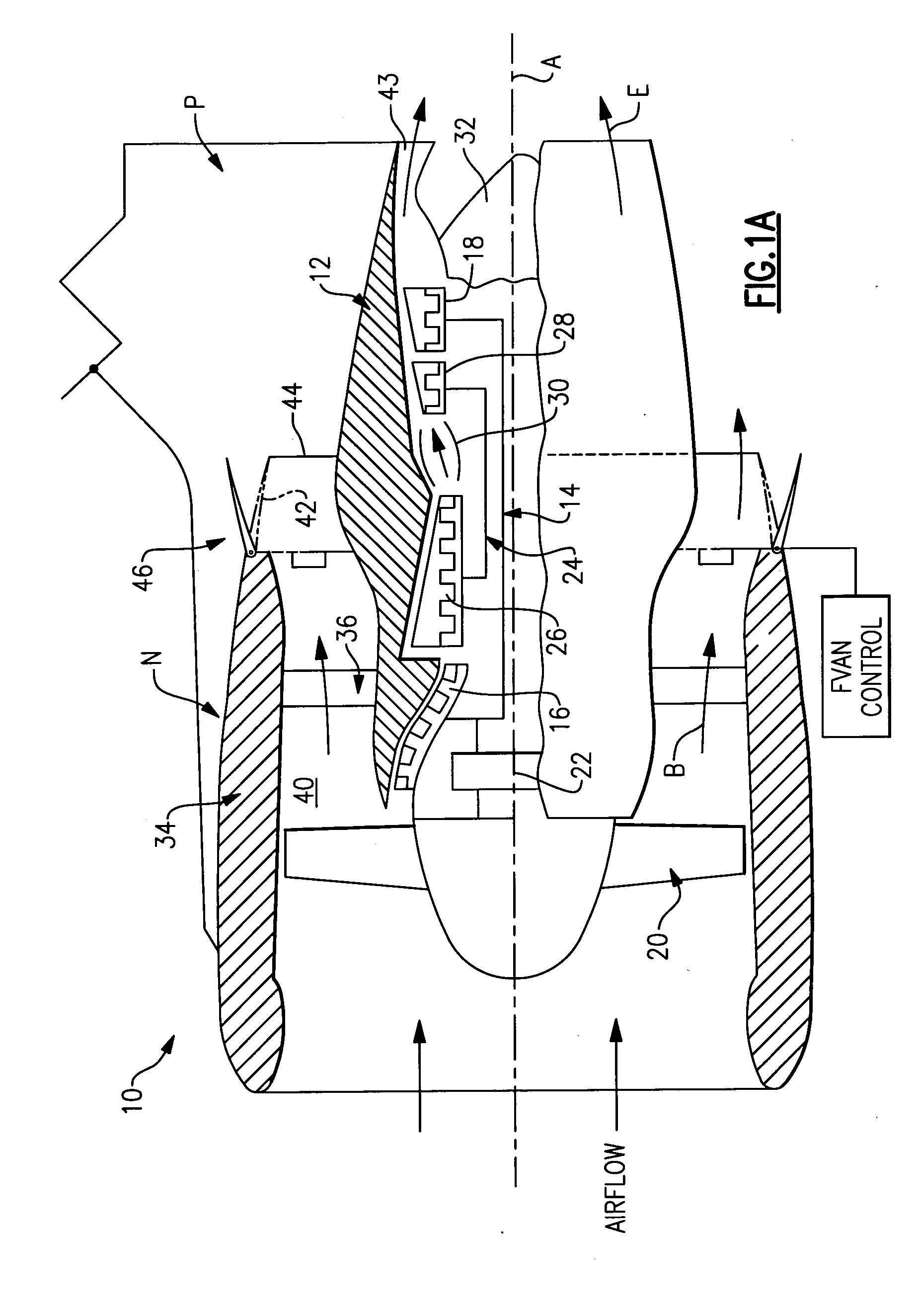

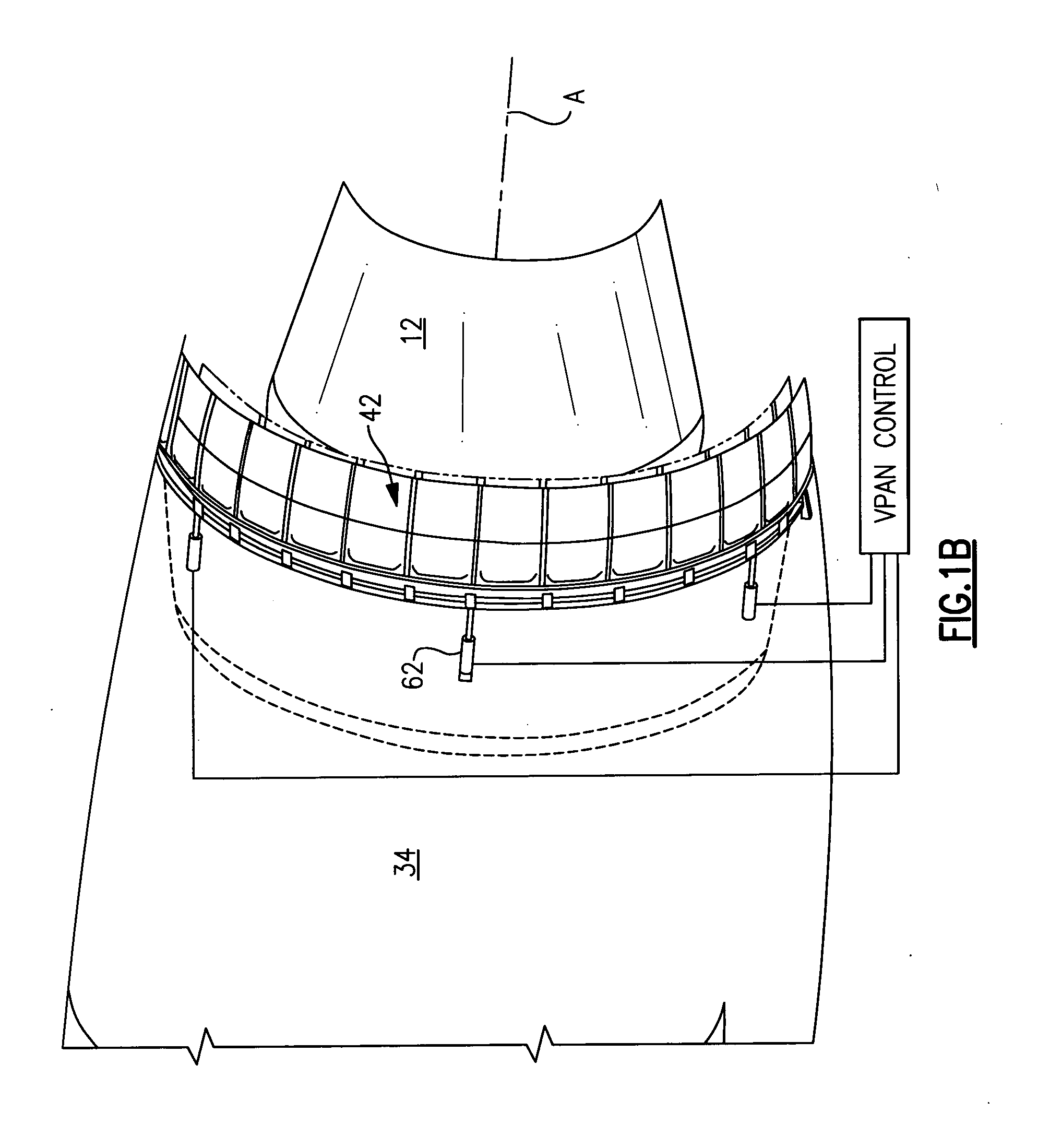

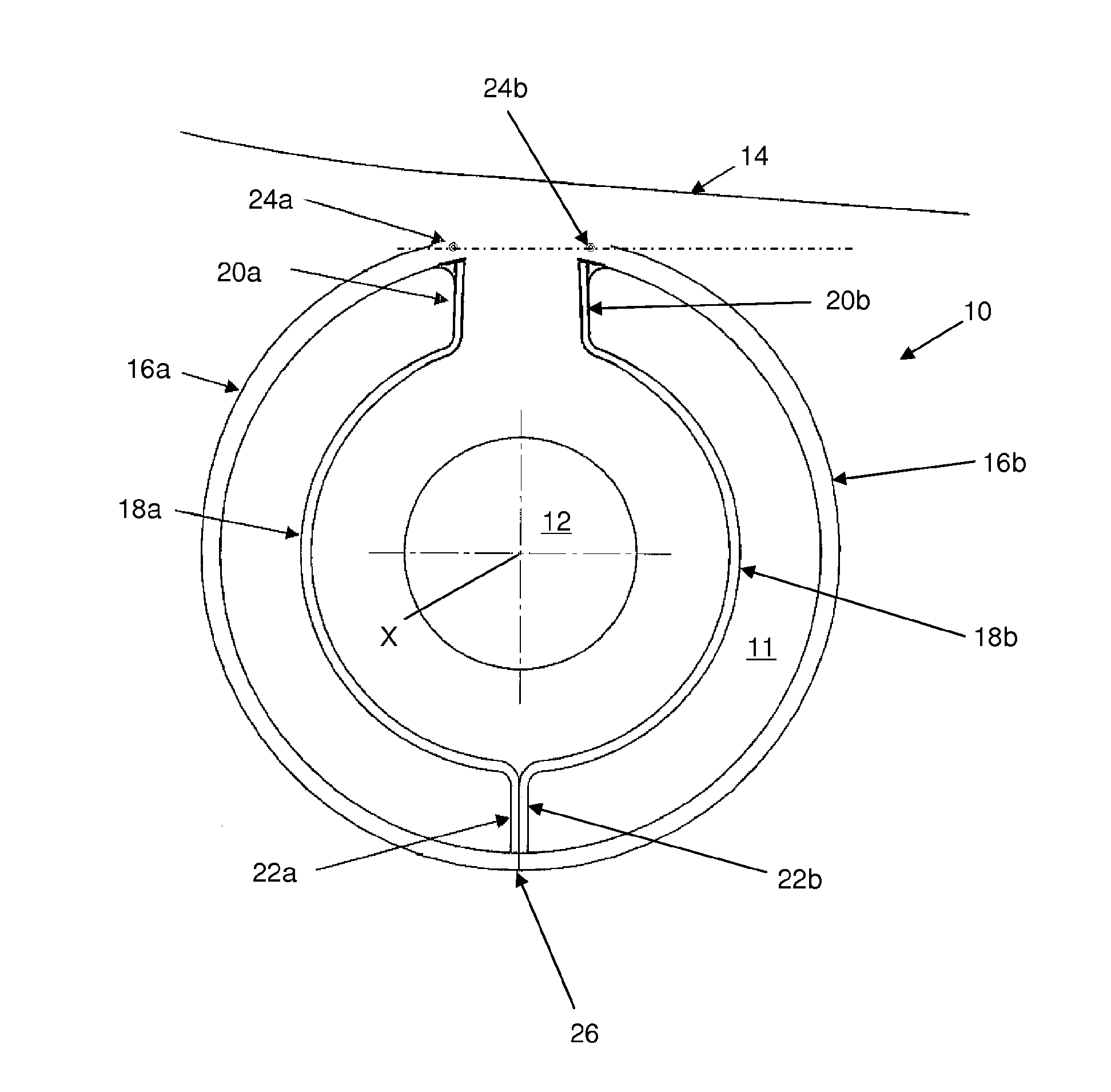

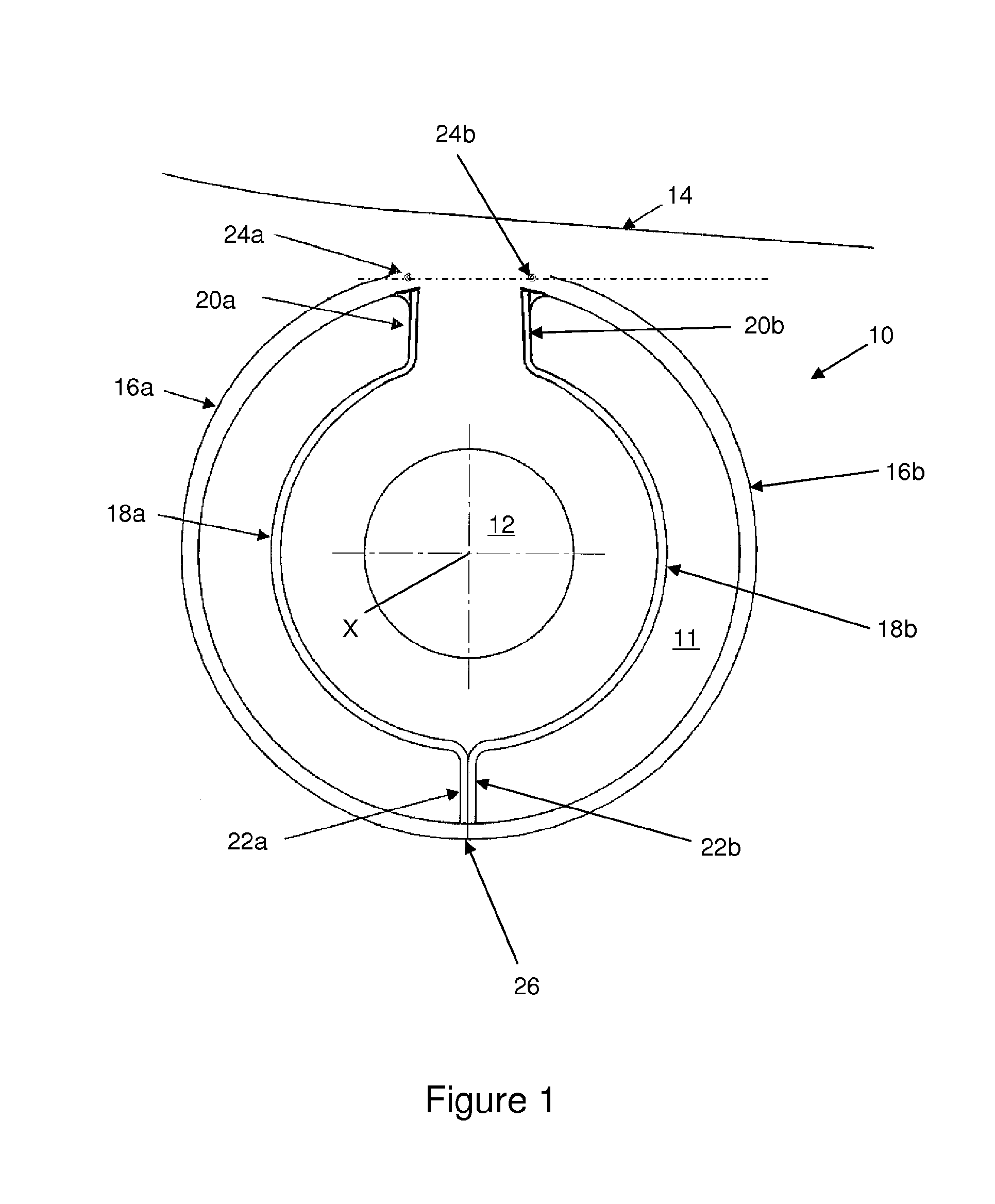

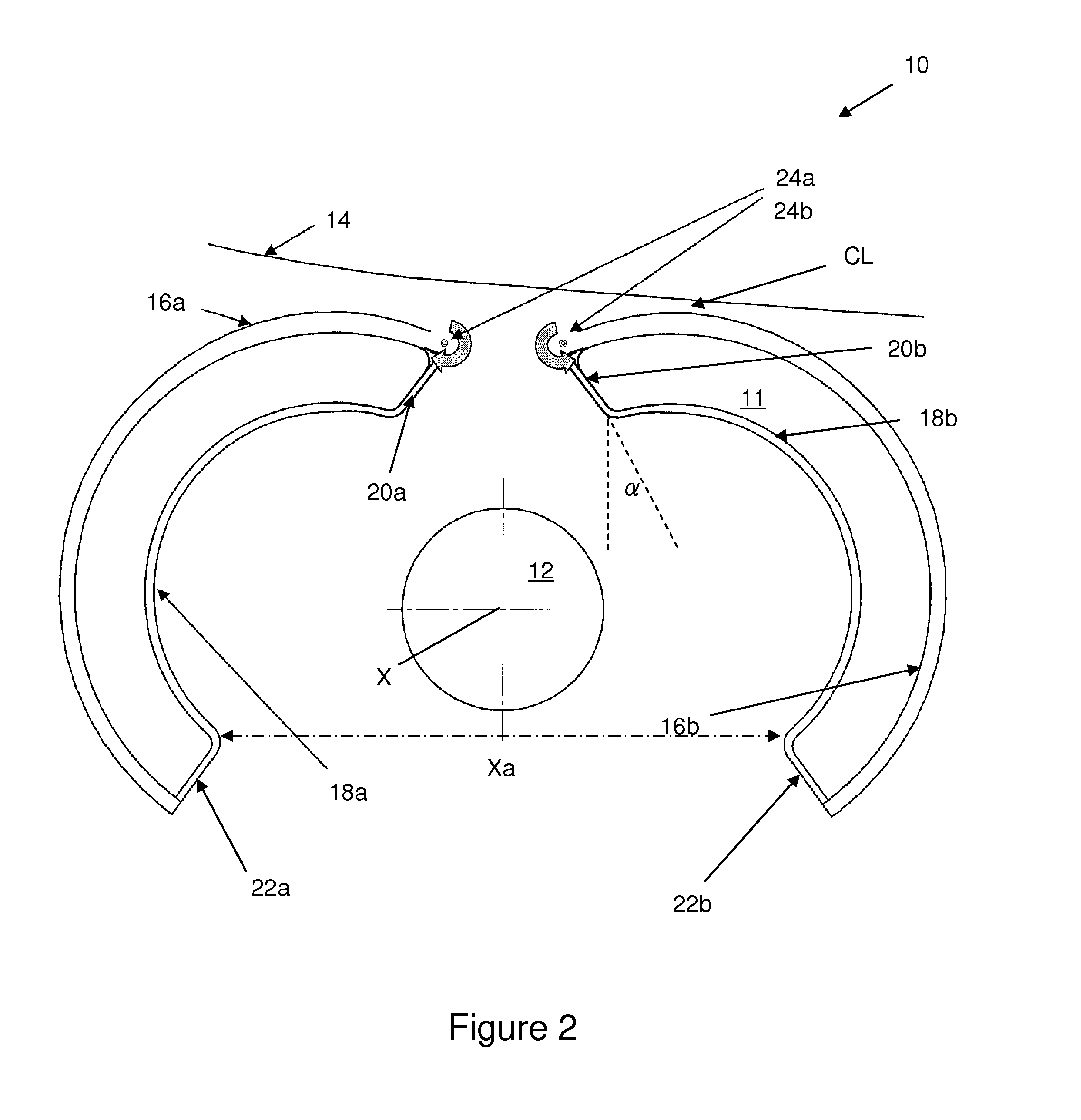

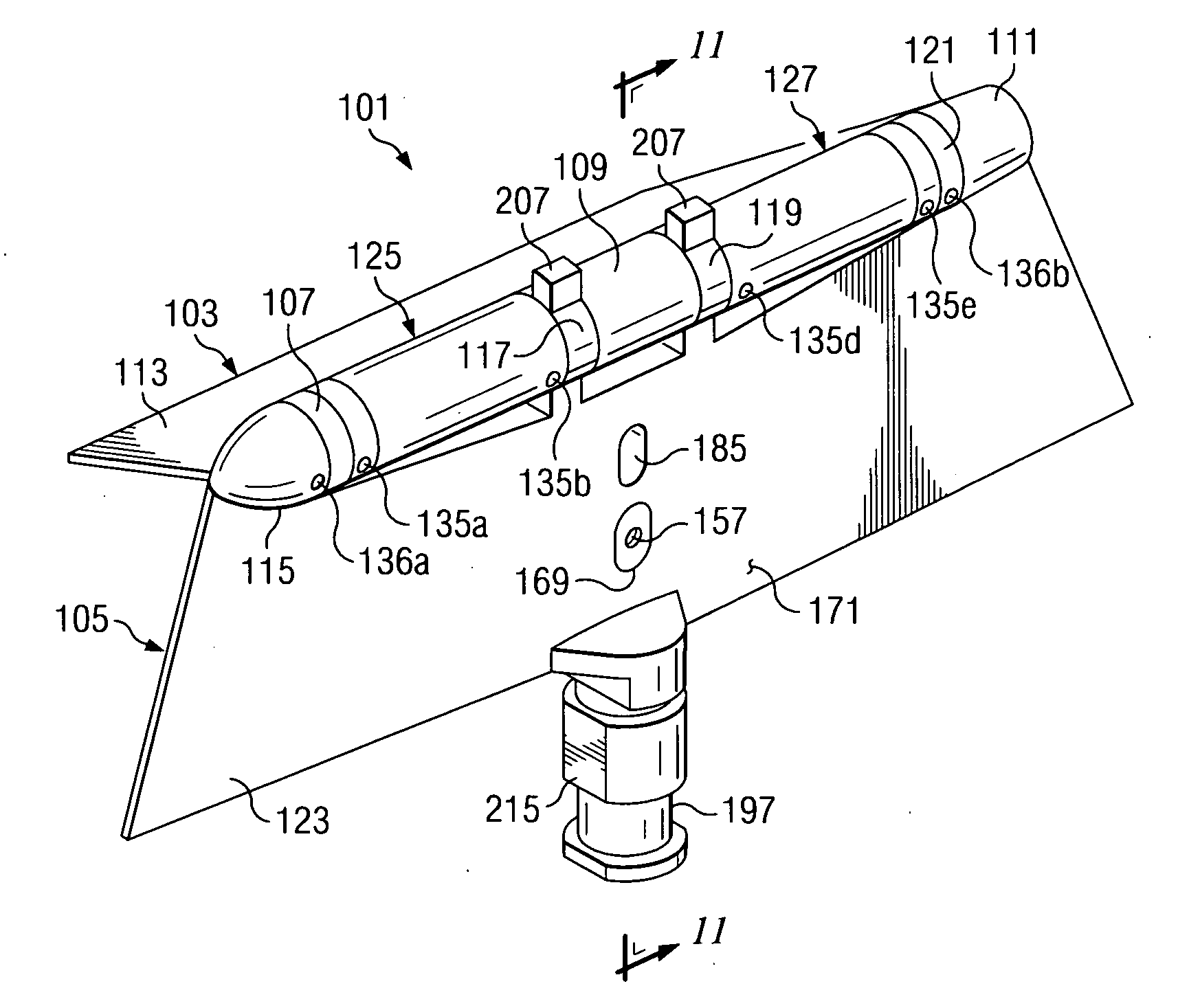

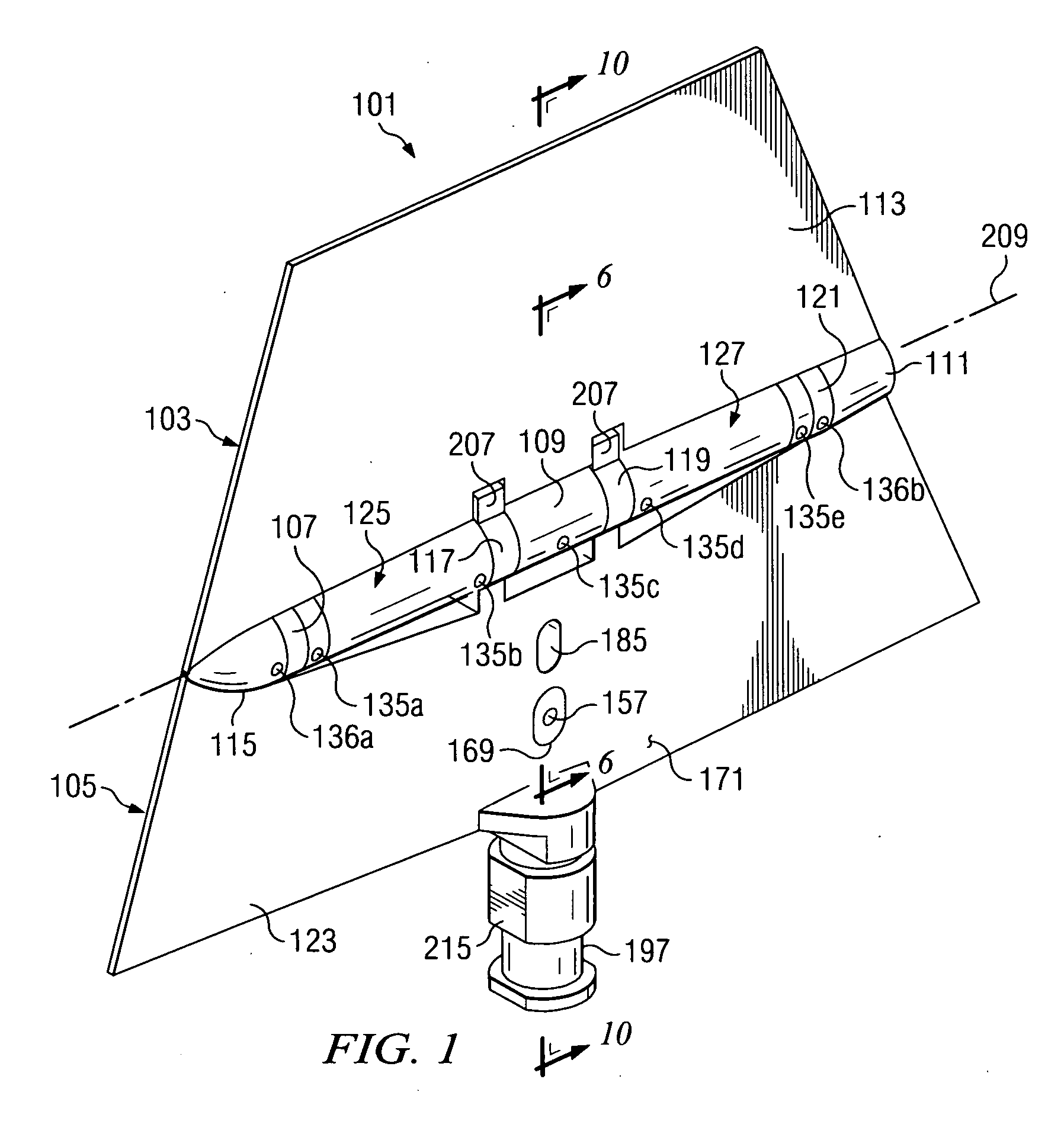

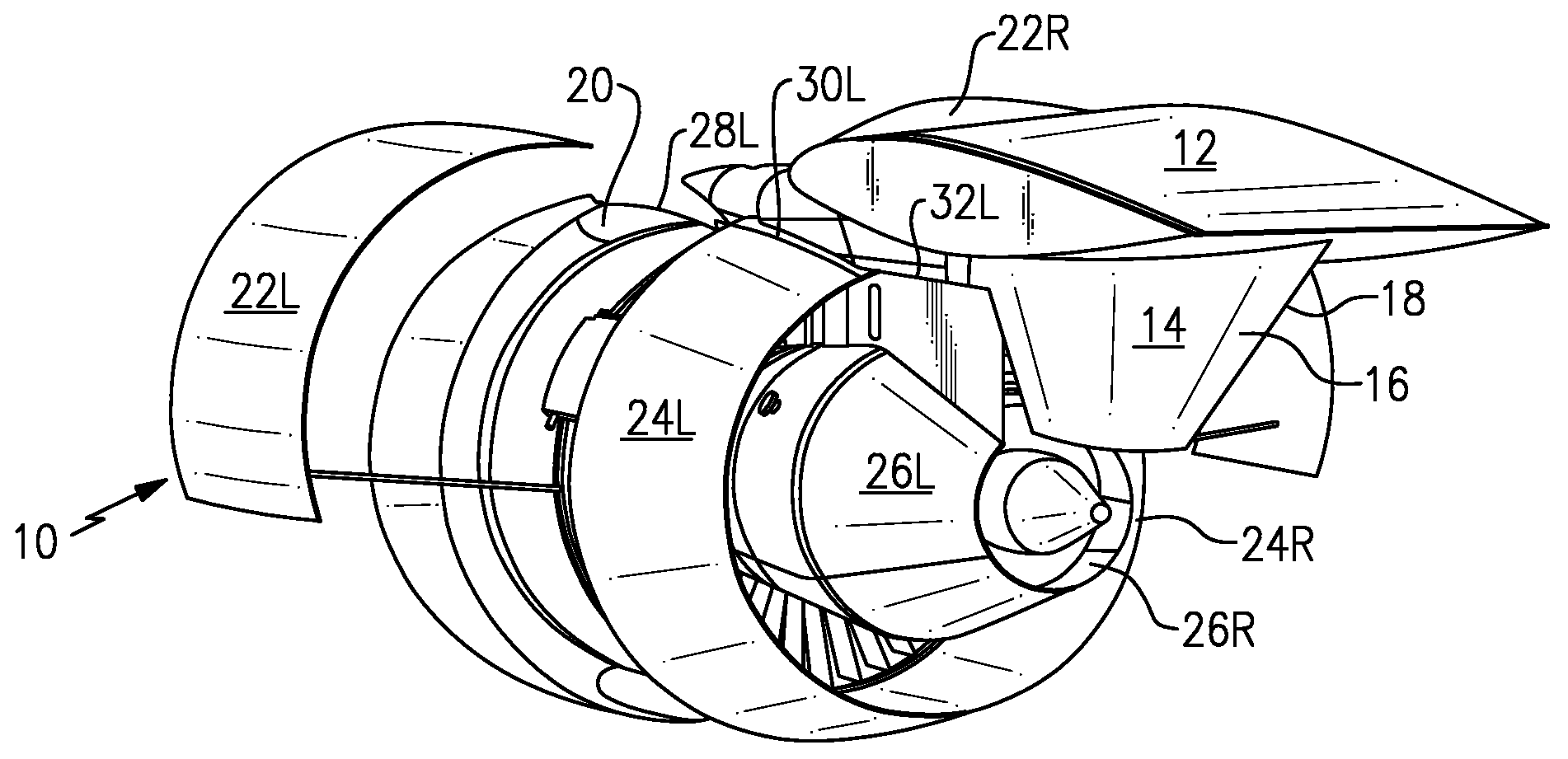

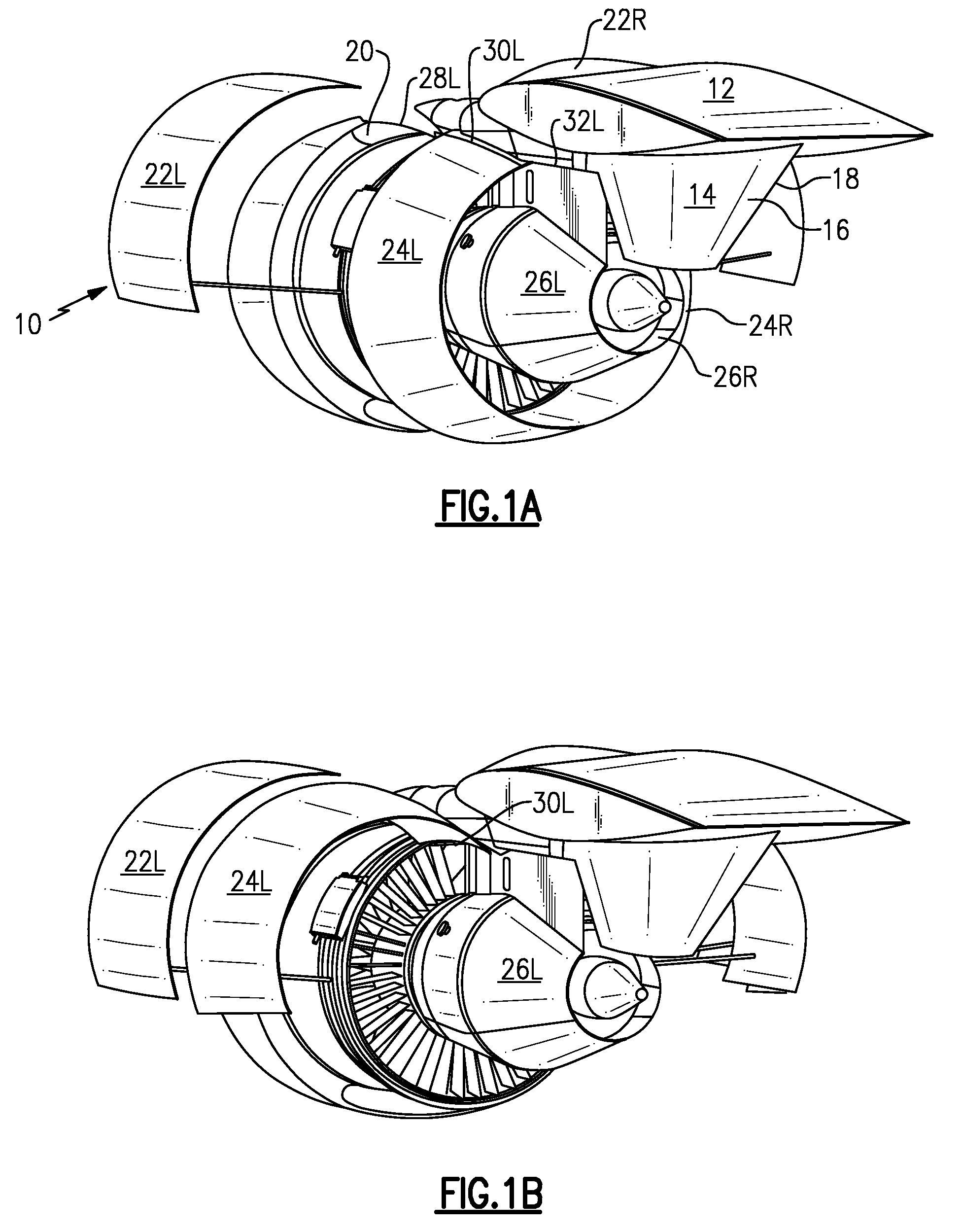

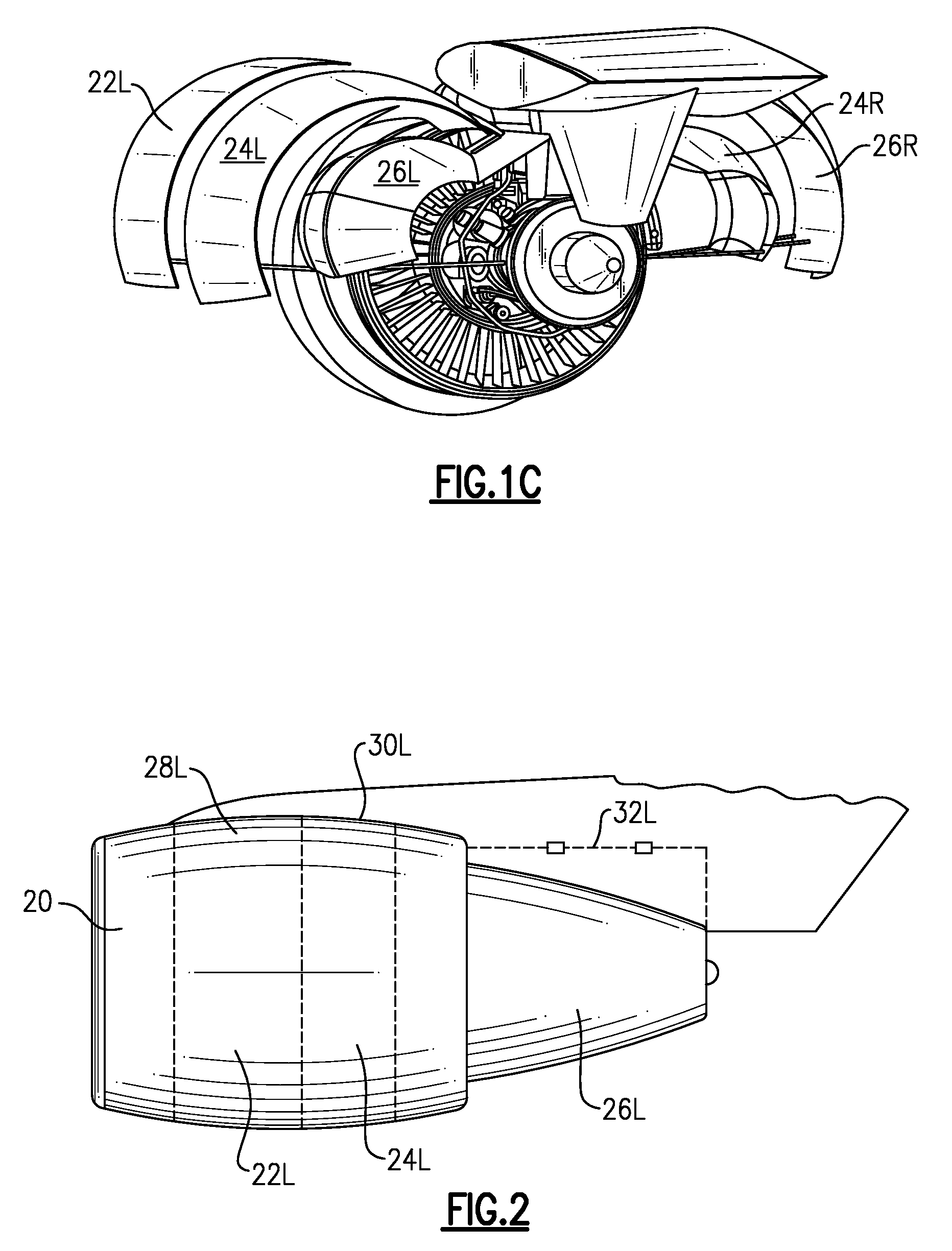

Fan variable area nozzle for a gas turbine engine fan nacelle with cam drive ring actuation system

A fan variable area nozzle (FVAN) includes a flap assembly which varies a fan nozzle exit area through a cam drive ring. The flap assembly generally includes a multiple of flaps, flap linkages and an actuator system. The actuator system rotationally translates the cam drive ring relative an engine centerline axis which results in a follower of the flap linkage following a cam surface to pivot each flap such that the flap assembly dilates about the circumferential hinge line. Rotation of the cam drive ring adjusts dilation of the entire fan nozzle exit area in a symmetrical manner. Another cam drive ring includes a multiple of movable cams which engages the follower of the flap linkage of each flap such that pivotable movement of a particular number of the multiple of movable cams about a respective cam pivot results in vectoring of the FVAN.

