Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Reduce purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

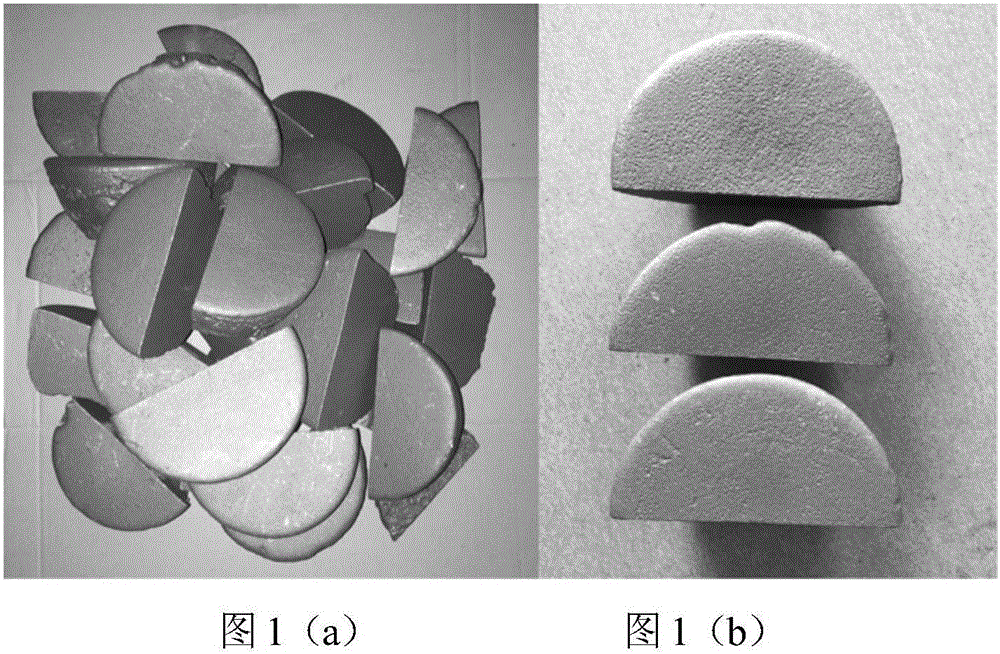

Improved process for preparing porous microsphere active carbon

The improved process for preparing high strength porous microsphere active carbon includes the following steps: oxidizing thermosetting resin ball at 60-400 deg.c in oxygen containing atmosphere or pre-treating thermosetting resin ball at 60-300 deg.c in oxidizing acid, SO2 or SO3; carbonizing at 600-1200 deg.c in helium, nitrogen or their mixture atmosphere; and activating at 600-1200 deg.c in activating water vapor atmosphere to obtain high strength porous microsphere active carbon with grain size of 10 micron to 2 mm, BET specific surface area of 500-4000 sq m / g, and grain strength of 50-200 MPa. The process is simple, low in cost and high in yield, and the prepared microsphere active carbon has high strength and high purity and is one excellent medical active adsorption material.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Oxygen-free copper bar suitable for cable and preparing method of oxygen-free copper bar

InactiveCN105369172AOvercome the shortcomings of too many impuritiesReduce puritySingle bars/rods/wires/strips conductorsRare-earth elementNitrogen

The invention discloses an oxygen-free copper bar suitable for a cable and a preparing method of the oxygen-free copper bar. The preparing method of the oxygen-free copper bar comprises the following steps that reclaimed copper is added into a smelting furnace to be molten and then refined, impurities are removed, and mixed gas of natural gas and nitrogen is introduced into molten copper for one to two hours for reduction and purification; and the molten copper is covered with crystalline flake graphite, so that a covering layer is formed, bar-shaped Cu-RE alloy penetrates through the covering layer to be added into the molten copper for alloying of rare earth elements, the percentage by weight of the rare earth elements is 0.1%-0.2%, a hollow crystallizer is directly stretched into the molten copper and cooled through a water spacer bush, the molten copper is condensed into a solid in the hollow crystallizer, and the upper end of the solid is drawn into the oxygen-free copper bar through a drawing mechanism.

Owner:JINYUAN ELECTRIC GRP

Casting method of low-alloy hydraulic pump stator casting

ActiveCN101823139AAddress mechanical propertiesReduce purityFoundry mouldsElectric furnaceIntermediate frequencyHydraulic pump

The invention discloses a casing method of a low-alloy hydraulic pump stator casting, comprising the steps of sand mulling, modeling, charge melting, tapping inoculation treatment, pouring, cooling, unpacking and casting cleanness. In the sand mulling and modeling steps, clay wet sand is produced into a casting model by using a vibratory squeezing slip flask molding machine. The charge melting step comprises charge preparing and melting, wherein the charge comprises the following raw materials in percentage by weight: 15-25 percent of pig iron, 45-55 percent of recirculated iron and 25-35 percent of scrap steel; and the melting is performed by adopting an intermediate-frequency induction electric furnace. The tapping inoculation treatment comprises tapping and inoculation treatment by a silicon-barium inoculant. For the stator casting product produced with the method, the tensile strength is more than 350MPa and the hardness is 220-280HBS; a graphite form of a gold phase tissue is mainly A type, the graphite length is 4-5 grades, the amount of the pearlite is more than 95 percent and the summation of carbide and phosphorus eutectic is less than 5 percent; and various parts of the casting have no casting defects.

