Method for preparing ultrafine tungsten copper composite powder by low-temperature combustion method

A low-temperature combustion and composite powder technology, applied in the field of material processing, can solve the problems that the performance cannot meet the increasingly high requirements of modern technology, the difficulty of sintering full densification, and the large porosity. Phase separation, the effect of increasing the speed of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

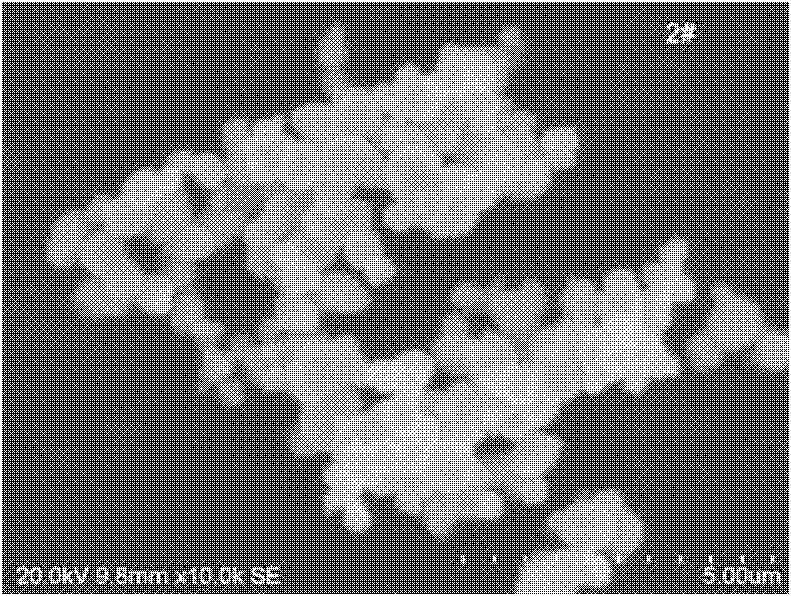

Image

Examples

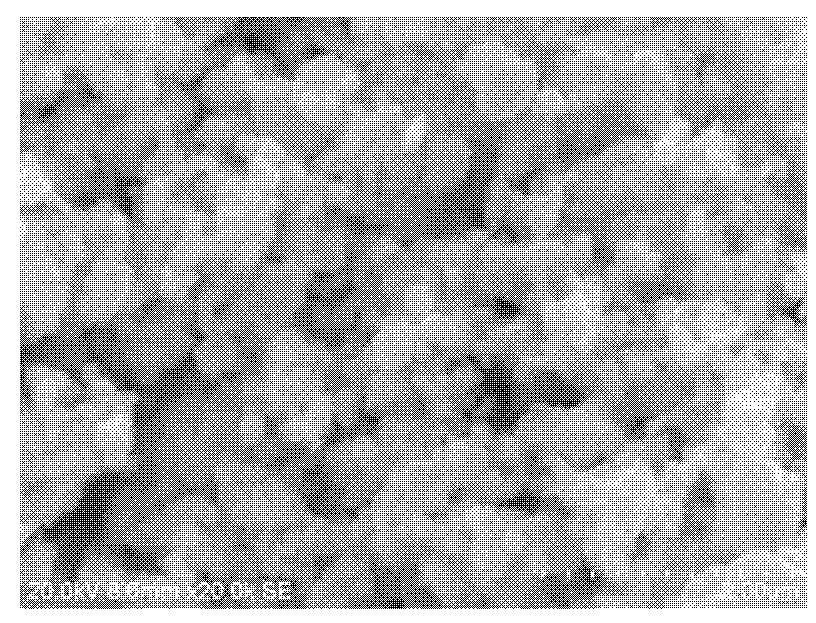

Embodiment 1

[0024] Embodiment 1, a method for preparing ultrafine tungsten-copper composite powder by a low-temperature combustion method of the present invention comprises the following steps:

[0025] Step a. adopting ammonium paratungstate (APT) and copper salt, citric acid and polyethylene glycol as raw materials;

[0026] Step b. Mix the above raw materials, and add water to configure a transparent citric acid sol system; wherein, the copper salt is copper nitrate; ammonium paratungstate (APT), copper nitrate, water, citric acid, polyethylene glycol are 55 : 183: 600: 250: 3 mass ratio is made into a solution, and a transparent sol system is formed after uniform stirring;

[0027] Step c. Place the above-mentioned sol system in a spray tower, dry it by spraying, and then pass the dried powder into a reaction kettle built in the spray tower to carry out a low-temperature combustion reaction. The temperature of the low-temperature combustion is 300 ° C, so that Obtain precursor powder...

Embodiment 2

[0034] Embodiment 2, a method for preparing ultra-fine tungsten-copper composite powder by a low-temperature combustion method of the present invention includes the following steps:

[0035] Step a. using ammonium metatungstate (AMT) and copper salt, citric acid and polyethylene glycol as raw materials;

[0036] Step b. Mix the above raw materials, and add water to configure a transparent citric acid sol system; wherein, the copper salt is copper nitrate; ammonium metatungstate (AMT), copper nitrate, water, citric acid, polyethylene glycol according to A mass ratio of 165:50:30:200:2 is prepared into a solution, and a transparent sol system is formed after uniform stirring;

[0037] Step c. Place the above-mentioned sol system in a spray tower, dry it by spraying, and then pass the dried powder into a reaction kettle built in the spray tower to carry out a low-temperature combustion reaction. The temperature of the low-temperature combustion is 200 ° C, so that Obtain precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com