Owner:RTX CORP

Fan Variable Area Nozzle for a Gas Turbine engine Fan Nacelle with Cam Drive Ring Actuation System

A fan variable area nozzle (FVAN) includes a flap assembly which varies a fan nozzle exit area through a cam drive ring. The flap assembly generally includes a multiple of flaps, flap linkages and an actuator system. The actuator system rotationally translates the cam drive ring relative an engine centerline axis which results in a follower of the flap linkage following a cam surface to pivot each flap such that the flap assembly dilates about the circumferential hinge line. Rotation of the cam drive ring adjusts dilation of the entire fan nozzle exit area in a symmetrical manner. Another cam drive ring includes a multiple of movable cams which engages the follower of the flap linkage of each flap such that pivotable movement of a particular number of the multiple of movable cams about a respective cam pivot results in vectoring of the FVAN.

Owner:RTX CORP

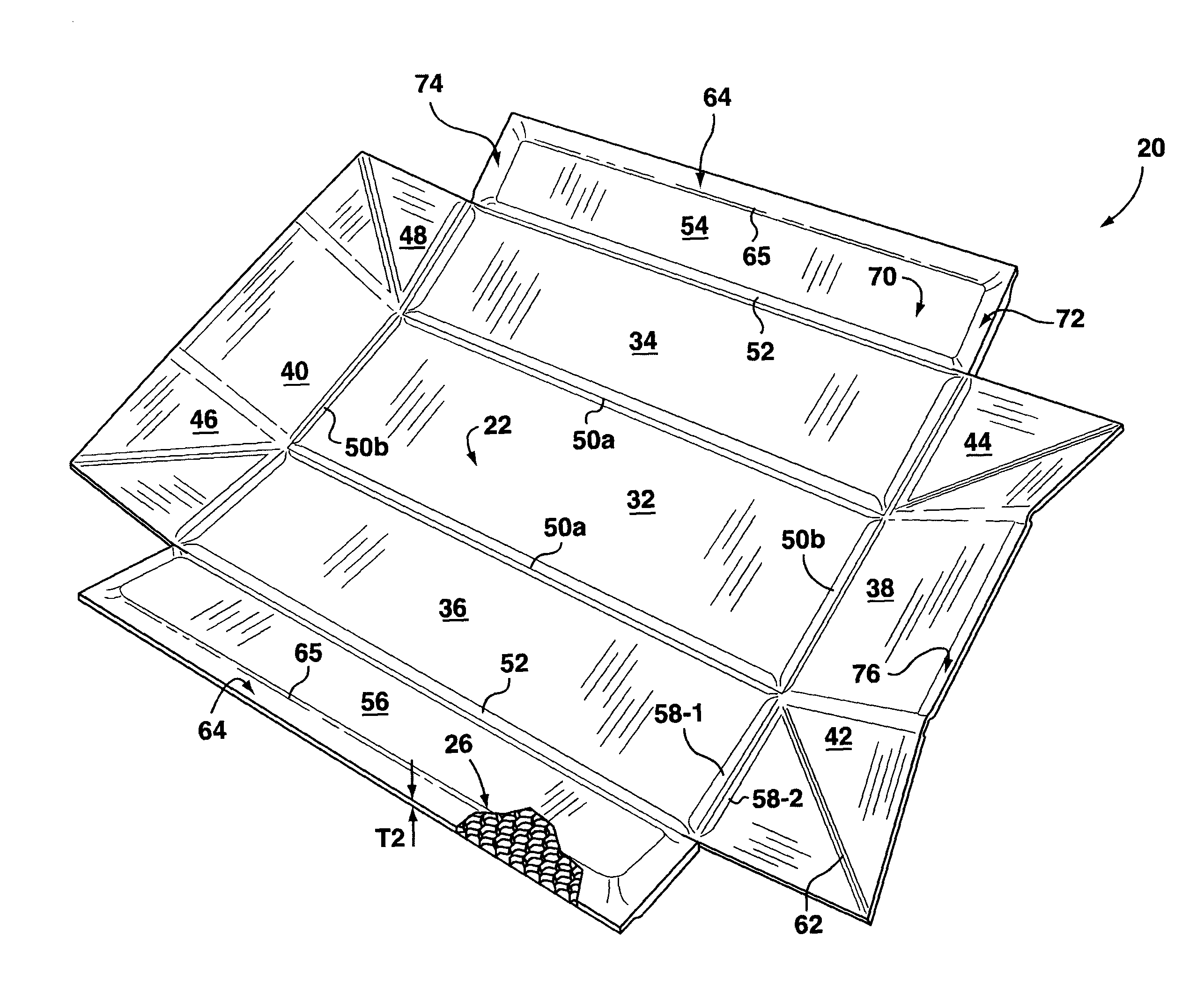

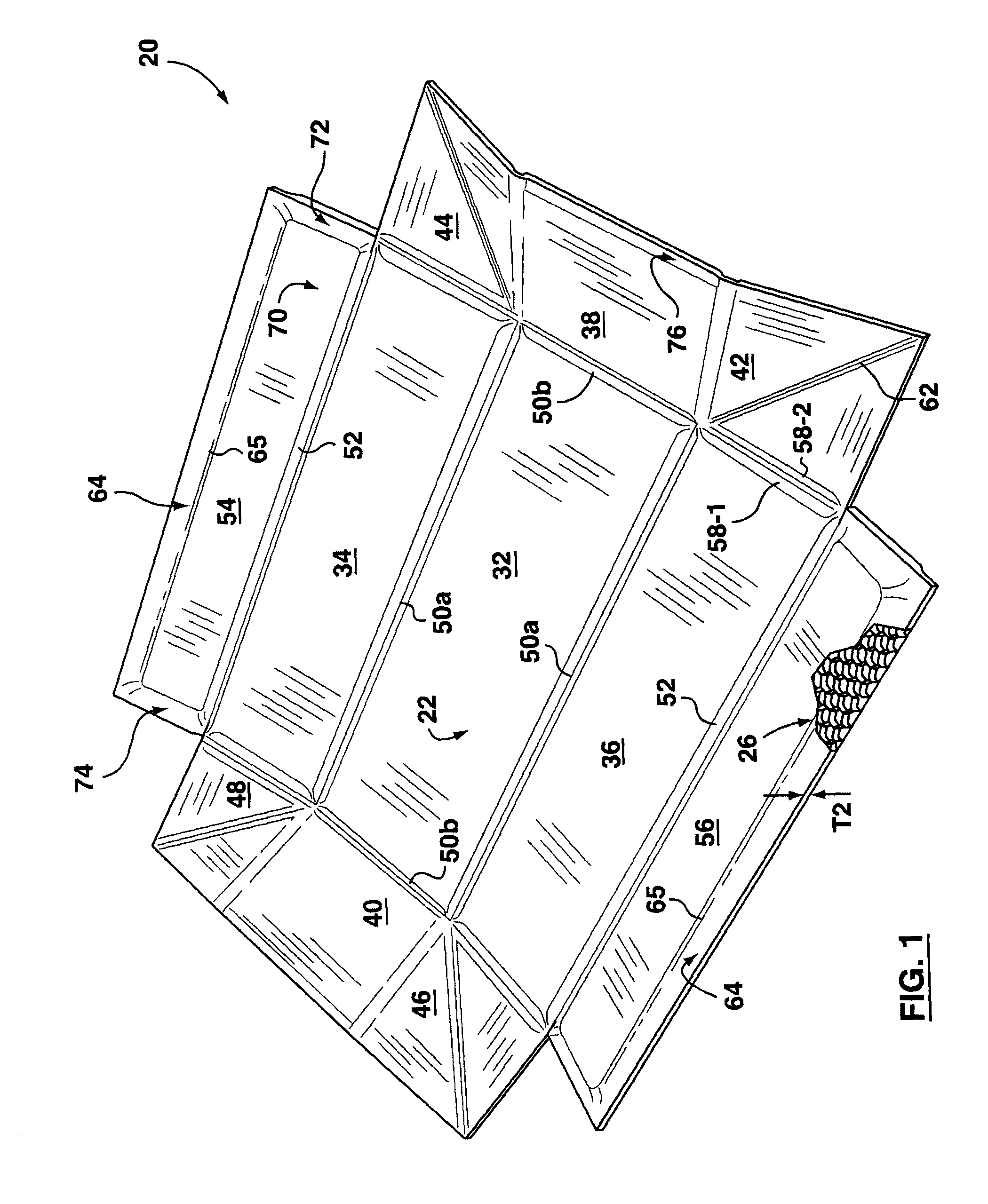

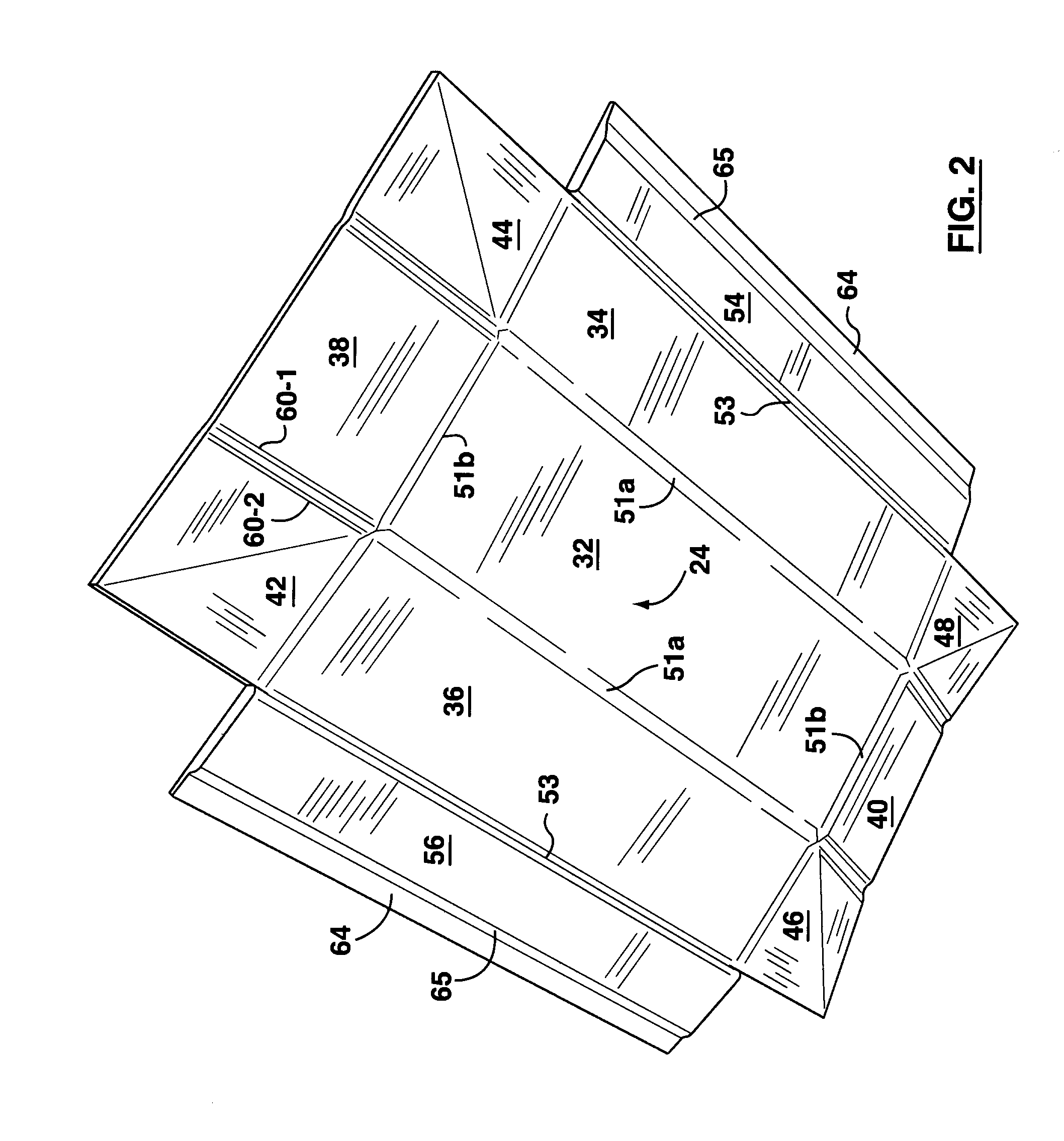

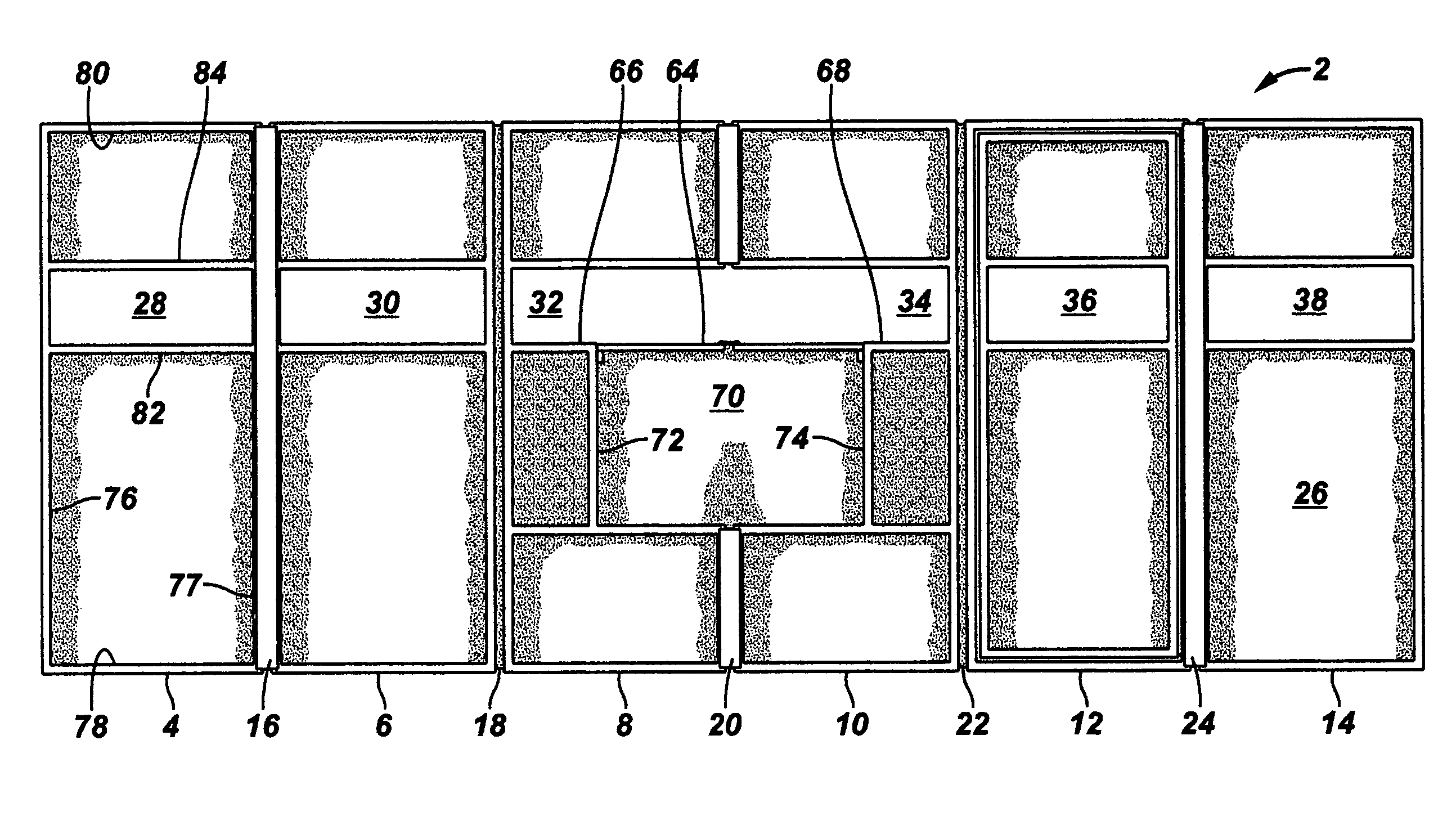

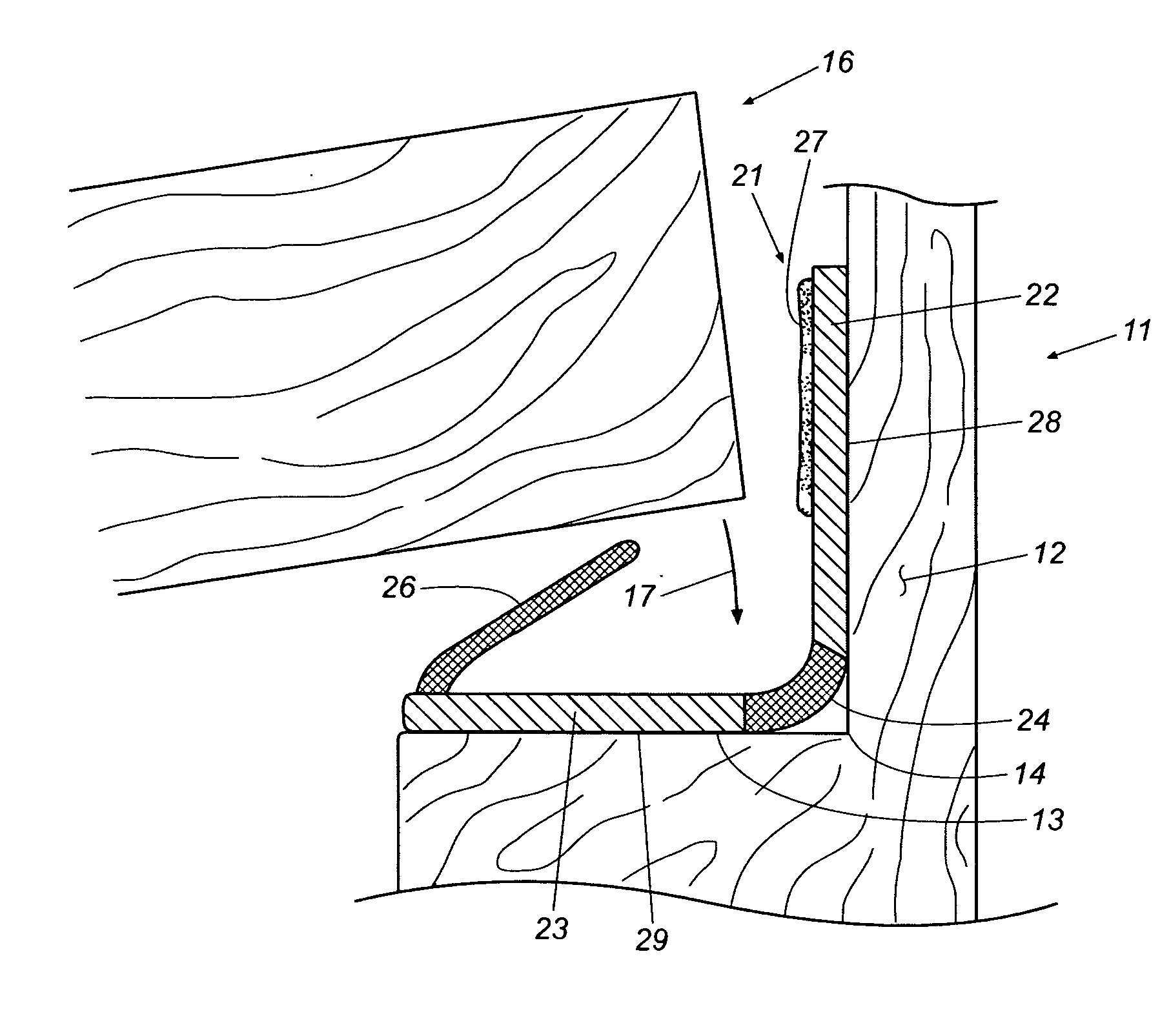

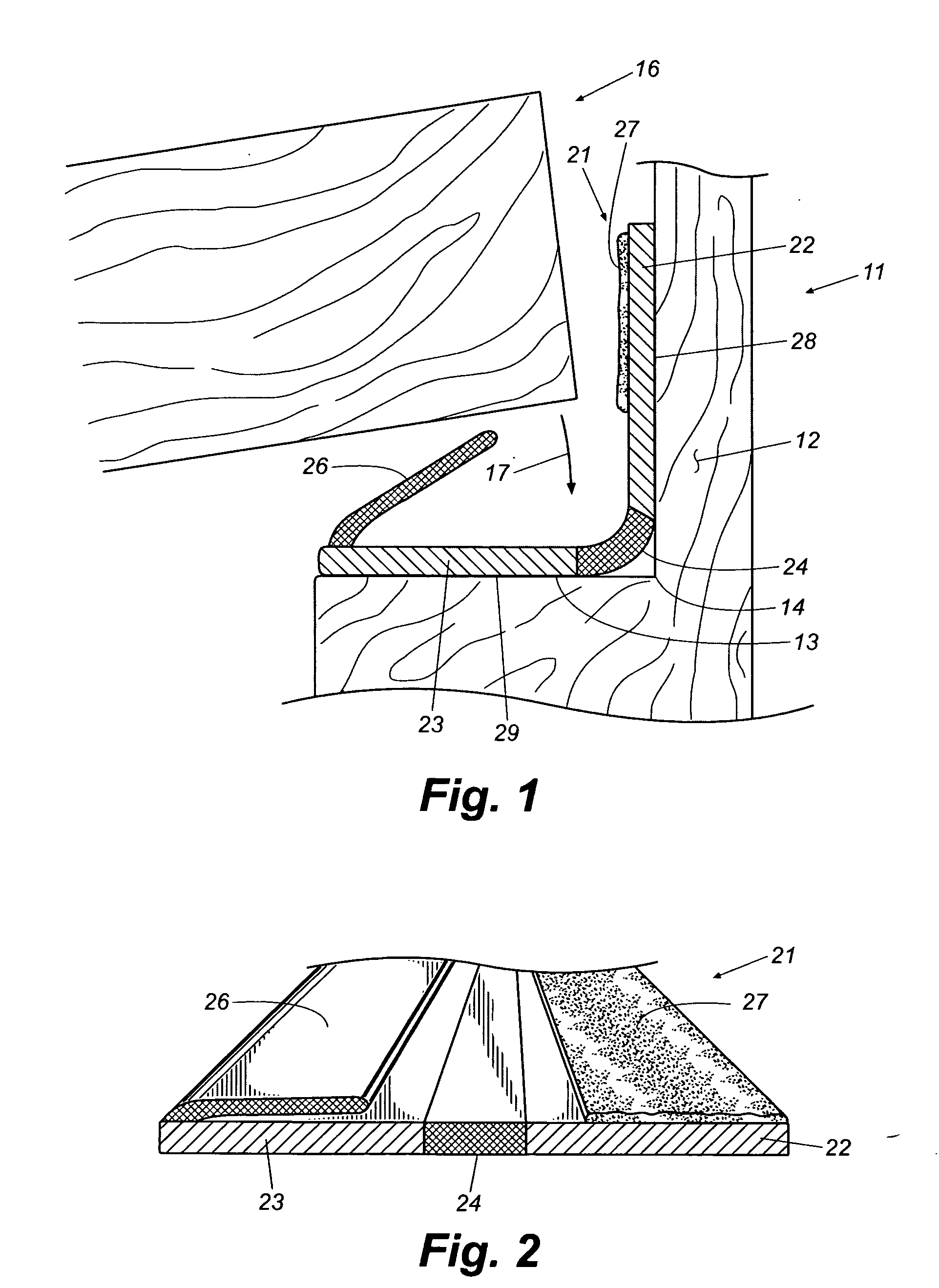

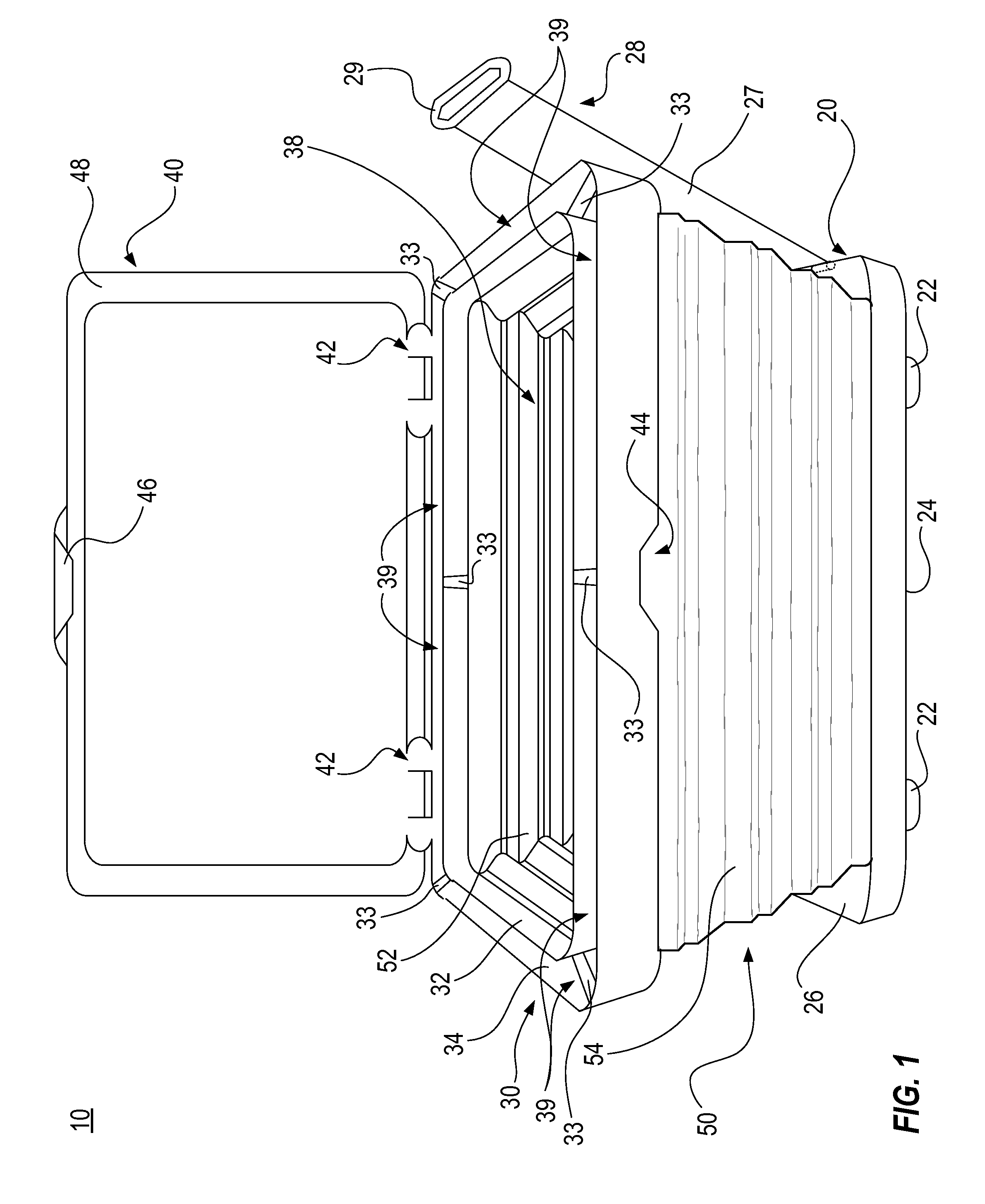

Thermal Container, Liner Therefor, and Liner Forming Dies

A thermal insulating liner for a container has a bottom panel, a pair of opposed end panels, a first side panel and an opposed second side panel. A first flap is hinged to the first side panel at a first hinge line and a second flap is hinged to the said second side panel at a second hinge line. The first flap and second flap are sized so that they are moveable between an open position whereat the first flap is spaced from said second flap and a folded position whereat a side margin of the first flap which extends along a side edge of the first flap opposite the first hinge line overlaps with a side margin of the second flap which extends along a side edge of the second flap opposite the second hinge line. Each flap comprises an outer sheet and an inner sheet spaced by a core with an innermost layer of the inner sheet comprising a metal foil layer. Each flap has a first thickness outside its side margin and a second, reduced, thickness, within its side margin. A thermal container may contain such a thermal insulating liner. A pair of dies can form a liner for a thermal container. A bottom a bottom die half has a bottom die pair of raised rectangular blocks and a top die half has a top die pair of raised rectangular blocks sized and positioned so as to register with the bottom die pair of rectangular blocks when the dies are brought together in use. The bottom die half has two spaced creasing rules between the bottom die pair of raised rectangular blocks and the top die half has two spaced creasing rules between the top die pair of raised rectangular blocks. The top spaced creasing rules are positioned so as to register with the bottom die spaced creasing rules when the dies are brought together in use.