Owner:上海华新合金有限公司

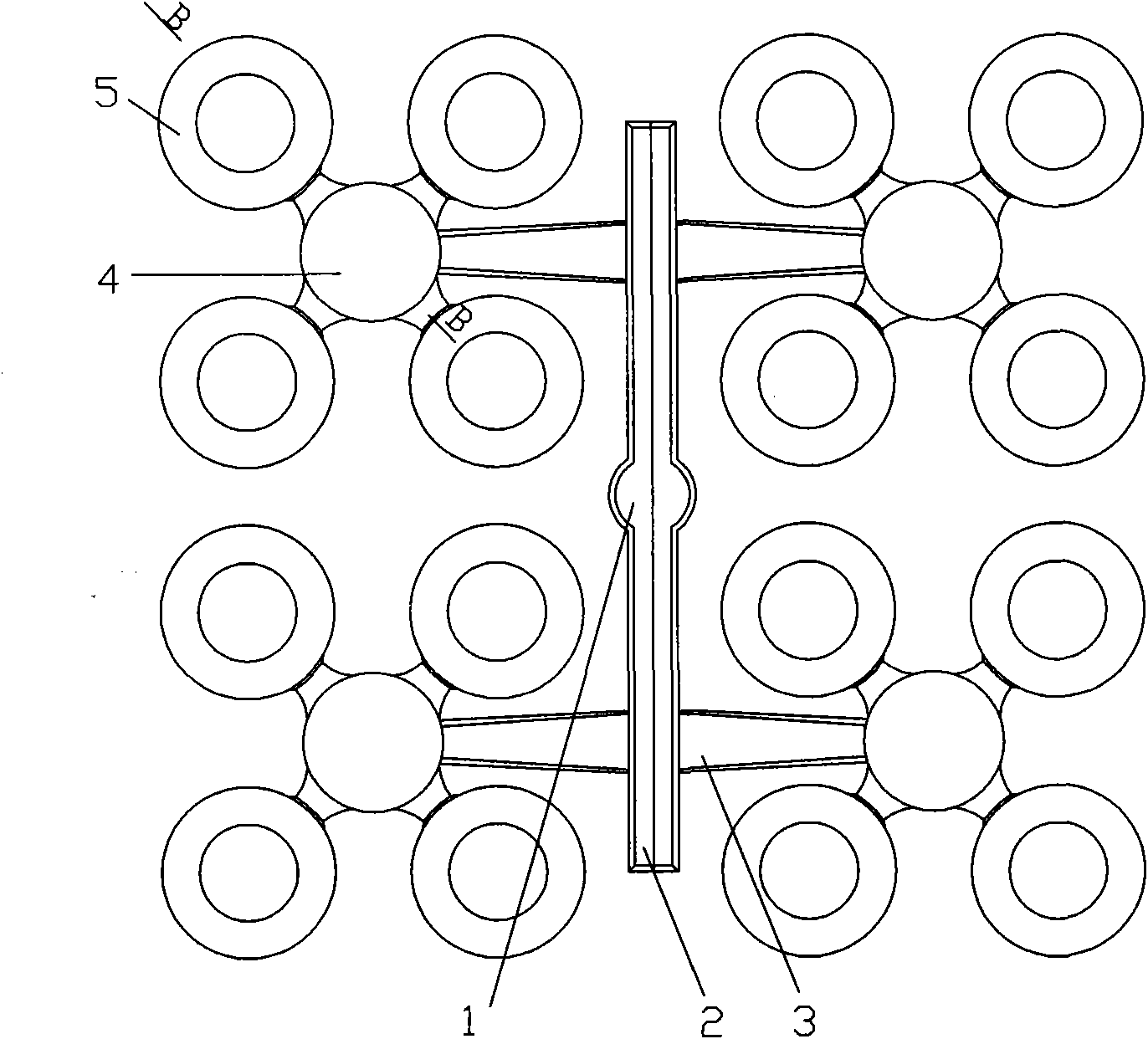

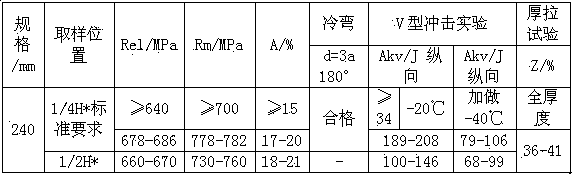

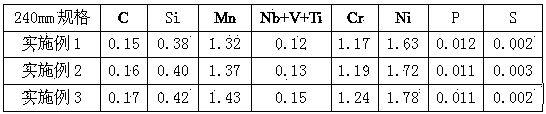

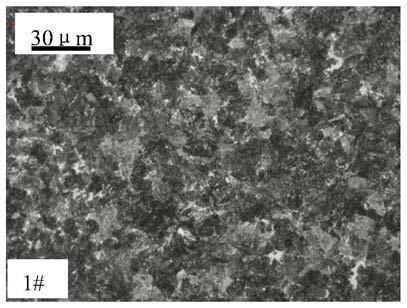

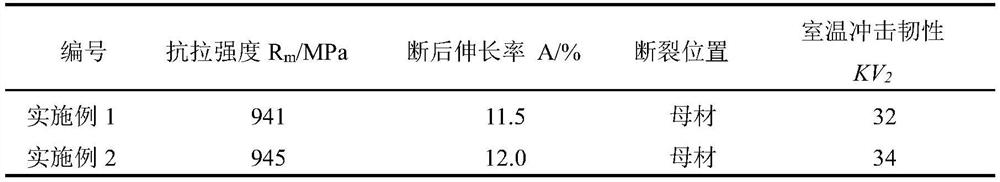

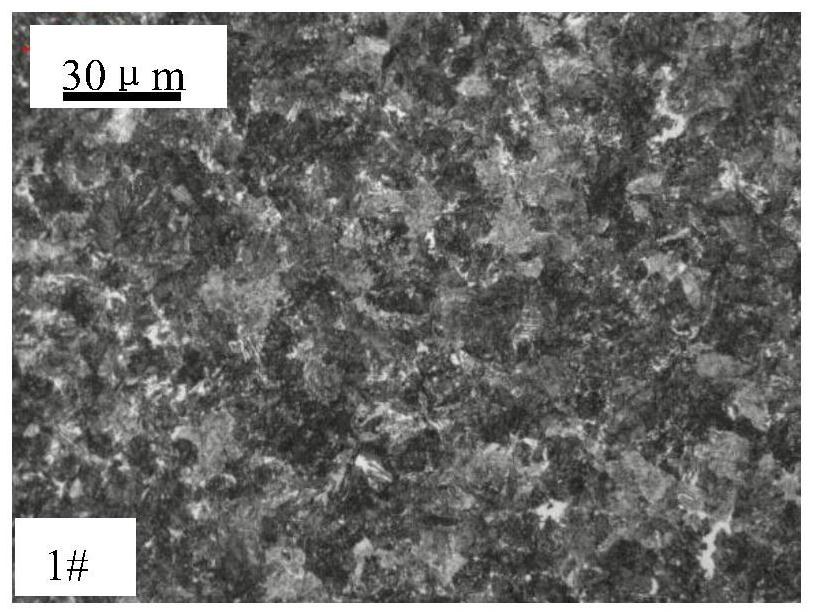

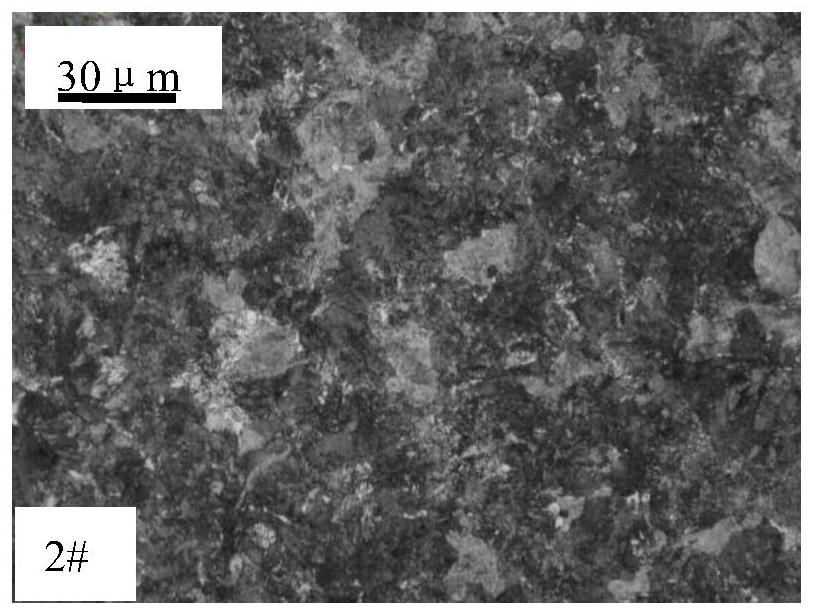

Steel HG785D for tower crane and production method

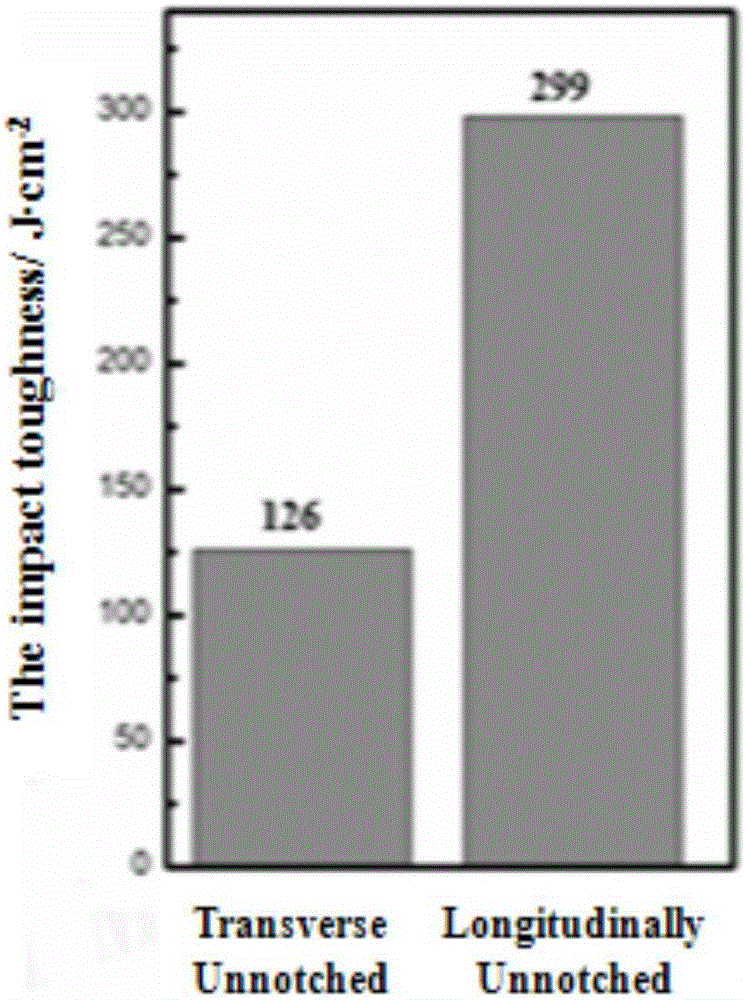

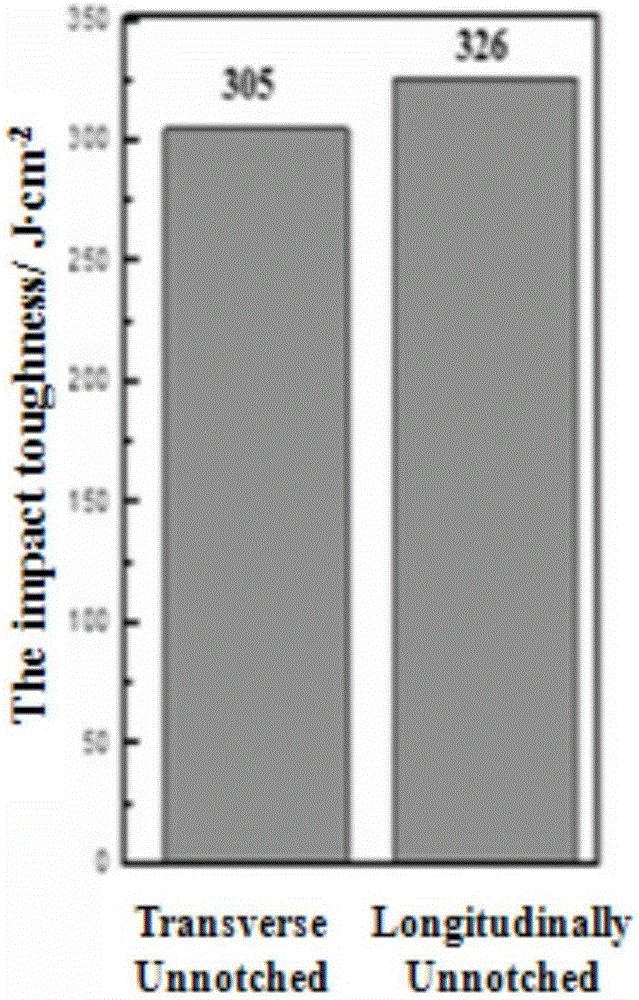

ActiveCN103469102AReduce purityMeet the requirementsProcess efficiency improvementImpact energyBainite

The invention discloses steel HG785D for a tower crane and a production method. The steel HG785D for the tower crane comprises the following components of, by weight, 0.14-0.17% of C, 0.38-0.42% of Si, 1.29-1.43% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.11-0.15% of Nb+V+Ti, 1.17-1.24% of Cr and 1.63-1.78% of Ni. The thickness of the steel HG785D is 160-240mm. The main process comprises the steps of LF refining, vacuum degassing processing, water-cooled copper plate crystallizer ingot mould casting, rolling, ACC laminar cooling and heating processing. The steel HG785D for the tower crane is large in strength and high in yield point, first-grade flaw detection can be ensured, the longitudinal impact energy at minus 20DEG C reaches 189-208J, lamellar tearing resisting performance meets the Z35 grade, microtexture comprises 64-72% of martensite and 19-25% of bainite, and the steel HG785D greatly meets the using demands of ultra-large type tower cranes.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Low-nickel austenite heatproof cast steel and smelting method thereof

The invention relates to low-nickel austenite heatproof cast steel and a smelting method thereof. The cast steel is characterized in that: the cast steel comprises components of, by weight: 0.70-1.0% of C, 2.50-3.50% of Si, 12.0-14.0% of Mn, 19.0-22.0% of Cr, 0.4-1.0% of Ni, 0.35-0.50% of N, and balance of Fe and inevitable impurities. The smelting method comprises steps of: raw material preparing, feeding, material melting, calcium silicon and rare earth deoxidating, electromagnetic stirring, calcium silicon deoxidating, and ingot casting. According to the method, the cast steel is smelted by using a medium frequency induction furnace; components of the heatproof cast steel are optimized; smelting power is regulated; an electromagnetic stirring + argon shield refining method is adopted; and a calcium silicon + rare earth combined deoxidation method is adopted, such that low-nickel austenite heatproof cast steel is smelted. Through the regulation of the contents and ratio of C, N, andMn elements in the low-nickel austenite heatproof cast steel, the nickel content can be reduced, and stable monophase austenite tissues can be formed.

Owner:沈阳科金特种材料有限公司

Steel wire rod for 2000 MPa-grade spring and production method of wire rod

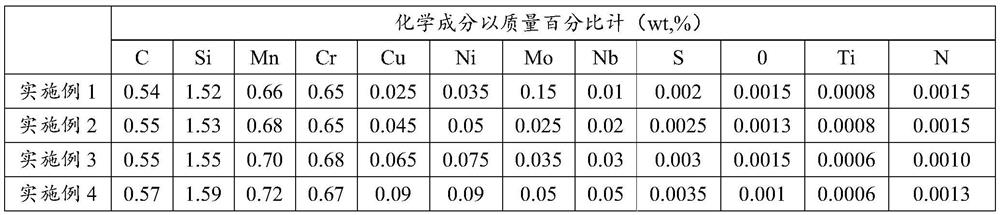

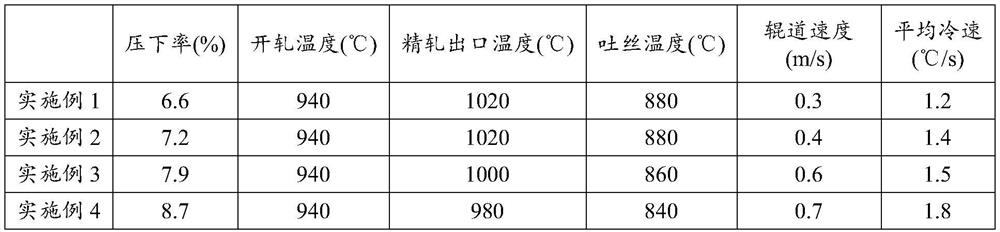

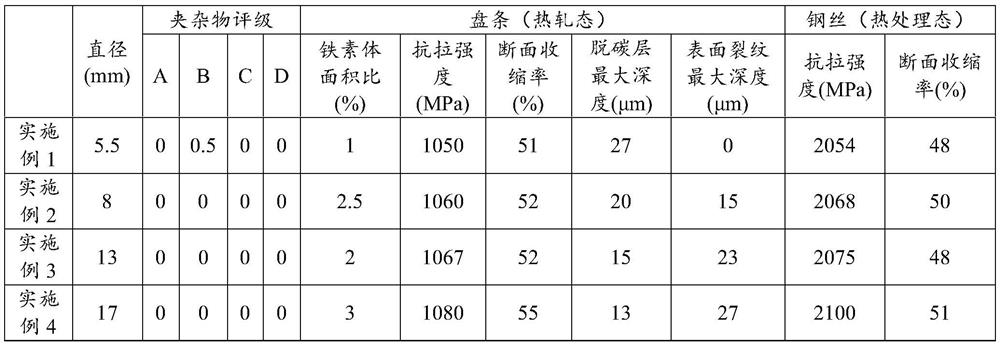

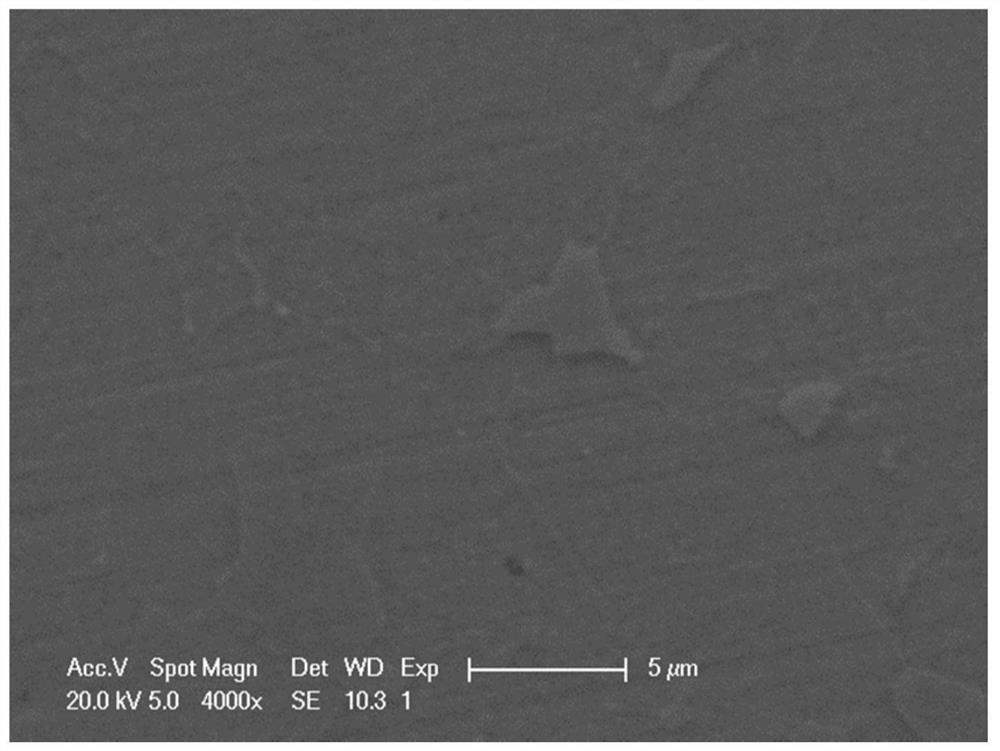

PendingCN112853220AImprove purityImprove metallographic structureProcess efficiency improvementPearliteChemical composition

