Active carbon for super capacitor and a preparation method thereof

A supercapacitor and activated carbon technology, which is applied in the manufacture of capacitors, hybrid/electric double layer capacitors, electrolytic capacitors, etc., to achieve the effects of low production costs, simple preparation methods, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

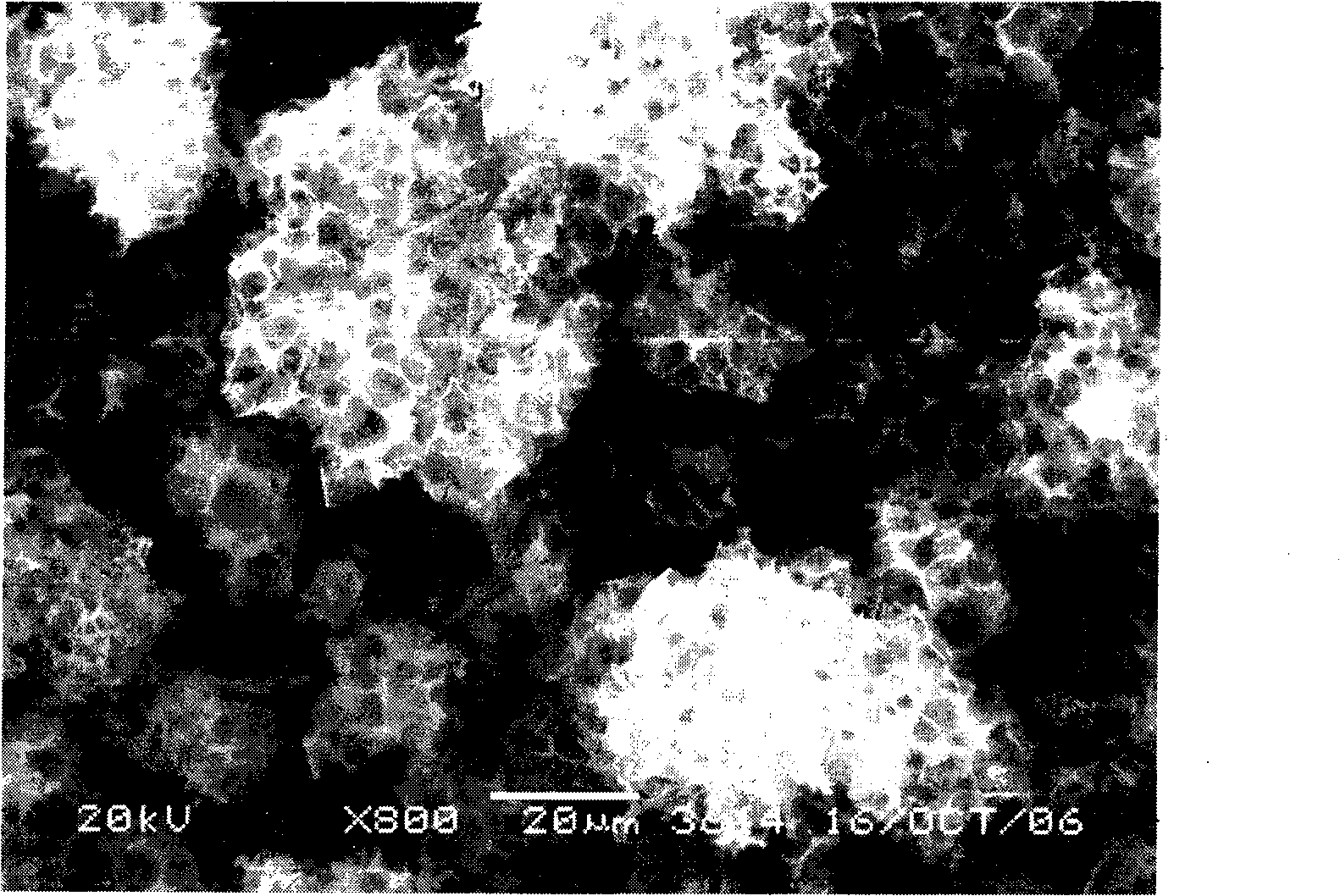

Image

Examples

preparation example Construction

[0023] The preparation method of activated carbon for supercapacitor provided by the invention, its steps are as follows:

[0024] 1) drying the starch with moisture; the starch is oxidized cross-linked starch, corn cationic starch, graft copolymerized starch, soluble starch or tapioca starch;

[0025] 2) Take the dried starch and place it in a resistance furnace, raise the temperature to 350-550°C under the protection of an inert gas, keep the temperature constant for 1-4 hours, take it out after cooling, and obtain the carbonized material;

[0026] 3) Grind the carbonized material and mix it evenly with the saturated solution of potassium hydroxide, dry the water and place it in a resistance furnace, raise the temperature to 750-850°C under the protection of an inert gas, keep the temperature for 1-4 hours, take it out after cooling, and grind it. It is washed until neutral and dried to obtain the product; the weight ratio of the carbonized material to potassium hydroxide so...