Owner:FRESH BAILIWICK

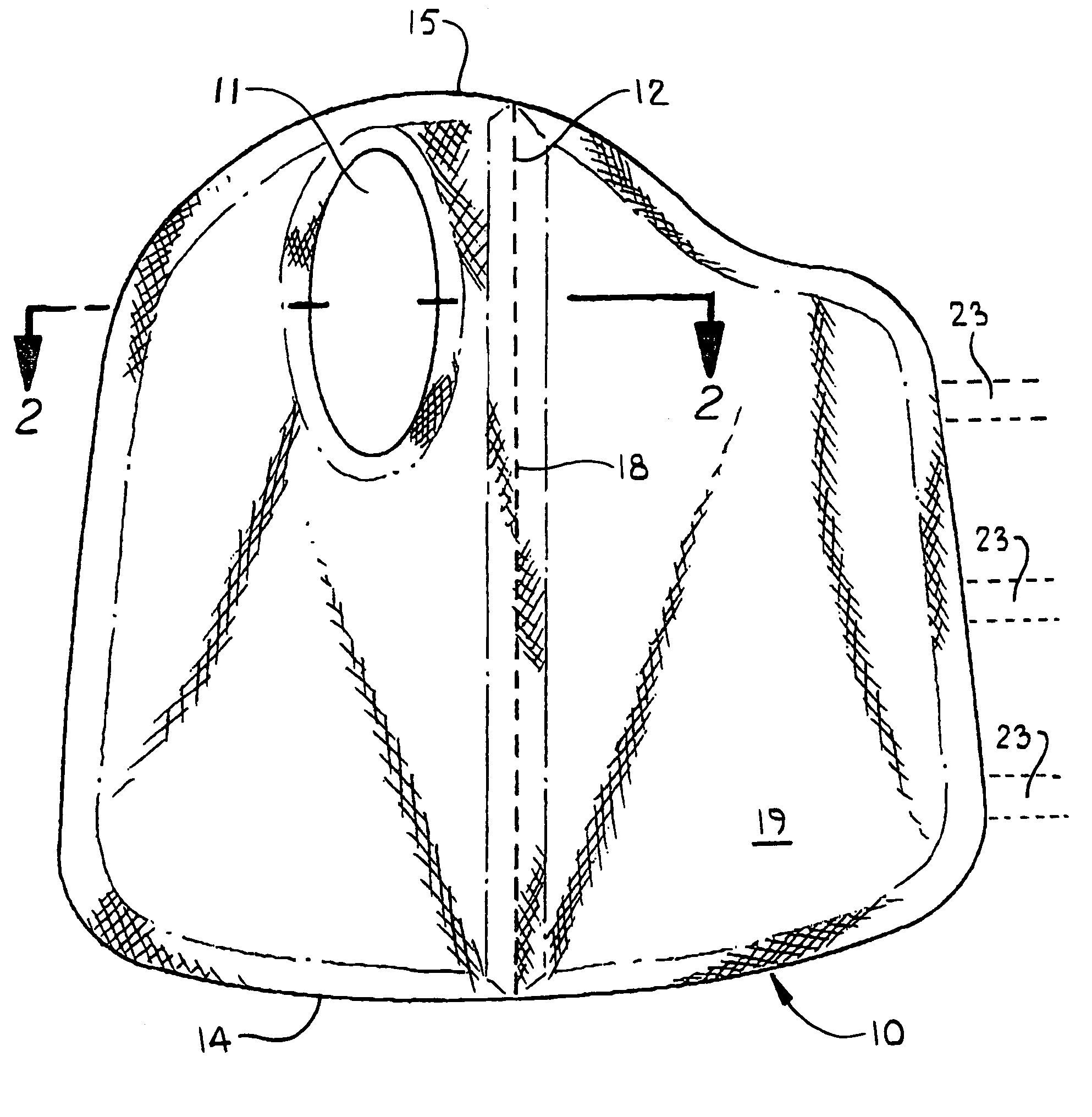

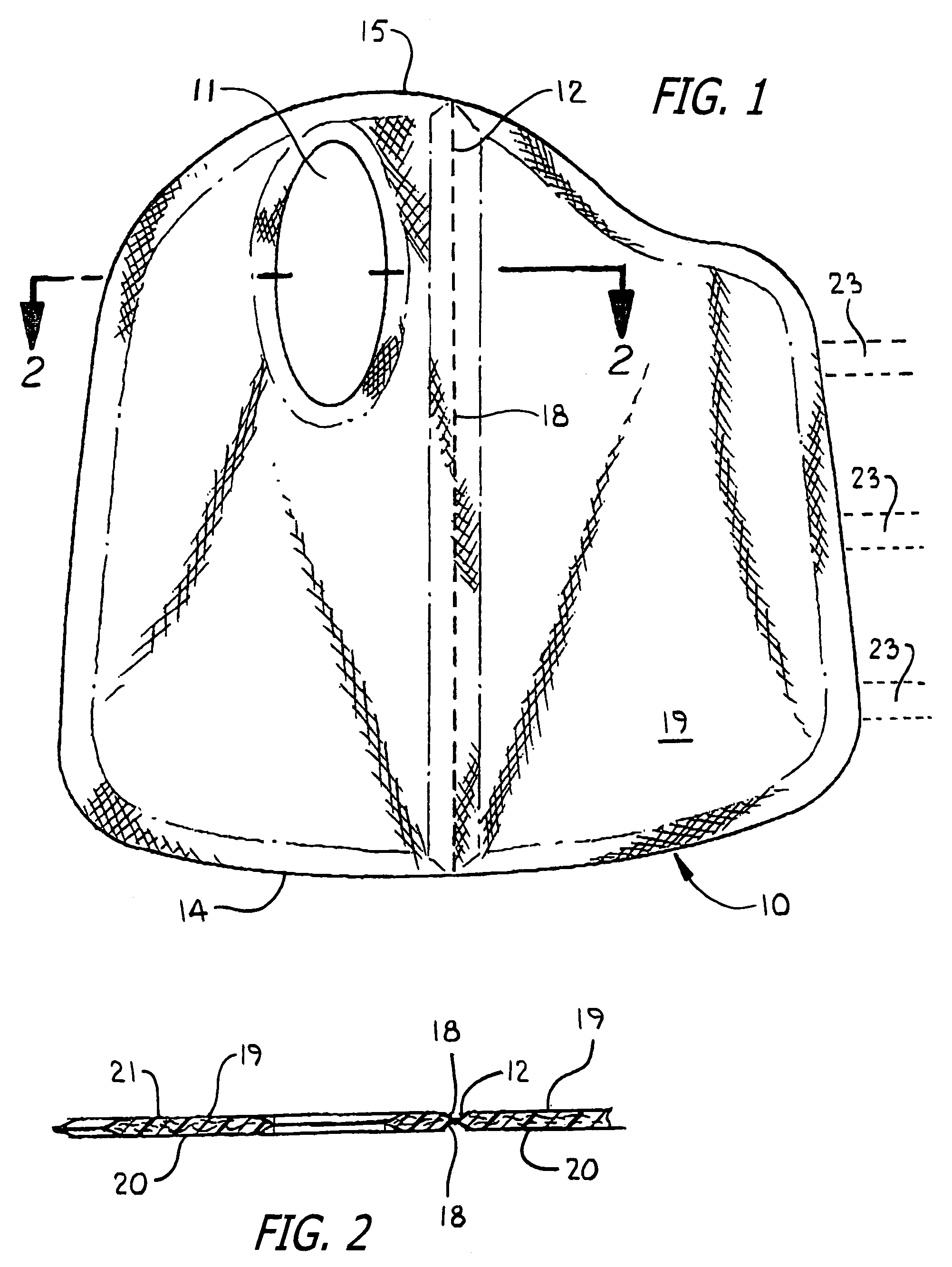

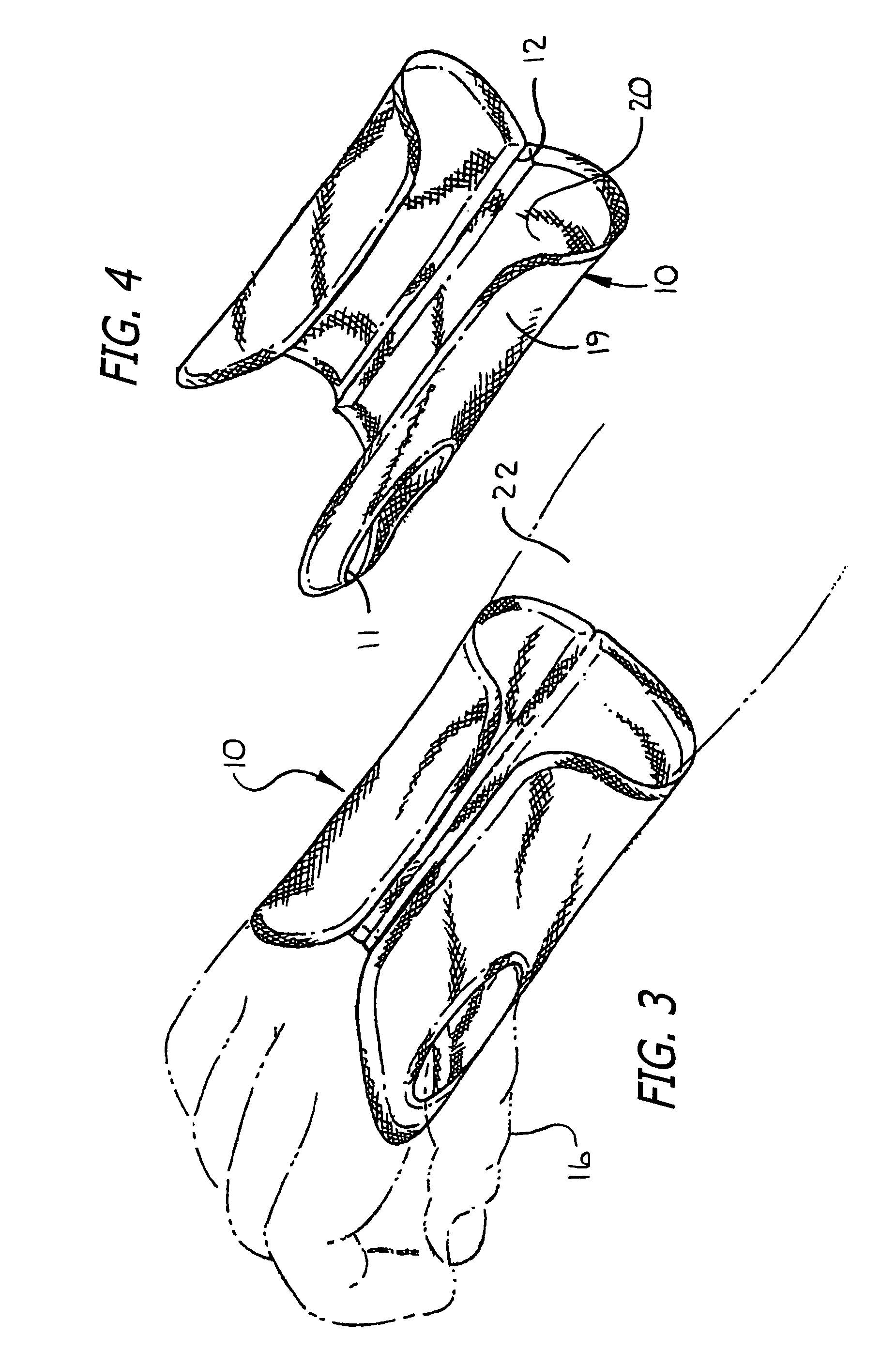

Versatile hardenable cast or support

InactiveUS7465281B2Reduce structural strengthProvide strengthNon-surgical orthopedic devicesHinge lineMaterials science

A cast or support for use in limiting movement of the anatomy to promote healing of an injured body part includes initially flexible and subsequently rigid double-knit material, or other casting blanks. There is a water-hardenable material impregnated into the casting blank. Certain areas of the blank have significantly reduced or no hardenable material. This construction may provide at least one hinge line which extends substantially across the double-knit material or other casting blank where the upper and lower layers are held in engagement with each other. The cast or support may be folded open along the hinge line to permit washing, inspection, or treatment of the portion of the anatomy to which the cast or support is applied or as one step in the preparation of a mold of a portion of the anatomy. More than one hinge line may be provided. Overlapping edges of the blank may also be of reduced thickness and with reduced hardening material to provide a smooth overlap to secure the cast or support in place.

Owner:KAUPTHING BANK

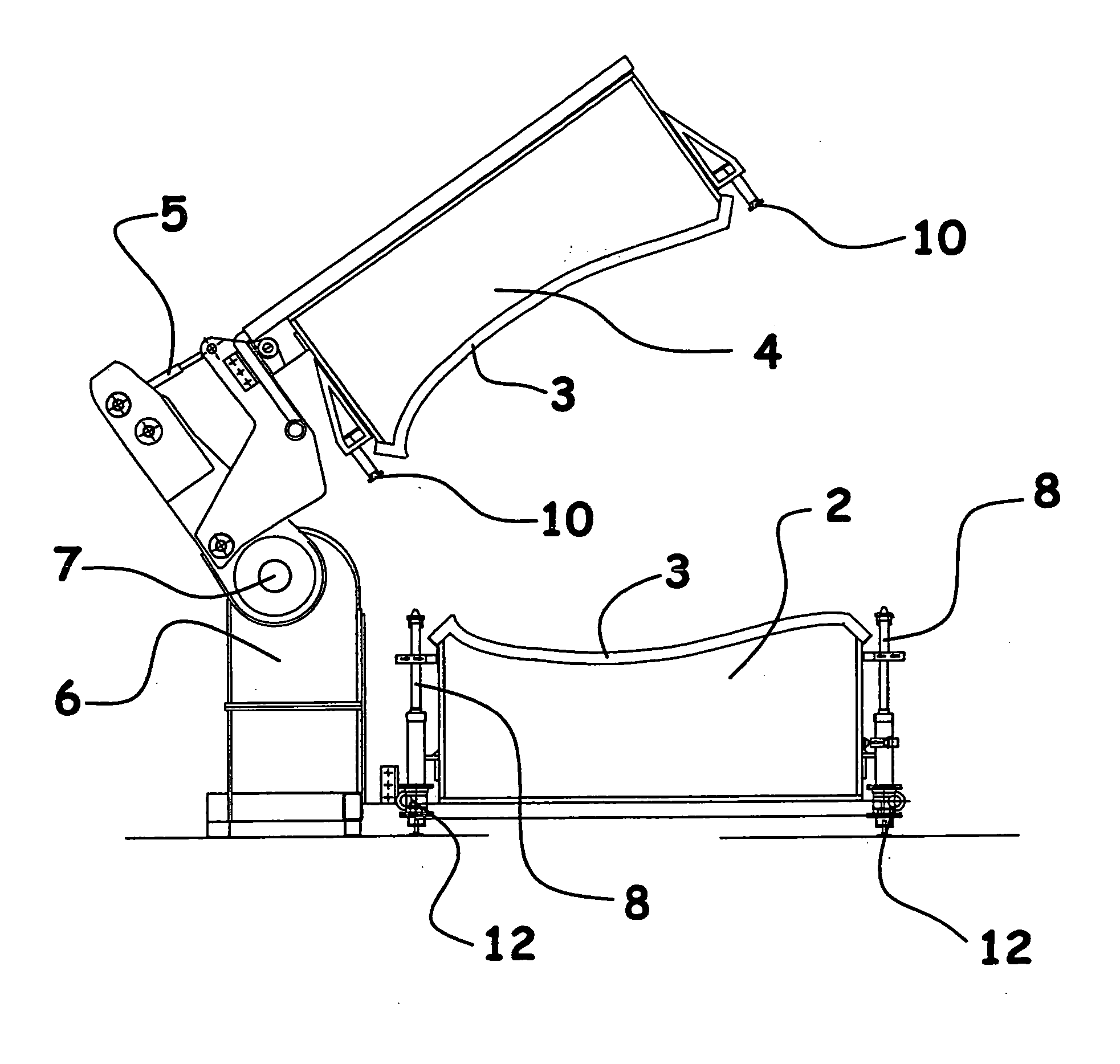

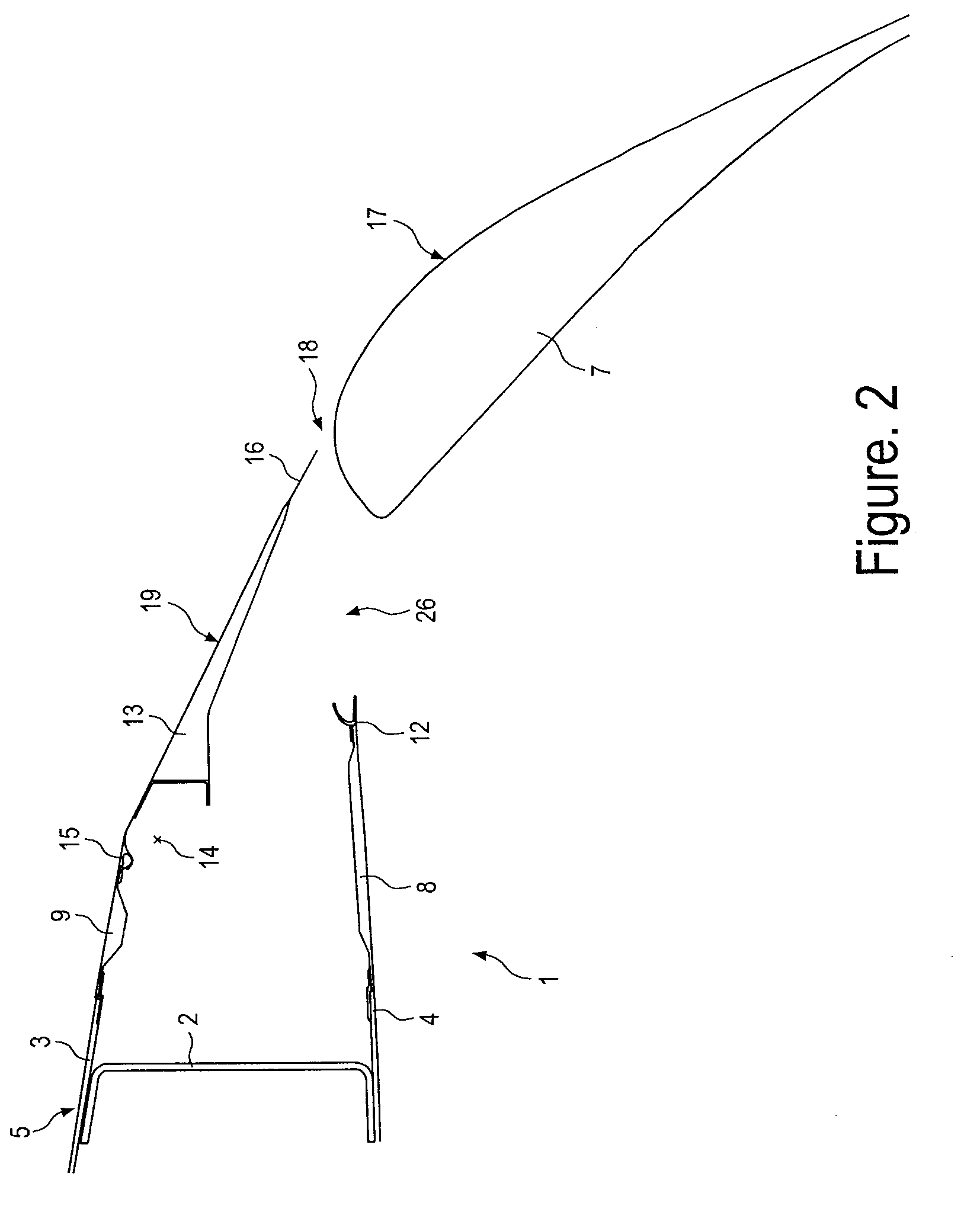

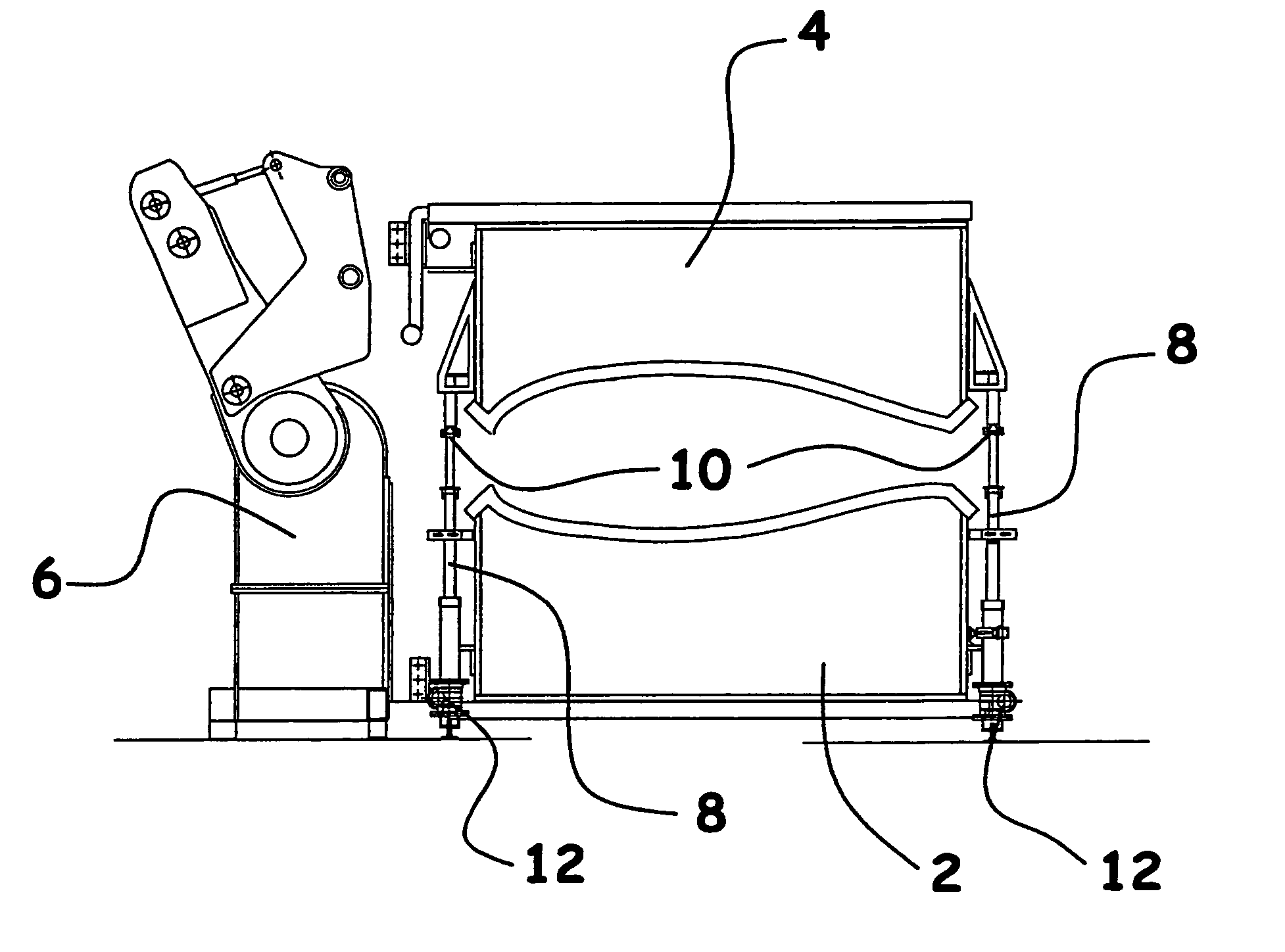

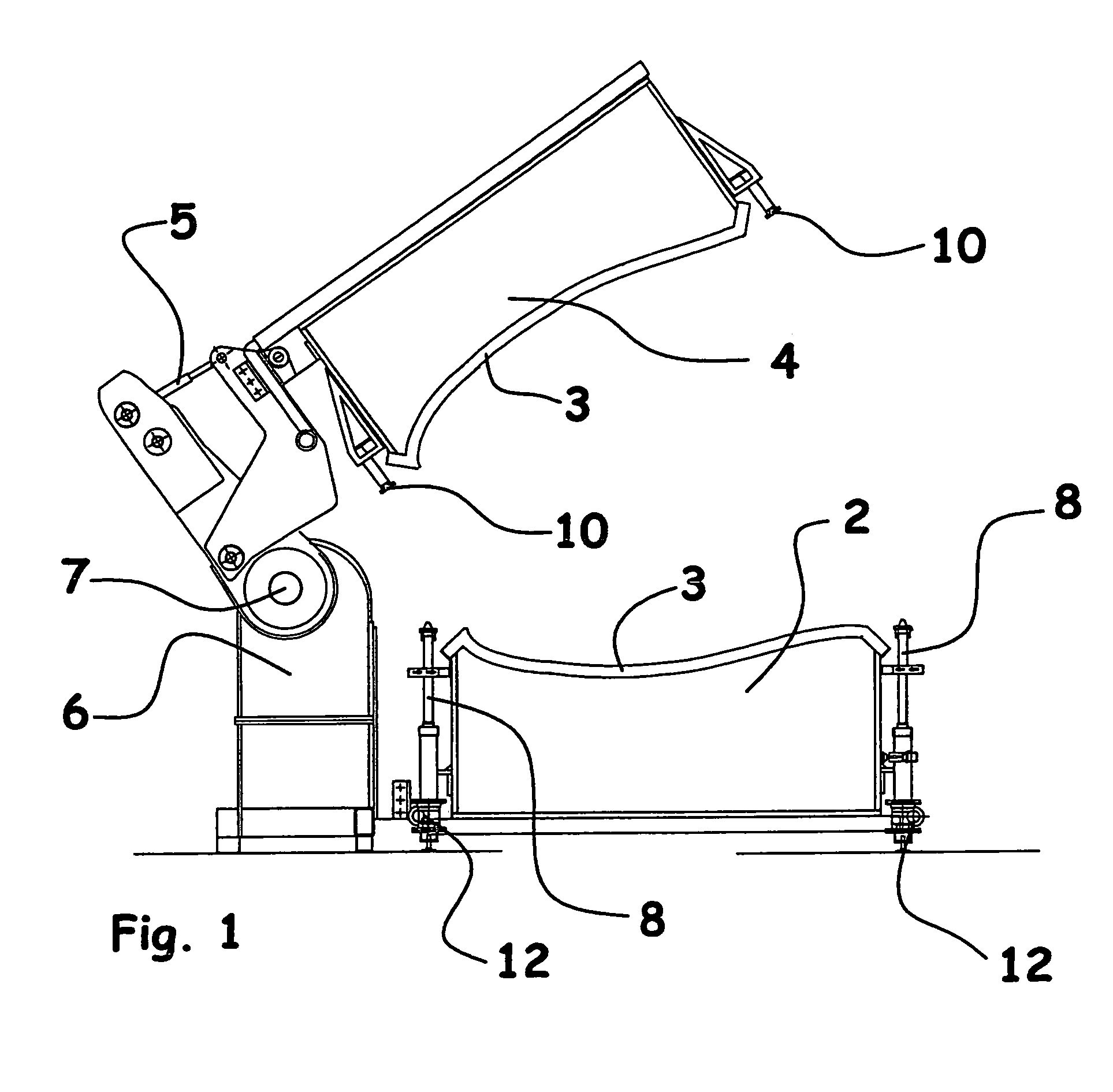

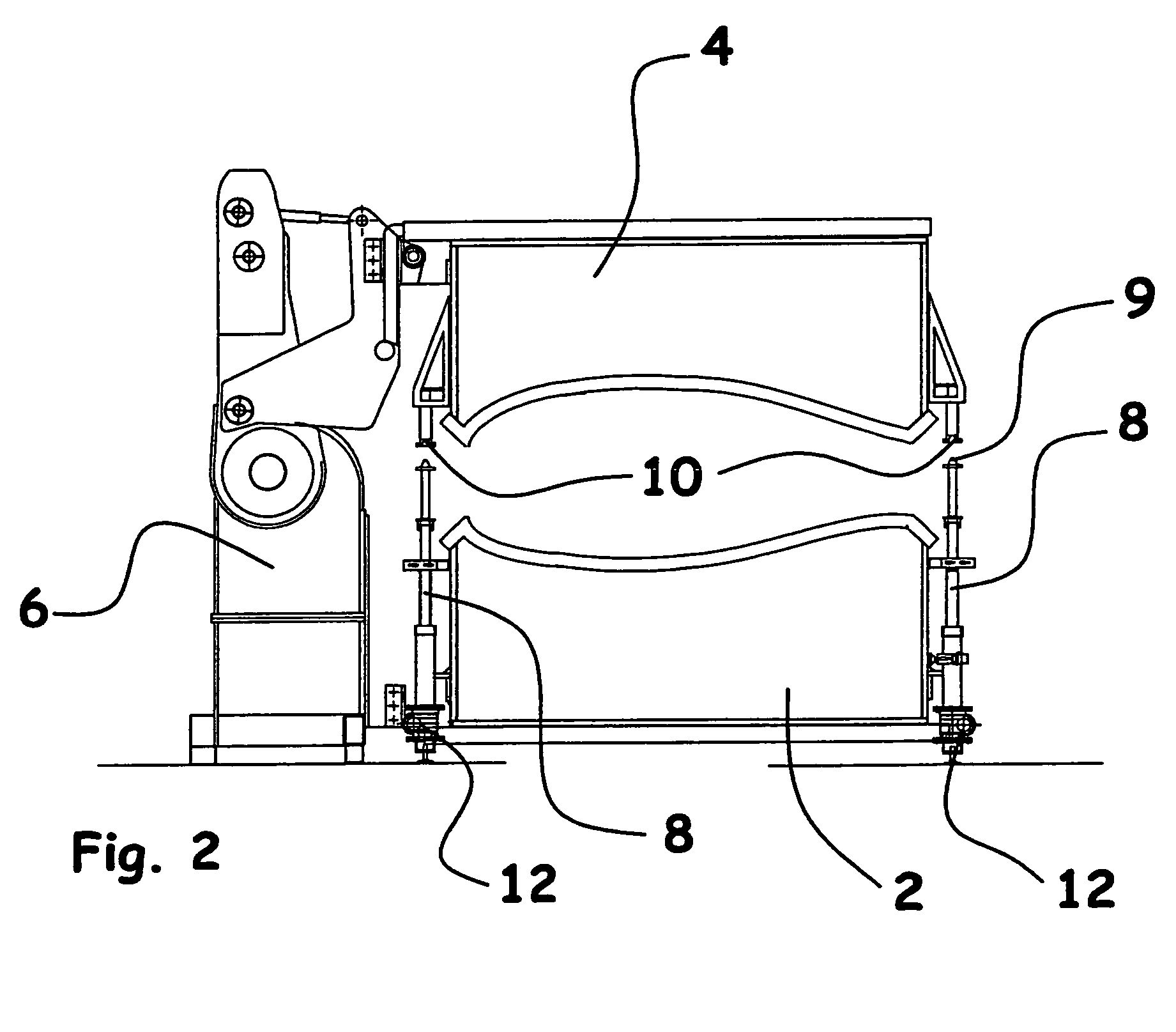

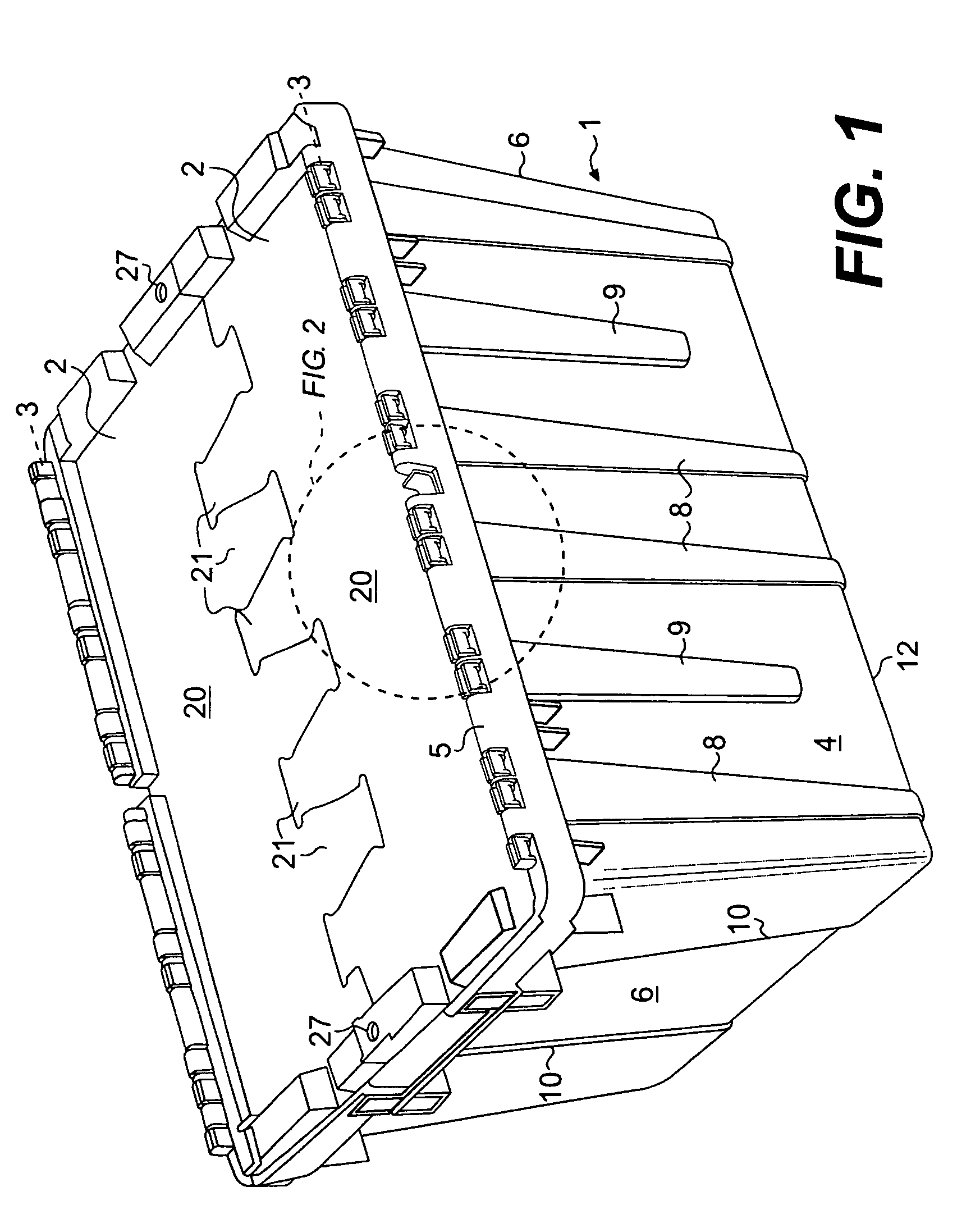

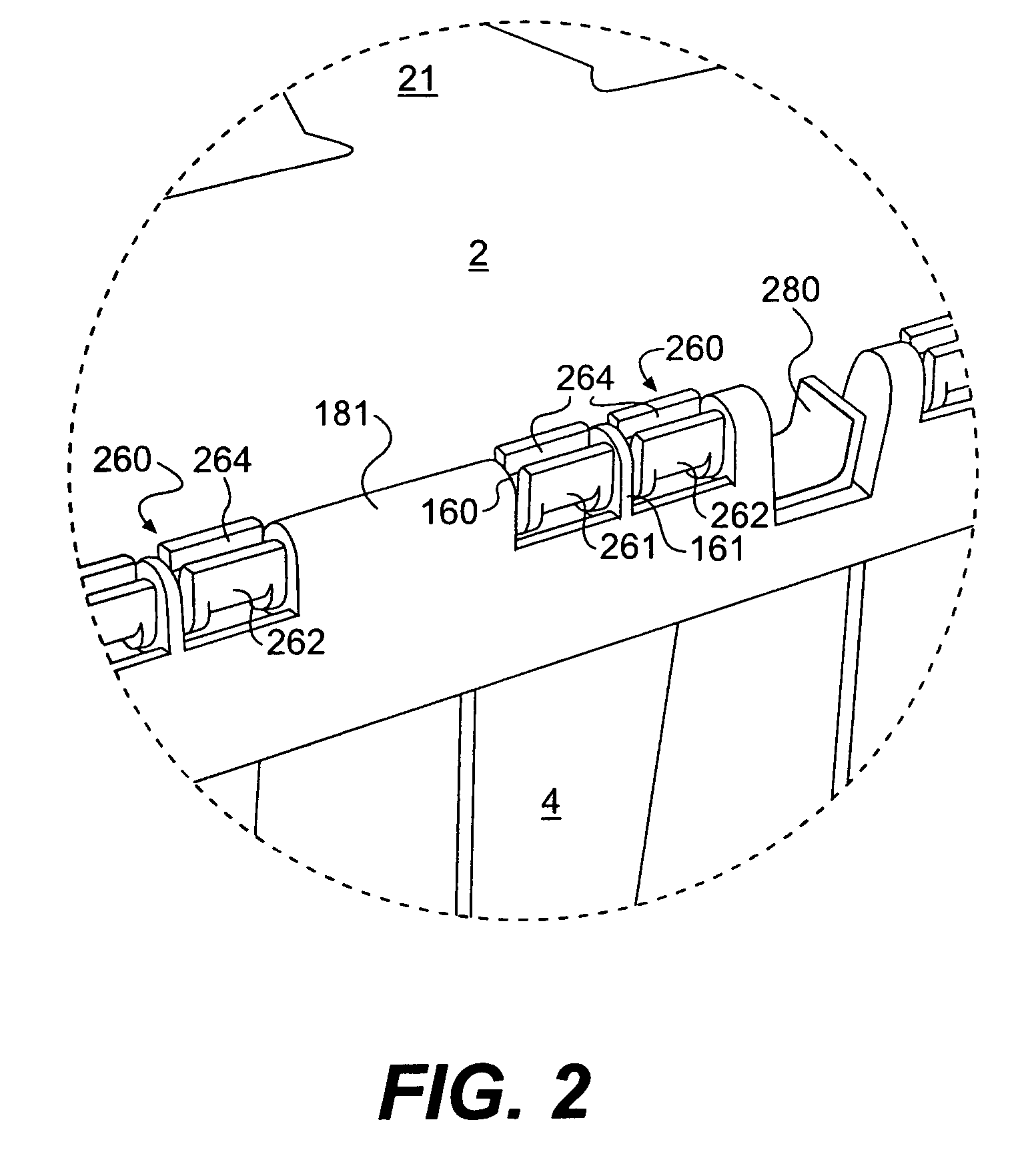

Mold assembly with closure mechanism

ActiveUS20060034971A1Simple and fast and accurate closure and openingSpeed up the processFinal product manufactureCeramic shaping apparatusFiberTurbine blade

