Low-temperature combustion catalyst for eliminating diesel engine carbon black

A low-temperature combustion and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. problem, to achieve the effect of simple preparation method, easy industrialization and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

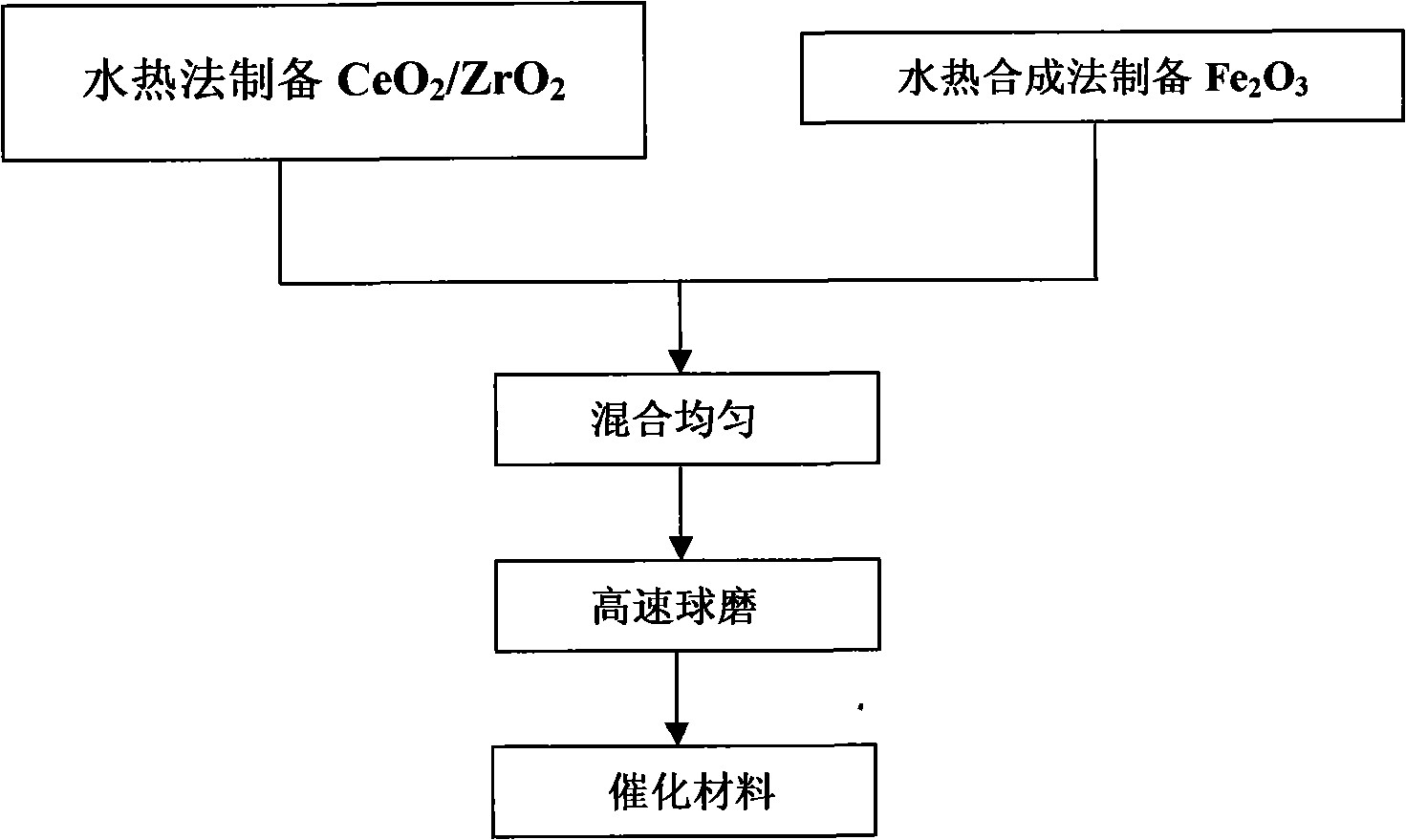

Image

Examples

Embodiment 1

[0020] Embodiment 1: the molar ratio is that Ce, Fe nitrate of 5: 5 are formulated into the solution that total concentration is 0.2mol / L, then add appropriate amount of H 2 o 2 , mix evenly. The mixed solution was dropped into 5mol / L ammonia water at a speed of 3ml / min to obtain a precipitate. Continue to stir for 30 min after the precipitation is complete. After aging for 60 minutes, the resulting slurry was moved into a high-pressure reactor (filling degree: 65%), and kept at 200° C. for 48 hours. The obtained product is washed with water, washed with alcohol and dried to obtain a cerium-iron composite oxide catalyst. The light-off temperature (T i ) is 257℃, the peak temperature (T p ) is 324°C, and the average selectivity of carbon dioxide is 98.6%. After calcination at 600℃ and 800℃ for 10h, i and T p They are 293°C and 380°C respectively, and the average selectivity of carbon dioxide is 97.8%.

Embodiment 2

[0021] Example 2: The nitrates of Ce and Fe are respectively prepared into a salt solution with a concentration of 0.25mol / L, and then an appropriate amount of H 2 o 2 , mix evenly. The mixed solution was dropped into 6M ammonia water at a speed of 5 ml / min to obtain a precipitate. Continue stirring for 60 min after the precipitation is complete. After aging for 60 minutes, the resulting slurry was moved into a high-pressure reactor (filling degree: 65%), and kept at 220° C. for 48 hours. The resulting product was washed with water, washed with alcohol, and dried to obtain pure CeO 2 and Fe 2 o 3 powder. According to the molar ratio of Ce and Fe is 5:5, the CeO 2 and Fe 2 o 3 Mix evenly, and after high-speed ball milling for 30 minutes, a cerium-iron composite oxide catalyst is obtained. The light-off temperature (T i ) is 273℃, the peak temperature (T p ) is 323°C, and the average selectivity of carbon dioxide is 98.9%. After calcination at 800℃ for 20h, T i and...

Embodiment 3

[0022] Embodiment 3: the mol ratio is that Ce, Fe, Zr nitrate of 0.5: 0.35: 0.15 are mixed with the solution that total concentration is 0.25mol / L, then add appropriate amount of H 2 o 2 , mix evenly. The mixed solution was dropped into 5M ammonia water at a speed of 5 ml / min to obtain a precipitate. Continue stirring for 60 min after the precipitation is complete. After aging for 90 minutes, the resulting slurry was moved into a high-pressure reactor (filling degree: 60%), and kept at 220° C. for 48 hours. The obtained product is washed with water, washed with alcohol and dried to obtain a cerium-iron-zirconium composite oxide catalyst. The light-off temperature (T i ) is 257℃, the peak temperature (T p ) is 318°C, and the average selectivity of carbon dioxide is 99.8%. After calcination at 800℃ for 20h, the activity of the catalyst is still high, T i and T p They are 276°C and 373°C respectively, and the average selectivity of carbon dioxide is 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com