Method for adding rare earth metal into steel to improve performance

A rare earth metal and performance technology, applied in the field of high-quality metal material manufacturing, can solve the problems of large inclusion aggregation, nozzle nodules, and rare earth elements cannot play a sustainable and stable role, avoiding the generation of large-sized inclusions and increasing the uniformity. , the effect of improving the flexibility of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1 - alloy dual phase steel

[0070] Material: DP600;

[0071] Molten steel weight: 100 tons (t) / furnace × 15 furnaces;

[0072] Production process: EAF-LF-VD-CC;

[0073] Purity of molten steel before adding rare earth metals: oxygen content is 32ppm, sulfur content is 74ppm;

[0074] Timing of adding rare earth metals: after VD;

[0075] Rare earth metal addition: 40kg (0.4kg / t steel);

[0076] Rare earth metal purity: total oxygen content 85ppm;

[0077] The rare earth metal is lanthanum-cerium mixed rare earth, and the weight ratio of lanthanum to cerium is 1:2;

[0078] Billet specification: 250mm×1600mm continuous casting slab;

[0079] Steel product specifications: 3.5mm×1600mm rolled plate;

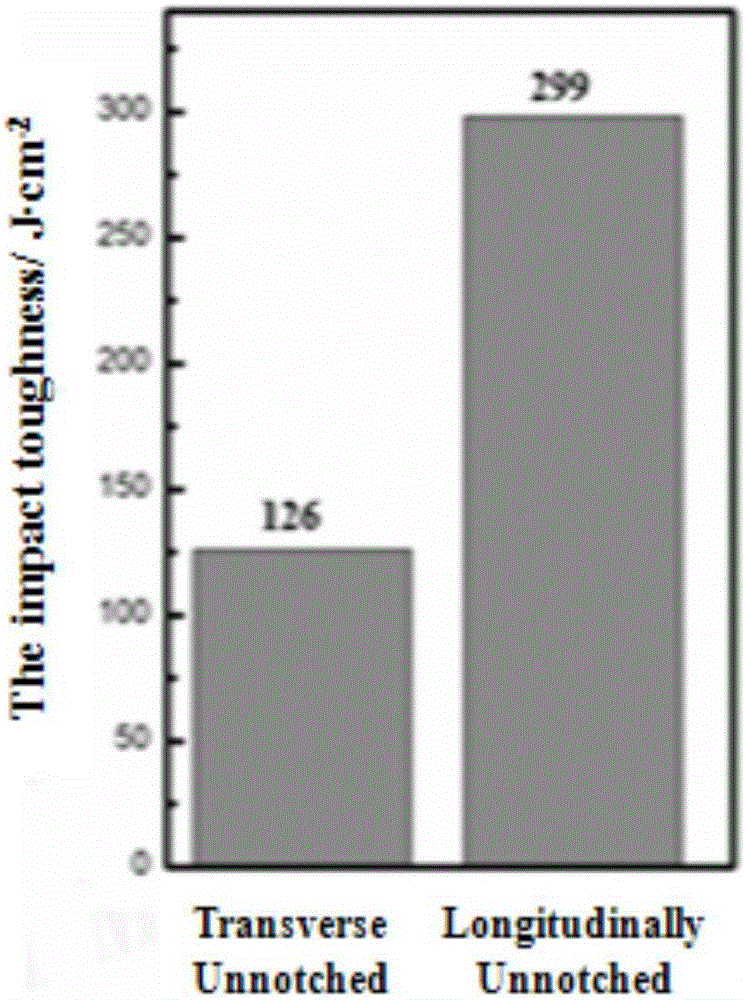

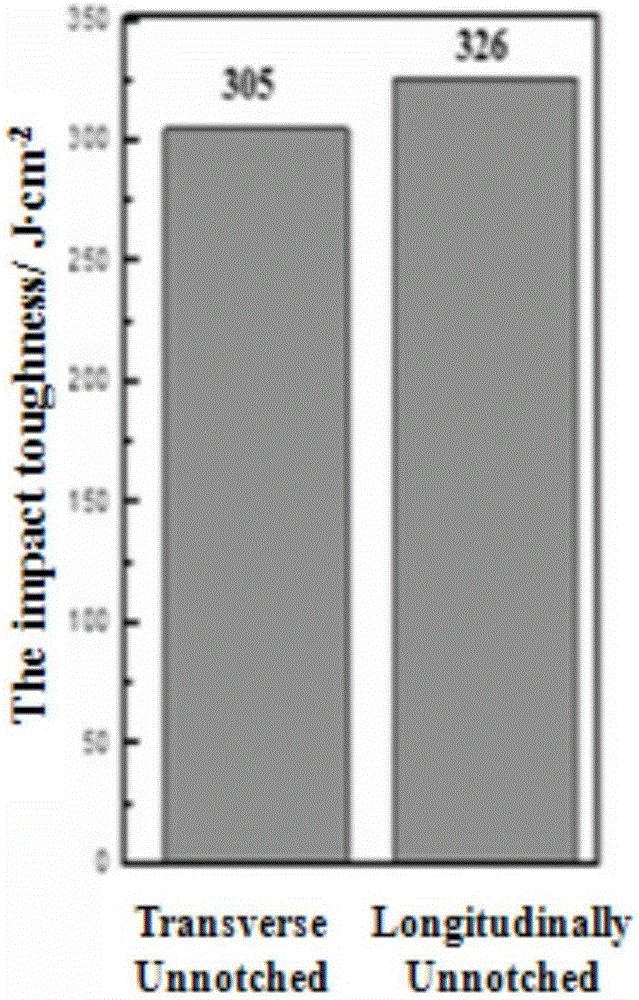

[0080] In this embodiment, the process of continuous casting was produced for 15 hours, and the process went smoothly. The impact performance of the finished plate of this embodiment is compared with that of the plate without rare earth metal treatment, such ...

Embodiment 2

[0085] Example 2 - high quality bearing steel

[0086] Material: GCr15;

[0087] Molten steel weight: 120t / furnace × 12 furnaces;

[0088] Production process: BOF-LF-RH-CC;

[0089] Purity of molten steel before adding rare earth metals: oxygen content is 10ppm, sulfur content is 30ppm;