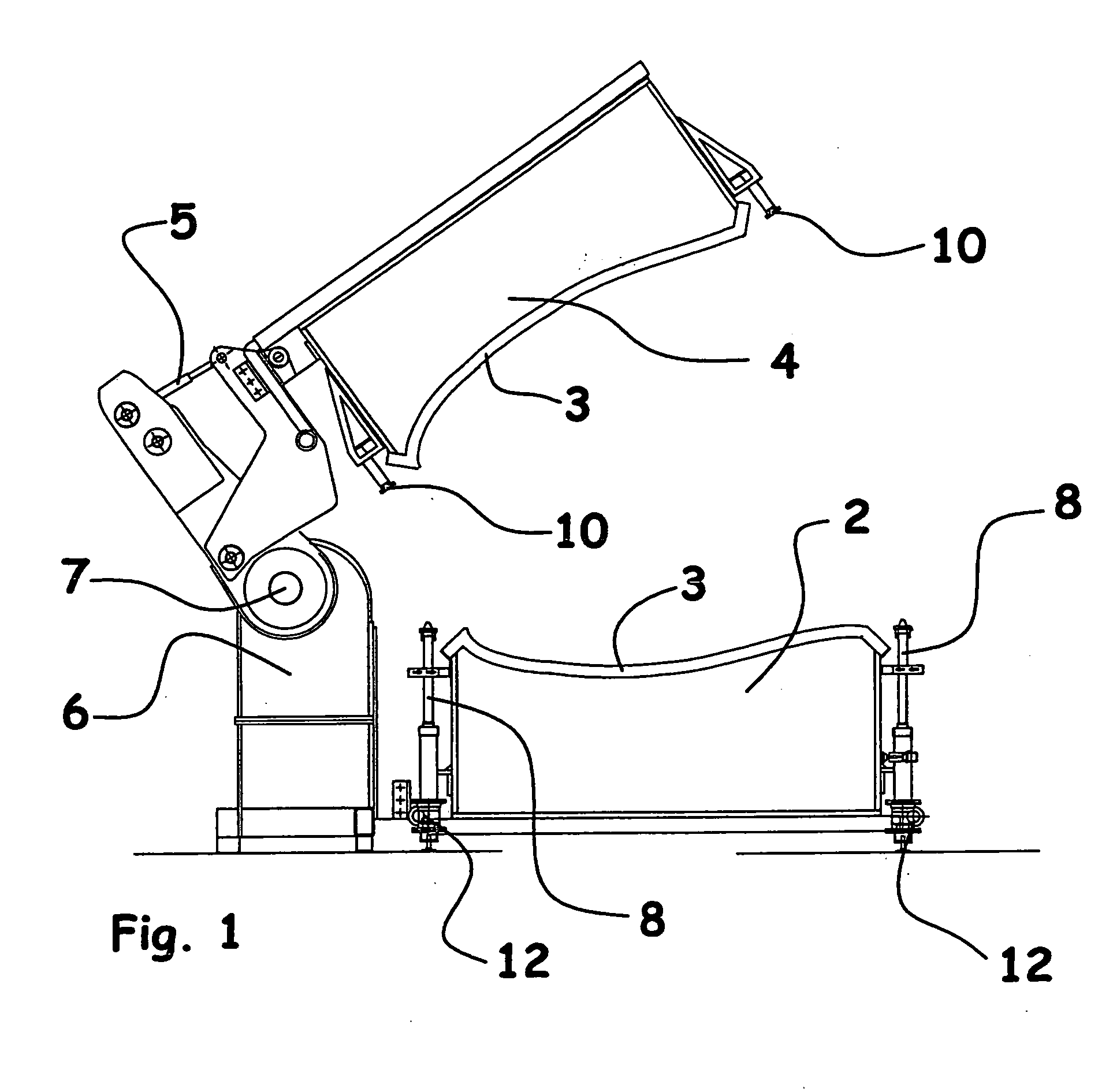

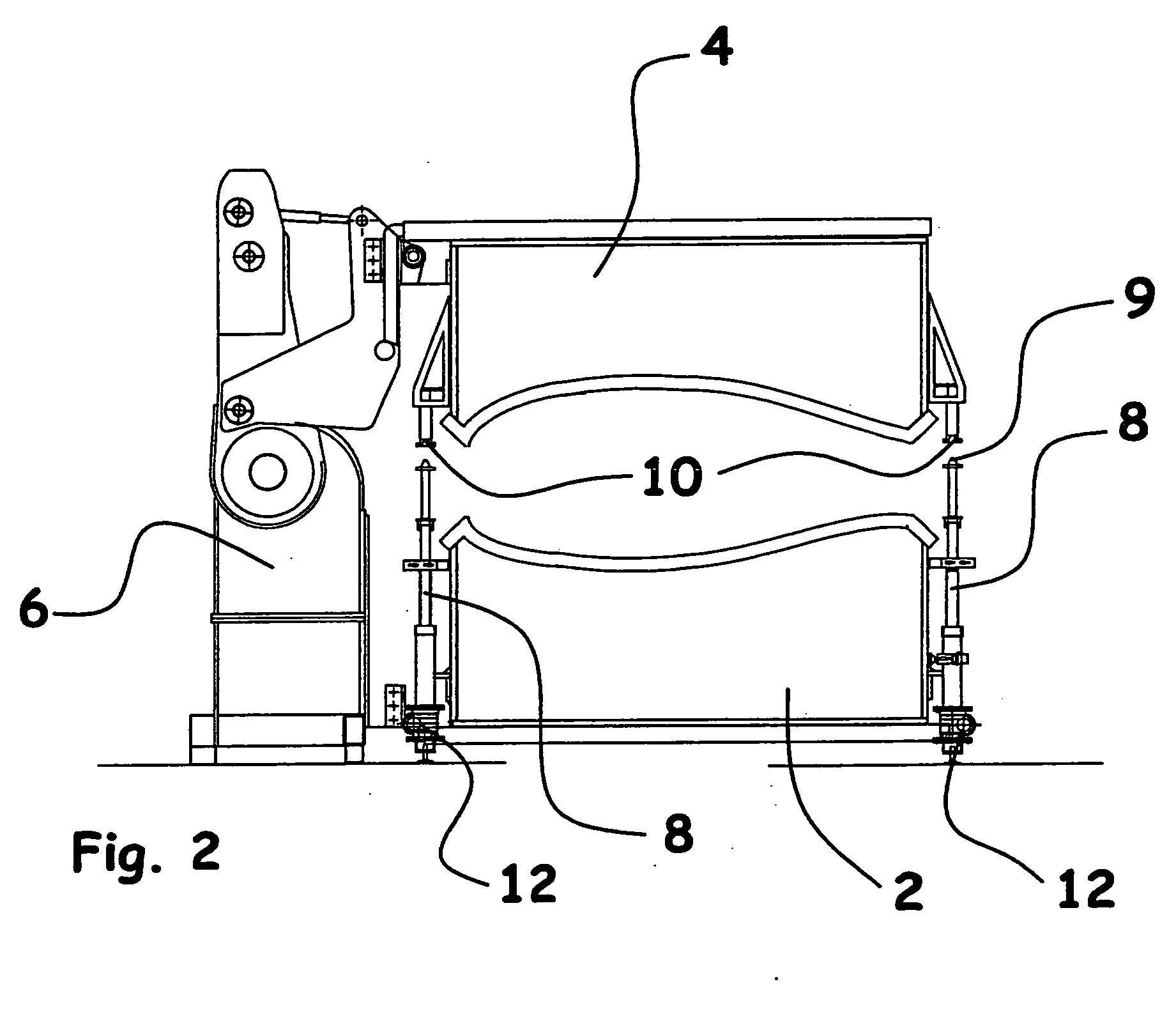

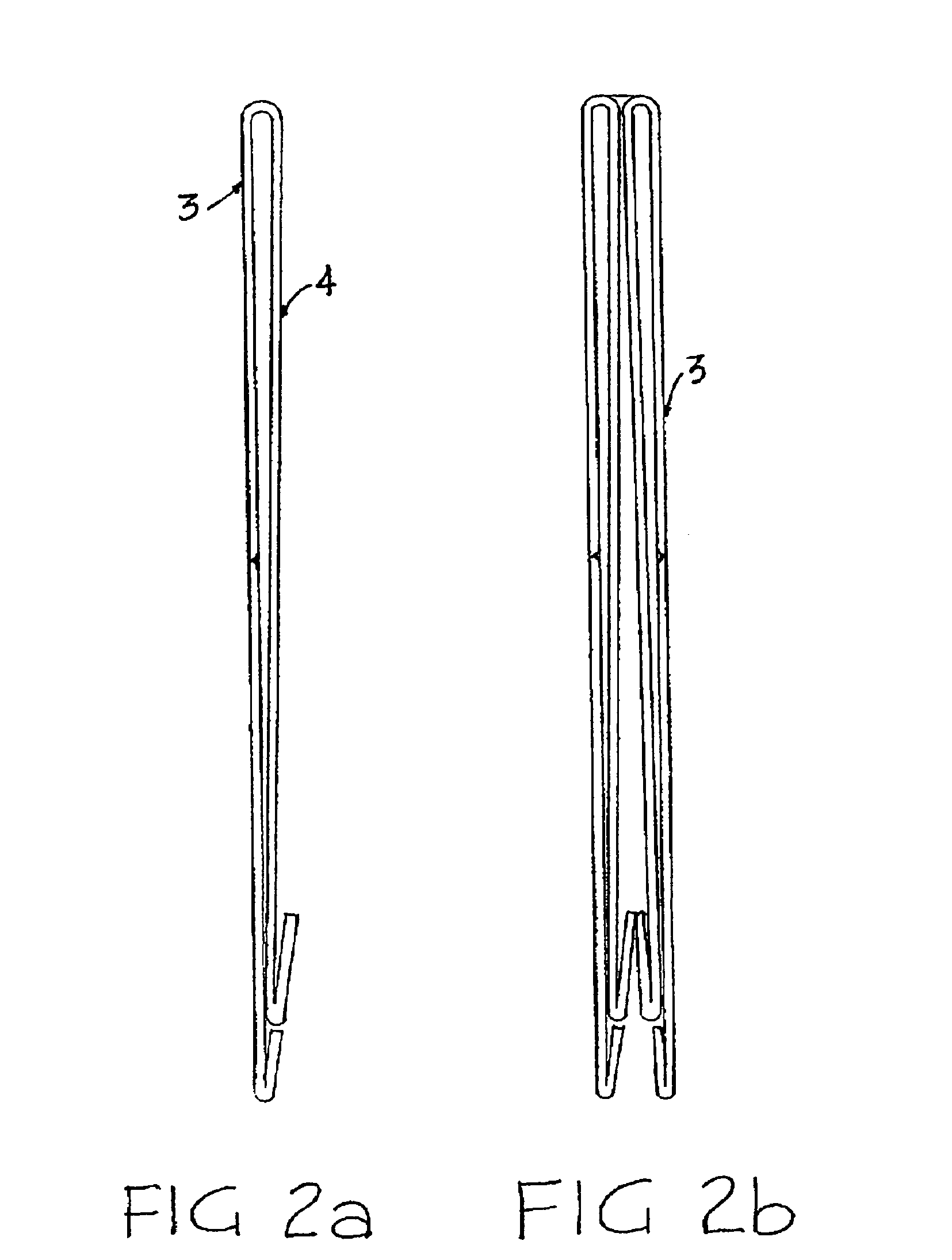

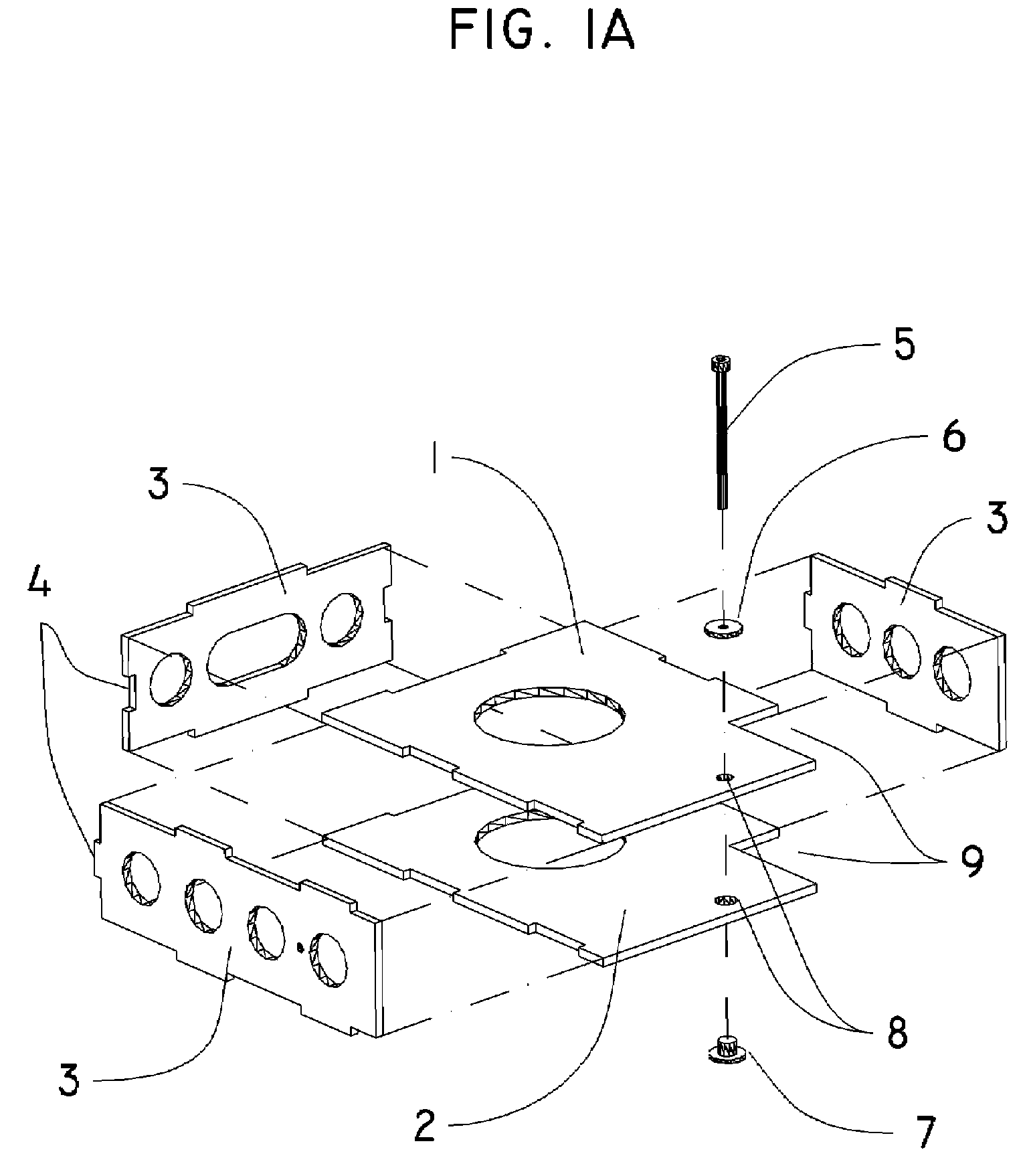

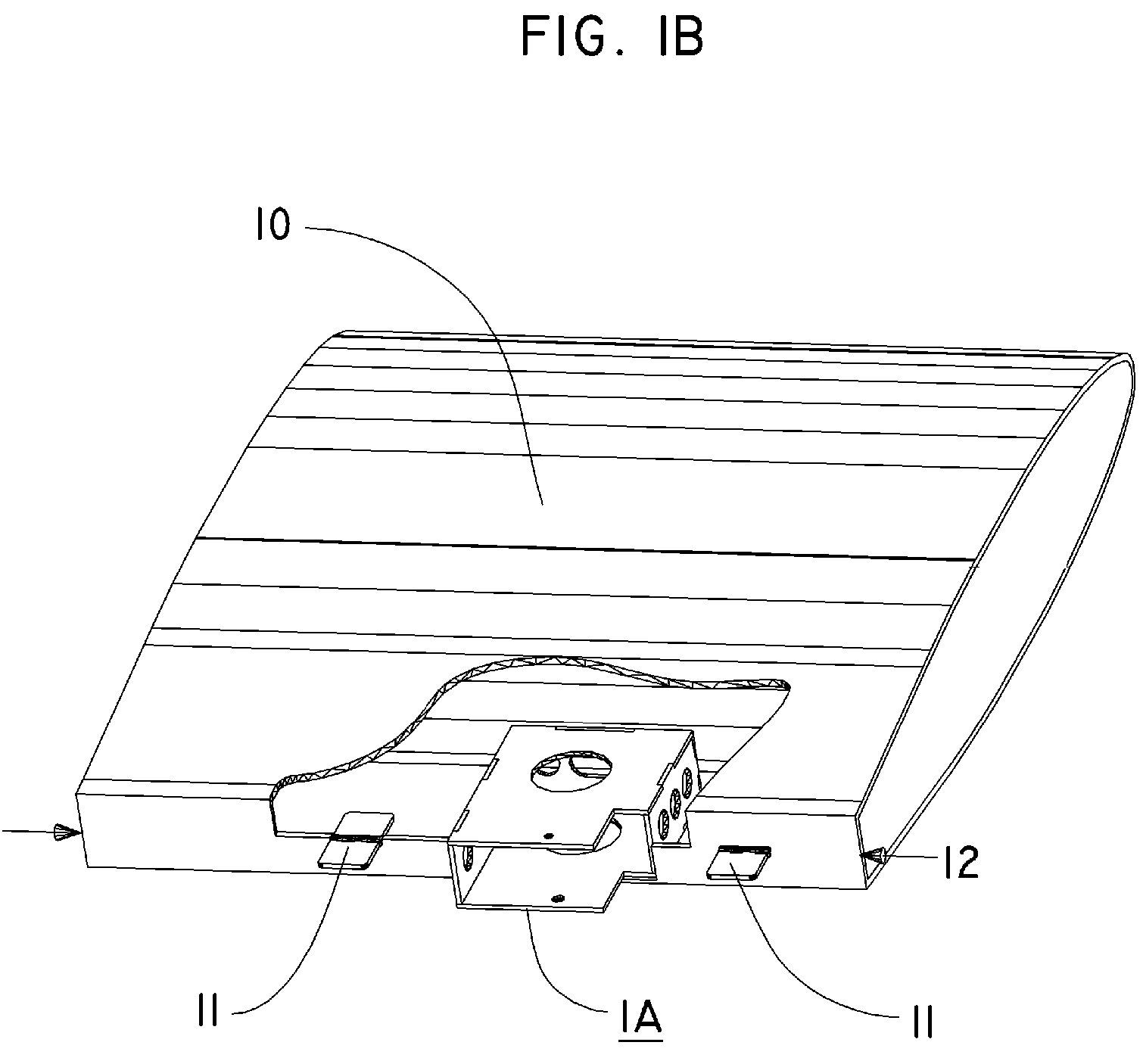

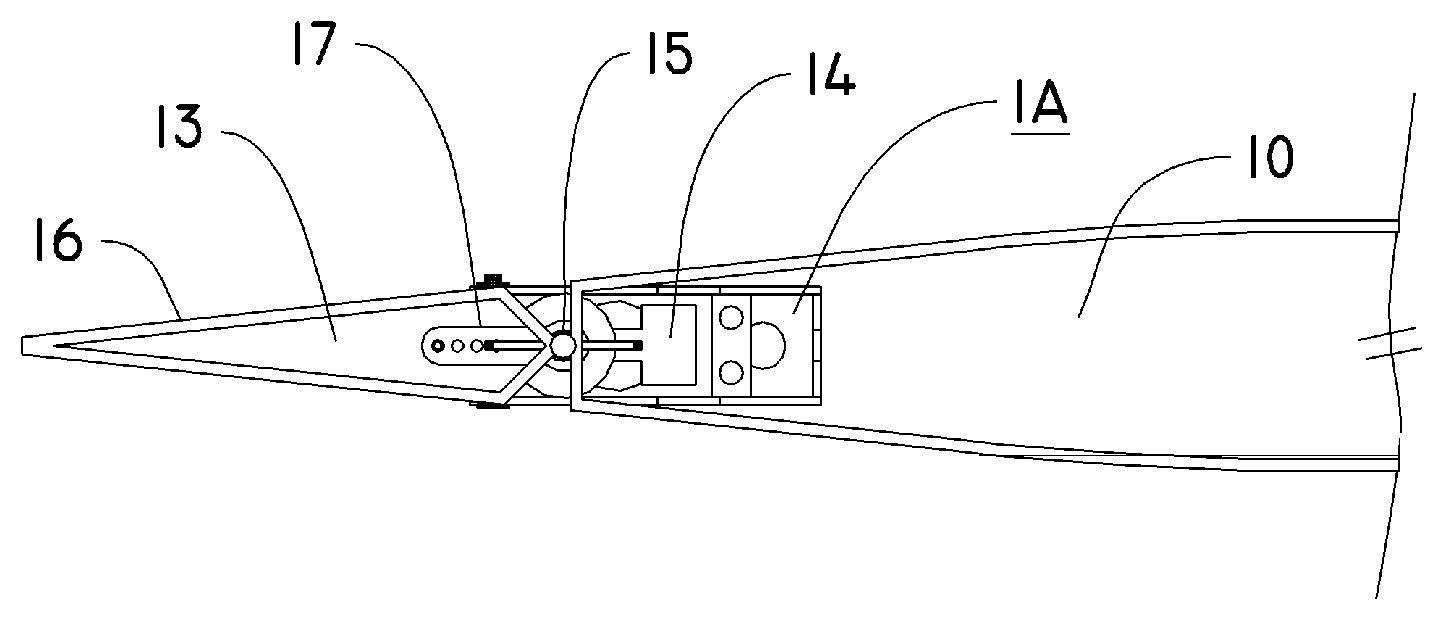

Mould assembly including a first mould part (2) and a second mould part (4) for moulding a substantially elongated, closed profile member, in particular a wind turbine blade of fibre-reinforced polymer, said mould assembly including a hinge mechanism (6) with a hinge line (7) extending parallel to the two mould parts in the longitudinal direction of the mould to allow turning of the mould parts in relation to each other between an open position and a closed position. The mould assembly includes displacement means for a rectilinear translational movement of the second mould part (4) between a partially closed position and a completely closed position. The displacement means are formed of guide rods (8) including drive means for displacing the guide rods (8) and thus for moving the two mould parts between the partially closed and completely closed positions. The invention further relates to a method of using the mould assembly.

Owner:LM GLASSFIBER

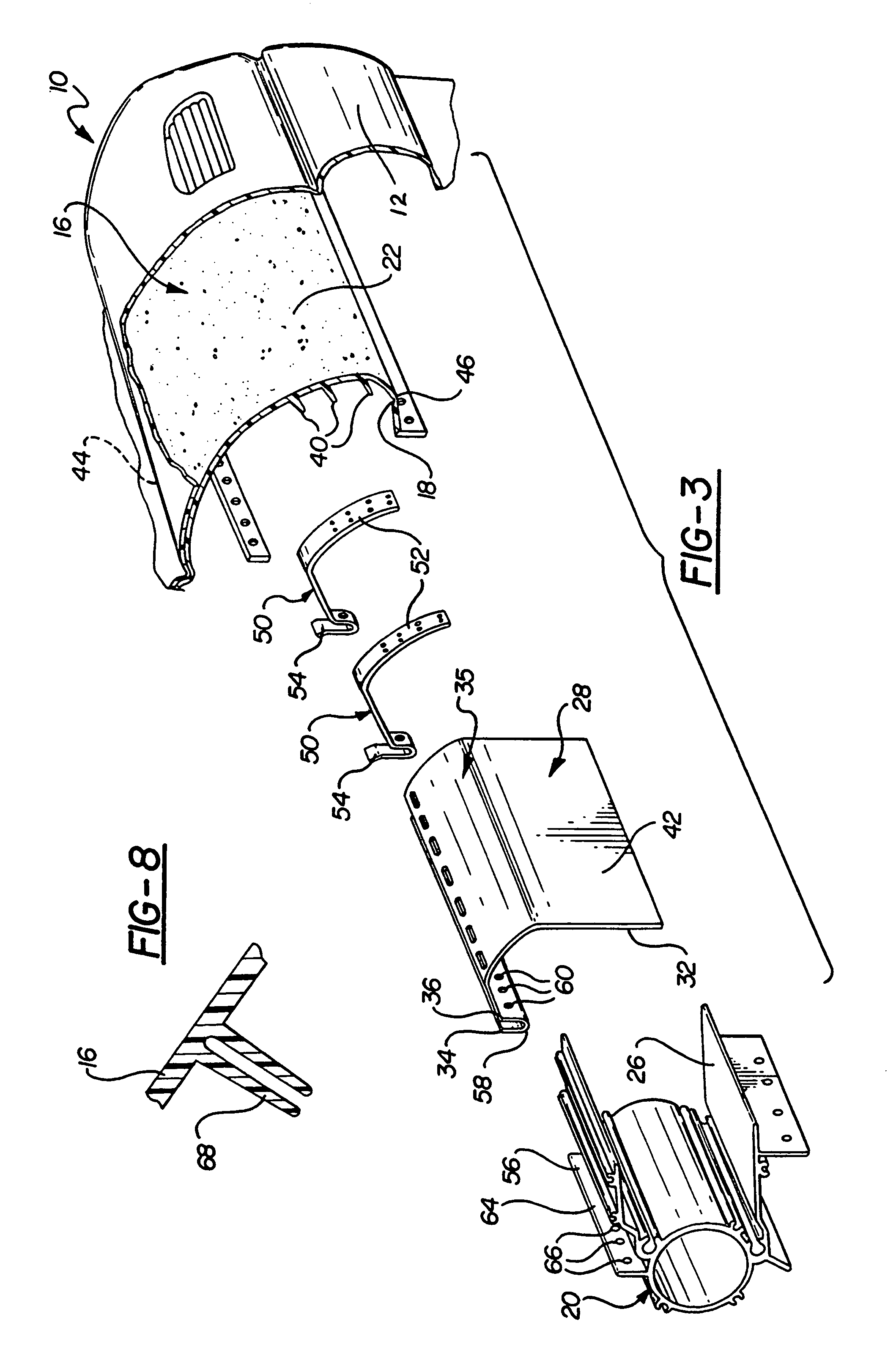

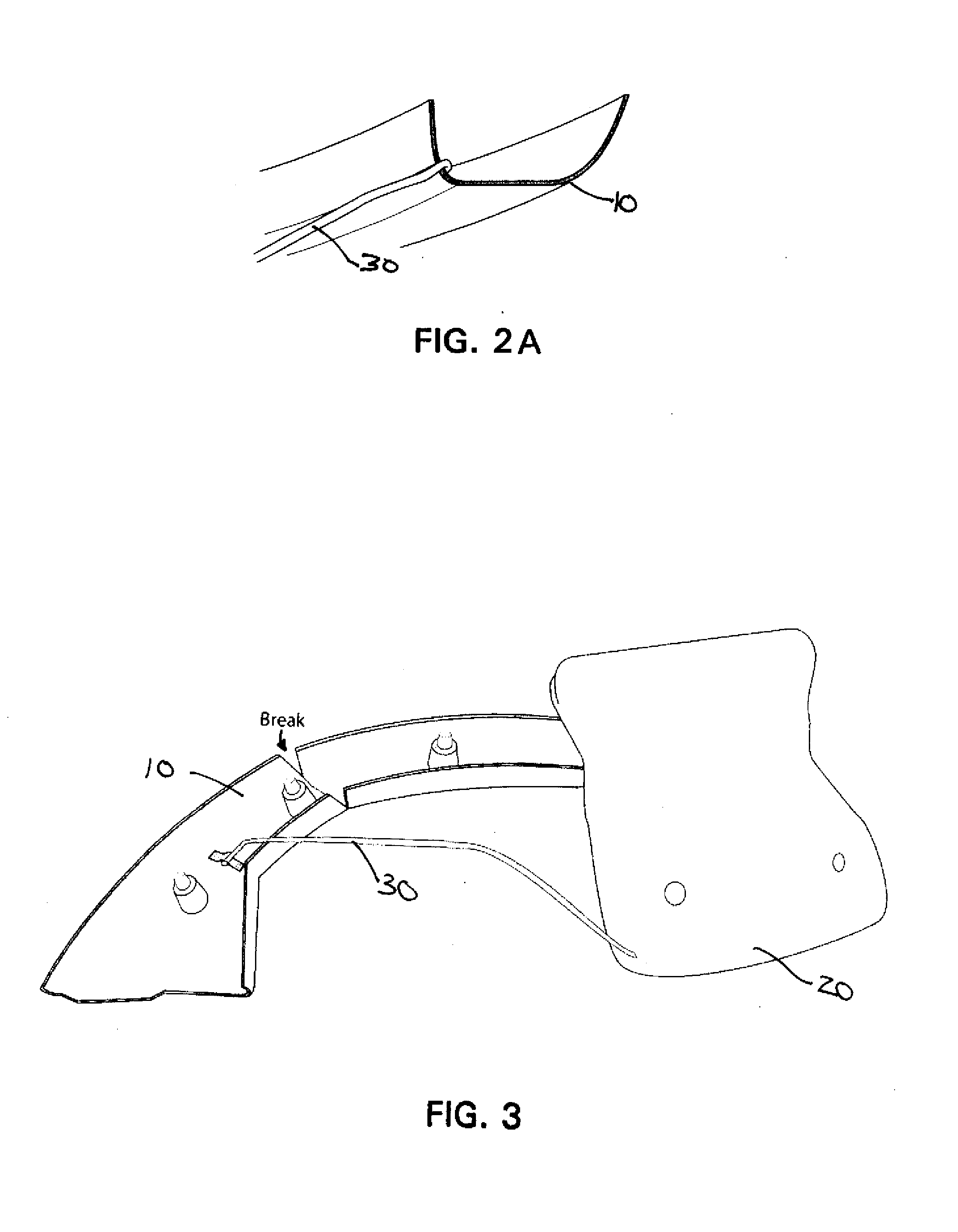

Apparatus for deploying an air bag through a hard panel

InactiveUS6955376B1Reduce chanceImprove structural rigidityPedestrian/occupant safety arrangementDomestic articlesDashboardHinge line

An apparatus for deploying an air bag through an automotive dash panel (12) includes an air bag door (16) integrally formed in the panel and defined by a door perimeter including a frangible edge (18) of reduced cross section. A dispenser (20) supports the air bag (24) behind the door. A metal reaction plate (28) is positioned between the air bag (24) and the door (16). When the air bag inflates, it forces the reaction plate (28) to bend around a horizontal hinge line (36). As the reaction, plate pivots it concentrates inflation force along a lower portion of the frangible door edge. This helps to predictably separate the door from the dash panel by tearing along the lower door edge and allowing the tear to propagate up two side edges. In one embodiment, the tear also propagates across an upper edge to completely separate the door from the panel. At least one, and preferably two or three tethers (50) limit how far the door can travel during air bag inflation. A stop member may be included to limit reaction plate bending. After deployment, the reaction plate remains in a position that prevents the door from returning to its original position. A retaining structure may be included to preclude at least a portion of the air bag door from tearing free of the vehicle panel. A hinge (44) may be embedded in the panel in a position spanning a portion of the door perimeter. A hollow channel may be formed into the panel along the frangible marginal edge to create a substantial strength differential with the door perimeter to promote bending along the hinge and / or to help confine tearing to the frangible marginal edge during air bag deployment.

Owner:COLLINS & AIKMAN PROD CO

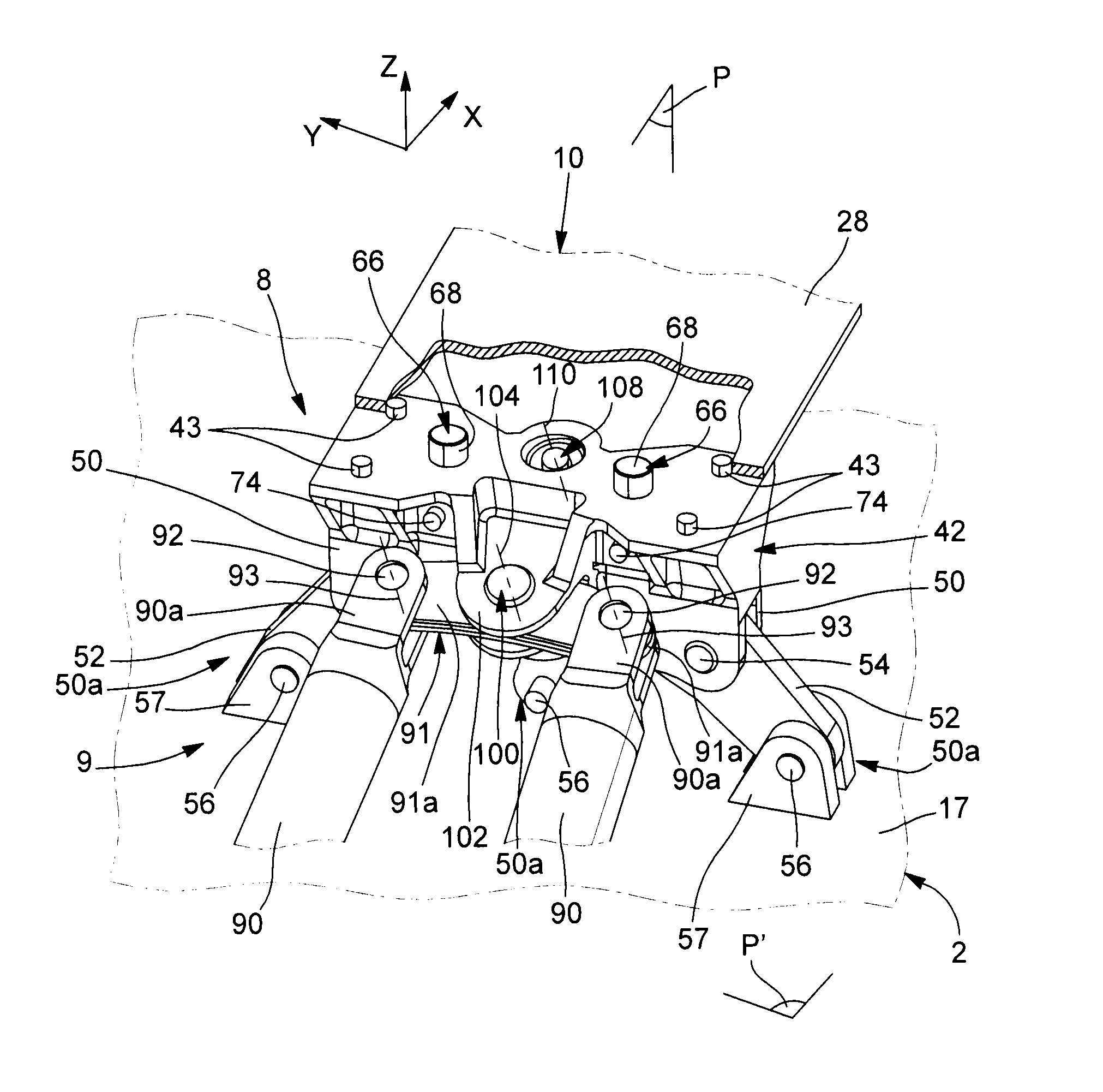

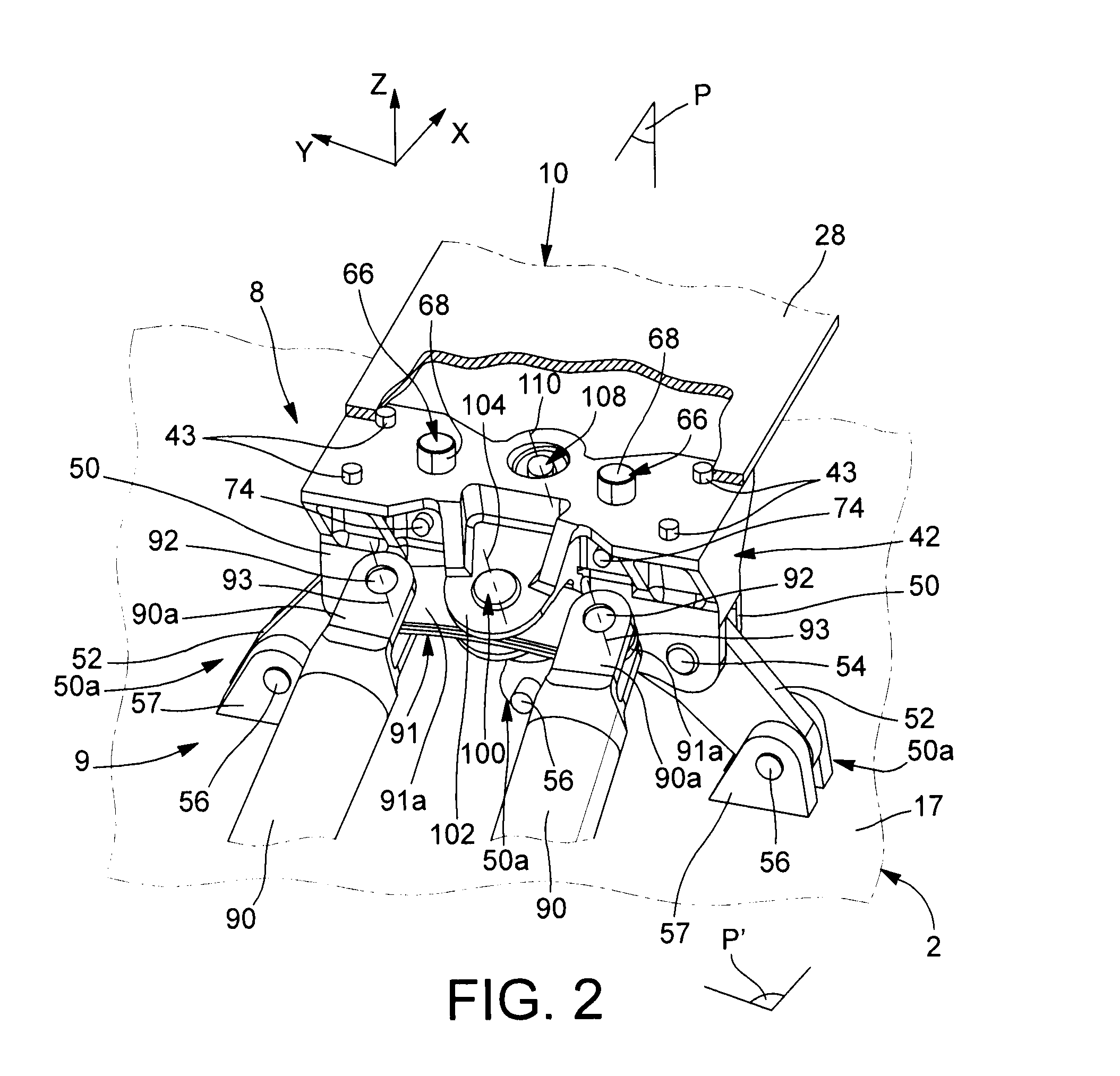

Engine mounting structure for aircraft having a beam spreader connected at four points

InactiveUS20100181419A1Small sizeGreater the observed leveragePower plant constructionFlight vehicleLight beam

An engine mounting structure for aircraft including an engine mounting system including a device for transmission of the thrust efforts fitted with two lateral connecting rods and with a spreader beam mounted in connected fashion on a support element, through a principal connecting device defining a principal spreader beam hinge line positioned in a plane. The spreader beam is also mounted in connected fashion with some play on the element, using a secondary connecting device located at some distance, as seen from above, from the device, and defining a secondary spreader beam hinge line, which is also positioned in a plane. The rotation of the spreader beam is stopped by device coming into contact with the spreader beam.