Embodiment 1

[0030] Weigh 10g of oxidized cross-linked starch, bake it in an oven at 120°C for 12h, place it in a stainless steel container and place it in a tubular resistance furnace, and then use a temperature controller to control the temperature rise rate to 1°C / min under the protection of Ar inert gas Raise the temperature to 350°C and keep the temperature constant for 4 hours to carbonize the starch into starch coke. The obtained starch coke was crushed to 150 mesh and mixed with KOH saturated solution (starch coke: KOH solid = 1:4, weight ratio, the same below); baked in an oven at 120°C for 24 hours, then placed in a tubular resistance furnace, Then, under the protection of Ar inert gas, the temperature was raised to 850°C at a rate of 1°C / min controlled by a temperature controller, kept at a constant temperature for 1.5h, and then naturally cooled to room temperature. Take it out and grind it to 150 mesh with a mortar, add an appropriate amount of hot water, stir for 12 hours und...

Embodiment 2

[0035] The starch used was 10 g of corn cationic starch, and the carbonization and activation conditions were the same as in Example 1. The measured specific surface area of the obtained activated carbon is 1876.2m 2 / g.

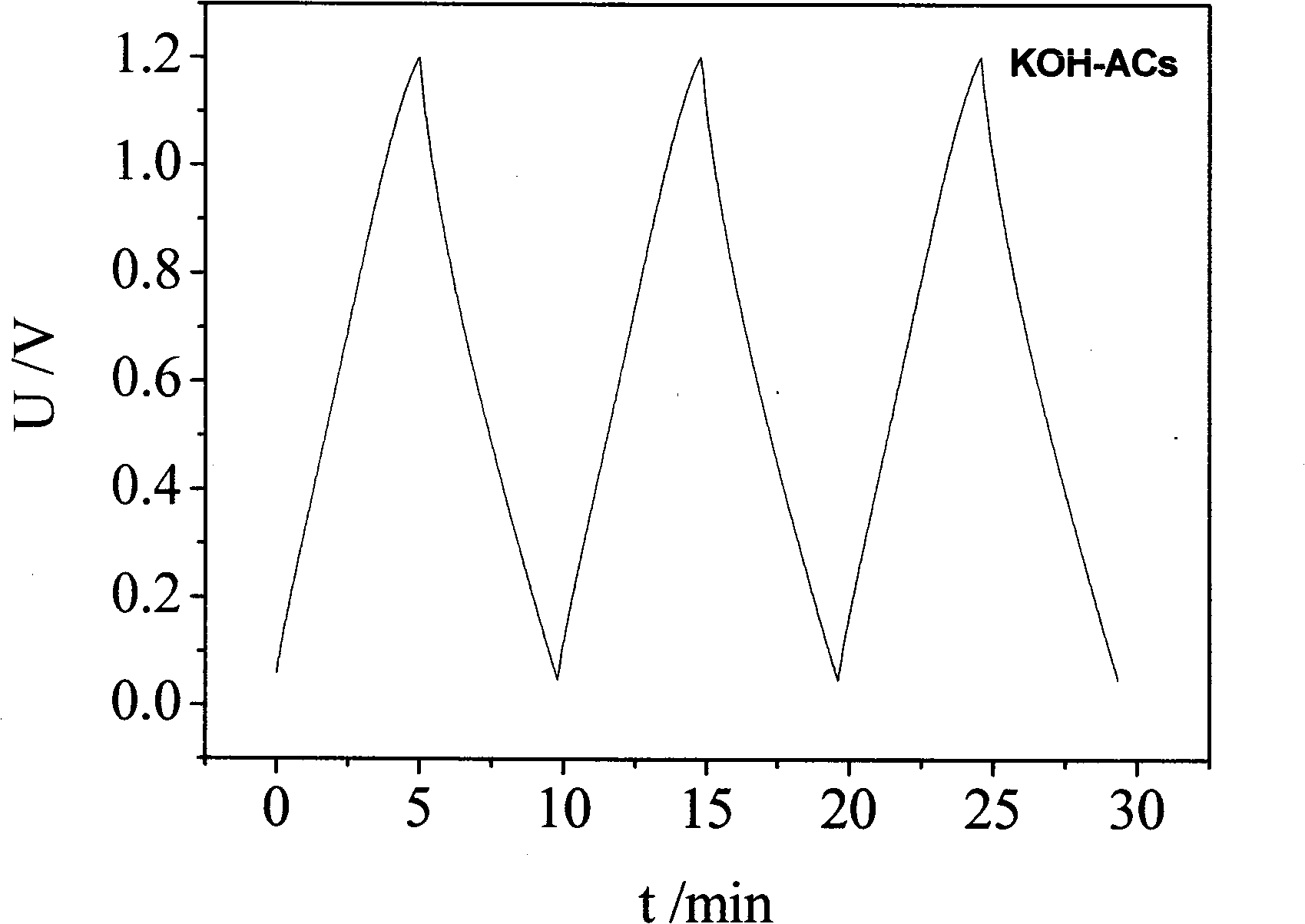

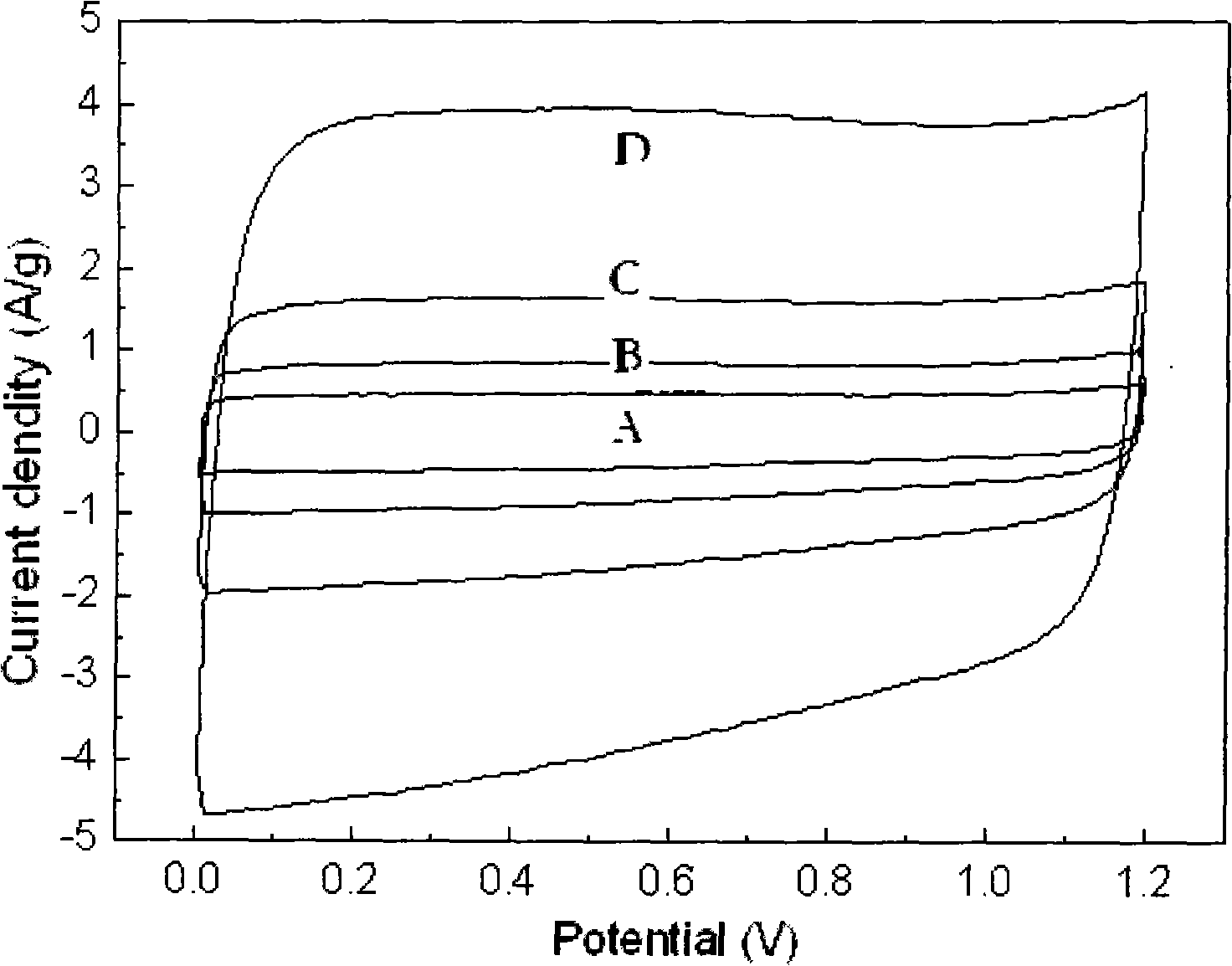

[0036]The obtained starch activated carbon was used as an electrode material to assemble a simulated supercapacitor, and the electrochemical performance test was carried out in 30% KOH electrolyte aqueous solution. The electrochemical performance test was carried out under the condition of current density of 0.5A / g and charge-discharge voltage of 0.00-1.20V. The first cycle specific capacity was 184.3F / g, the charge-discharge curve showed a typical triangular symmetrical distribution, and the cyclic voltammetry curve A relatively regular rectangle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com