The invention discloses a wire rod for a 2000 MPa-grade spring and a production method of the steel wire rod. The steel wire rod is prepared from the following chemical components of, 0.53%-0.57% of C, 1.51%-1.59% of Si, 0.65%-0.72% of Mn, 0.63%-0.7% of Cr, 0.01%-0.1% of Cu, 0.01%-0.1% of Ni, 0.01%-0.05 % of Mo, 0.01%-0.05% of Nb and the balance Fe and impurities. In a production method, a continuous casting reduction rate is 6.6%-8.7%, an initial rolling temperature of high-speed wire rolling is 910-950 DEG C, a finish rolling outlet temperature is less than or equal to 1020 DEG C, a spinning temperature is 820-880 DEG C, and a cooling speed of Stelmor cooling is 1.2-2.0 DEG C 11. The steel wire rod is of a bainite and pearlite structure, a tensile strength is 950 Mpa-1150 MPa, the percentage reduction of area is larger than or equal to 50%, and the steel wire rod can be used for preparing a spring with a strength of 2000 MPa.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

Copper-iron alloy material and preparation method and application thereof

The invention provides a copper-iron alloy material and a preparation method and application thereof. The copper-iron alloy material comprises, by weight, 5-20wt. % of iron, 0.002-0.05wt.% of RE and the balance copper. The copper-iron alloy material is easy to operate, the smelting temperature is greatly reduced, the smelting temperature in a crucible furnace is 1200-1250 DEG C, and compared withthe temperature of 1600 DEG C or above in a traditional method, energy consumption can be reduced; a vacuum smelting technology is adopted, oxidation in the high-temperature process can be avoided, the high purity of the material is guaranteed, and the oxygen element content can be lower than 150ppm; and the vacuum smelting technology is adopted, subsequent cold drawing deformation is combined, the structure components of a copper-iron alloy wire are uniform, the ductility of the copper-iron alloy wire can reach 24% or above, the wire breaking problem in electromagnetic shielding wire preparation can be reduced, the yield is increased, and the performance requirements for electric conduction and magnetic shielding of the electromagnetic shielding material can be met.

Owner:SOUTHEAST UNIV

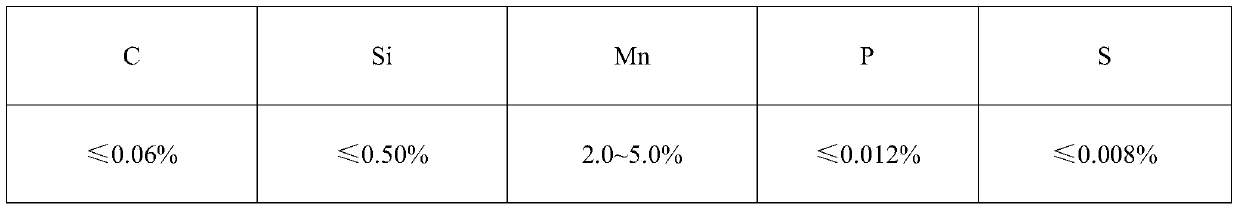

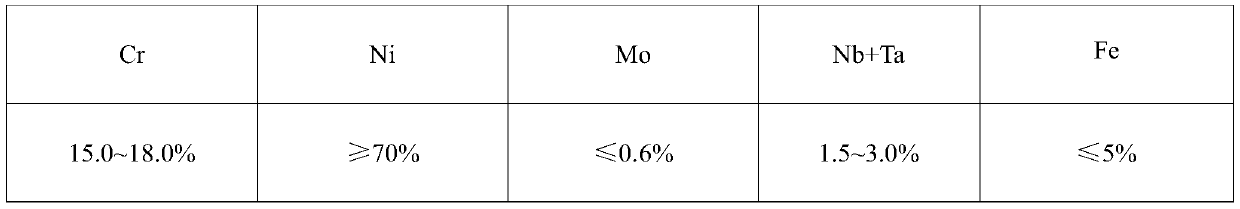

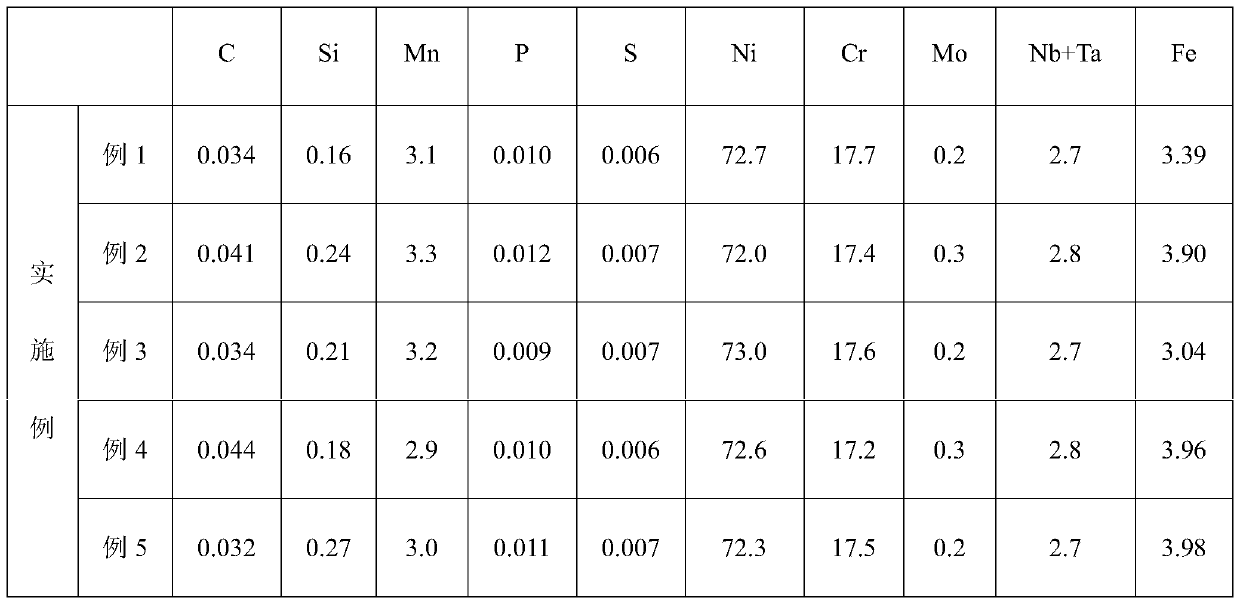

9% Ni steel matched nickel-based welding rod special for overhead welding

ActiveCN111590240AReduce distractionsReduce porosityWelding/cutting media/materialsSoldering mediaSlag (welding)Nichrome

The invention discloses a 9% Ni steel matched nickel-based welding rod special for overhead welding. The welding rod is composed of a welding core and a coating, wherein the outer wall of the weldingcore is coated with the coating, the coating accounts for 0.3-0.5% of the total weight coefficient of the welding rod, the welding core is a nickel-chromium-iron welding core, and the coating is composed of a CaCO3-MgCO3-CaF2 low-hydrogen slag system with high alkalinity. The welding rod has excellent all-position weldability, especially overhead welding position weldability, and extremely low overhead welding shooting porosity; and the welding rod has excellent overhead welding property, stable electric arc, excellent deslagging property and excellent weld joint forming property, the weldingrod has extremely low overhead welding porosity, and the overhead welding high-definition radiographic inspection TOFD shooting qualification rate can reach 99.5% or above.