Owner:AIRBUS OPERATIONS (SAS)

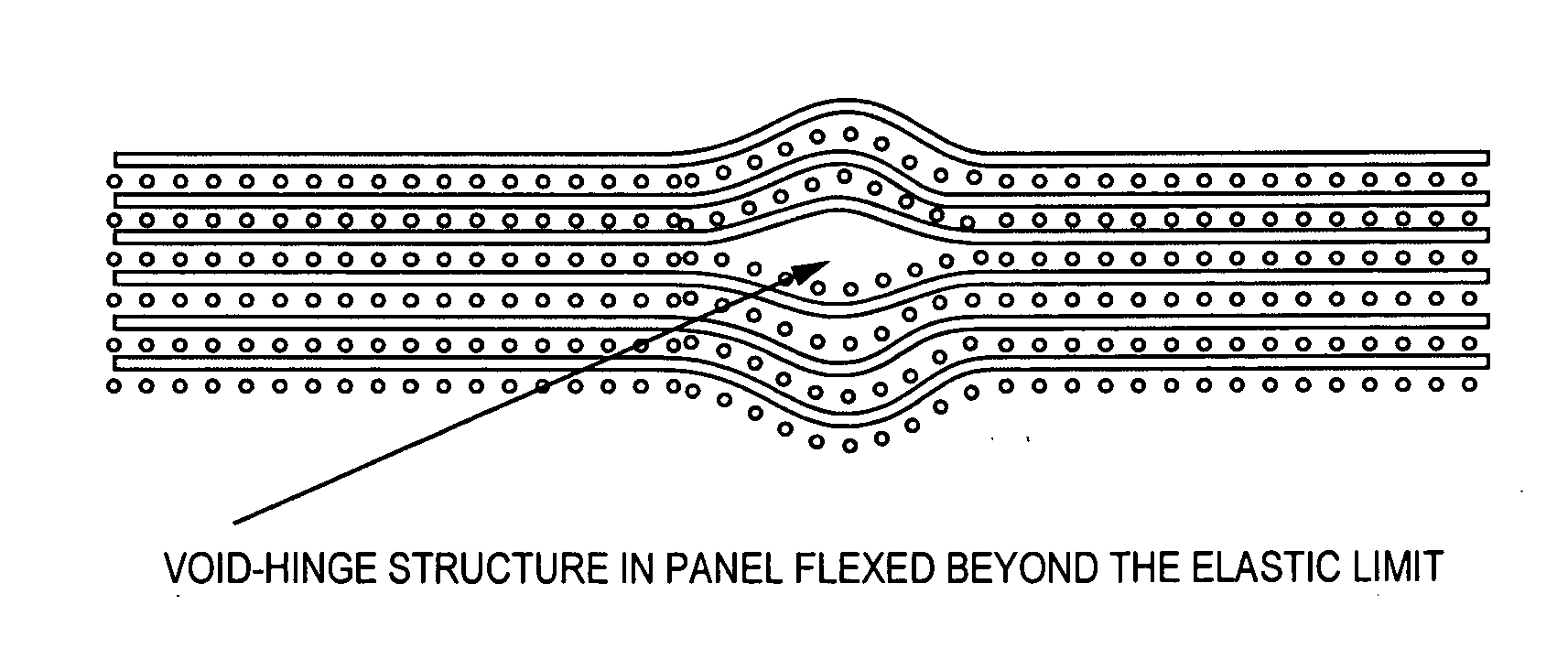

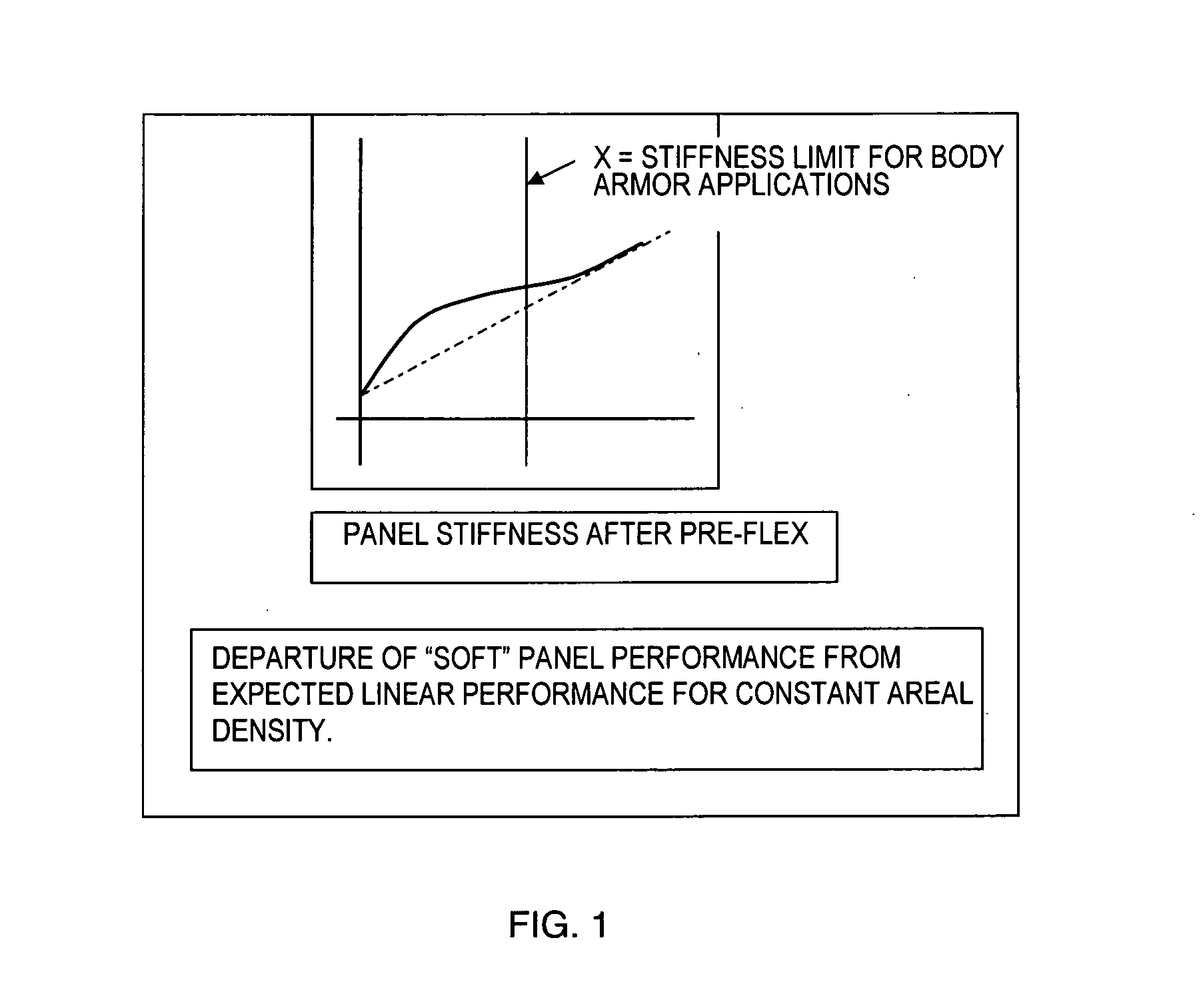

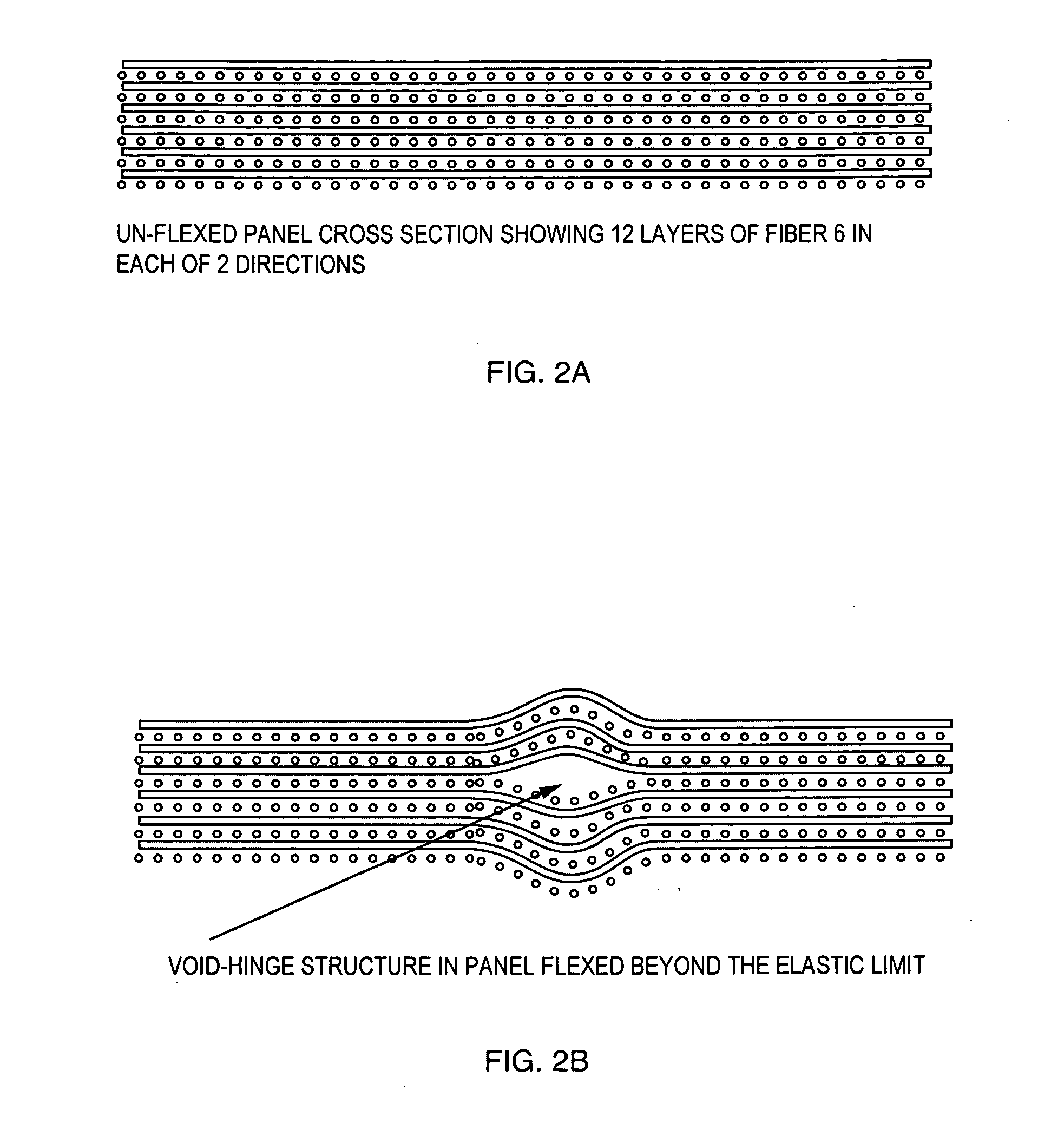

Soft plate soft panel bonded multi layer armor materials

ActiveUS20120152098A1Lower its effective stiffnessPermit flexureProtective equipmentLayered productsFiberHinge line

A flexible armor system includes a rigid panel of a stiffness calculated to resist penetration by a known ballistic object, made from multiple layers of Ultra High Molecular Weight Poly-Ethylene fibers or other high tenacity fibers, which is then pre-flexed beyond its elastic bending limit to create a distributed pattern of surface buckling, with localized areas of interior delamination, which together function as bending or hinge lines to provide flexibility to the otherwise rigid panel and thereby lower its overall stiffness to less than that calculated for the rigid panel to resist the ballistic object. The areas of delamination have a width of less than one half the diameter of the ballistic object.

Owner:WARWICK MILLS INC

Cross-bleed dam

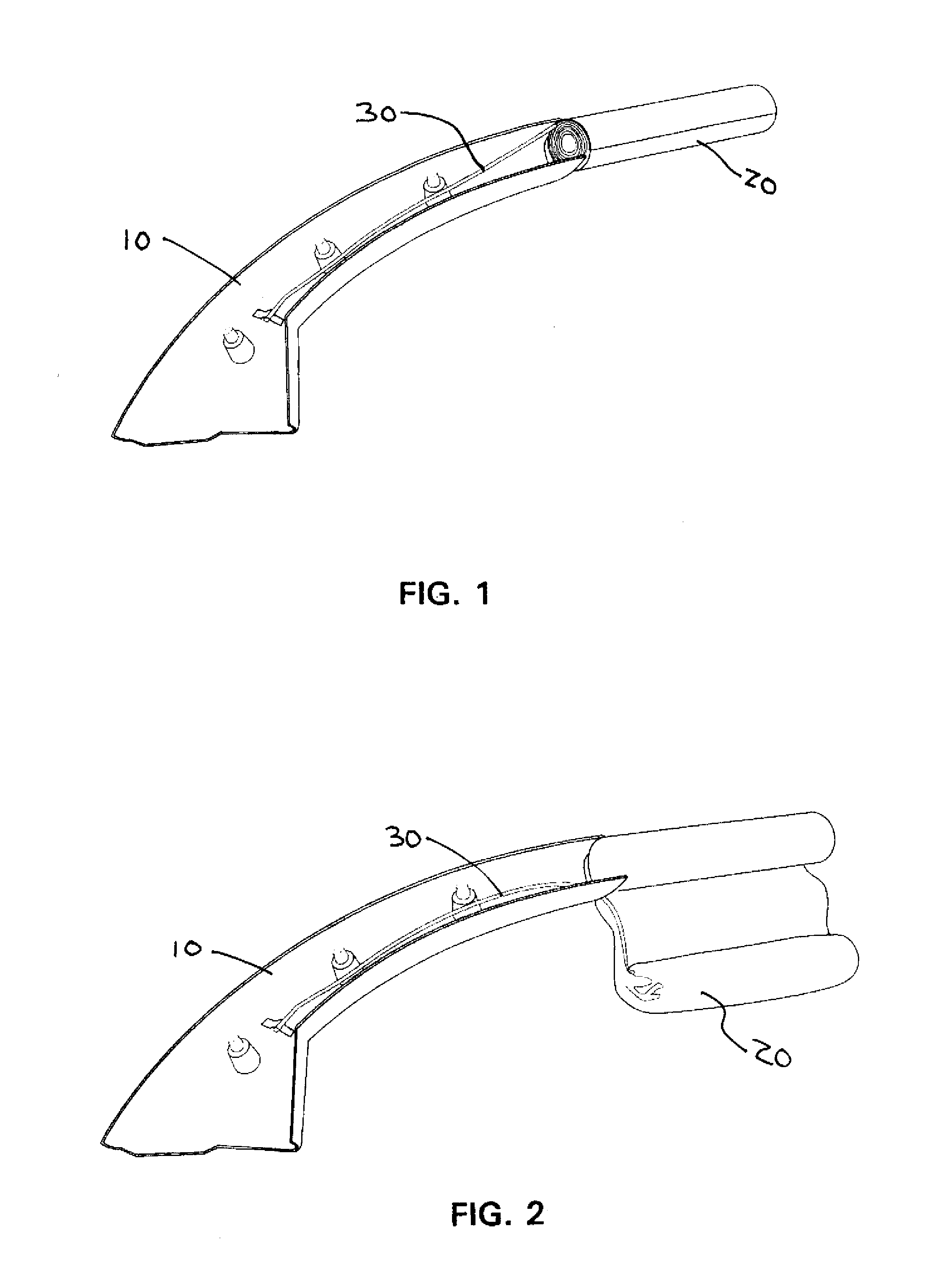

ActiveUS20100327121A1Improve efficiencyImprove seal protection effectEngine sealsAircraft stabilisationLeading edgeHinge line

A panel assembly for an aircraft including a panel having an upper aerodynamic surface and a leading edge, and a hinge fitting connected to an underside of the panel, defining a hinge line for the direction of rotation of the panel. The upper surface of the leading edge has an arcuate portion centered about the hinge line, and has an upturned portion forward of the arcuate portion. The panel assembly is pivotally connected to its hinge fitting to the trailing edge of the fixed wing portion and rotatable between a first position wherein the upper surfaces of the fixed wing portion and the panel are substantially flush, and a second position wherein the panel is rotated downwardly from the first position. A seal member attached to the trailing edge of the fixed wing portion, has a lower surface which seals against the upper surface of the panel during its movement.

Owner:AIRBUS OPERATIONS LTD

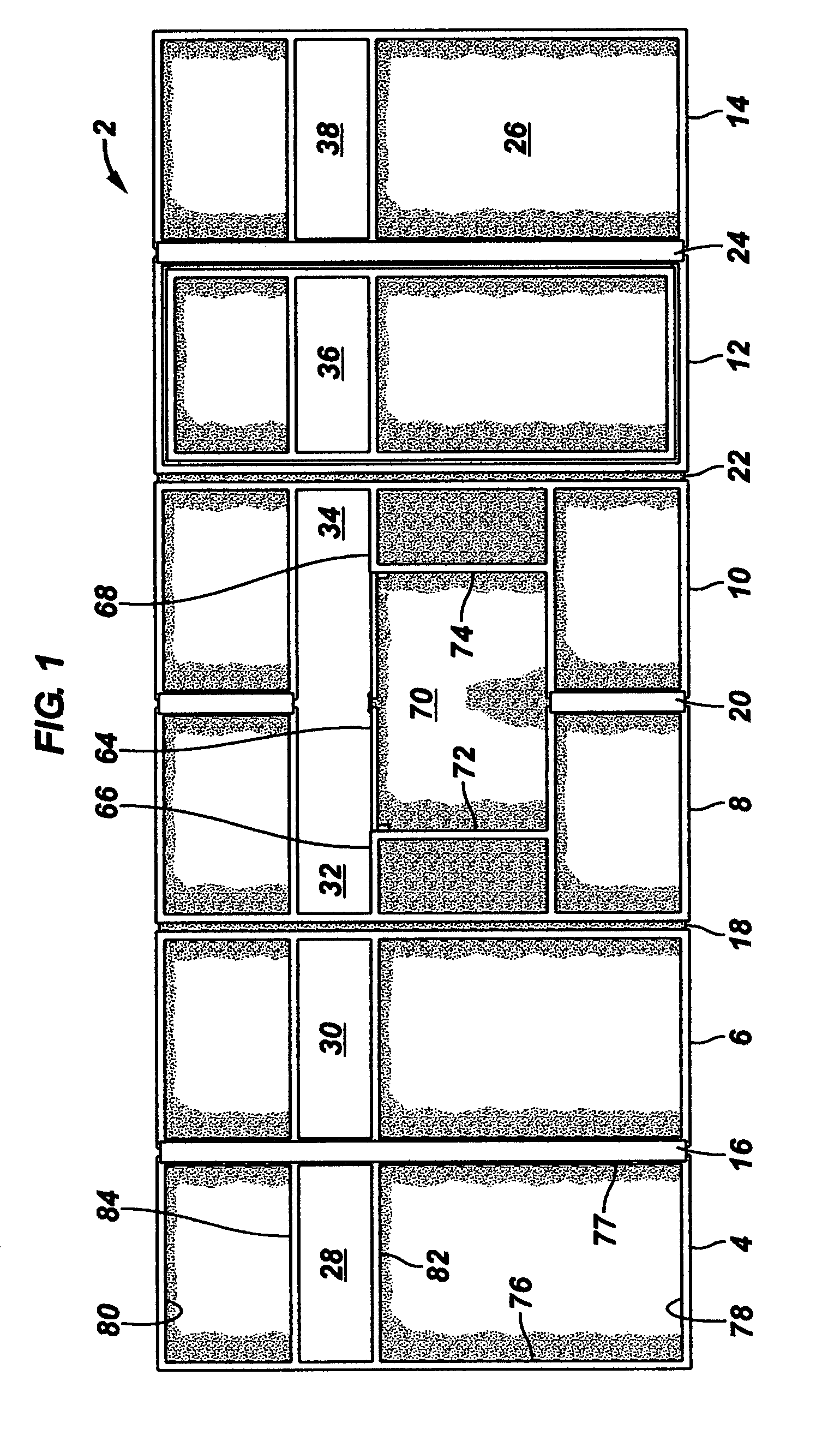

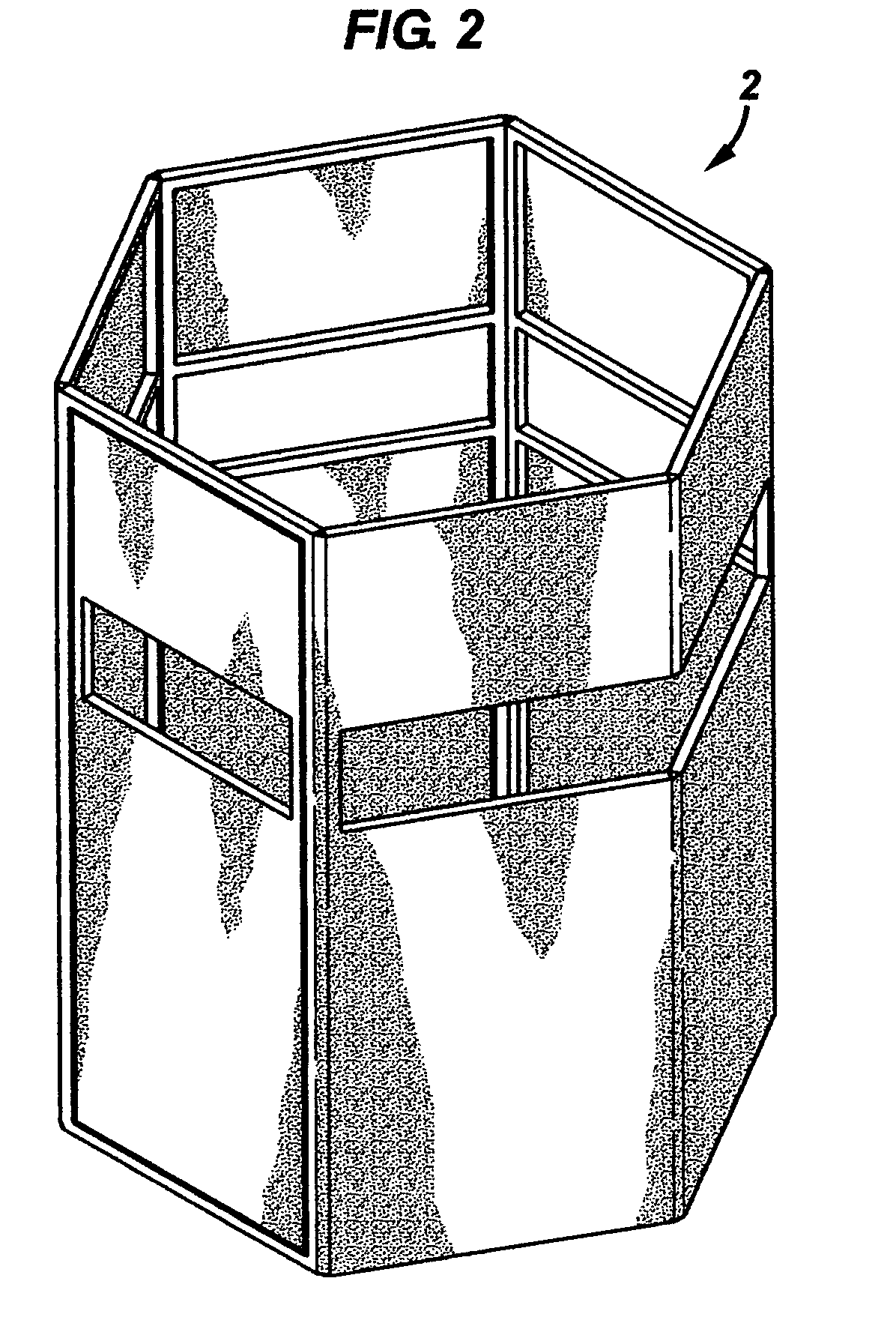

Reconfigurable portable hunting blind

A portable reconfigurable hunting blind assembly is disclosed comprising six rectangular frames joined together side edge to side edge along five hinge lines for accordion folding, and a camouflage covering mounted to each of the frames to define six panel-shaped wall units, the camouflage covering defining a window in at least some of the wall units.

Owner:GOOD SPORTSMAN MARKETING LLC

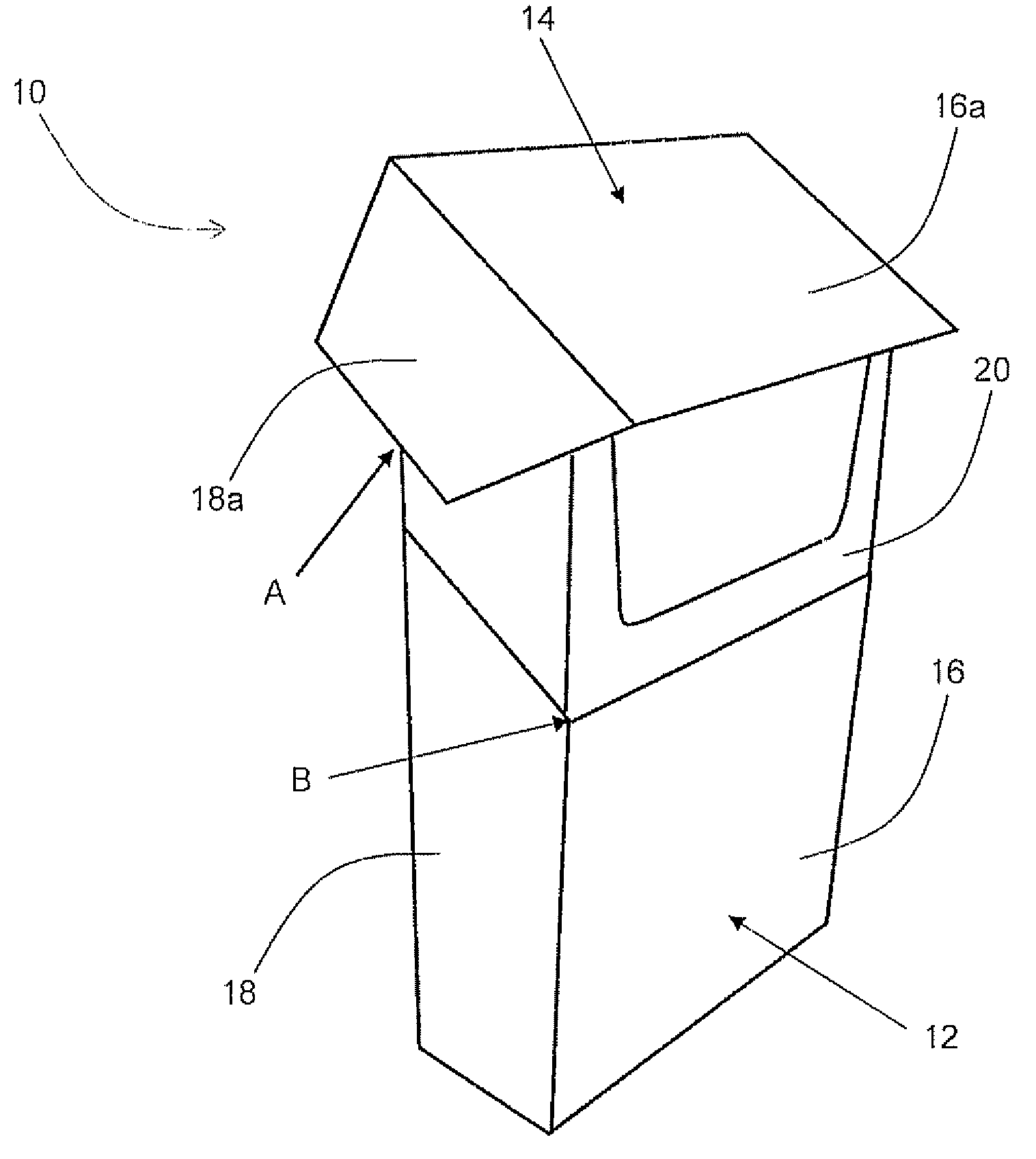

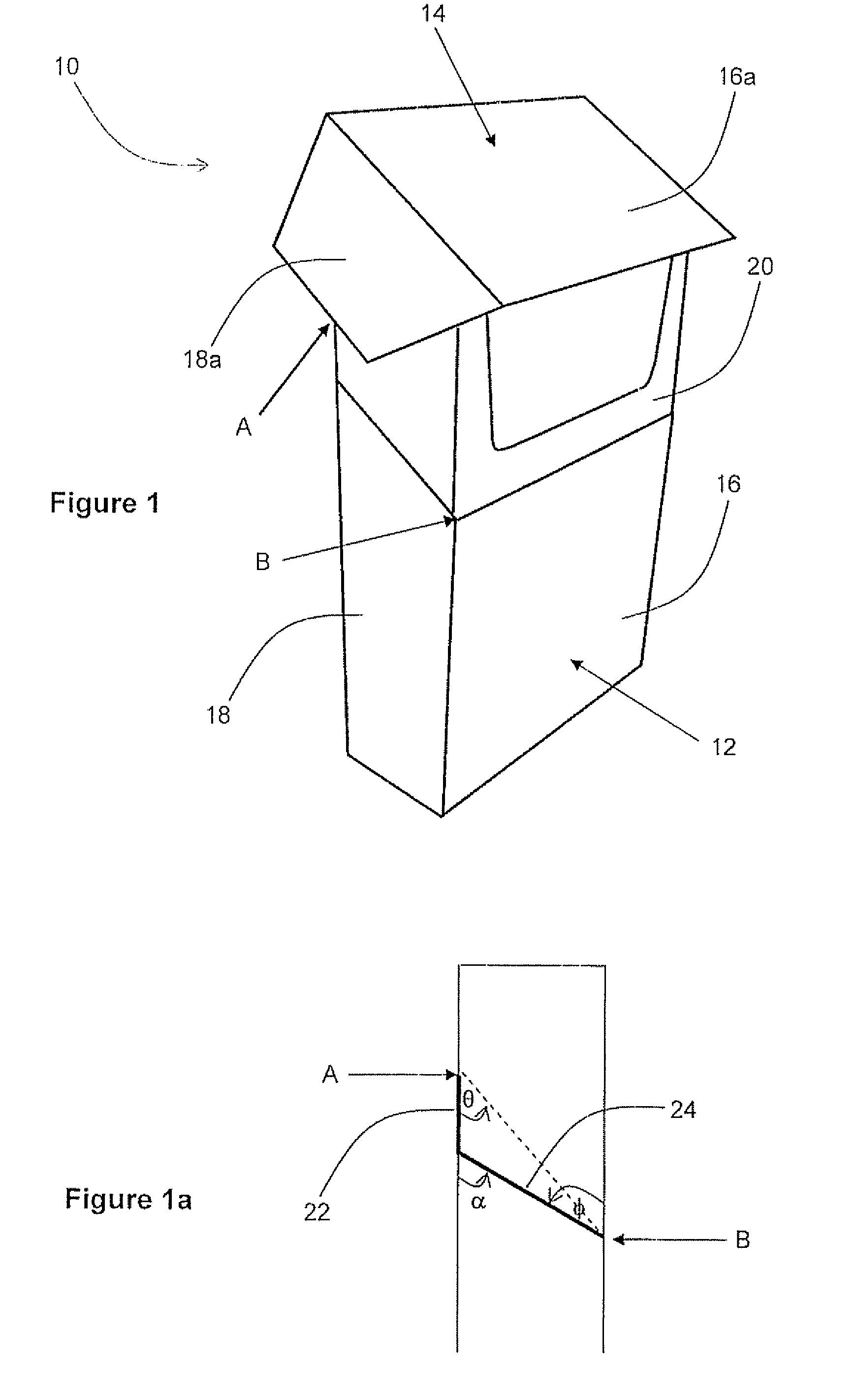

Hinge lid container

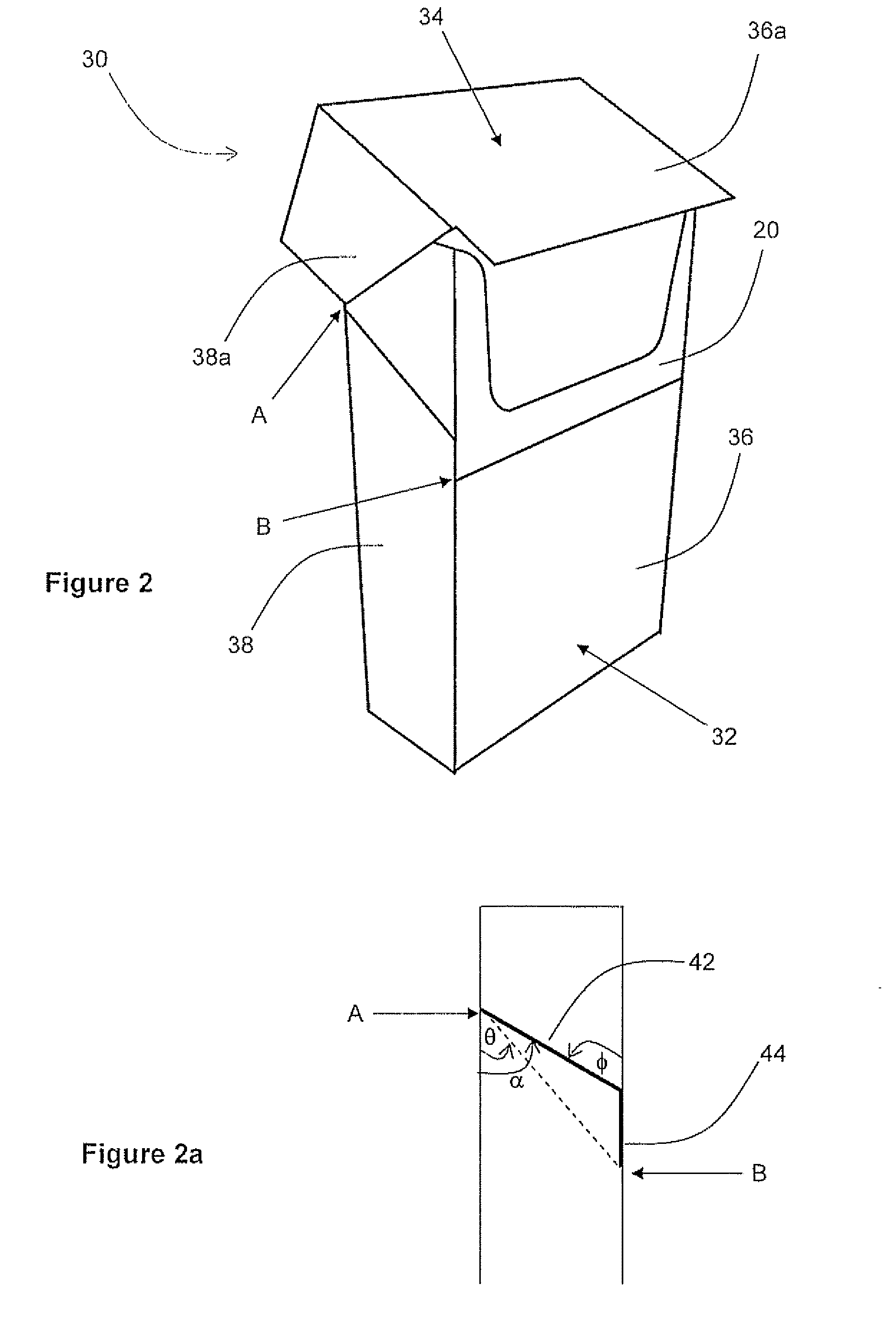

InactiveUS20090184158A1Increase visible internal surface areaDurable and strongLidsNon-removalbe lids/coversHinge lineFront edge

A hinge lid container for smoking articles having a front wall, a rear wall and opposed side walls extending therebetween comprises: a box portion; and a lid portion hinged to the box portion along a hinge line extending across a rear wall of the container. At each side wall of the container, the angle □ between the front edge of the side wall of the lid portion and the lower edge thereof is greater than the angle □ defined between the rear edge of the side wall and a straight line extending between a first point (A) where the hinge line meets the side wall and a second point (B) where the upper edge of a front wall of the box portion meets the side wall.

