Steam-type sludge drying machine

A sludge drying and steam technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of underutilization of high temperature, increased energy consumption of exhaust gas treatment, large exhaust gas emission, etc., to improve energy-saving effect, The effect of improving efficiency and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

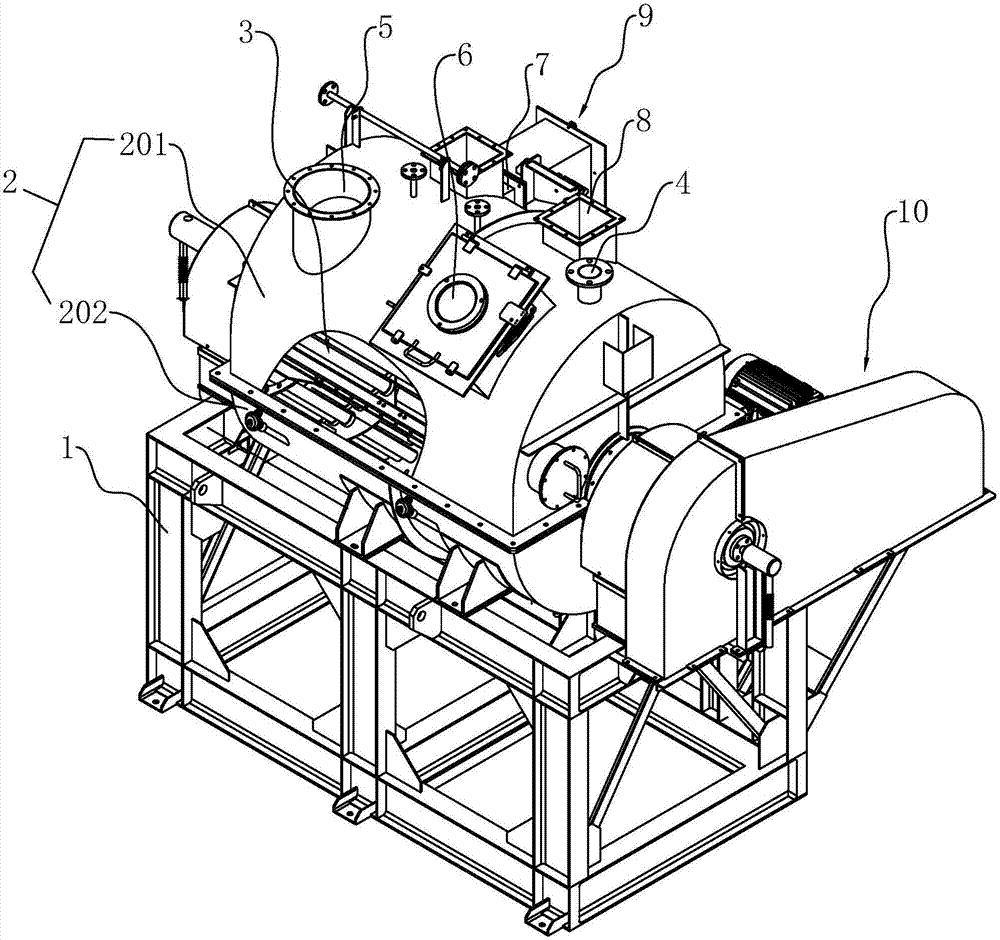

[0048] See attached figure 1 , a steam sludge dryer, mainly used for drying municipal or industrial sludge, which includes a frame 1, a fixed cylinder 2 arranged on the frame 1 and a heating assembly 3 arranged in the fixed cylinder 2 ; During work, the sludge is fully heated by the heating component 3 in the fixed cylinder 2, so that the moisture in the wet sludge continues to evaporate, and the sludge is dried.

[0049] The fixed cylinder 2 includes two parts, the upper cylinder 201 and the lower cylinder 202. The lower cylinder 202 is fixedly connected with the frame 1 by bolts, while the upper cylinder 201 and the lower cylinder 202 are fixedly connected by bolts. In the cavity where the above-mentioned heating element 3 is installed.

[0050] Both sides of the upper side of the upper cylinder 201 in the longitudinal direction are respectively provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com