Owner:KUSN GINTUNE WELDING

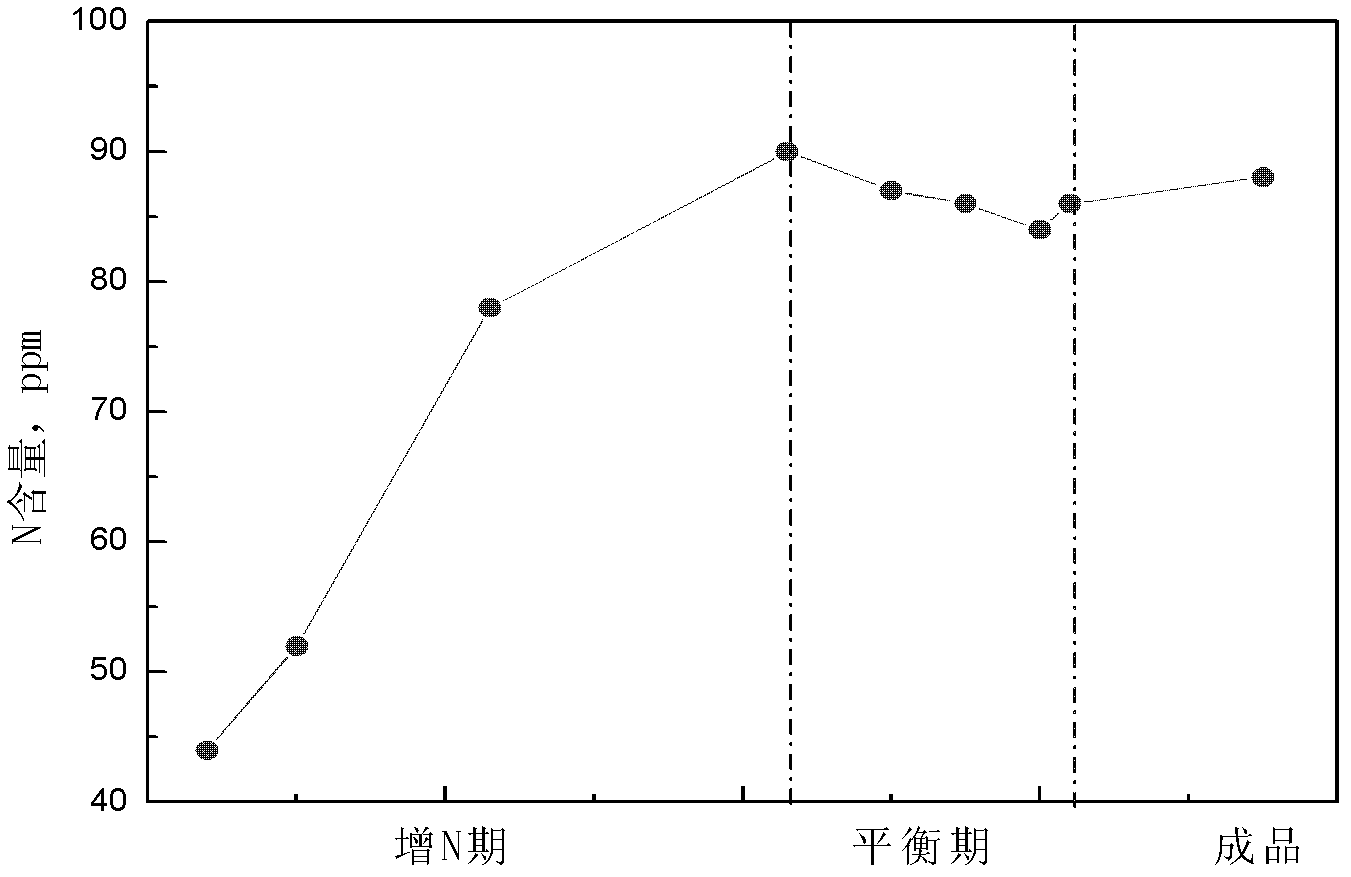

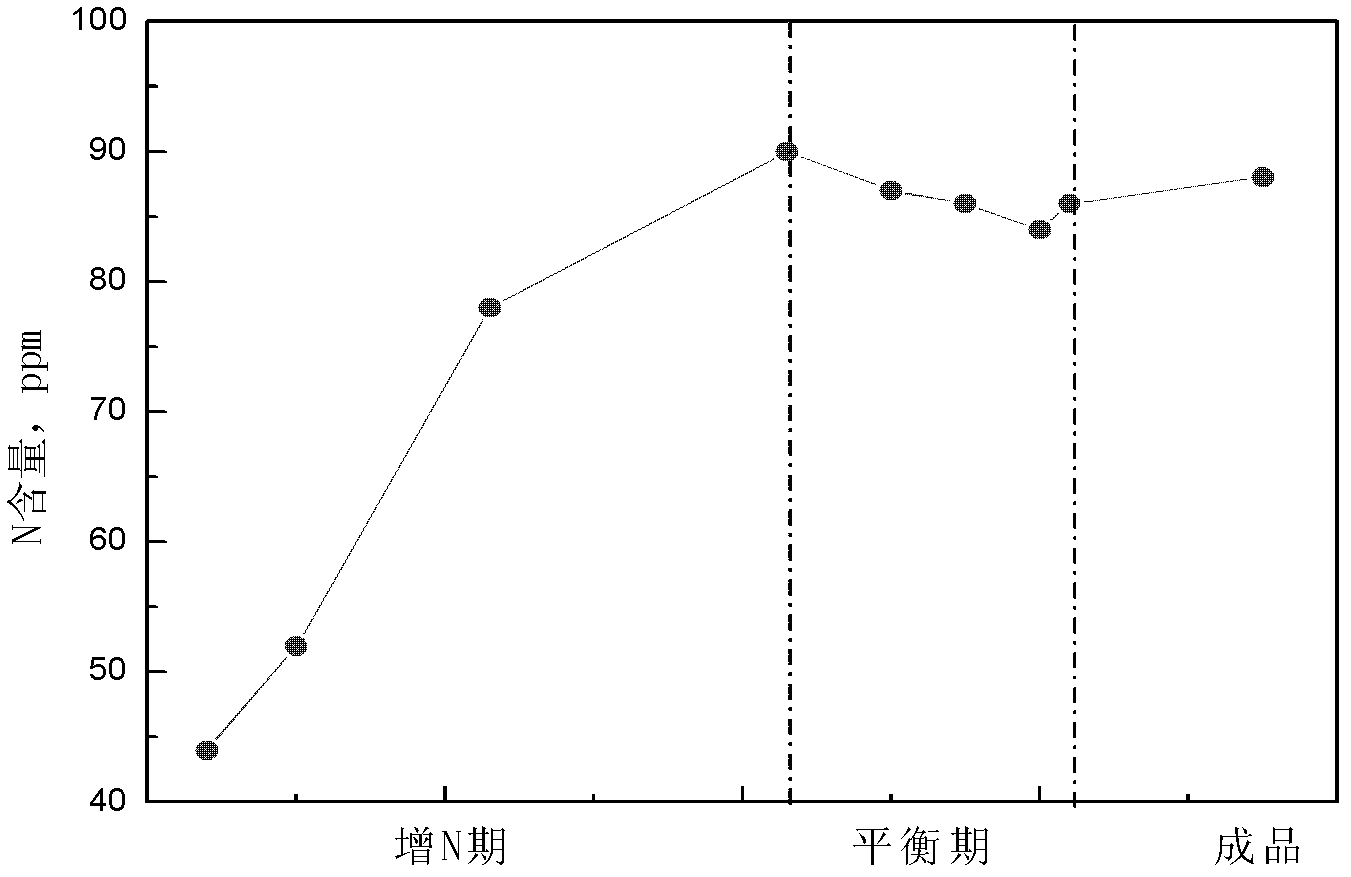

Method for controlling nitrogen content of high-permeability-grade oriented electrical steel belt

ActiveCN102634643AReduce purityMeet the requirements of nitrogen content accuracySteelmakingElectrical steel

The invention relates to the technical field of steelmaking, in particular to a method for controlling the nitrogen content of a high-permeability-grade oriented electric steel belt. The method particularly includes following steps that molten steel is connected with bottom flushing nitrogen after reaching an RH (relative humidity) refining furnace, and nitrogen flushing treatment is performed for the molten steel; ultimate vacuum treatment is performed at the preliminary stage of RH refining treatment, RH ultimate vacuum degree is smaller than or equal to 200Pa, and nitrogen circulates in anRH vacuum chamber in the whole process; and after the ultimate vacuum treatment is performed for 12 minutes to 15 minutes, RH vacuum degree is reset according to the initial nitrogen content of the molten liquid, RH refining nitrogen adding treatment is performed, and the RH vacuum degree is reduced after a nitrogen adding target value is reached. By means of reasonably controlling nitrogen flow and the RH vacuum degree in an RH refining process, requirements on nitrogen content precision for production of the high-permeability-grade oriented electric steel belt are met. Besides, the method is simple, is high in applicability, and does not affect controlling to purity and H content of the high-permeability-grade oriented electric steel belt.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Free-machining pinion steel smelting method and free-machining pinion steel

The invention provides a free-machining pinion steel smelting method. The method comprises the following steps of: performing primary smelting to molten iron in a converter; tapping the molten steel which is subjected to primary smelting into a steel ladle, adding an aluminum-iron deoxidizer into the steel ladle in a process that tapping is performed to 20 to 30 percent, and adding the first batch of refining slag into the steel ladle in a process that tapping is performed to between 40 and 60 percent to realize that the S content in the molten steel after tapping is 0.05 to 0.08 weight percent; performing LF (ladle furnace) steel ladle refining to the steel ladle, and adding the second batch of refining slag and deoxidized aluminum particles in an LF steel ladle refining process to realize that the S content in the molten steel which is subjected to LF steel ladle refining is between 0.02 and 0.025 weight percent; and performing RH (ruhrstahl-hausen) vacuum refining to the molten steel which is subjected to LF steel ladle refining. According to the technical scheme of the invention, the sulfur content in the molten iron of the raw material is sufficiently utilized, and the addition amounts of refining slag and deoxidizer are controlled according to changes of sulfur content in the smelting process, so that the required sulfur content is ensured, and purity and impurities of the molten steel are controlled.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

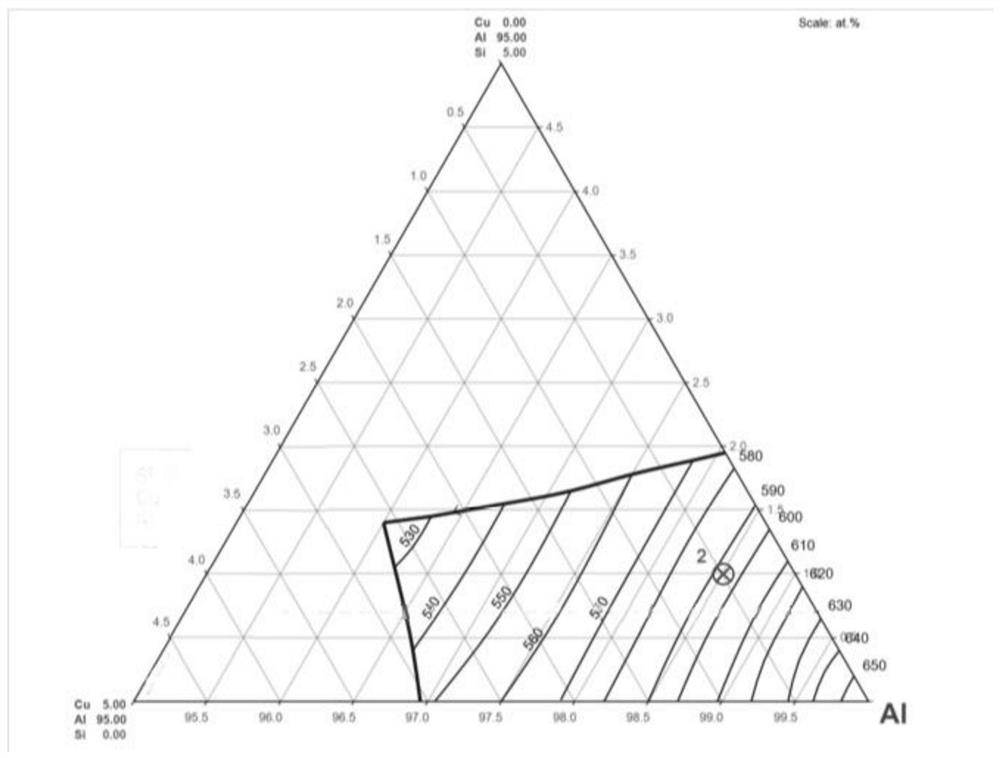

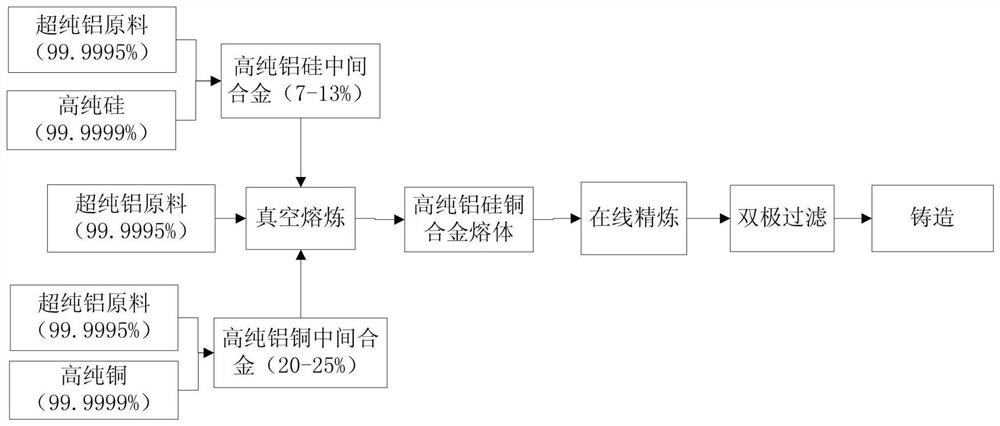

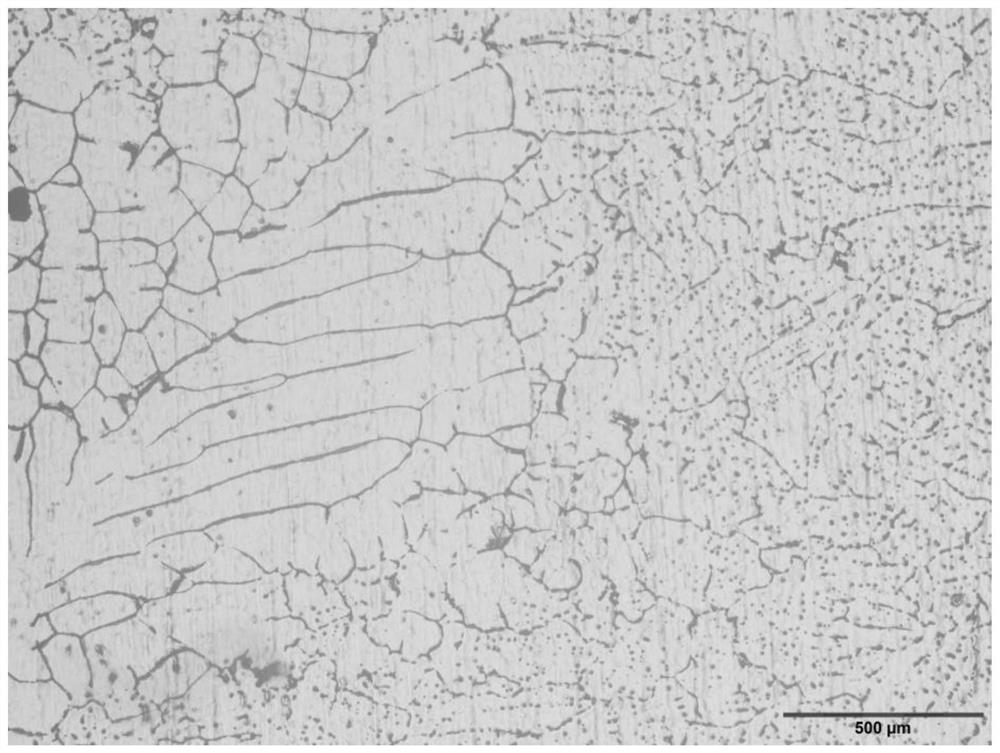

Preparation method of fine-grained high-purity aluminum silicon copper alloy target blank for sputtering