Owner:PHILIP MORRIS USA INC

Fold out ramp

ActiveUS20090271934A1Suitable for useRefuse receptaclesLoading/unloading vehicle arrangmentMoving floorReciprocating motion

A ramp assembly is suitable for use with a vehicle having a floor. The ramp assembly includes a ramp rotatably coupled within the vehicle, and a moving floor having an inboard panel and an outboard panel. The outboard panel has an outboard end hingedly coupled to the inboard end of the ramp to define an outboard hinge line that moves between a raised position when the ramp is in a stowed position and a lowered position when the ramp is in a deployed position. An outboard end of the inboard panel is hingedly coupled to an inboard end of the outboard panel. A reciprocating mechanism reciprocates an inboard end of the inboard panel between a lowered position and a raised position.

Owner:ELEVATOR U DIV OF HOGAN MFG

Fan variable area nozzle for a gas turbine engine fan nacelle with sliding actuation system

A fan variable area nozzle (FVAN) includes a flap assembly which varies a fan nozzle exit area. An actuator system drives a sliding drive ring relative a multitude of slider tracks mounted to a fan nacelle to adjust each flap of the flap assembly through the flap linkage to pitch the flap assembly about a circumferential hinge line to vary the diameter of the annular fan nozzle exit area between the fan nacelle and the core nacelle. The FVAN may be separated into a multiple of drive ring sectors which are each independently adjustable by an associated actuator of the actuator system to provide a low profile drag asymmetrical fan nozzle exit area.

Owner:RAYTHEON TECH CORP

Mould assembly with closure mechanism

InactiveUS7223091B2Simple and fast and accurate closure and openingSpeed up the processMouldsFinal product manufactureTurbine bladeHinge line

A mould assembly includes a first mould part (2) and a second mould part (4) for moulding a wind turbine blade of fibre-reinforced polymer. The assembly has a hinge mechanism (6) with a hinge line (7) extending parallel to the two mould parts in the longitudinal direction of the mould to allow turning of the mould parts in relation to each other between an open position and a closed position. It also has a displacement mechanism for a rectilinear translational movement of the second mould part (4) between a partially closed position and a completely closed position. The displacement mechanism has guide rods (8) including drives for displacing them and thus for moving the two mould parts between the partially closed and completely closed positions.

Owner:LM GLASSFIBER

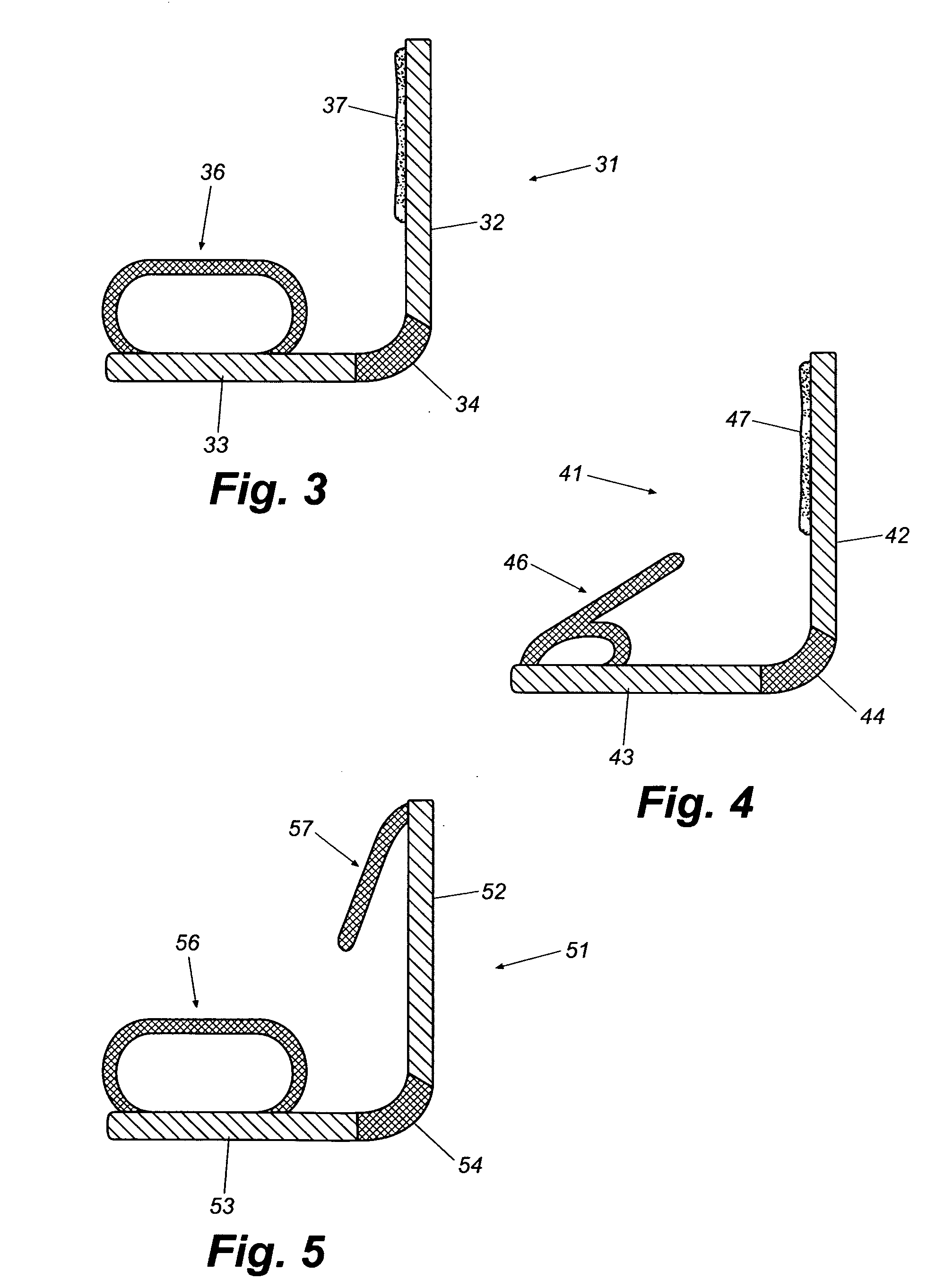

Rollable door seal with integral intumescent strips

InactiveUS20050268559A1Prevent smoke infiltrationPrecise positioningFireproof doorsSills/thresholdHinge lineEngineering

A door seal system is provided for forming a seal between a closed door and its door frame. The system includes a unitary co-extruded seal member having first and second legs connected by a flexible hinge. A traditional flexible seal is formed along one leg and, preferably, a strip of intumescent material is formed along the other leg. The member can be folded flat along the hinge line for rolling into a compact storage and shipping configuration. For installation, a length is pulled from the roll, cut off, bent into a right angle along the hinge, and fixed to the door frame with one leg extending along the jamb and the other extending along the stop. The flexible seal bears and seals against the outside face of a closed door and the intumescent strip is positioned in the gaps between the door edges and the door frame.

Owner:REESE ENTERPRISES

Nacelle with hinged cowl doors enabling access to the engine

ActiveUS20130259641A1Easy accessWide openPump componentsRotary non-positive displacement pumpsNacelleHinge line

A nacelle for an engine has outer and inner cowl doors that are independently rotatable about offset hinge lines. A connection device is provided for selectively connecting the outer and inner cowl doors so as to cause them to open simultaneously. The inner cowl door is arranged to rotate by a greater angle than the outer cowl door so as to improve access to the engine for maintenance purposes.

Owner:SHORT BROTHERS

Atomic oxygen and electrostatic-resistant, flexible structure for space applications

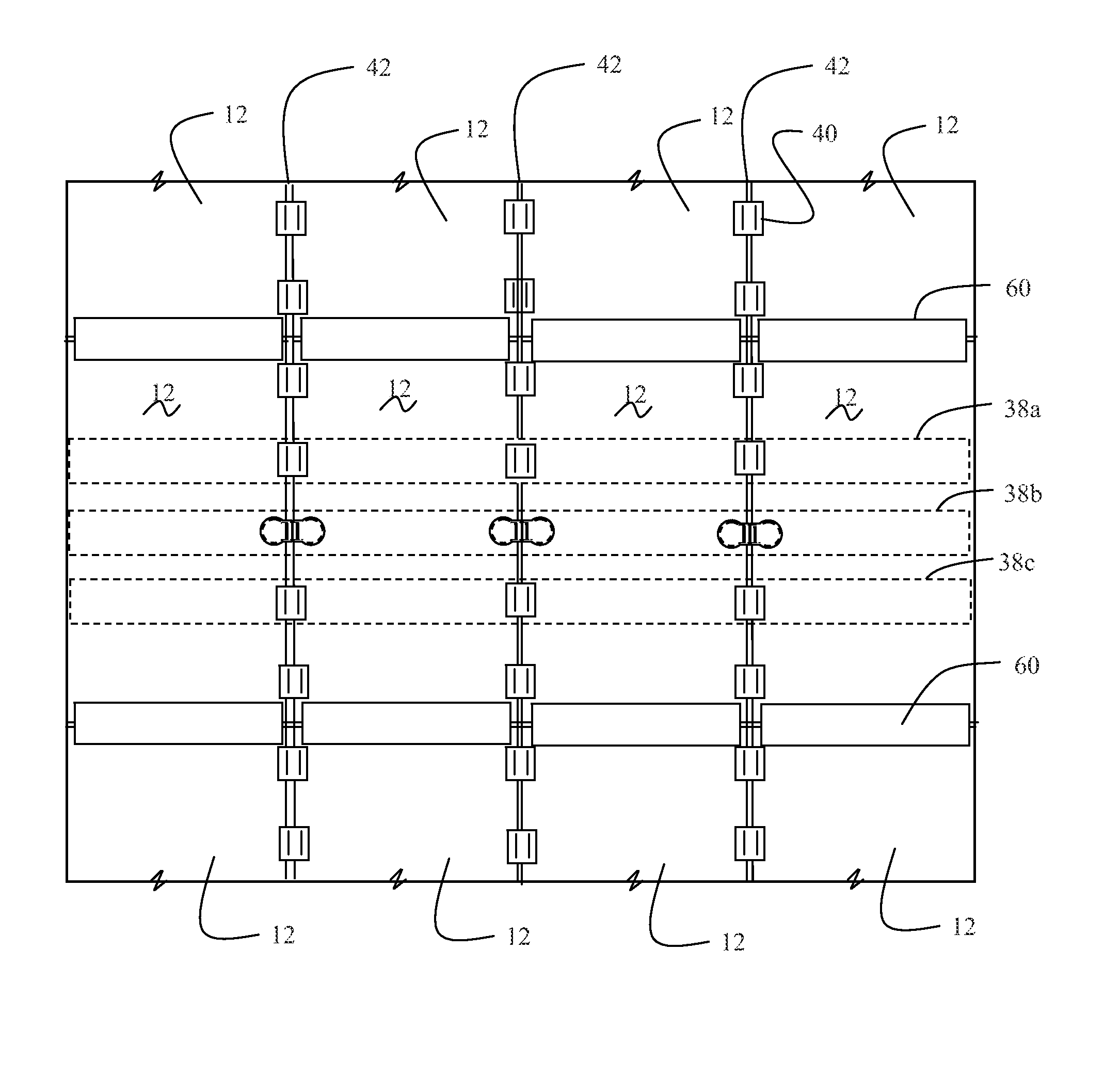

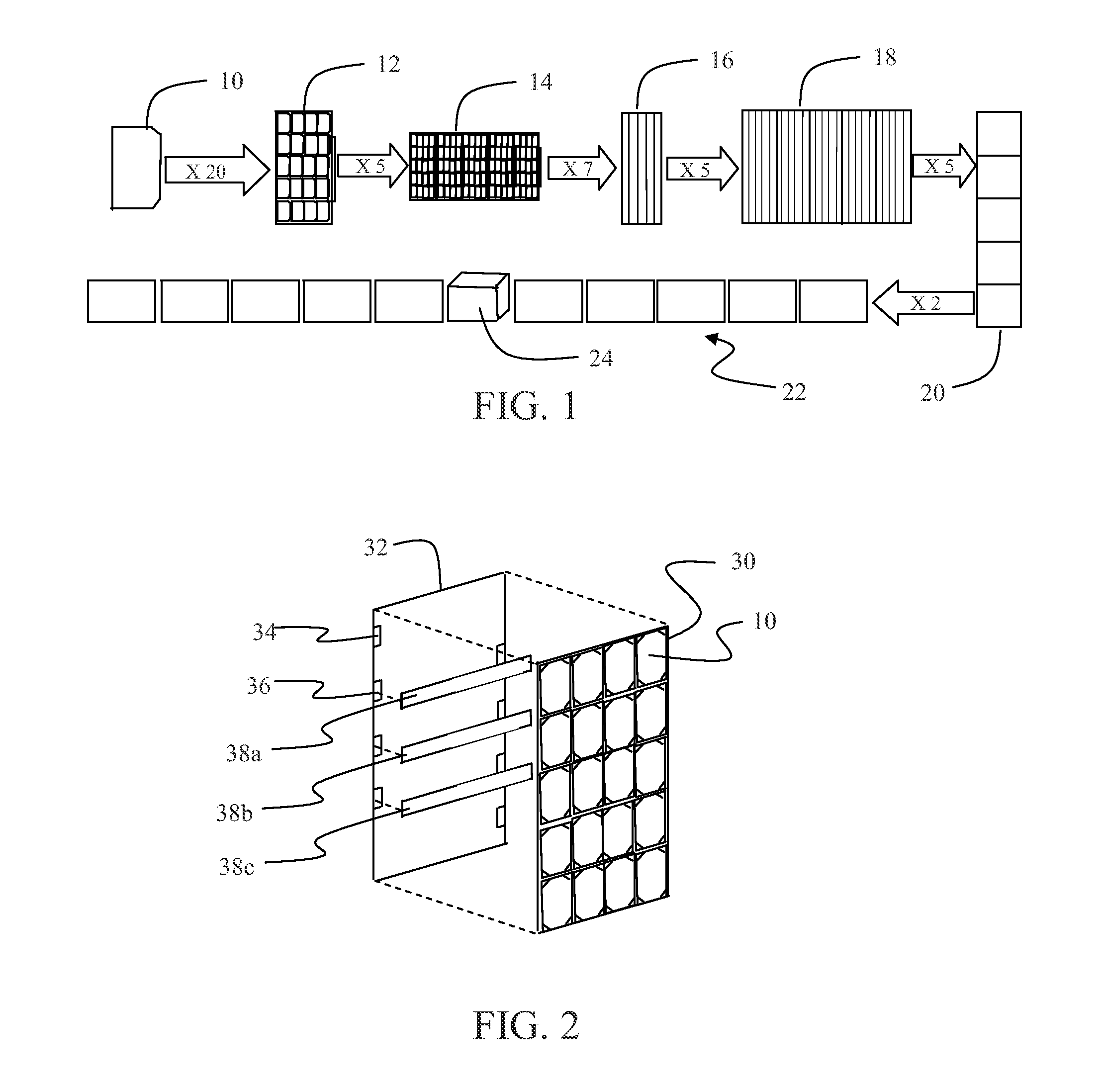

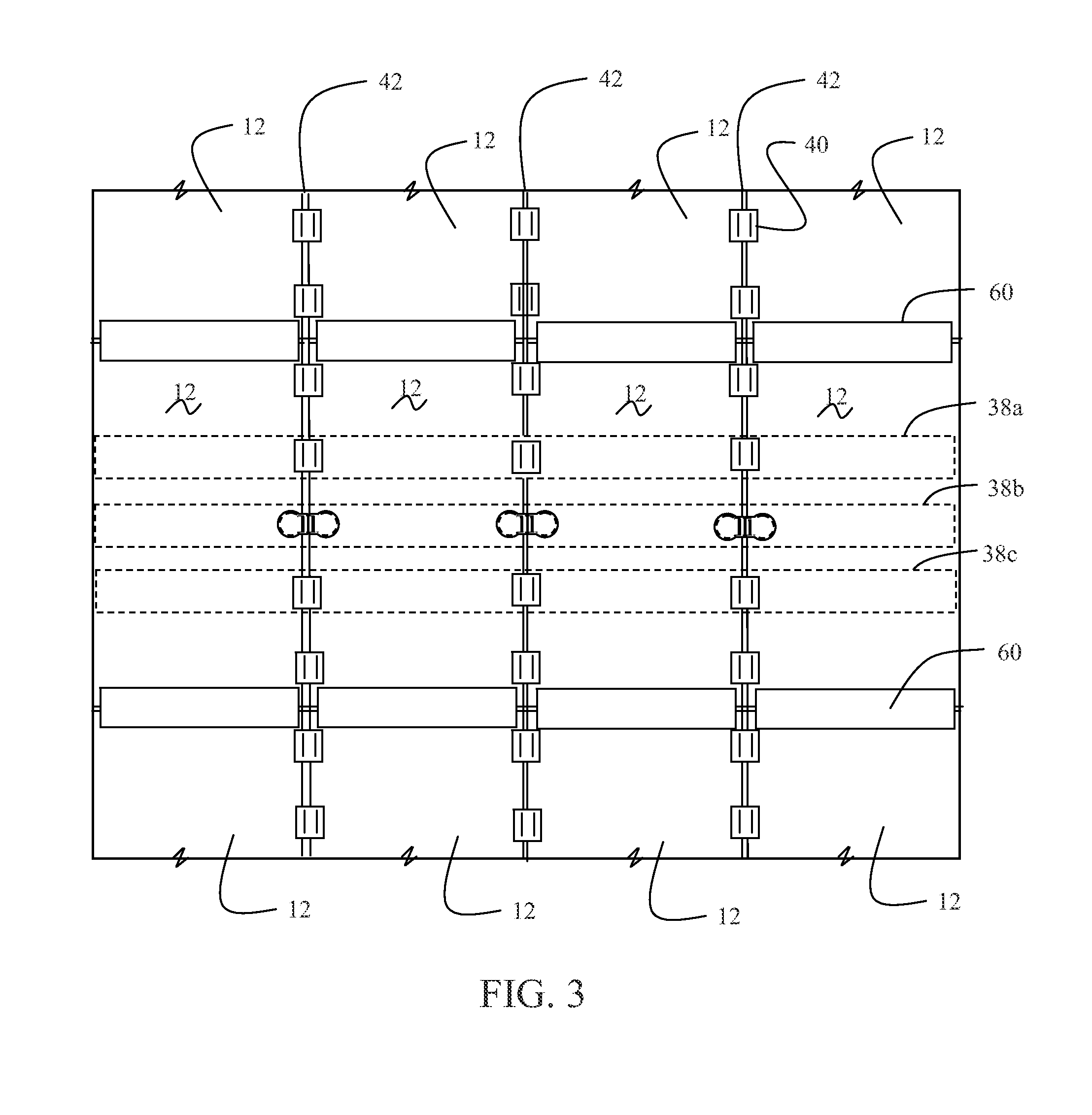

ActiveUS8872018B1Cosmonautic environmental control arrangementCosmonautic vehiclesSpatial structureConductive coating

A flexible space structure such as a solar array is composed of multiple solar cell modules (SCMs) each supporting an arrangement of solar cells on a frontside layer and incorporating a backside layer with a surface opposite from the frontside layer having a conductive coating. A selected portion of the SCMs have structural ground extension harnesses intermediate the frontside layer and backside layer. Conductive tapes secure vertically adjacent SCMs by attachment to the conductive coating and electrical jumpers interconnect the structural ground extension harnesses across gapped hinge lines of laterally adjacent SCMs.

Owner:THE BOEING CO

Foldable, lockable control surface and method of using same

InactiveUS20070045466A1Limit flutterGuaranteed normal transmissionSelf-propelled projectilesLocking mechanismHinge line

A foldable, lockable control surface includes an inner control surface member and an outer control surface member hingedly attached along a hinge line to the inner control surface member. The control surface further includes a biasing assembly disposed on the hinge line, the outer control surface being operably associated with the inner control surface member and the outer control surface member and a locking mechanism operably associated with the outer control surface member. An apparatus includes a foldable, lockable control surface having a control surface actuation shaft extending therefrom and a control surface actuator having a control surface actuator output port in which the control surface actuation shaft is received. The apparatus further includes means for clocking the control surface actuation shaft in the control surface actuator output port.

Owner:LOCKHEED MARTIN CORP

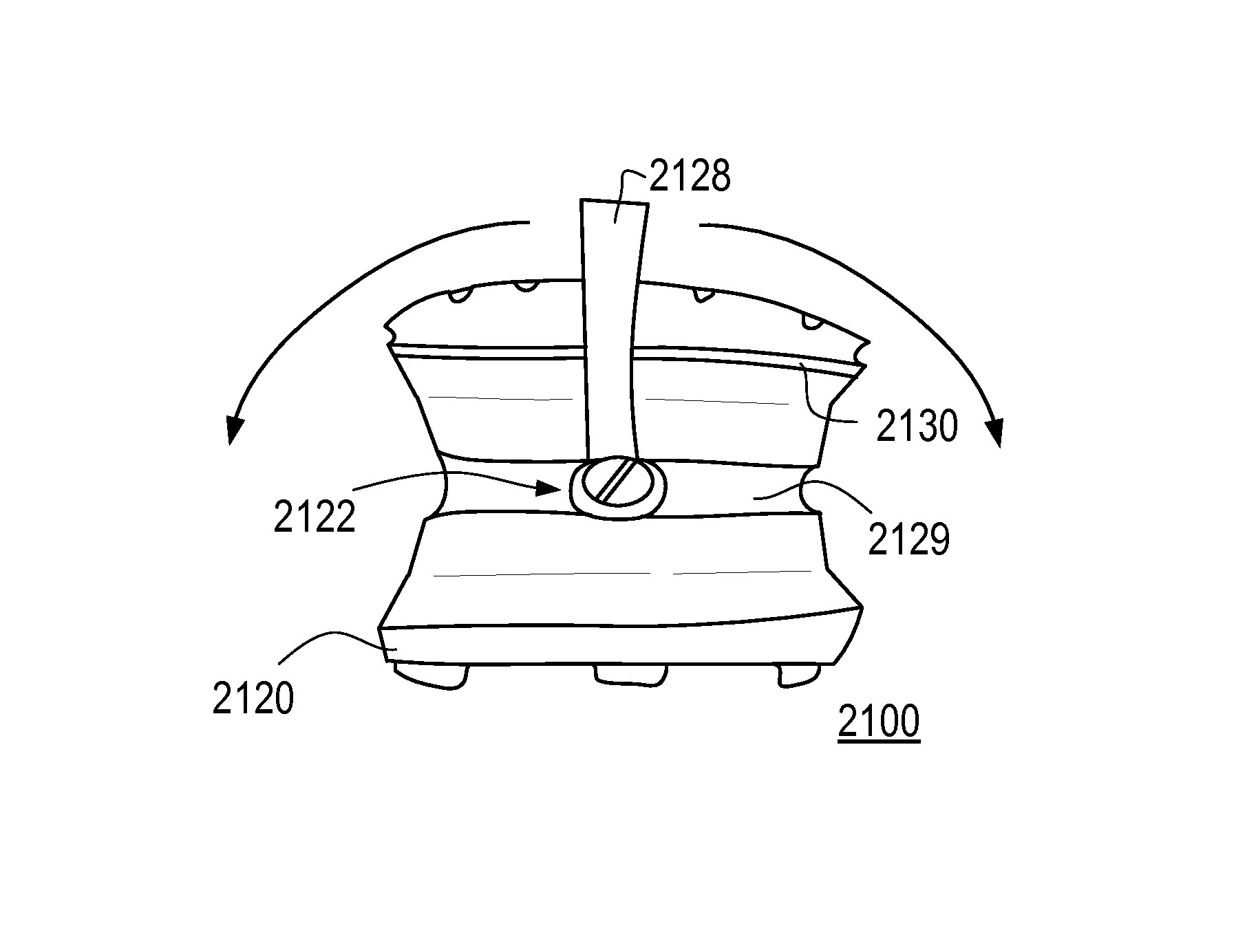

Collapsible coolers

A cooler includes a base defining a bottom portion of the cooler; an upper rim defining an upper portion of the cooler; a collapsible cooler wall, extending between and attached to said base and said upper rim and surrounding an interior storage space of the cooler, and including a membrane having a plurality of hinge lines at which the membrane is configured to bend such that the membrane is transitional between a collapsed configuration and an expanded configuration, wherein the cooler is transitional between an expanded configuration for use of the cooler, and a collapsed configuration during nonuse of the cooler, by bending along the hinge lines, each of the configurations corresponding to a stable configuration of the cooler; and a handle for lifting of the cooler, wherein the handle is attached to the base and is configured for rotational movement relative to the base about a pivot axis.