[0090] Timing of adding rare earth metals: after RH;

[0091] Rare earth metal addition: 120kg (1.0kg / t steel);

[0092] Rare earth metal purity: total oxygen content 65ppm;

[0093] The rare earth metal is cerium;

[0094] Billet specification: Φ350mm continuous casting round billet;

[0095] Steel finished product specification: Φ50mm rolled bar;

[0096] The size of the inclusions is very important to the fatigue performance of the bearing steel. Table 1 shows the distribution ratio of the inclusions in different size ranges in Example 2 and its comparison with that of the bearing steel without adding rare earth. It can be seen that the large-size inclusions larger than 5 μm are elim...

Embodiment 3

[0107] Example 3 - stainless steel

[0108] Material: 410S;

[0109] Molten steel weight: 80t / furnace × 6 furnaces;

[0110] Production process: MFF-AOD-CC;

[0111] Purity of molten steel before adding rare earth metals: oxygen content is 25ppm, sulfur content is 40ppm;

[0112] Timing of adding rare earth metals: after AOD;

[0113] Rare earth metal addition: 12kg (0.15kg / t steel);

[0114] Rare earth metal purity: total oxygen content 80ppm;

[0115] The rare earth metal is lanthanum-cerium mixed rare earth, and the weight ratio of lanthanum to cerium is 1:2;

[0116] Billet specification: 200mm×1700mm continuous casting slab;

[0117] Specifications of finished steel products: 3mm×1800 rolled plates;

[0118] In this embodiment, continuous pouring can be realized for 6 hours, and production runs smoothly.

[0119] The size of the inclusions is an important index affecting the deep drawing performance of this type of stainless steel. Table 2 shows the comparison of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com