ActiveCN111719059AUniform compositionLow content of impurities and trace elementsVacuum evaporation coatingSputtering coatingAluminiumCopper alloy

The invention discloses a preparation method of a fine-grained high-purity aluminum silicon copper alloy target blank for sputtering. The preparation method of the fine-grained high-purity aluminum silicon copper alloy target blank for sputtering comprises the steps that S10, an intermediate alloy is prepared, specifically, the intermediate alloy is an aluminum copper intermediate alloy and an aluminum silicon intermediate alloy; S20, the intermediate alloy is melted with high-purity aluminum with 99.9995% purity in a vacuum smelting furnace, alloy liquid is obtained after complete melting, and in the alloy liquid, the silicon content is 0.9-1.1 wt%, and the copper content is 0.45-0.55 wt%; S30, the alloy liquid is subjected to on-line refining with high-purity argon; S40, the alloy liquidafter on-line refining is subjected to two-stage filtration; and S50, the alloy liquid after two-stage filtration is casted into a phi 120-164 mm bar blank to obtain the fine-grained high-purity aluminum silicon copper alloy target blank for sputtering. According to the preparation method of the fine-grained high-purity aluminum silicon copper alloy target blank for sputtering, the prepared high-purity AL-1 wt% Si-0.5 wt% Cu target blank for sputtering has very low content of trace impurity elements, good sputtering film-forming performance and uniform composition.

