UHMWPE sheet material manufacturing method

A manufacturing method and sheet technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the difficult problems of uniform fiber height arrangement, prepreg thickness uniformity control, fiber spreading uniformity to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The manufacturing method of the UHMWPE sheet of this embodiment includes the following steps: unwinding the commercially available ultra-high molecular weight polyethylene fiber 800D / 840F (strength 36cN / dtex, modulus 1300cN / dtex) successively through the creel, clustering frame, stretching Reed arrangement, and then use the spreading equipment to spread the thread arrangement, and then glue the spread fiber bundle through the dipping tank. In this embodiment, polyurethane emulsion adhesive is used, and the glue amount is about 30%. It is dried at 65°C in a hot shaft, and finally wound up by a winding device.

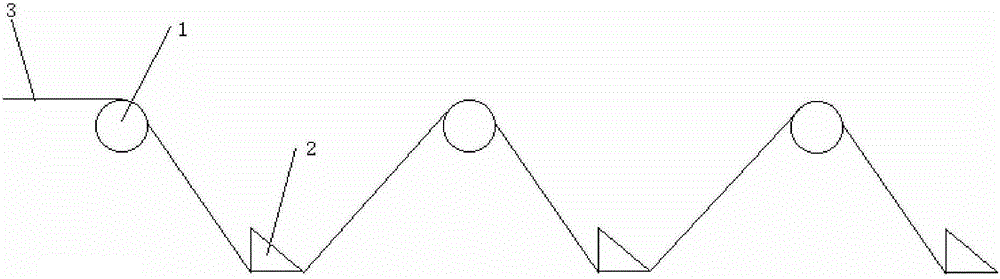

[0041] The spinning equipment used in this embodiment is as figure 1As shown, it includes four spreading units arranged at intervals, and each spreading unit includes a first spreading member—a spreading roller 1, a second spreading member—a spreading beam 2 located downstream of the first spreading member , wherein the spreading roller 1 is cylindrical with a di...

Embodiment 2

[0046] The manufacturing method of the UHMWPE sheet of the present embodiment comprises the following steps: unwinding the commercially available ultra-high molecular weight polyethylene fiber 400D / 400F (strength 37cN / dtex, modulus 1350cN / dtex) successively on the creel, clustering on the cluster frame, stretching Reed arrangement, and then use the spreading equipment to spread the thread arrangement, and then glue the spread fiber bundle through the dipping tank. In this embodiment, polyurethane emulsion adhesive is used, and the glue amount is about 25%. Dry at 70°C through a hot shaft, and finally wind up through a winding device.

[0047] The spinning equipment in this embodiment is as figure 2 As shown, different from Embodiment 1, in this embodiment, each spreading unit is provided with two first spreading members with different diameters—the spreading roller 1, and the diameter of the spreading roller 1 located downstream is 50mm, the diameter of the spreading roller ...

Embodiment 3

[0052] The manufacturing method of the UHMWPE sheet of the present embodiment comprises the following steps: unwinding the commercially available ultra-high molecular weight polyethylene fiber 800D / 360F (strength 38cN / dtex, modulus 1450cN / dtex) successively on the creel, clustering on the cluster frame, stretching Reed arrangement, and then use the spreading equipment to spread the thread arrangement, and then glue the spread fiber bundle through the dipping tank. In this embodiment, polyurethane emulsion adhesive is used, and the glue amount is about 22%. Dry at 68°C in a hot shaft, and finally wind up with a winding device.

[0053] The spinning equipment in this embodiment is as image 3 As shown, different from Embodiment 1, the spreading beam 2 in this embodiment is a triangular prism with a side length of 95 mm in cross section, and the diameter of the spreading roller is 94 mm. same.

[0054] In this embodiment, during spinning, the rotational speeds of the first spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com