Owner:M & C INNOVATIONS

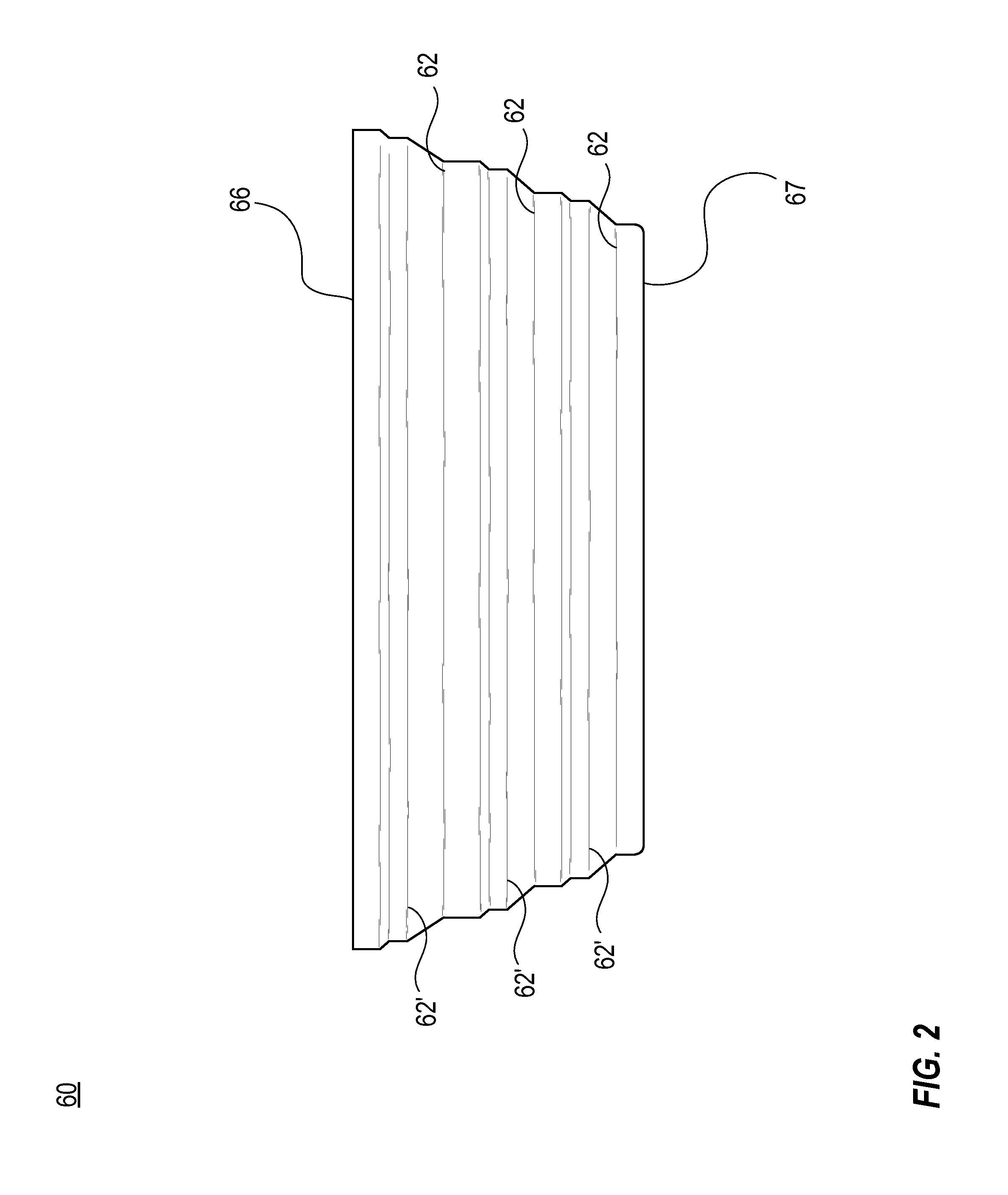

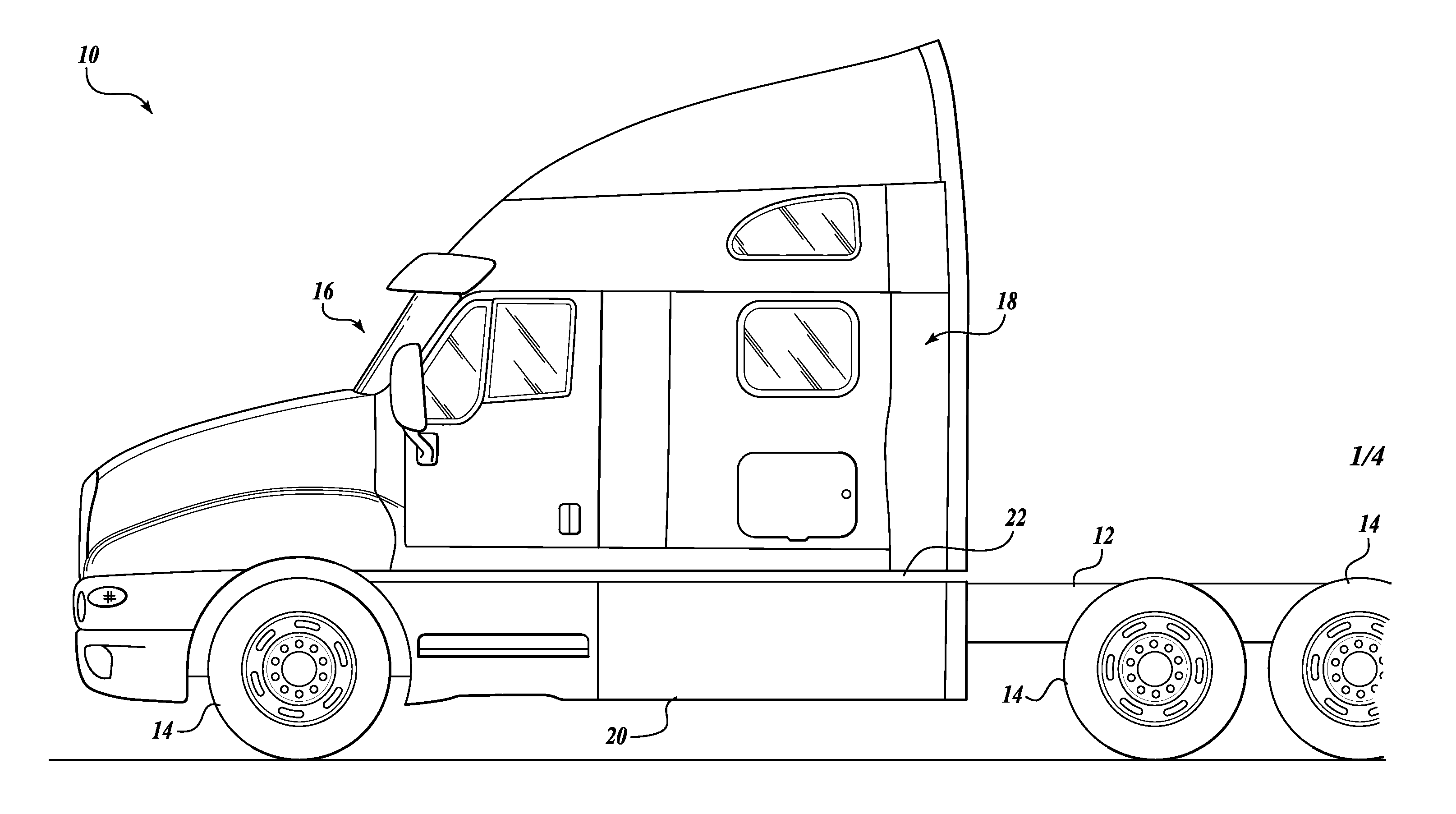

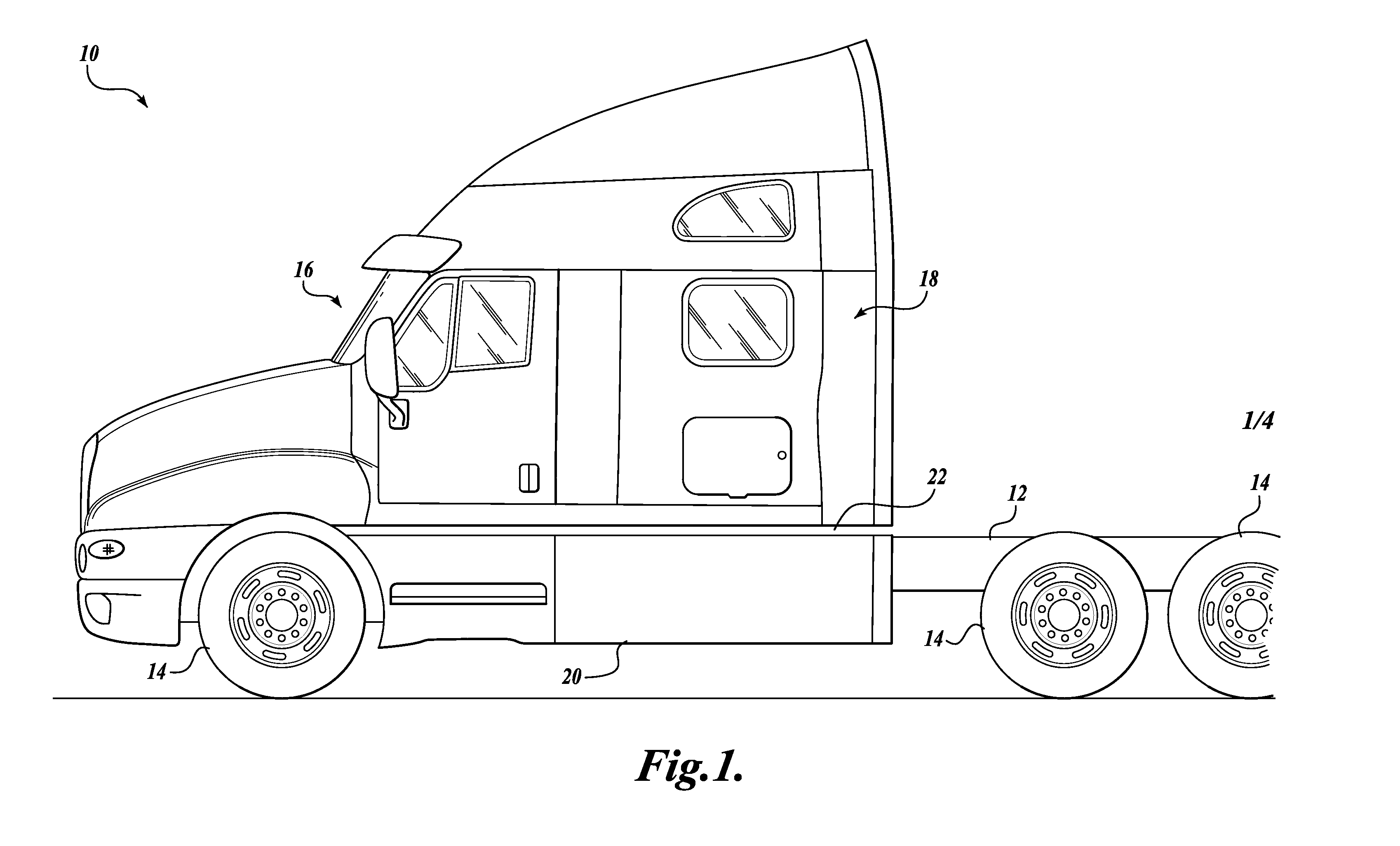

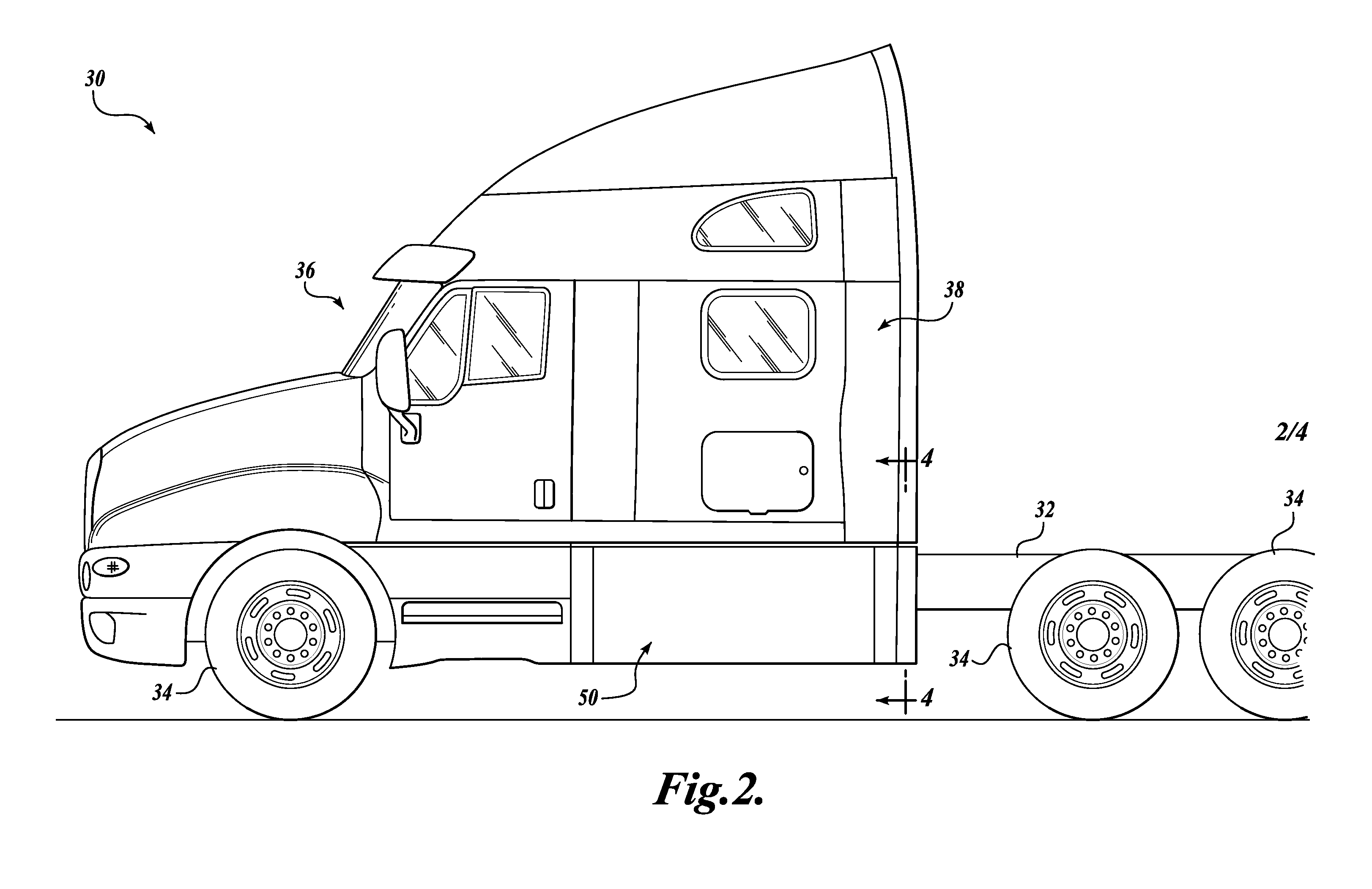

Fairing mounting system

A fairing assembly is suitable for use with a heavy duty vehicle having a cab mounted to a frame, wherein relative motion occurs between the cab and the frame during vehicle operation. The fairing assembly extending downwardly from a lower portion of the cab and includes a fairing panel and a hinge for hingedly connecting an upper portion of the fairing panel to a lower portion of the cab. The hinge defines a hinge line extending in a generally longitudinal direction. The fairing assembly further includes a link having a first end rotatably connected to a lower portion of the fairing panel and a second end rotatably connected to the frame. The link substantially limits rotation of the fairing panel about the hinge line and rotates relative to the fairing panel to allow for relative motion between the frame and the cab.

Owner:PACCAR INC

Nacelle assembly without lower bi-fi splitter

InactiveUS20080258016A1Reduce resistanceImprove performancePower plant arrangements/mountingAircraft power plant componentsNacelleHinge line

A nacelle assembly provides thrust reverser doors and core cowl doors with separate thrust reverser door hinge lines and core cowl doors hinge lines for independent operation to eliminate the requirement of a lower bi-fi splitter. The removal of the lower Bi-Fi splitter provides improved aerodynamic packaging with improved performance by reducing drag in the bypass fan stream.

Owner:UNITED TECH CORP

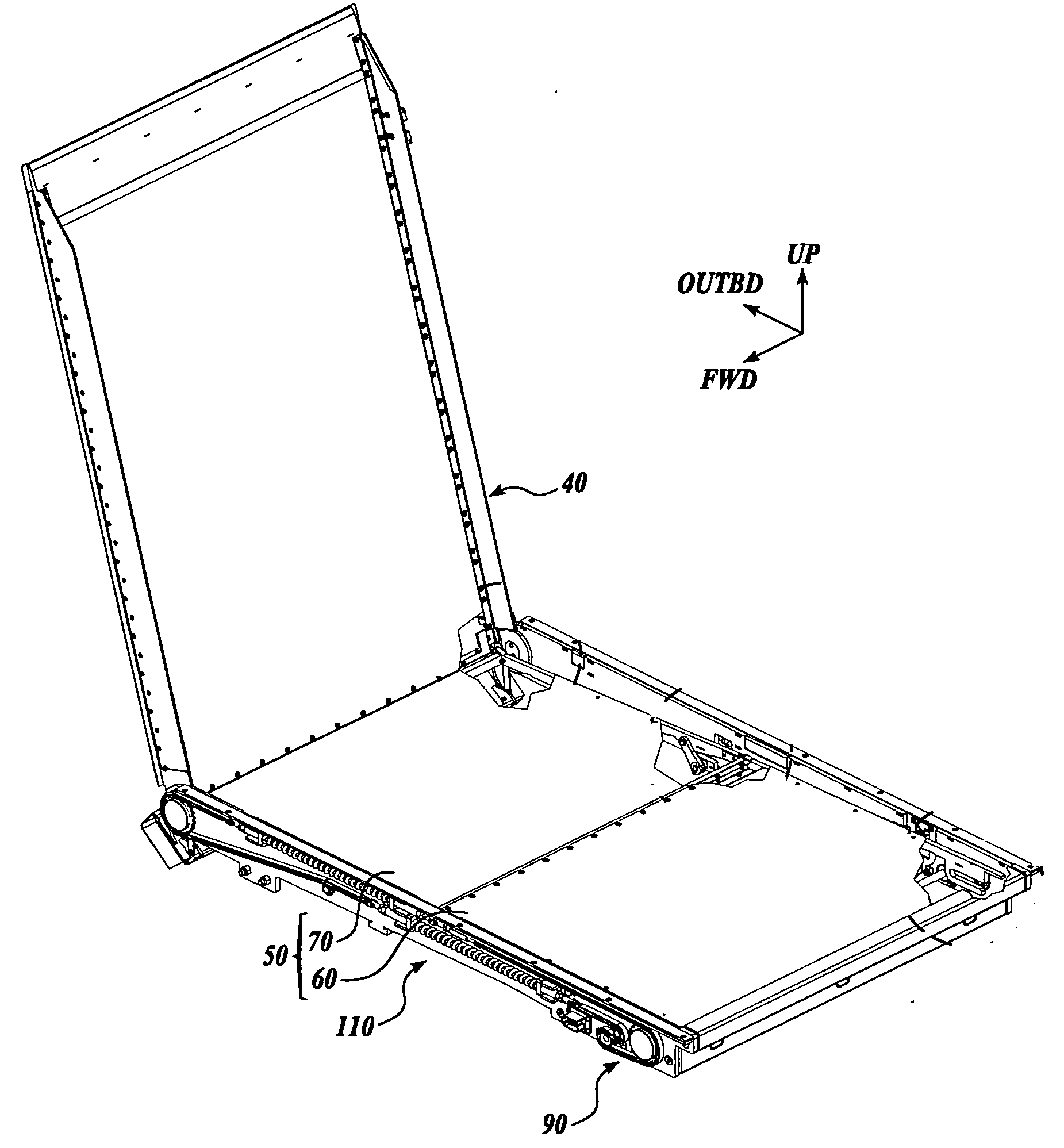

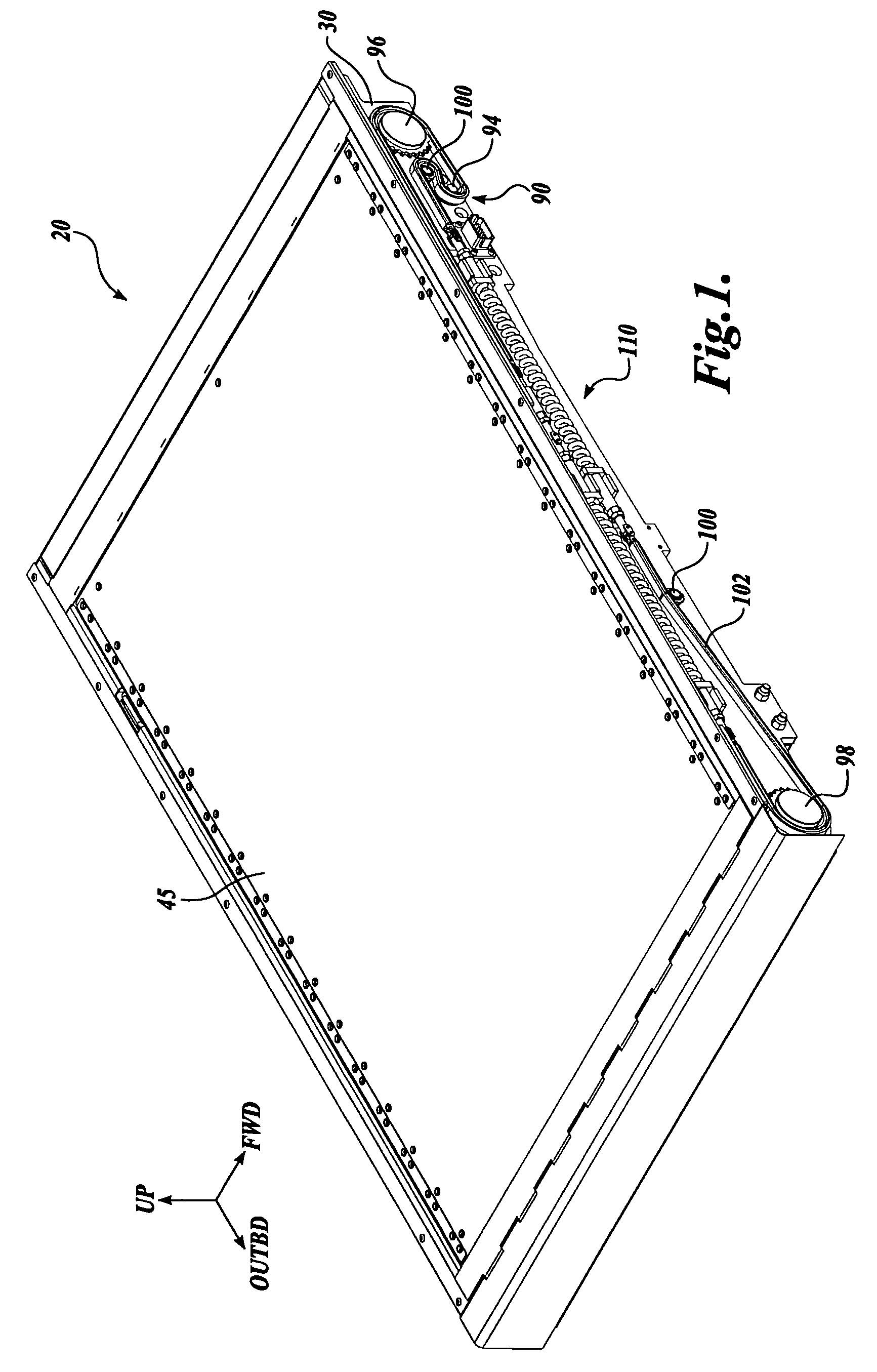

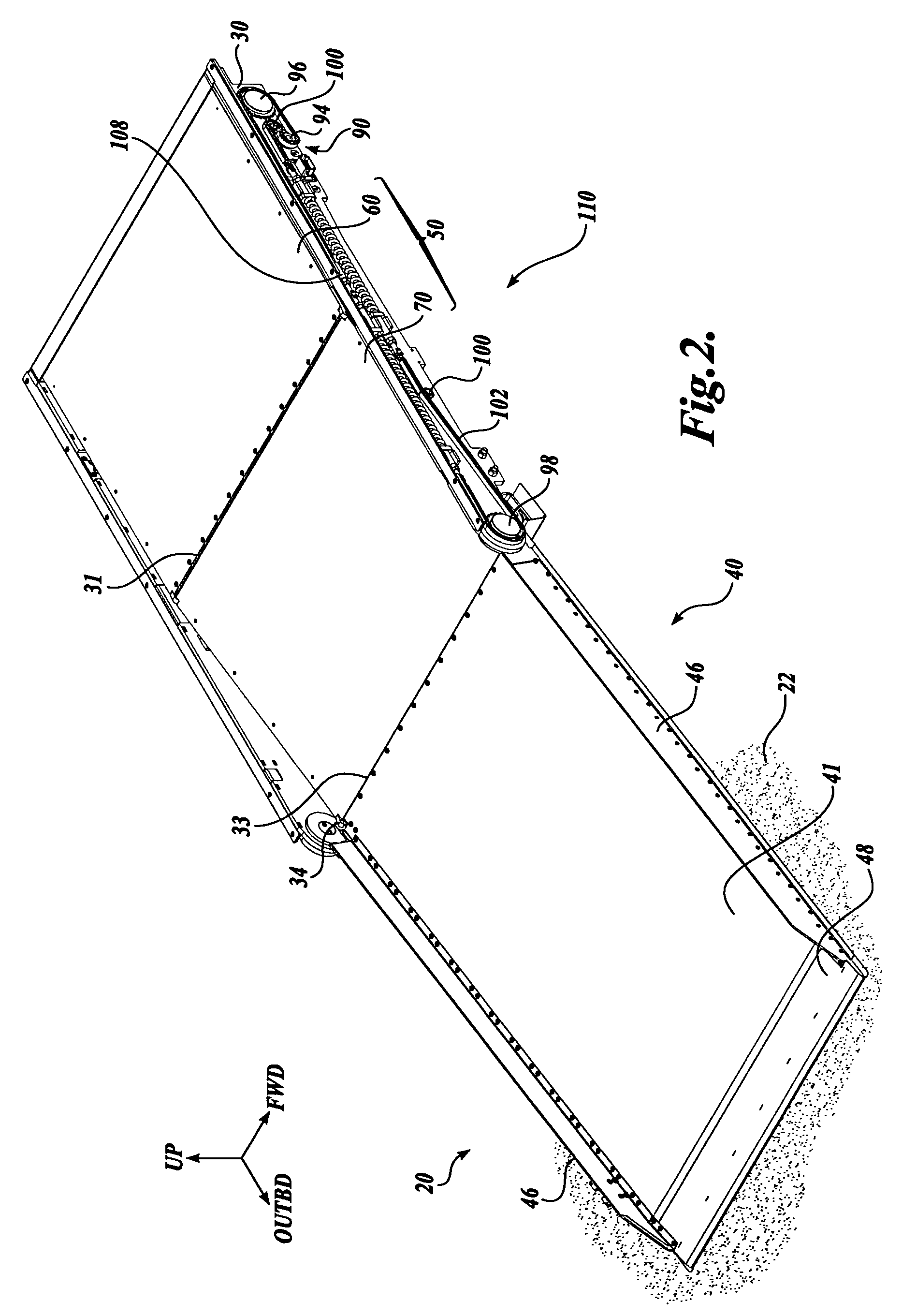

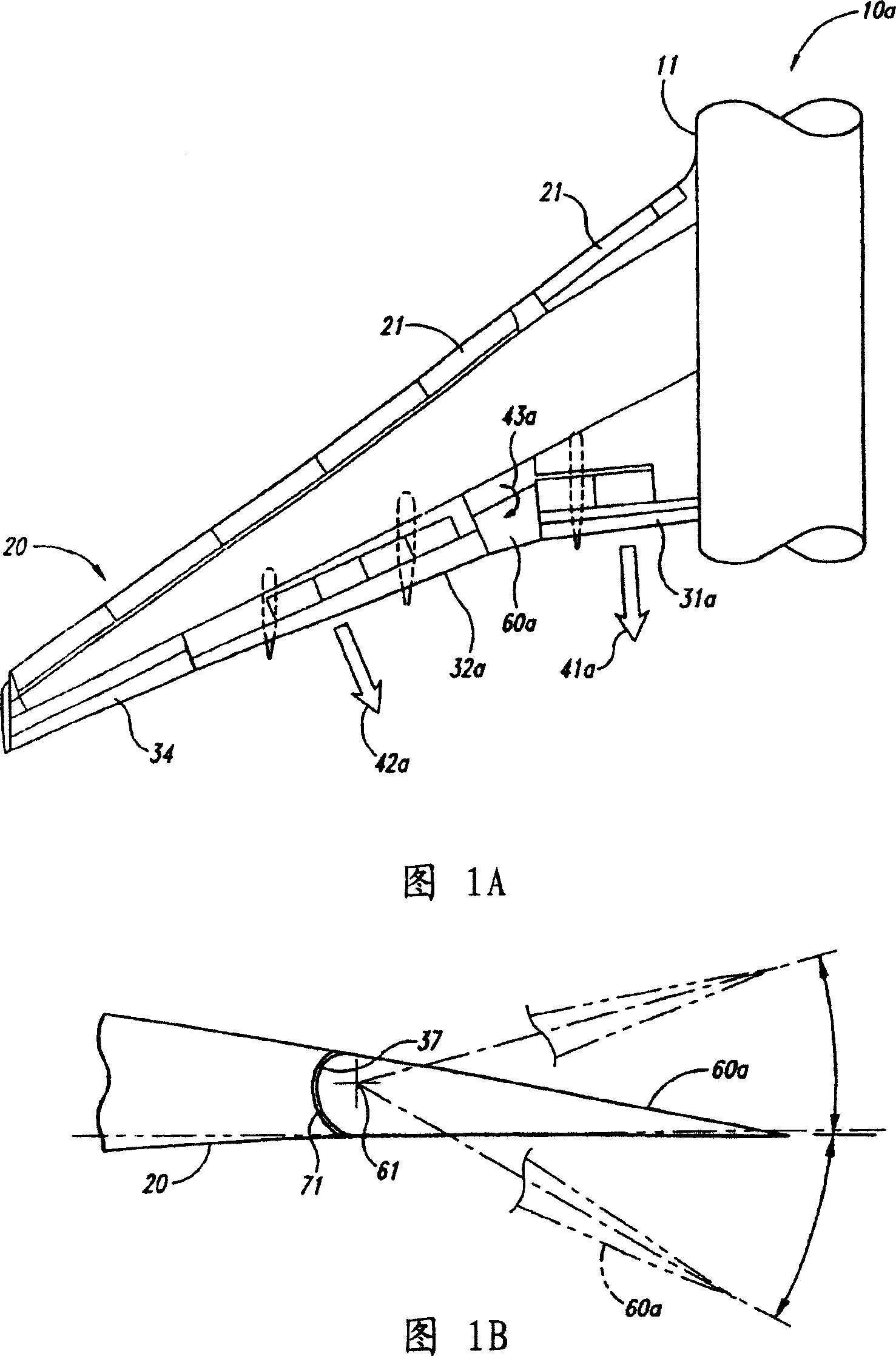

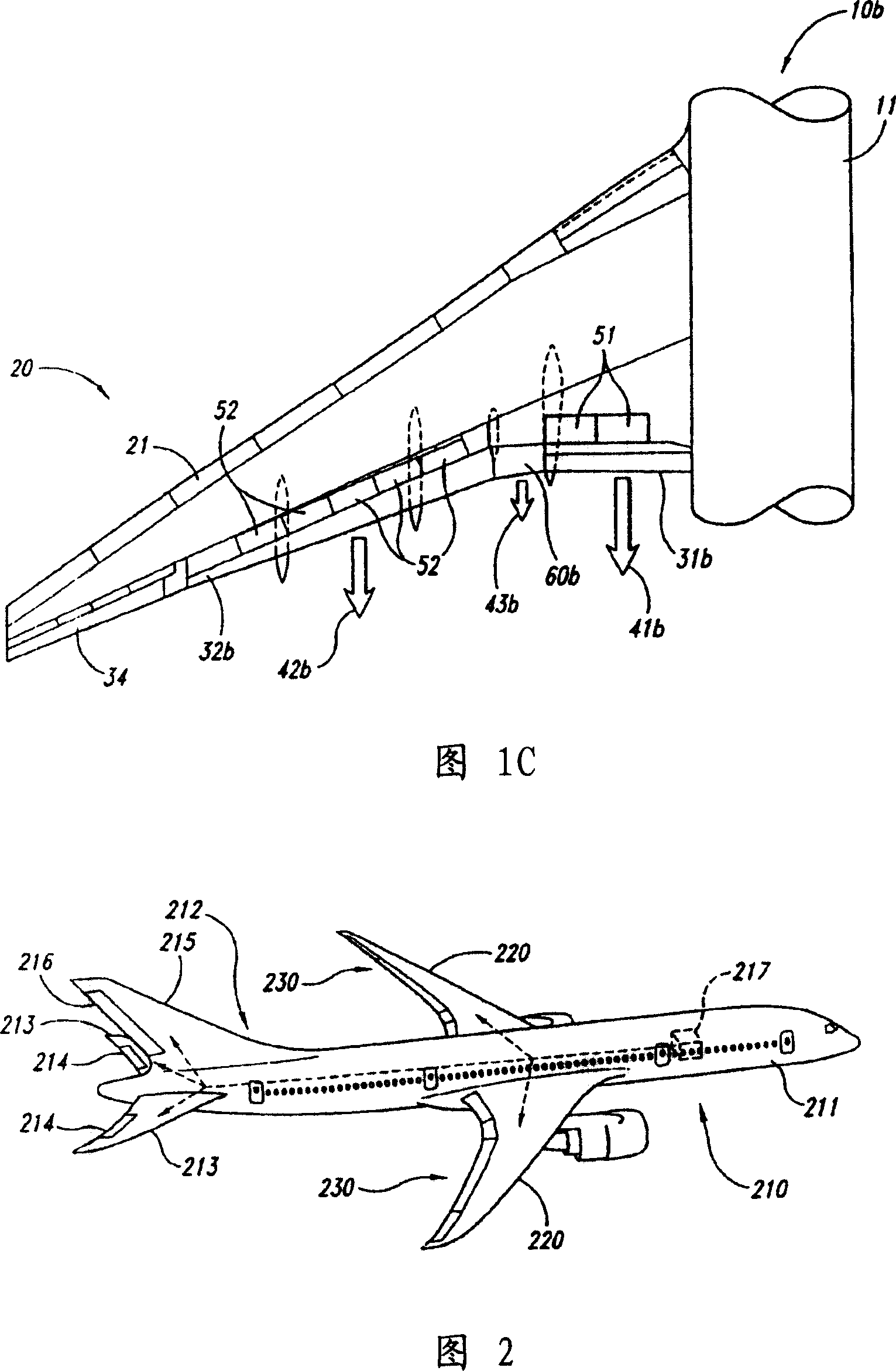

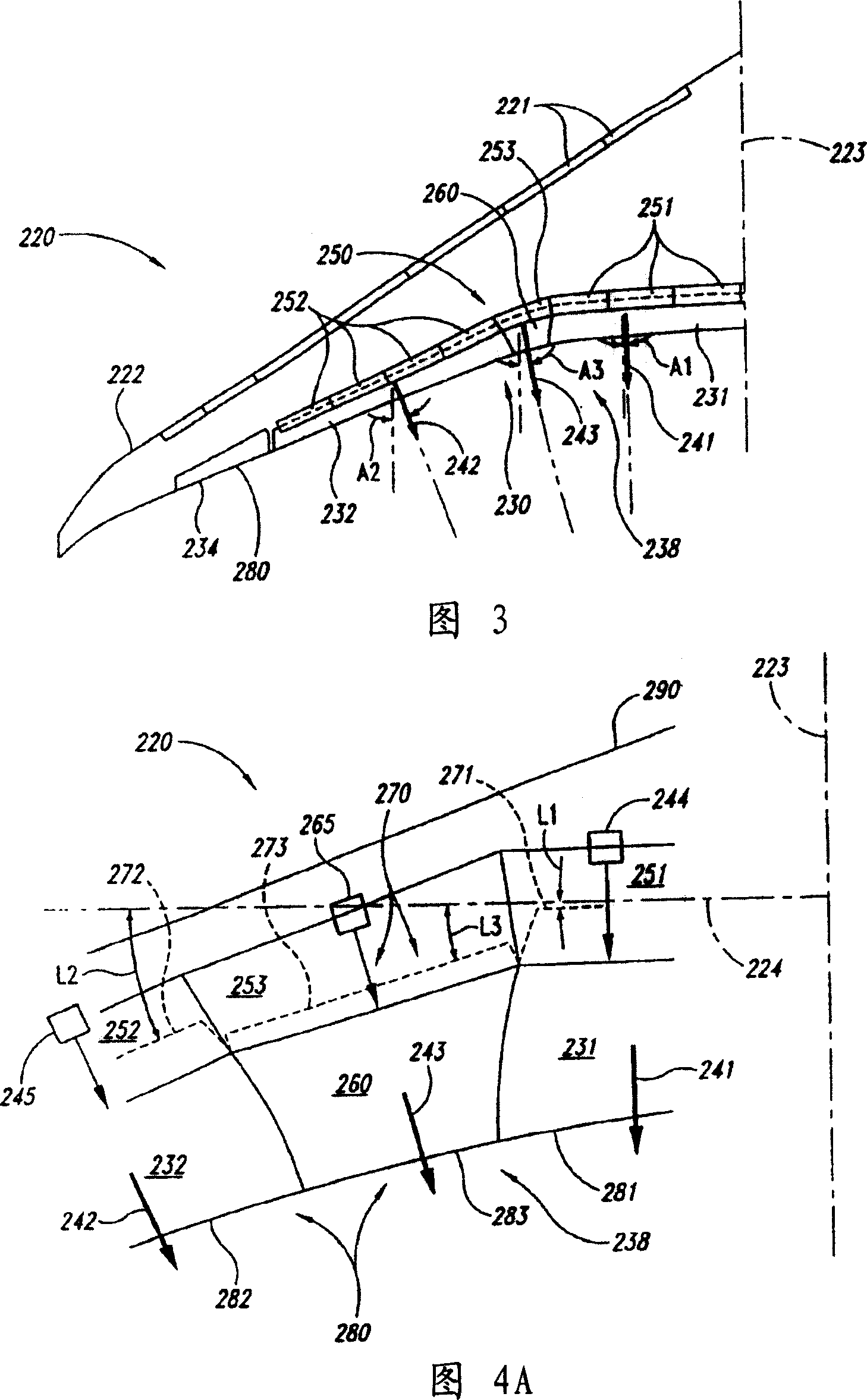

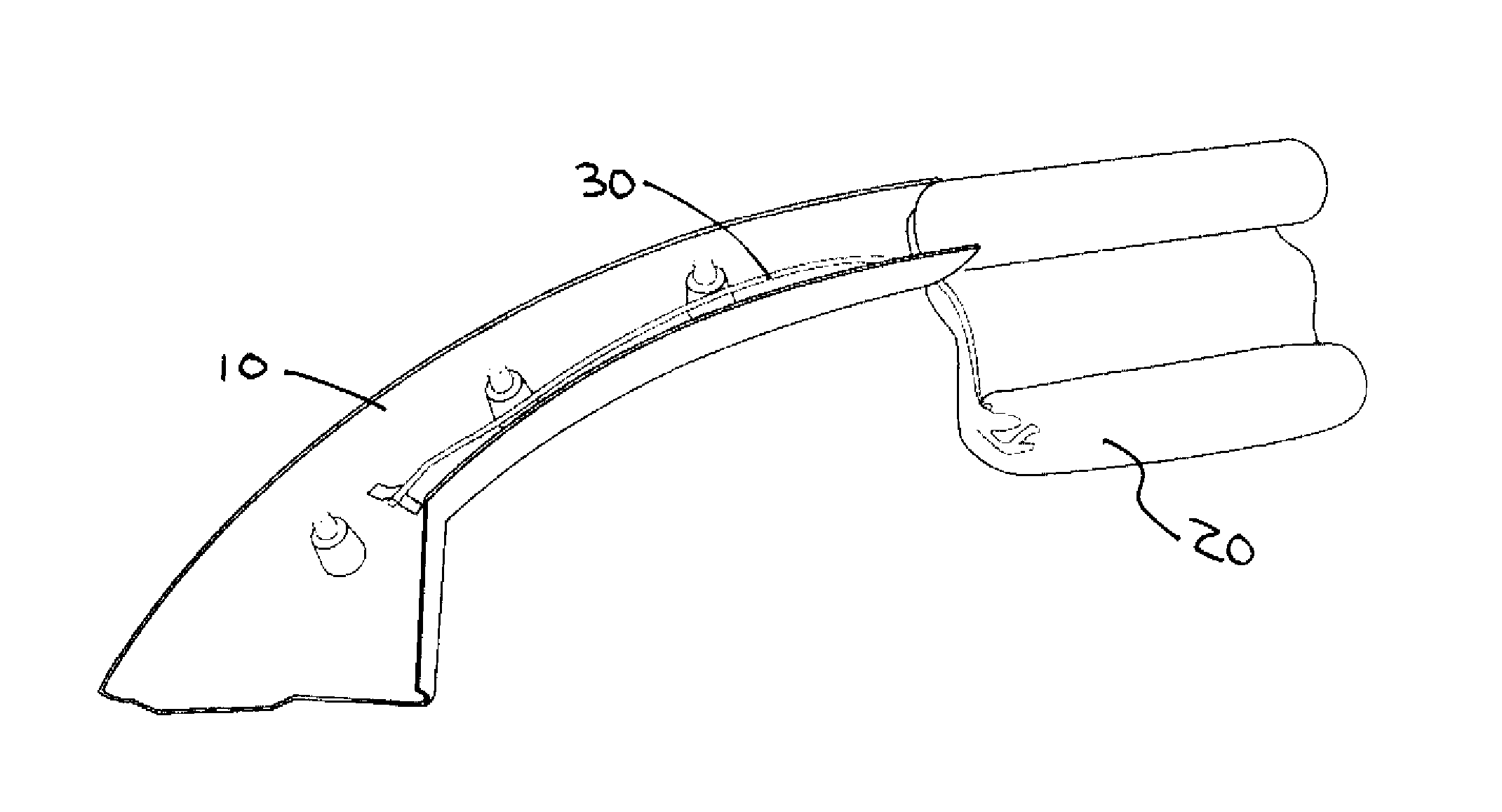

Aircraft trailing edge devices, including devices having forwardly positioned hinge lines, and associated methods

Aircraft trailing edge devices, including devices having forwardly positioned hinge lines, and associated methods are disclosed. An aircraft system in accordance with one embodiment of the invention includes a wing and a trailing edge device coupled to the wing. The trailing edge device can be movable relative to the wing between a stowed position and a deployed position, with the trailing edge device having a leading edge, a trailing edge, an upper surface, and a lower surface. The upper surface can have an intersection point with the wing when the trailing edge device is in the stowed position. The motion of the trailing edge device relative to the wing can include rotational motion about a hinge line positioned forward of the intersection point, and a gap can be positioned between the trailing edge of the wing and the leading edge of the trailing edge device when the trailing edge device is in the deployed position.