Owner:XINJIANG JOINWORLD CO LTD

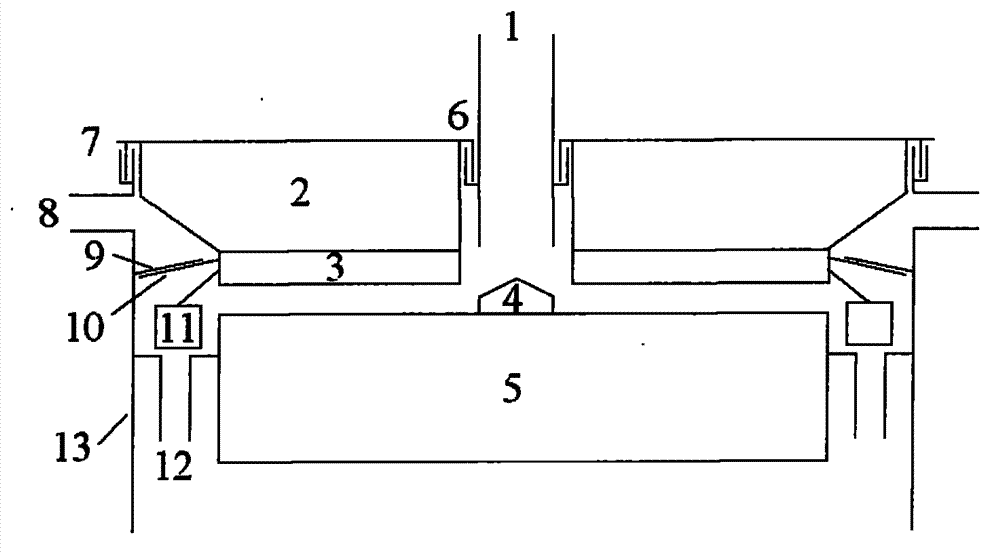

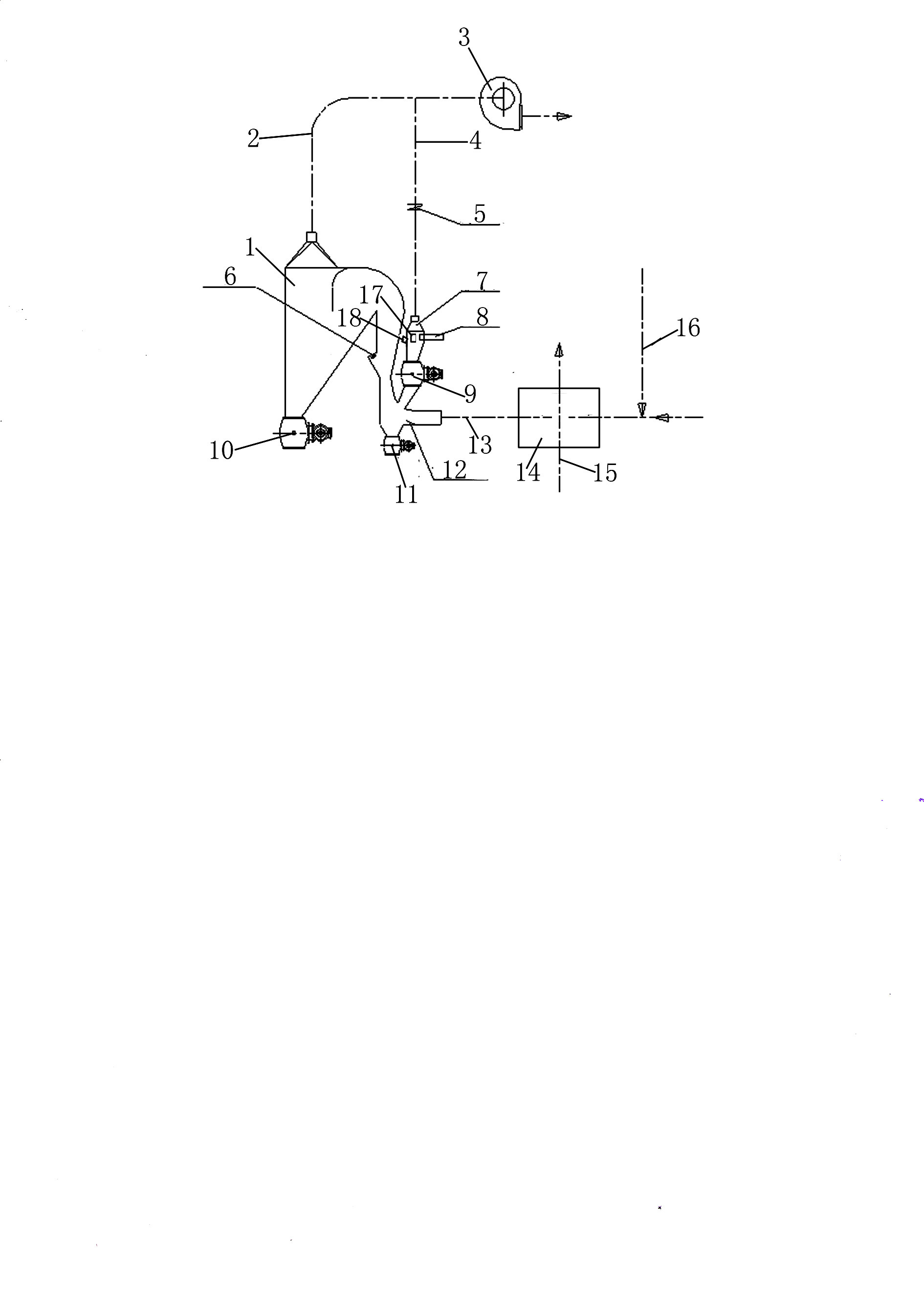

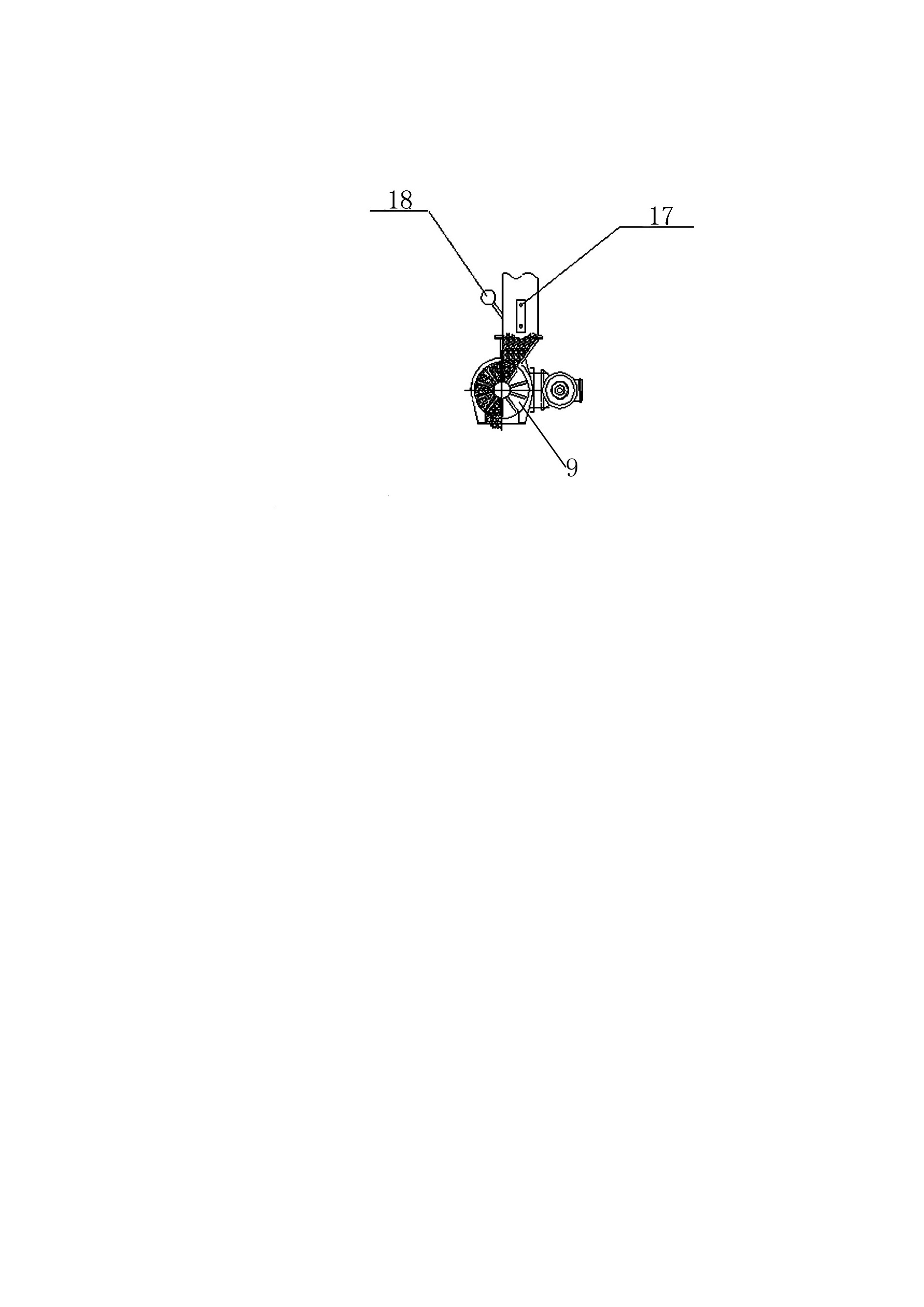

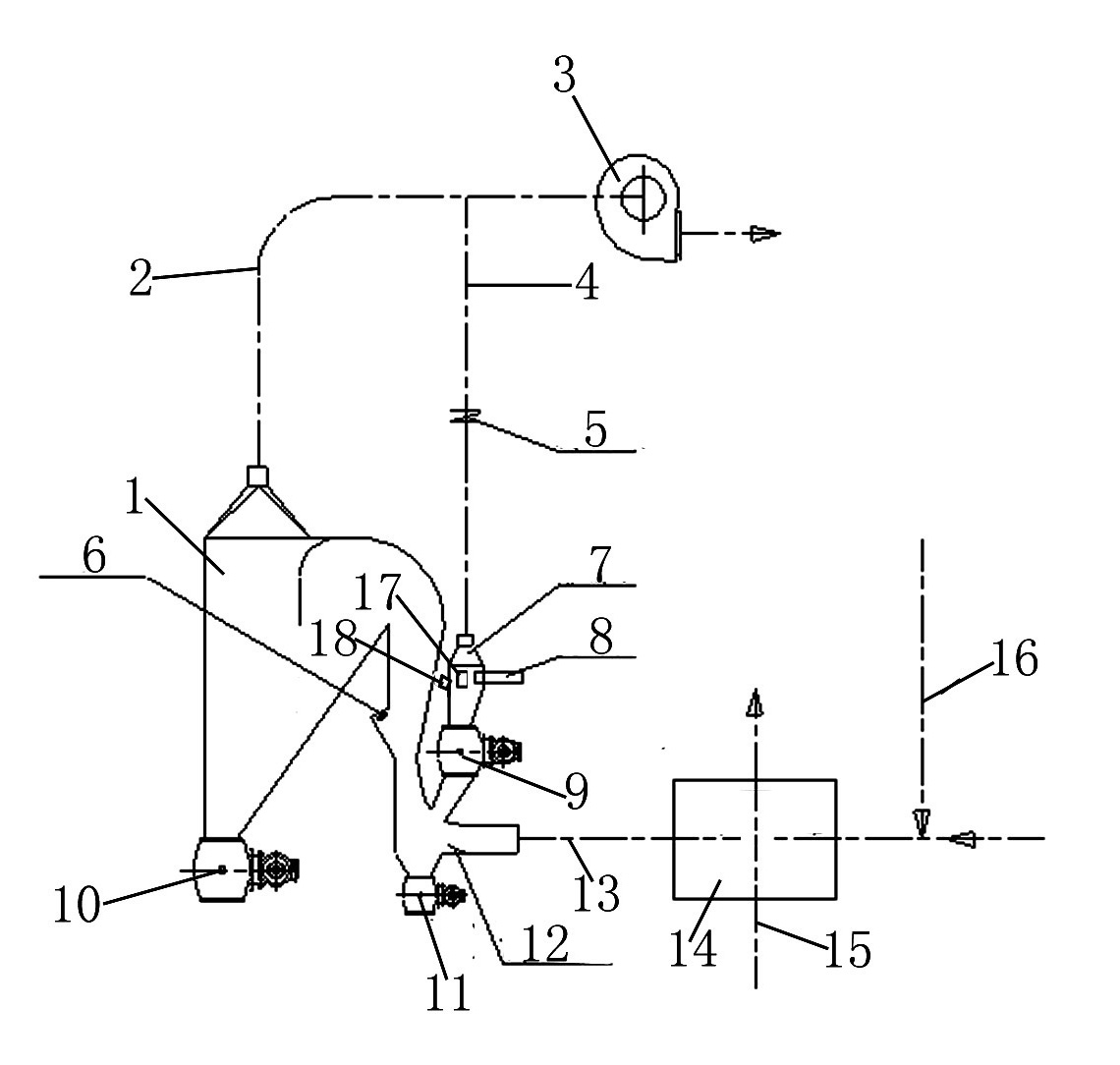

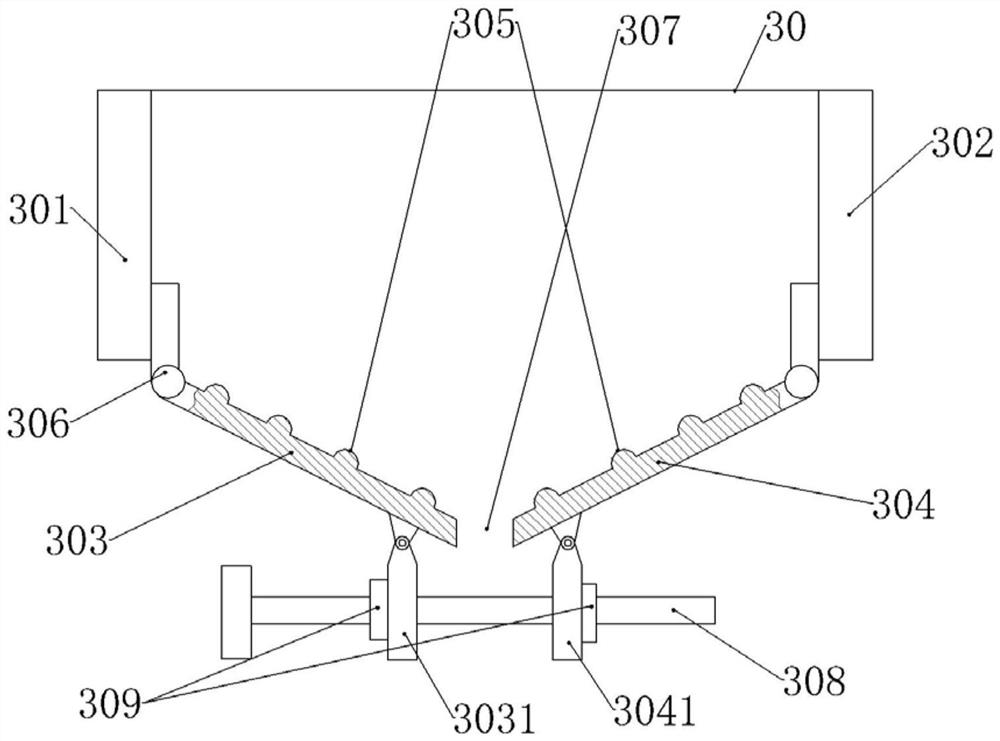

Grinding-disc pyrolysis reactor

InactiveCN103242868AShorten pyrolysis timePyrolysis time guaranteeLiquid hydrocarbon mixture productionSpecial form destructive distillationEngineeringHeating furnace

The invention provides a grinding-disc pyrolysis reactor. A main body of the grinding-disc pyrolysis reactor consists of an upper furnace plate, a distributing plate, dust boards and scraping plates which are rotatable around a feeding pipe, and a lower furnace plate and a furnace wall which are fixed, wherein a the feeding pipe is arranged in the center of the furnace plate, and the distributing plate is arranged at the bottom of the furnace plate; a circle of dust boards and a pair or a plurality of pairs of scraping plates are arranged at the periphery of the distributing plate; a water seal or a sand seal is arranged between the upper furnace plate and the feeding pipe as well as the upper furnace plate and the furnace wall; the distributing plate is a mosaic grinded surface with a plurality of radial tooth grooves formed in the mosaic grinded surface, and through the rotation of the distributing plate, material distributing, turning and discharging functions can be achieved simultaneously; and the lower furnace plate is a flat thermal storage heating stove. The reactor is simple in structure, reliable in operation, convenient to maintain, large in productive capacity, wide in raw material adaptability, and especially suitable for pyrolysis of low metamorphic coal, oil shales, oil sand, biomasses, junked tires, plastic, garbage and the like.

Owner:柯妍

Production method of conductive carbon black for environment-friendly cable shielding material

ActiveCN112322077AHighly structuredModerate structurePigment physical treatmentElectric cablesElectrically conductive

The invention discloses a production method of conductive carbon black for an environment-friendly cable shielding material, and mainly relates to the field of carbon black production. The method comprises the steps of raw material control, raw material pretreatment, carbon black cracking preparation, carbon black collection, binder addition and granulation, carbon black drying and desorption, carbon black refining and volume resistivity test. The preparation method has the beneficial effects that the produced carbon black is good in high temperature resistance, good in electrical property athigh temperature, excellent in high-temperature extrusion property and higher in purity, and the use requirements of the environment-friendly non-crosslinked cable shielding material are fully met.

Owner:山东联科新材料有限公司 +1

Feeding device for gas flow equipment

InactiveCN101982387AMoisture stableReduce purityTobacco preparationFinal product manufactureCross connectionEngineering

The invention discloses a feeding device for gas flow equipment. The feeding device comprises blanking units of branched cylinders, wherein the lower part of the blanking unit of one branched cylinder is provided with a discharge gas lock, and the upper part of the blanking unit is connected with a dehumidifying fan; the lower part of the blanking unit of the other branched cylinder is provided with a three-way port; the lower port of the three-way port is provided with an impurity removal gas lock, the horizontal port of the three-way port is connected with a dehumidifying process gas pipeline and a supplementary steam pipeline after being in cross connection with burner flue gas pipelines, and the upward inclination port of the three-way port is provided with a feed gas lock and a dehumidifying pipeline; the lateral cylinder of the blanking unit on the upper part of the impurity removal gas lock is provided with a charging nozzle; a cache straight pipe section with a dehumidifying hood is installed between the feed gas lock and the pipeline; and the intersection of a burner flue gas pipeline outlet and the dehumidifying process gas pipeline is provided with a heat-pipe heat exchanger. The feeding device disclosed by the invention has the functions of energy recovery, air-separation impurity removal, quantitative feeding, outlet moisture stabilization and uniform charging, and satisfies the process requirements of a gas flow drying technology in tobacco processing.

Owner:QINHUANGDAO TOBACCO MACHINERY

Alloy structural steel wire rod for shaft and preparation method of alloy structural steel wire rod

The invention belongs to the field of steel material preparation, and particularly relates to an alloy structural steel wire rod for a shaft and a preparation method of the alloy structural steel wirerod. The alloy structural steel wire rod comprises the following elements including, by weight percent, 0.35%-0.44% of C, 0.15%-0.37% of Si, 0.50%-0.80% of Mn, 0.60%-0.90% of Cr, 1.25%-1.65% of Ni, 0.15%-0.25% of Mo, not larger than 0.030% of P / S, not larger than 0.30% of Cu and the balance Al, Fe and inevitable impurities. The preparation method comprises the steps of converter smelting, LF external refining, RH vacuum degassing, bloom continuous casting, intermediate billet rolling, finishing and wire rod rolling. The prepared alloy structural steel wire rod is uniform in structure, wire rod drawing and cold heading machining can be conducted through a softening annealing process, and the technical problems that the structure uniformity of the alloy structural steel wire rod for the shaft is poor, spheroidizing annealing must be adopted before drawing, and the quality stability is poor are solved.

Owner:ZENITH STEEL GROUP CORP +1

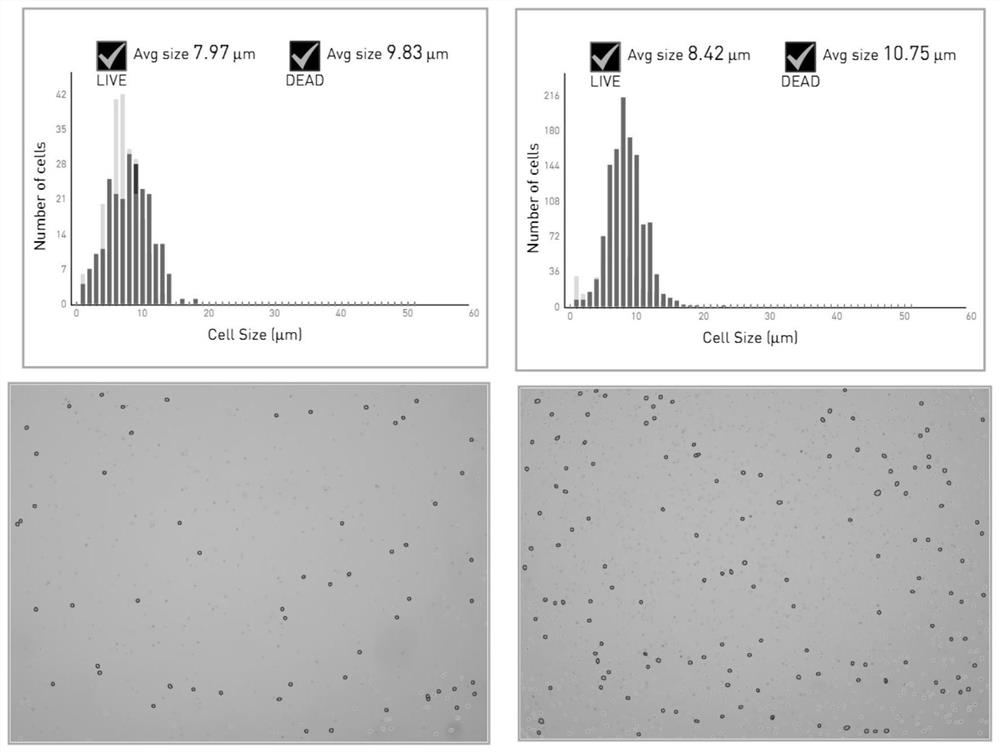

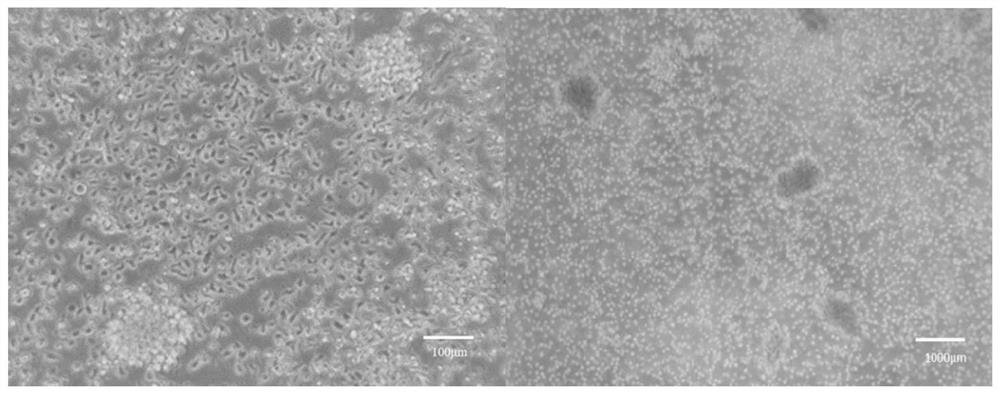

Exosome sorting method for NK cell activation stage

PendingCN112251406AImprove consistencyImprove uniformityCell dissociation methodsCulture processBiophysicsUmbilical cord

