Preparation of Mn-base metal oxide catalyst through H2O2 quick reduction method and application of Mn-base metal oxide catalyst to volatile organic chemicals (VOCs) low-temperature catalytic combustion

A low-temperature catalysis, H2O2 technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst activation/preparation, etc., can solve high hydrothermal temperature, waste water and residue, long reaction cycle etc. to achieve high catalytic activity, good adsorption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

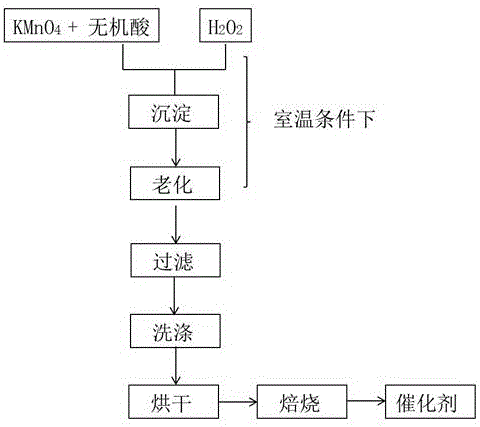

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 2 g of KMnO 4 and 0.8 g of 98% H 2 SO 4 Dissolved in 100 mL of deionized water to form a deep purple aqueous solution 1, in which KMnO 4 The concentration is about 0.02 g / mL;

[0029] (2) Mix 2 mL of analytically pure (30%) H 2 o 2 Dilute to solution 2 with 100 mL deionized water;

[0030] (3) At room temperature with rapid stirring, solution 2 was added dropwise to solution 1 to form a large amount of precipitate accompanied by a large amount of O 2 generate;

[0031] (4) Leave the precipitate to age overnight, filter and wash with water for 3-5 times;

[0032] (5) at 110 o C drying overnight, roasting in air to 400 o C and keep for 2 h, you can get MnO x catalyst powder;

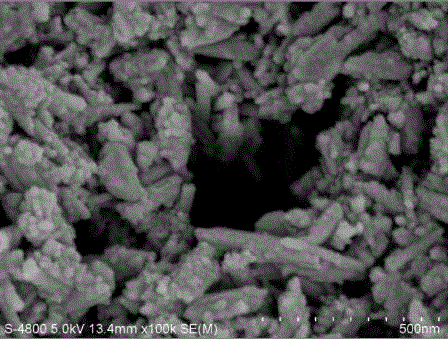

[0033] (6) Characterized by scanning electron microscopy, the MnO synthesized in Example 1 x Amorphous solid particles on the microscopic scale, see figure 2 ;Characterized as α-MnO by XRD 2 ; via N 2 Static adsorption and desorption characterization, and the BET method was u...

Embodiment 2

[0036] (1) Add 3 g of KMnO 4 and 0.8 g of 98% H 2 SO 4 Dissolved in 100 mL of deionized water to form a deep purple aqueous solution 1, in which KMnO 4 The concentration is about 0.03 g / mL;

[0037] (2) Mix 8 mL of analytically pure (30%) H 2 o 2 Dilute to solution 2 with 100 mL deionized water;

[0038](3) At room temperature with rapid stirring, solution 2 was added dropwise to solution 1 to form a large amount of precipitate accompanied by a large amount of O 2 generate;

[0039] (4) Leave the precipitate to age overnight, filter and wash with water for 3-5 times;

[0040] (5) at 110 o C drying overnight, roasting in air to 400 o C and keep for 2 h, you can get MnO x catalyst powder;

[0041] (6) Characterized by scanning electron microscopy, the MnO synthesized in Example 2 x Hierarchical structures formed for rod-like and granular packing on the microscopic scale, see image 3 ; Characterized as amorphous MnO by XRD 2 ; via N 2 Characterized by static adsor...

Embodiment 3

[0046] (1) Add 3 g of KMnO 4 and 0.5 g of 95% H 3 PO 4 Dissolved in 100 mL of deionized water to form a deep purple aqueous solution 1, in which KMnO 4 The concentration is about 0.02 g / mL;

[0047] (2) Mix 8 mL of analytically pure (30%) H 2 o 2 Dilute to solution 2 with 100 mL deionized water;

[0048] (3) At room temperature with rapid stirring, solution 2 was added dropwise to solution 1 to form a large amount of precipitate accompanied by a large amount of O 2 generate;

[0049] (4) Leave the precipitate to age overnight, filter and wash with water for 3-5 times;

[0050] (5) at 110 o C drying overnight, roasting in air to 400 o C and keep for 2 h, you can get MnO x catalyst powder;

[0051] (6) The catalyst is characterized by XRD as amorphous MnO 2 ;

[0052] (7) In the fixed-bed reactor, evaluate the catalytic combustion performance of high-concentration toluene, the catalyst dosage is 0.2 g, and the catalyst is 40-60 mesh solid particles after sieving, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com