Low-alloy high-strength cast steel, and smelting and heat treatment method thereof

A low-alloy high-strength, smelting method technology, applied in the field of low-alloy cast steel, can solve the problems such as the inability to meet the manufacturing requirements of large-scale steel castings for wind power, the complex heat treatment process, the difficulty of industrial smelting control, etc., and the tendency to shrink porosity is not obvious. , Excellent casting process performance, convenient for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0048] The chemical composition (mass percentage) of the low alloy cast steel of this embodiment is: carbon 0.18%, silicon 0.33%, manganese 0.94%, phosphorus 0.012%, sulfur 0.013%, nickel 0.48%, chromium 0.68%, molybdenum 0.53% , copper 0.10%, the rest is iron and unavoidable impurities, the impurity content is less than 0.1%.

[0049] The low-alloy cast steel in this embodiment can be smelted by an electric arc furnace oxidation-reduction method, or can be smelted by an intermediate frequency induction furnace.

[0050] The following steps are involved in the steelmaking by the electric arc furnace redox method:

[0051] ① Loading, after cleaning and derusting the discarded carbon steel, put it into the furnace body of the electric arc furnace at the same time as metal nickel.

[0052] ② Oxidation, turn on the corresponding electrical switches, and when the temperature of the molten pool in the electric arc furnace reaches 1560 ° C ~ 1580 ° C (1560 ° C in this embodiment), a...

Embodiment 2 to Embodiment 12)

[0082] The chemical compositions of the low-alloy cast steels of Examples 2 to 12 are shown in Table 1, and the unavoidable impurity content in the low-alloy cast steels of each embodiment is lower than 0.10%:

[0083] Table 1 Chemical composition (wt%), the rest is iron and unavoidable impurities

[0084]

[0085] The smelting method of the low-alloy cast steel in the above examples 2 to 12 is the same as the smelting method adopted in the example 1. During smelting, the tapping temperature is controlled above 1620°C, and the pouring temperature is controlled at 1550°C-1570°C.

[0086] The heat treatment method of the low-alloy cast steel in the above embodiments 2 to 12 is the same as the heat treatment process of the embodiment 1.