The invention discloses an exosome sorting method for an NK cell activation stage, and relates to the field of biology. The invention aims to solve the problem that no technology for directionally sorting specific exosomes of umbilical cord blood exists at present. According to the invention, cell exosome separation in the NK cell period ofthe umbilical cord blood after specific stimulation and activation is adopted, NK cells are proliferated through IL-2, IL-12, IL-15, GM-SCF and Fit3-L can promote activation of the NK cells, and CD34<+> stem cells can be induced to differentiate into the NKcells; the NK cells are sorted and collected on about the 10th day of in-vitro culture so as to obtain more exosomes secreted by the NK cells; the characteristics of an innovative optimized NK cell factor culture method and feeding method are utilized, and the activated NK cell exosomes are extracted on a large scale and used for achieving the purpose of activating the NK cells; and the method isapplied to the field of exosomes.

Owner:曹峰林

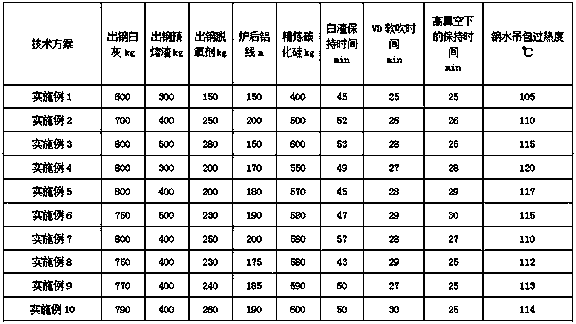

Steel wire rod for deep drawing of cold-drawn spring steel wire and preparation method thereof

ActiveCN111197140AReduce purityImprove the level ofTemperature control deviceWire rodChemical composition

The invention discloses a steel wire rod for deep drawing of a cold-drawn spring steel wire and a preparation method thereof. By taking a series of measures such as electric furnace smelting, LF furnace refining, VD furnace treatment and continuous casting process control and organically combining chemical composition optimization design, smelting process control and a controlled rolling and controlled cooling process, the level of steel purity of the steel wire rod for deep drawing is greatly improved, the N content is controlled to be within 70 PPm, the central carbon segregation is controlled to be less than or equal to 1.09, the sorbite rate is greater than or equal to 85%, and the mechanical property of the whole rod (the same circle) fluctuates within 50 MPa. The influence of electric furnace smelting residual elements and the N content on the drawing property is overcome, and the synergy of the tensile strength and the sorbite rate is realized. By optimizing process tests, partof deep-drawn products can be produced without a VD furnace under certain conditions, and the production cost is reduced. With the steel wire rod for deep drawing of the cold-drawn spring steel wire obtained by the method, a downstream user can reduce the drawing breakage rate and the coil spring breakage rate in the cold drawing process during usage, the working efficiency is improved, and an excellent fatigue property is obtained.

Owner:SHOUGANG CORPORATION

Preparation method of ultra-pure G102Cr18Mo stainless bearing steel

ActiveCN113088623AImprove purityReduce oxygen contentElectric furnaceDie castingSS - Stainless steel

The invention discloses a preparation method of ultra-pure G102Cr18Mo stainless bearing steel, and belongs to the technical field of metal smelting. According to the method, firstly, base metal needed for preparing the ultra-pure G102Cr18Mo stainless bearing steel is obtained through intermediate frequency furnace smelting, LF furnace refining, sedation treatment and die casting, the oxygen content ranges from 20 ppm to 30 ppm, and conditions are created for ultra-pure stainless steel bearing steel smelting; then, the base metal is subjected to forging and scaling treatment and then is put into a vacuum induction furnace to be melted and refined, and no alloy element is added in the vacuum induction treatment process; a consumable electrode subjected to vacuum induction melting is subjected to vacuum consumable remelting twice, and the G102Cr18Mo stainless bearing steel with extremely high purity can be obtained.

Owner:ANHUI FUKAI STAINLESS STEEL

Martensitic stainless steel cold-rolled steel strip for food-grade cutter and production method thereof

PendingCN112522600AGuaranteed temperatureReduce purityProcess efficiency improvementMartensitic stainless steelSteel belt

The invention discloses a production method of a martensitic stainless steel cold-rolled steel strip for a food-grade cutter. The production method comprises the following steps: S1, dephosphorizing molten iron; S2, performing smelting in a refining furnace; S3, performing refining in an LF refining furnace; S4, performing continuous casting by a continuous casting machine; S5, annealing a plate blank; S6, grinding the plate blank; S7, performing heating by a heating furnace; S8, performing hot rolling; S9, performing annealing; S10, performing acid pickling; and S11, performing cold rolling.The production method has the advantages of favorable processability, smooth steel strip plate surface, flat plate shape and high dimensional precision.

Owner:山东泰山轧钢有限公司

Sofflower injection and its prepn. method

A safflower injection with high curative effect is prepared from fresh safflower through cold storage in nitrogen gas, reflux seeping by the aqueous solution of alcohol, filter, concentrating, treating it by petroleum ether, removing petroleum ether and conventionally preparing injection.

Owner:王锋

Production method of plastic die steel ZW636

ActiveCN113684412AOvercoming the large temperature drop of molten steelReduce manufacturing costManufacturing convertersProcess efficiency improvementSemi-steelScrap

The invention provides a production method of plastic die steel ZW636. The production method comprises the following steps that vanadium extraction blowing and desulfurization are sequentially carried out on vanadium-containing molten iron to obtain desulfurized semi-steel; the desulfurized semi-steel and nickel-containing pig iron are mixed, and converter steelmaking, ladle refining and vacuum refining are sequentially carried out to obtain treated molten steel; and the treated molten steel is sequentially subjected to round billet continuous casting and casting billet slow cooling, and the plastic die steel ZW636 is obtained. According to the production method, semi-molten steel is added in converter steelmaking, the nickel-containing pig iron is added, extra scrap steel is not added, the end-point nickel content of a converter is increased, the defects that in the prior art, after alloy is added, molten steel temperature drop is large, slagging and heating are rapid in ladle refining, the molten steel purity is low, and the internal quality and the surface quality of a continuous casting large round billet have defects can be overcome, and the production cost can be greatly reduced.

Owner:CHENGDE JIANLONG SPECIAL STEEL

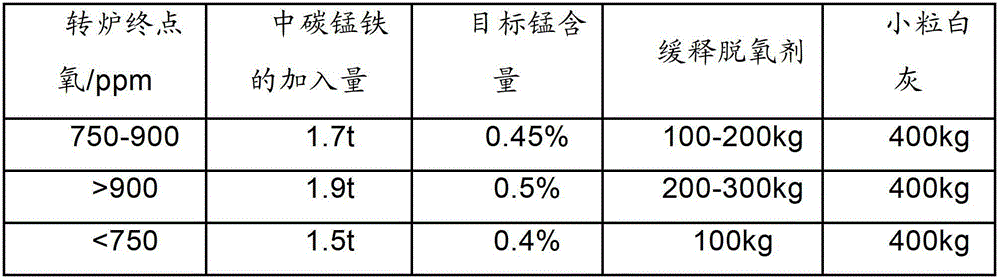

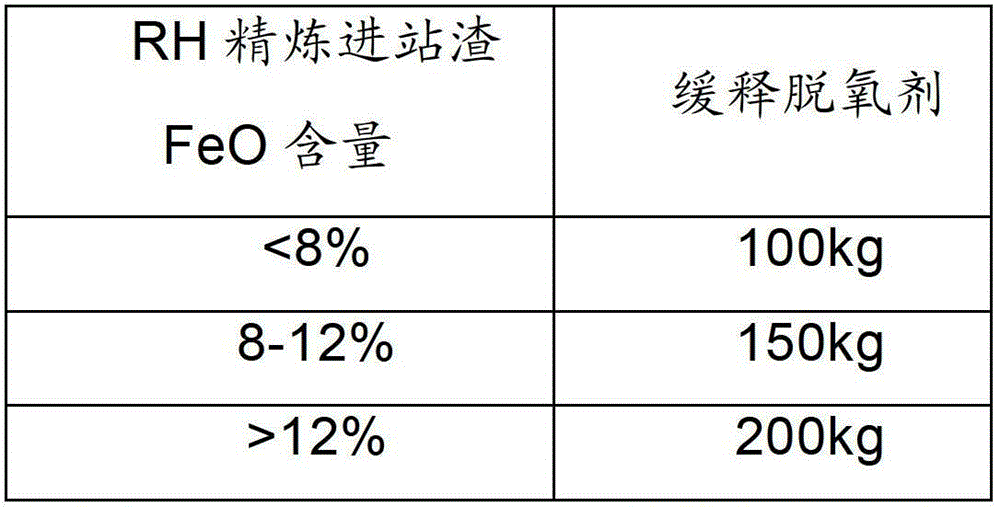

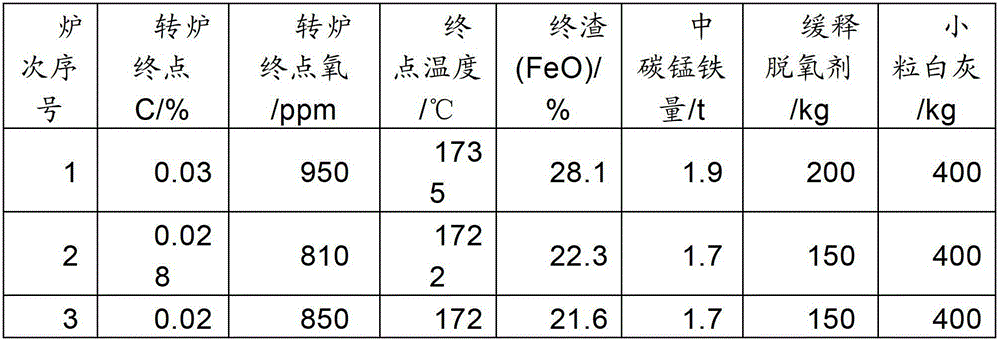

Smelting method of high-strength IF steel

The invention discloses a smelting method of high-strength IF steel, which comprises the following steps of: adding the desulfurized molten iron into a dephosphorization converter and a decarbonization converter to perform duplex smelting, and then performing RH refining; controlling the blowing of the decarbonization converter until the concentration of O is 800-1,000ppm, the concentration of C is 0.025-0.04% and the destination temperature is 1,715-1,730 DEG C; directly tapping steel after the blowing of the decarbonization converter ends, wherein mid-carbon ferromanganese alloy and slag material for modifying slag are added in the steel tapping process at the same time, the slag material includes small-particle lime and controlled-release deoxidizing agent, and the RH refining is in a deep decarbonization mode; and after the decarbonization and vacuum breaking, adding the controlled-release deoxidizing agent to modify the slag respectively, wherein the controlled-release deoxidizing agent contains 40-50% of metal aluminum.