Owner:THE BOEING CO

Air Bag Deployment Ramp

InactiveUS20070241542A1Facilitate emergenceDirection easyPedestrian/occupant safety arrangementHinge lineEngineering

A ramp for directing the deployment of an expanding air bag may be formed to extend from a surface of a trim panel. The ramp may comprise one or more projections having a hinge or fold line. After molding of the trim panel, the projection may be folded along the hinge line towards the surface of the panel to form a ramp structure to promote the emergence, direction and / or placement of an expanding air bag. The ramp structure may be formed on any surface of trim panels lying adjacent or over an air bag system.

Owner:COLLINS & AIKMAN PROD CO

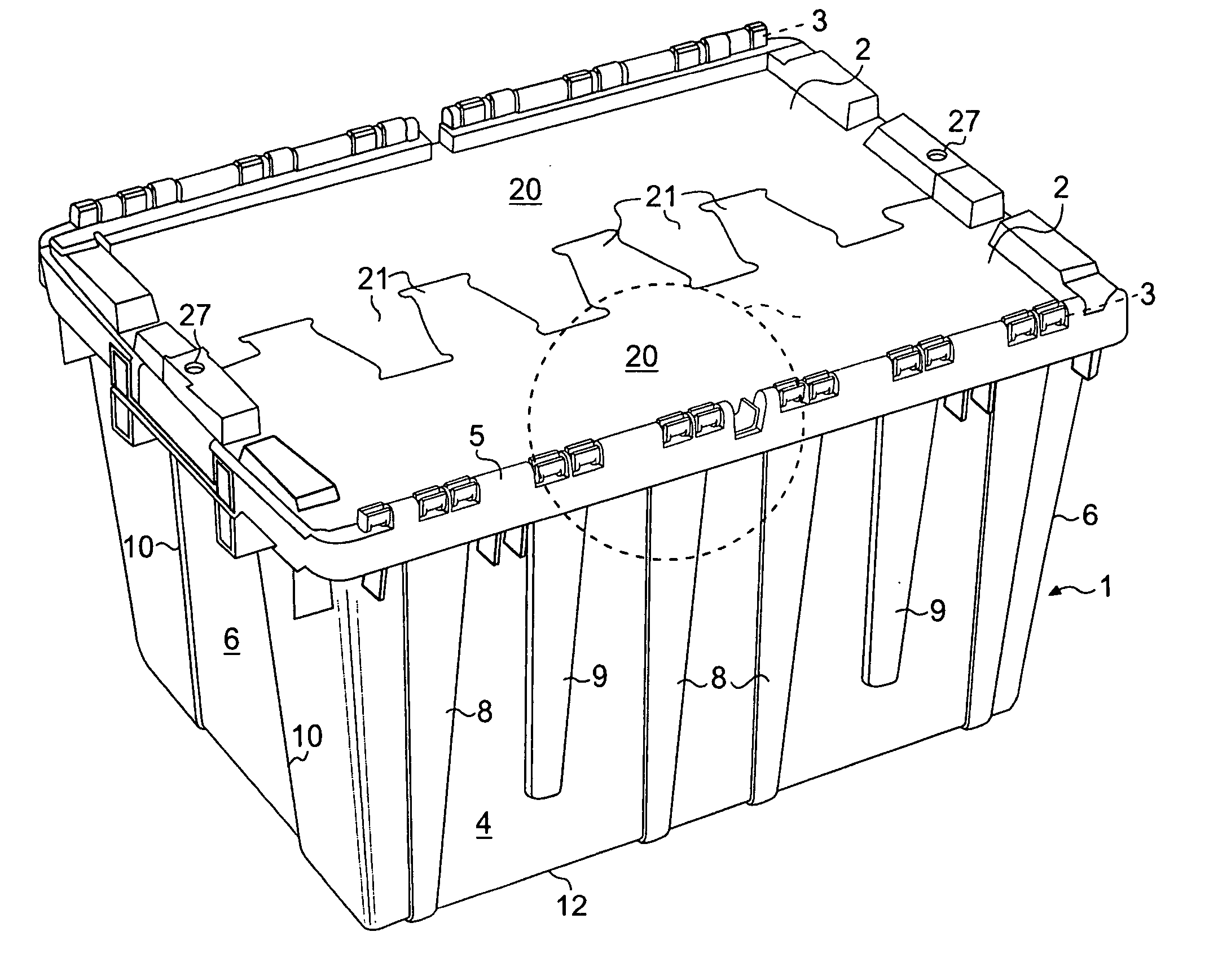

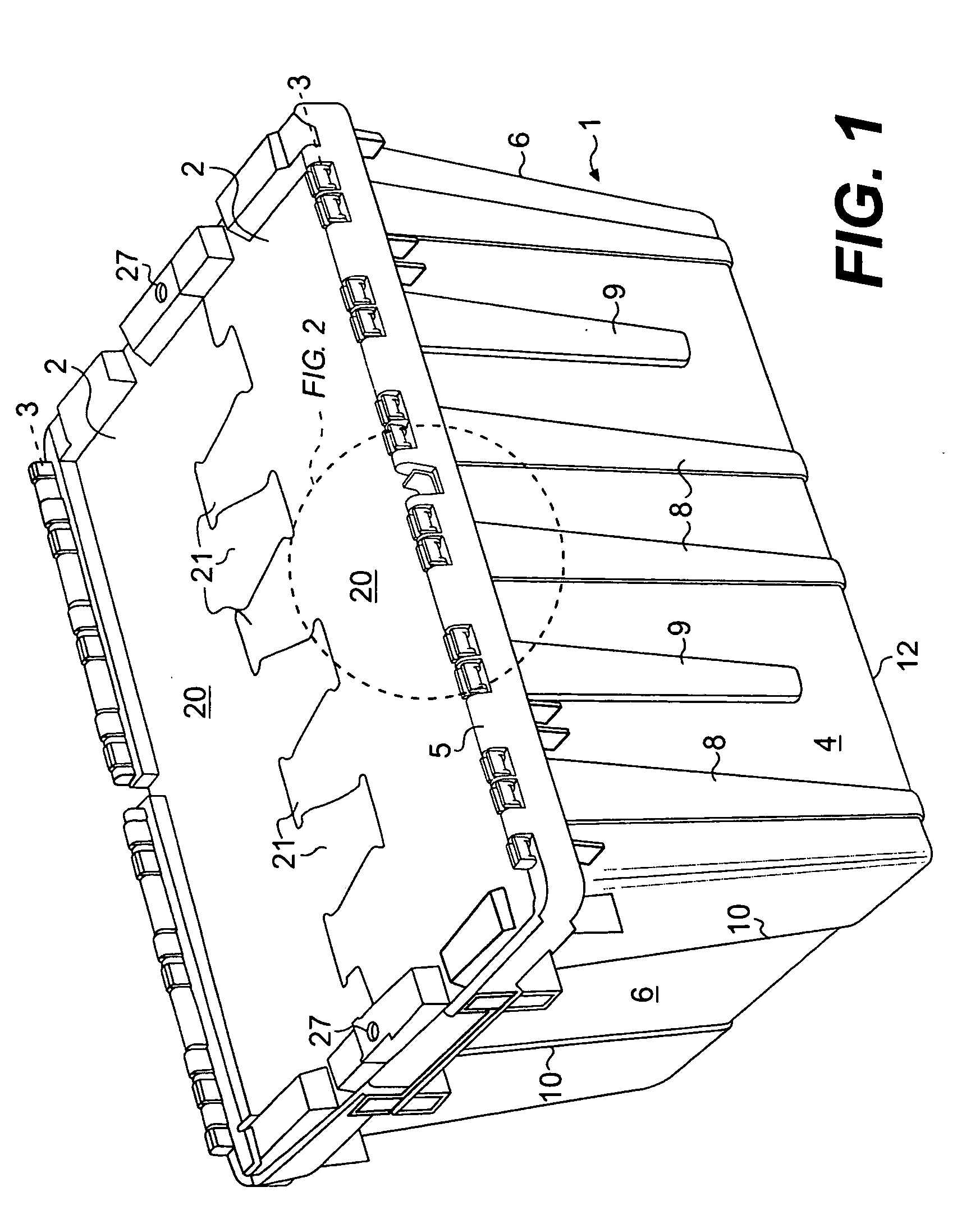

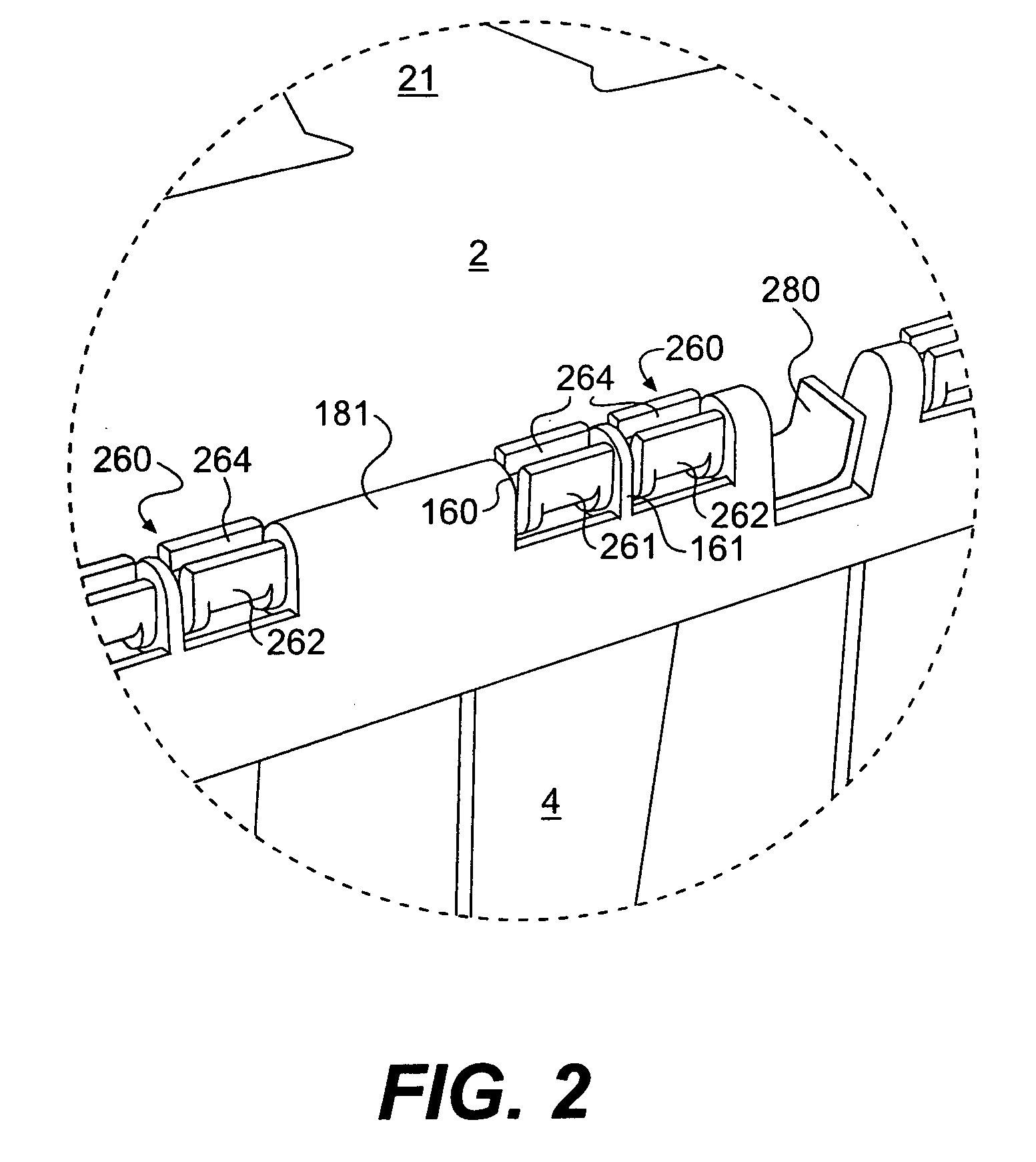

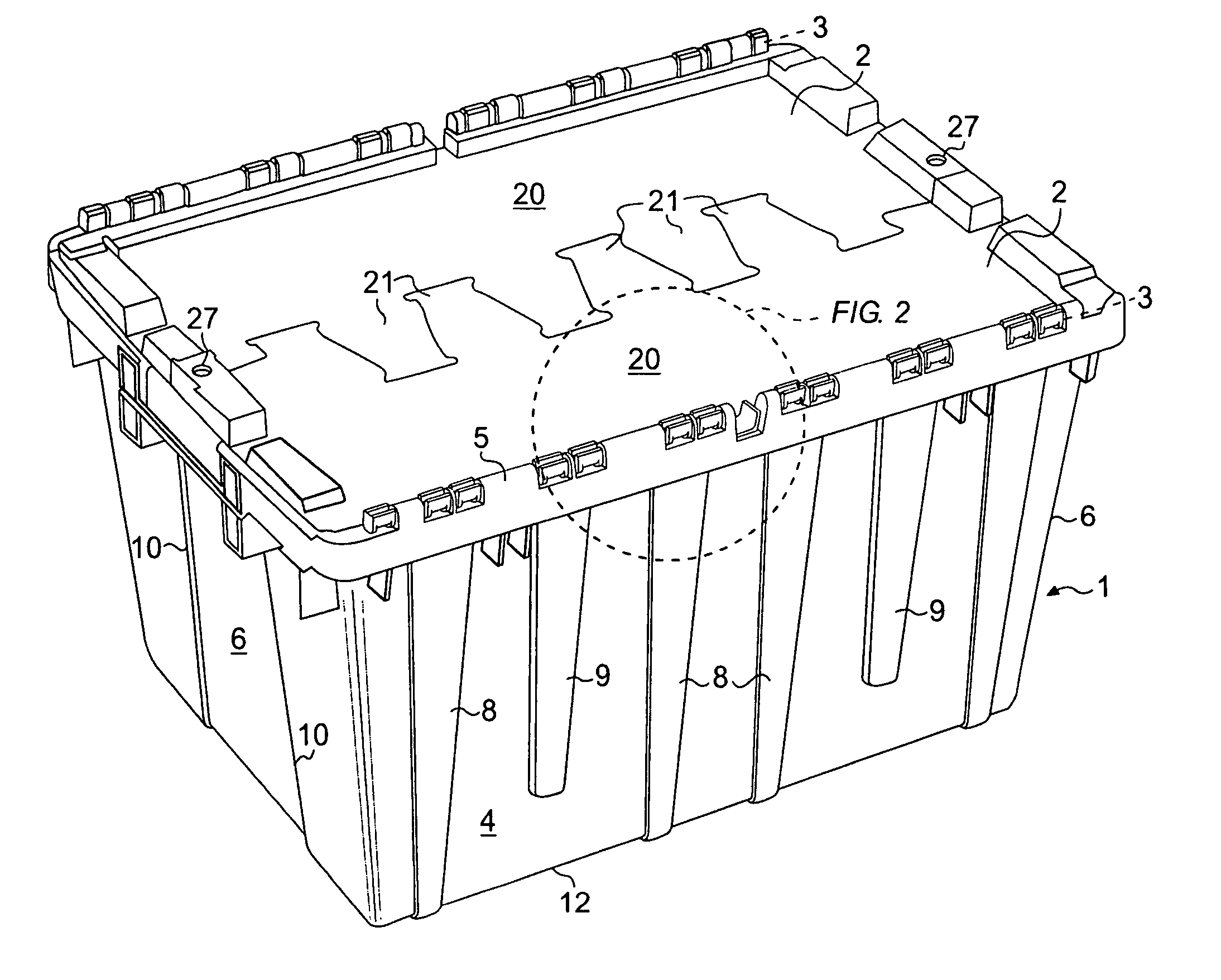

Container with hinged lids and method of molding the container and assembling the hinged lids on the container in the molding process

An attached lid container has lids that are hinged to the top edges of the side walls of the container. When the lids are closed, the free edges of the lids engage one another to form a joint that interlocks the lids together. The lids are attached to the container at the hinge joints after the molding of the container and lids, while the molded parts are still in the mold press. Specifically, the lids are molded next to the container and then moved laterally to be aligned with the hinge line of the container after the mold cavity is withdrawn. Then, the ejectors push the lids out toward the container. The force of the outward movement causes the hinge parts of the lids and container to snap together. Subsequently a robot arm removes the container from the mold press with the hinged lids assembled on the container.

Owner:BUCKHORN +1

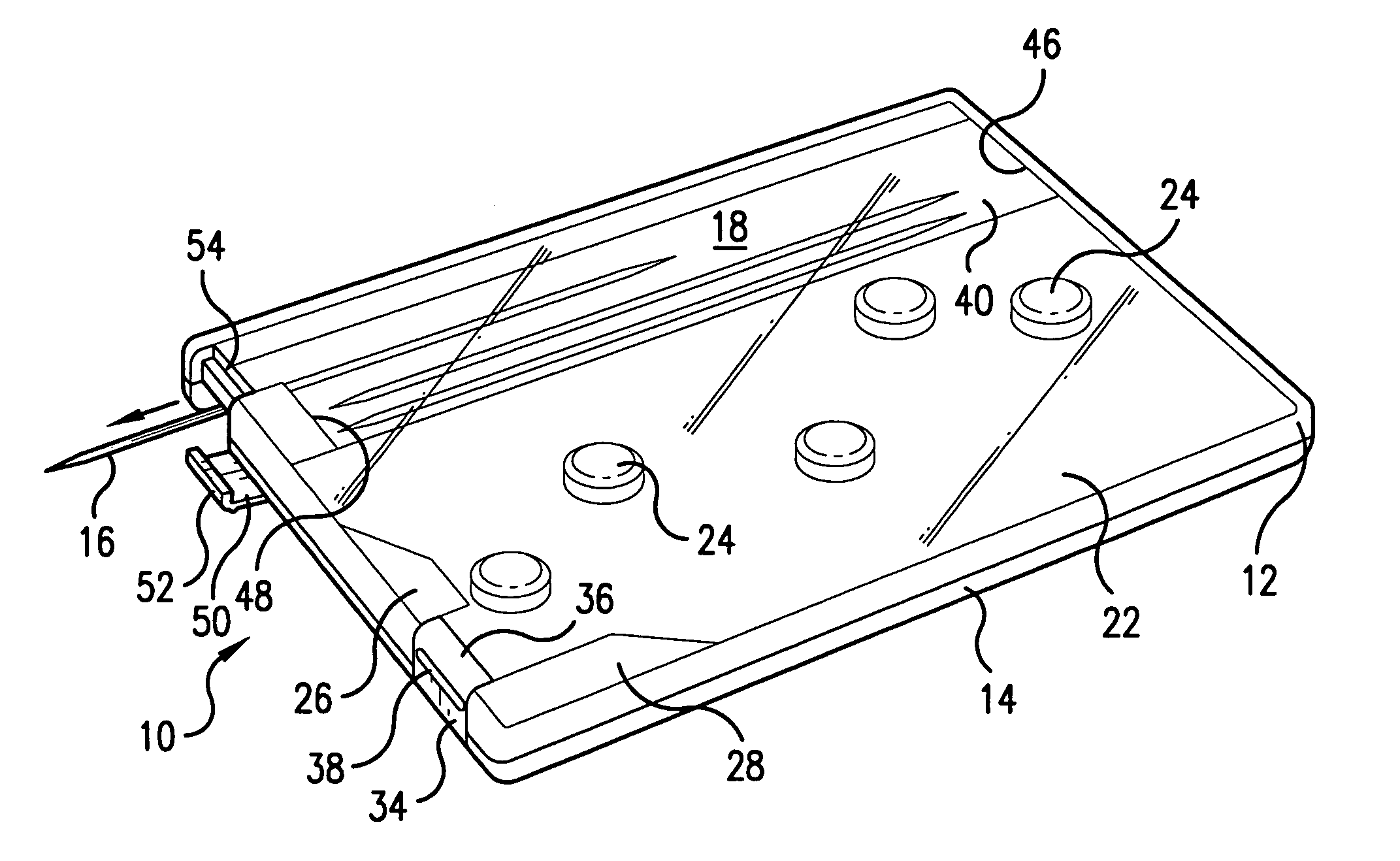

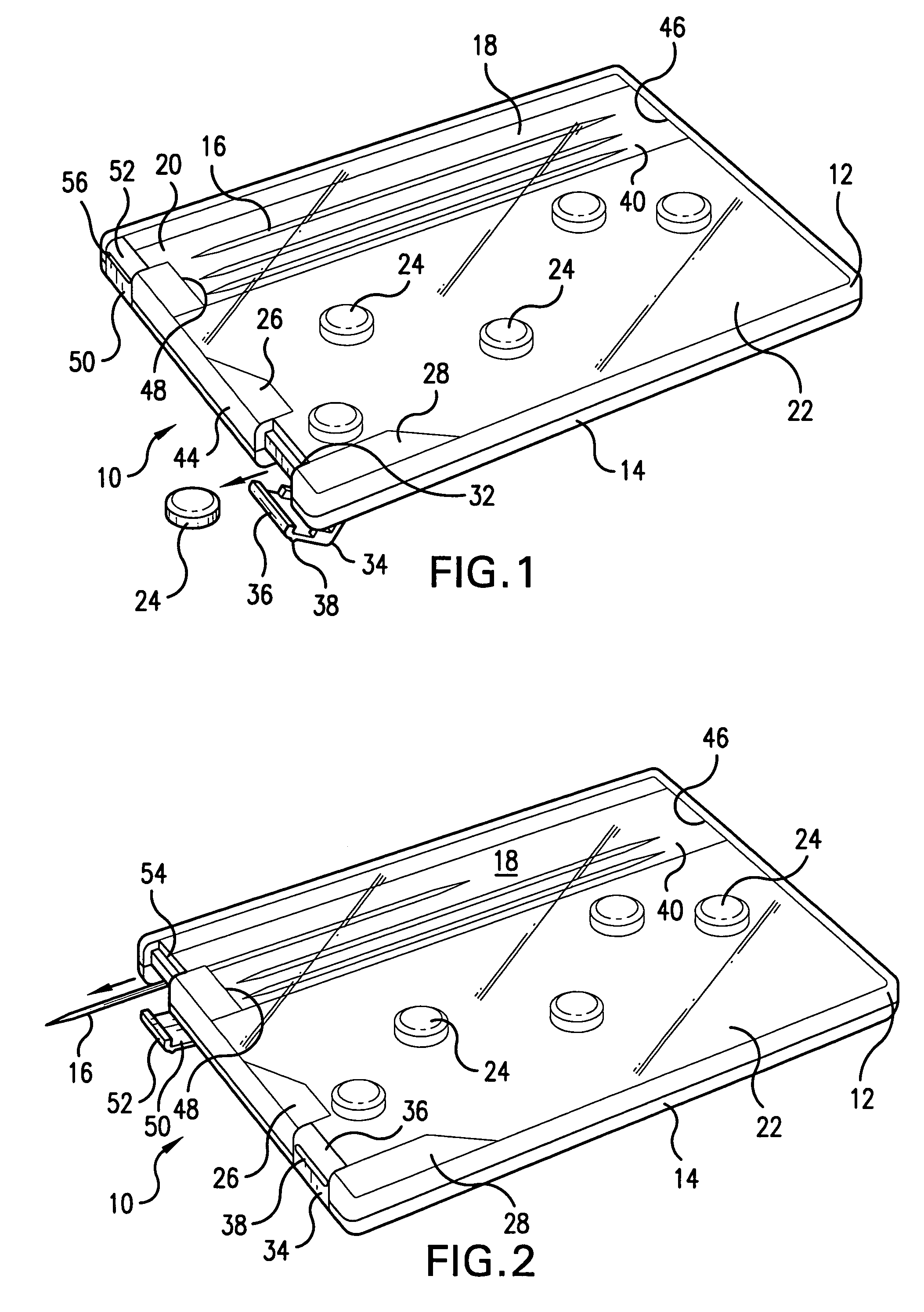

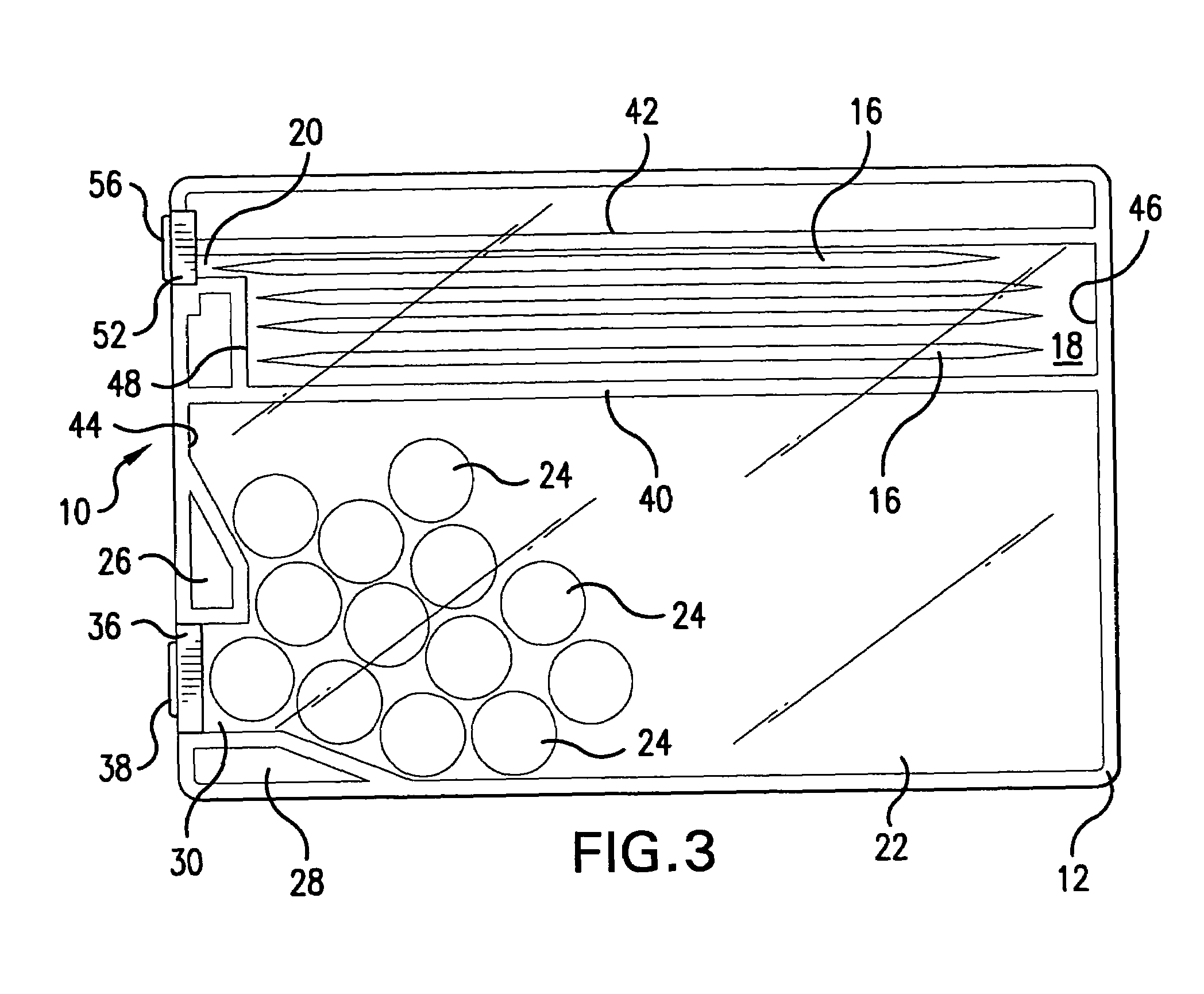

Combined toothpick and mint dispenser

A thin, plastic dispenser for discharging toothpicks, and / or mints through distinct discharge passages in the dispenser. The dispenser has a body comprising a first housing and a second housing that are aligned and snapped together to form the body of the dispenser. A well is defined in the body for storing toothpicks, and a first discharge passage is provided in the well. A larger chamber is defined in the body for storing mints, and a second discharge passage is provided in the chamber. Locking levers, integrally formed with one of the housings, normally seal the discharge passages in the well and the chamber. When the user wishes to discharge a toothpick and / or mint, the manually engages a locking lever and pivots same about its hinge line to expose the adjacent discharge passage. The contents of the well and / or chamber can then be discharged, through the exposed discharge passages vacated by the movement of the locking lever. Guides, ramps, and abutments in the well and chamber limit the width of the discharge passages and insure that the toothpicks are mints are discharged, one at a time, when the dispenser is tilted.

Owner:COHEN HARRIS

Molded container with hinged lids having a knuckle and pin connection

A container having a bottom and two pairs of opposed walls connected together to form a container body having an open top covered by a pair of hinged lids. The upper edges of one pair of opposed walls have a plurality of pin segments formed thereon along a hinge line and an edge of each of the lids has a plurality of generally U-shaped knuckles formed thereon along the hinge line with each knuckle having opposed sidewalls forming a slot having an opening at one end and a bearing portion at an opposite end which opens upwardly with respect to a top surface of the lid. The opposed sidewalls of the slot of each knuckle have ribs protruding inwardly to retain a corresponding pin segment of the container body. When the lids are connected to the container body and rotated to a closed position, the slots of each knuckle face upwardly in a direction away from the top surface of the lid.

Owner:BUCKHORN +1

Lightweight combined folder and variable position display/book stand

InactiveUS7537192B2Effective document support toolEasy to transportHanging devicesPicture framesHinge lineEngineering

A multi-purpose portfolio formed from a sheet of rigid card with transverse hinged lines dividing the card into a number of panels that may be completely folded into its closed or carrying position, partially unfolded to access pen, pad, and the likes, and fully erectable for use as a podium, book holder or display stand. The major front panel and major back panel are secured together at their upper edges by a hinge line, and each has a narrow panel hinged along its bottom edge. In its fully erect position, the major front panel is inclined to hold books. Each panel has a hinge line along its bottom edge that secures a narrow panel.

Owner:AL HALEEM ABDEL KHALID +1

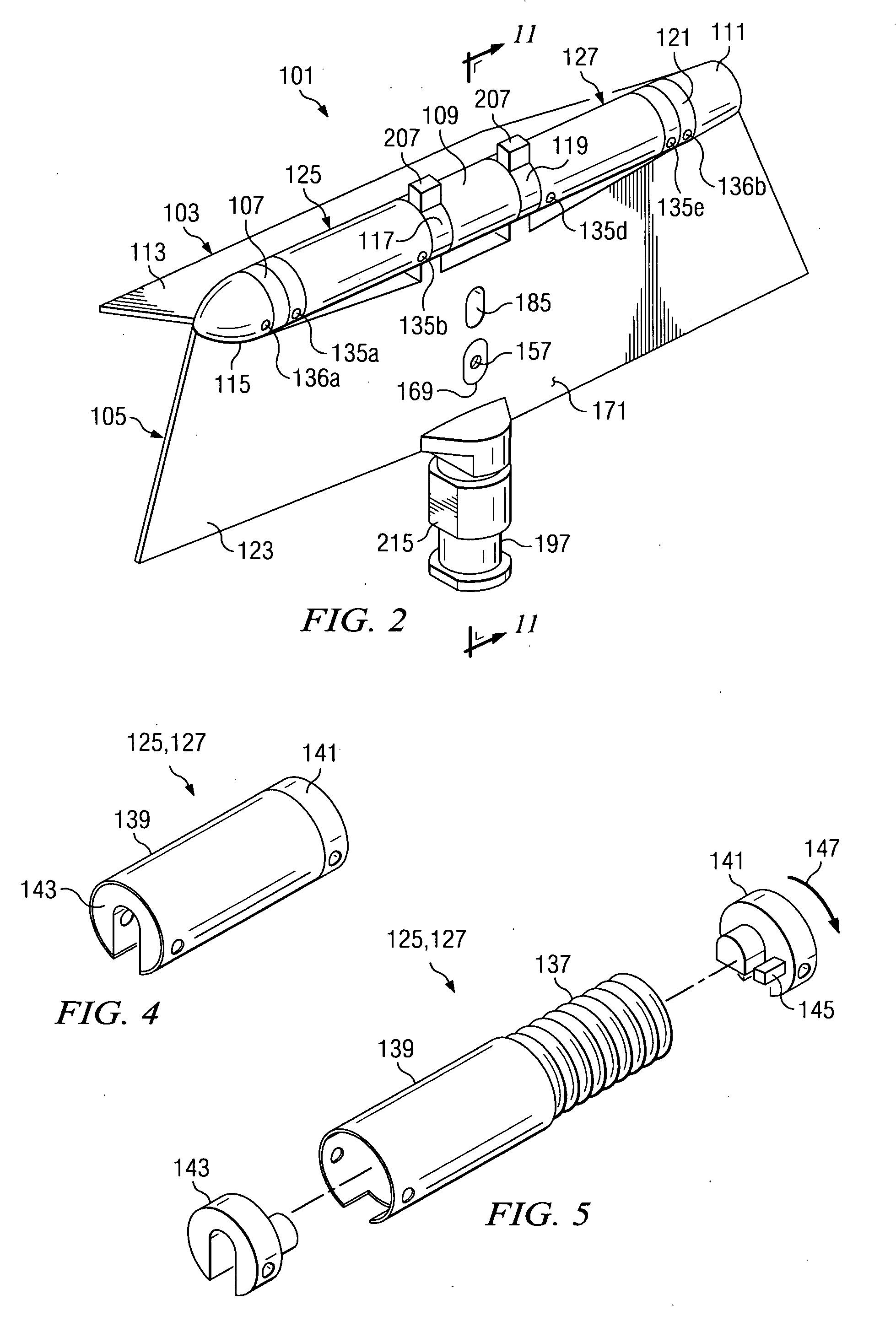

Servo mounting system for direct drive of an aircraft control surface

InactiveUS7229046B2Improve reliabilityConserve rotational motionAircraft stabilisationWith power amplificationHinge lineEngineering

This invention is a servo mounting system, which allows a servo with a rotating output shaft to directly power an aircraft control surface. A specially designed servo mount securely positions the servo with the central axis of its rotational output shaft on, and axially aligned with, the hinge line of the control surface it drives. The servo shaft and servo body are directly connected to the airframe and control surface, thereby conserving rotational motion while driving control movement. Electronic means are then used to control the neutral point and the limit of travel of the servo. The system eliminates lost motion without generating adverse linear loads within the drive assembly.

Owner:DURANT JOHN

Servo Mounting System for Direct Drive of an Aircraft Control Surface

InactiveUS20070102588A1Improve reliabilityConserve rotational motionAircraft stabilisationWith power amplificationFlight vehicleHinge line

This invention is a servo mounting system, which allows a servo with a rotating output shaft to directly power an aircraft control surface. A specially designed servo mount securely positions the servo with the central axis of its rotational output shaft on, and axially aligned with, the hinge line of the control surface it drives. The servo shaft and servo body are directly connected to the airframe and control surface, thereby conserving rotational motion while driving control movement. Electronic means are then used to control the neutral point and the limit of travel of the servo. The system eliminates lost motion without generating adverse linear loads within the drive assembly.

Owner:DURANT JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com