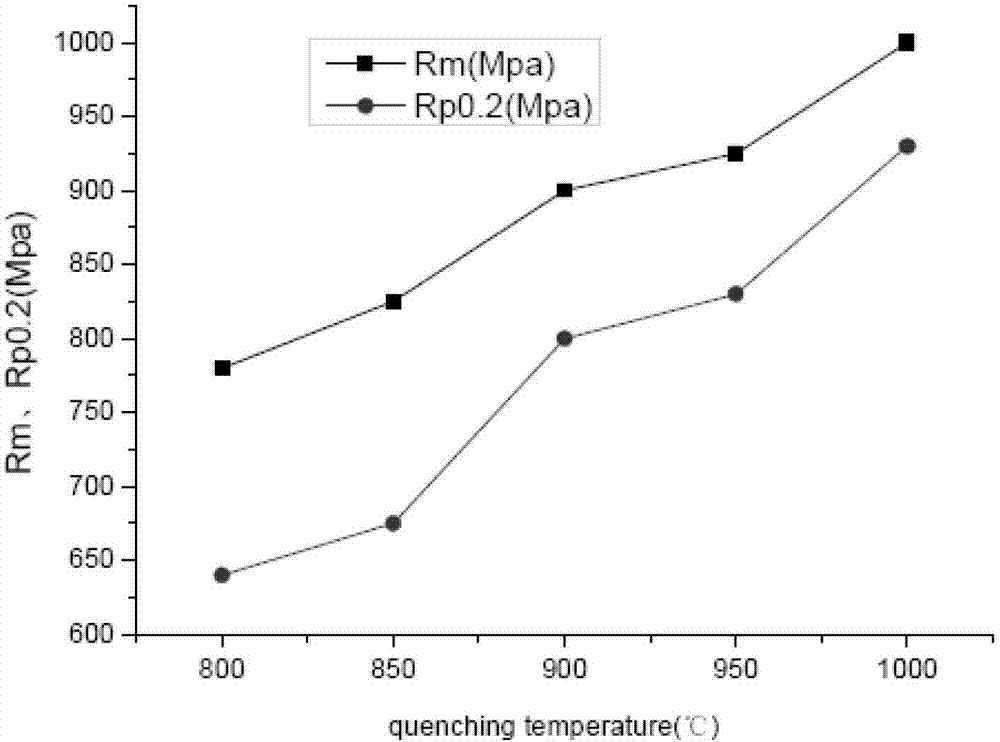

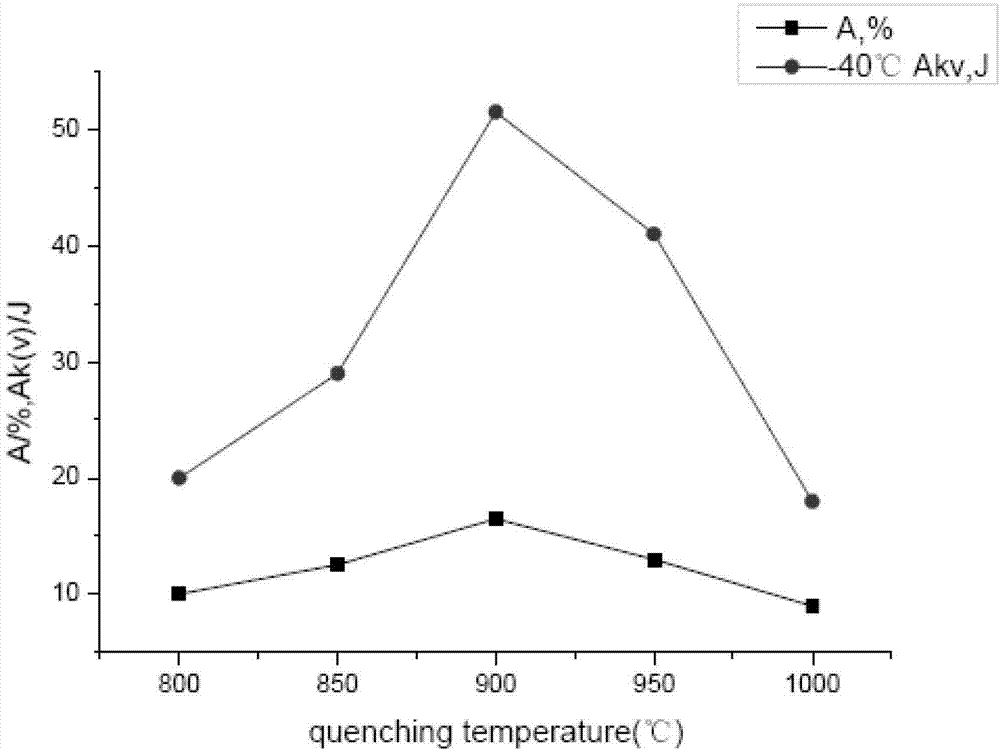

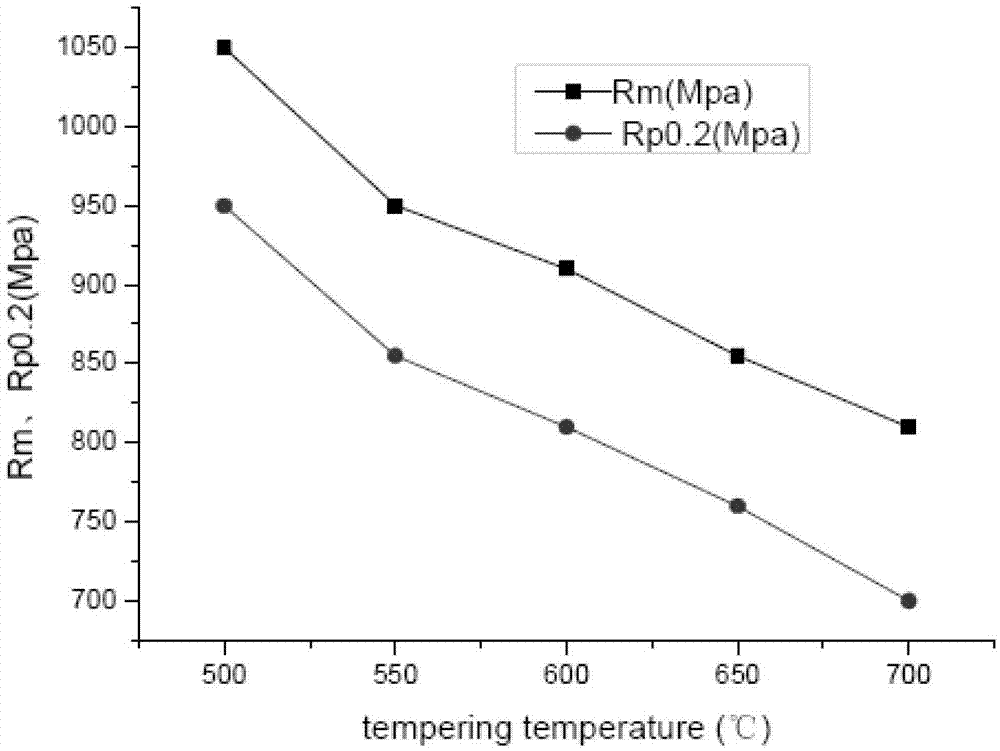

[0087] The mechanical property detection data of the samples of 330mm (length) × 80mm (width) × 80mm (height) poured and heat-treated from Example 1 to Example 12 are shown in Table 2 below (Rm in Table 2 is the tensile strength, Rp0.2 Yield...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com