Owner:SHOUGANG CORPORATION

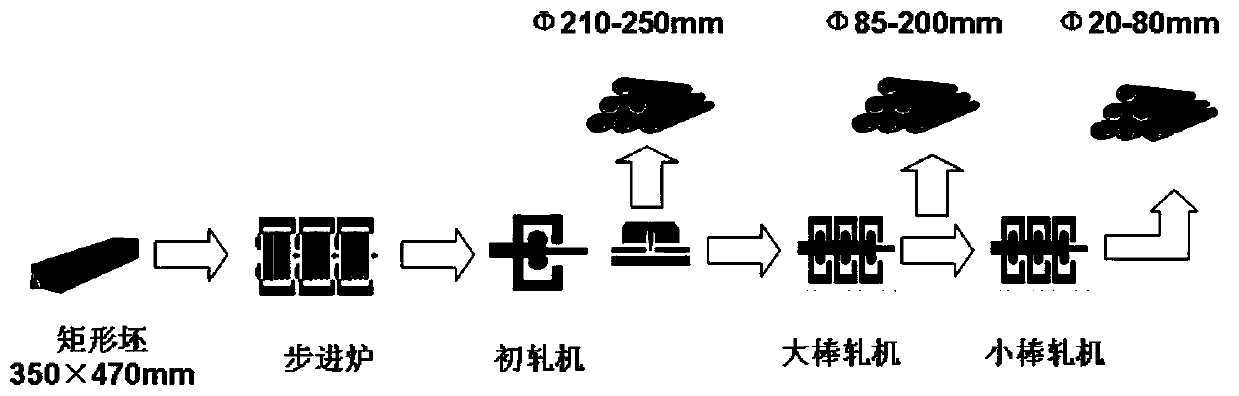

Excavator track steel BG45MnCrB and preparation method thereof

InactiveCN110904388AReduce purityGuaranteed uniformityProcess efficiency improvementExcavatorContinuous rolling

The invention belongs to the technical field of steel manufacturing and relates to excavator track steel BG45MnCrB and a preparation method thereof. The excavator track steel BG45MnCrB is produced byadopting a 180t converter+LF+RH+350*470 rectangular blank+ 800 continuous rolling process, the high-density and high-purity excavator track steel smelting technology is achieved, and the steel purityis effectively controlled.

Owner:BENGANG STEEL PLATES

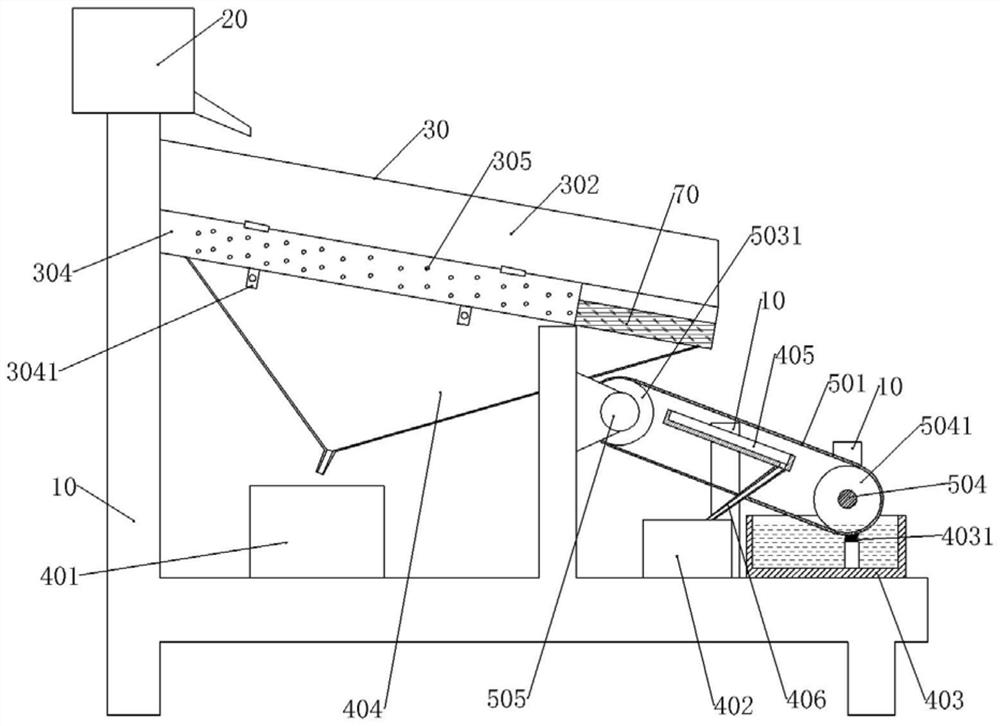

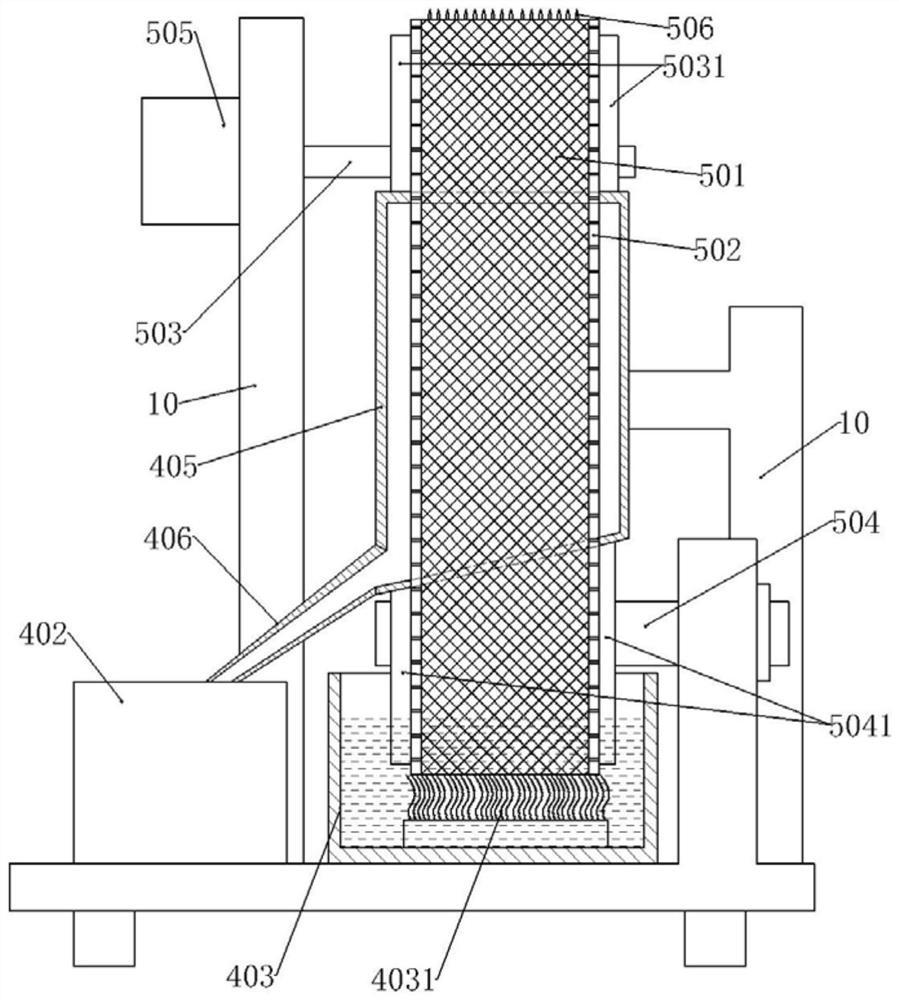

Egg yolk separating device for extracting lecithin

ActiveCN113115854AAchieve separationImprove purityProtein composition from eggsGroup 5/15 element organic compoundsYolkLecithin

The invention relates to the technical field of egg yolk and egg white separation, in particular to an egg yolk separating device for extracting lecithin. The egg yolk separating device comprises a rack, a feed hopper and a separation tank, wherein the feed hopper and the separation tank are both fixedly connected with the rack, the feed hopper communicates with the separation tank, an egg white collection box is arranged below the separation tank, the separation tank is obliquely arranged, a V-shaped groove running through the separation tank is formed in a bottom plate of the separation tank in the length direction of the separation tank, and a liquid leakage seam communicating with an inner cavity of the separation tank and the space below the separation tank is formed in the bottom of the V-shaped groove. The egg yolk separating device further comprises a membrane breaking mechanism, wherein the membrane breaking mechanism comprises a fine mesh plate arranged below the lower end of the separation tank, a plurality of upwards-protruding pointed objects are arranged on the fine mesh plate, the mesh diameter of the fine mesh plate is smaller than the width of the liquid leakage seam, and an egg yolk collection box is arranged below the fine mesh plate. According to the scheme, through separation of the separation tank and the membrane breaking mechanism, thorough separation of egg white liquid and egg yolk liquid is achieved, the purity of the egg yolk liquid used for extracting lecithin is improved, and then the extraction rate of the lecithin is increased.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

Smelting process for improving near-surface flaw detection defects of shaft rudder system steel

InactiveCN110669903AReduce near-surface flaw detection defectsReduce scrap rateSmelting processPropeller

The invention relates to a smelting process for improving near-surface flaw detection defects of shaft rudder system steel. The smelting process comprises the following steps of: (1) tapping by a converter; (2) refining; (3) high vacuumizing; (4) feeding wires after VD is broken; (5) pouring molten steel; (6) baking a draft tube; (7) pouring molten steel in a tundish; (8) pouring molten steel; (9)baking a steel ingot heat insulation cap opening; (10) pouring tundish molten steel; and (11) ending pouring of the tundish. By improving the smelting and pouring processes, the near-surface flaw detection defects of forgings such as marine propeller shafts, intermediate shafts and rudders are reduced, the near-surface flaw detection percent of pass is greatly improved, the rejection rate is reduced, and the economic benefit is remarkably improved.

Owner:石钢京诚装备技术有限公司

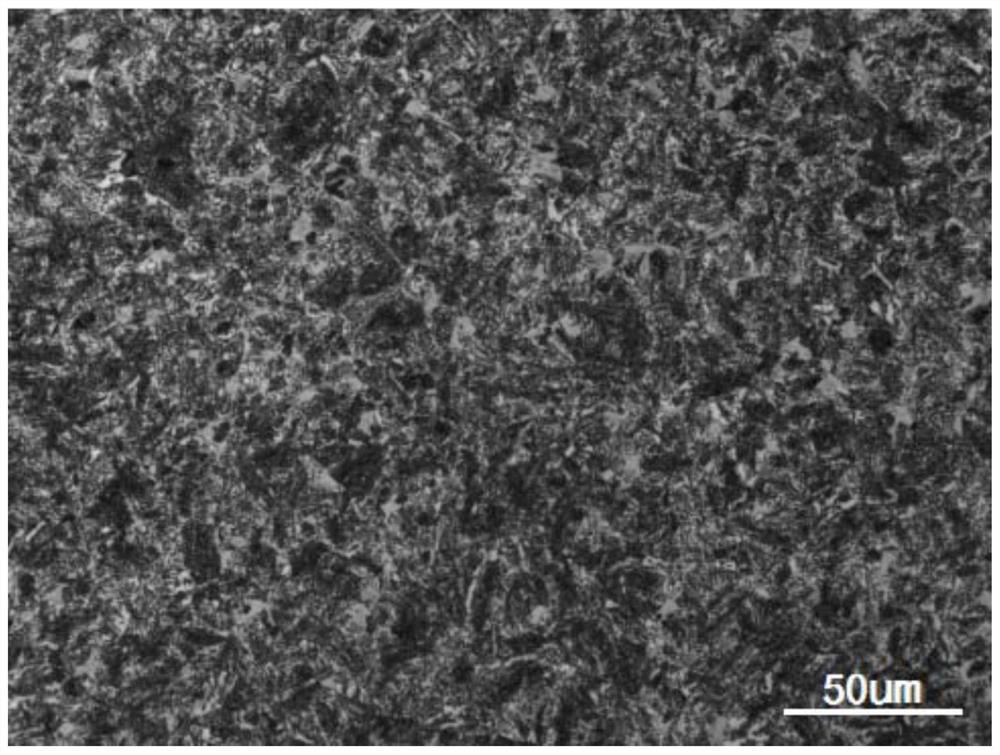

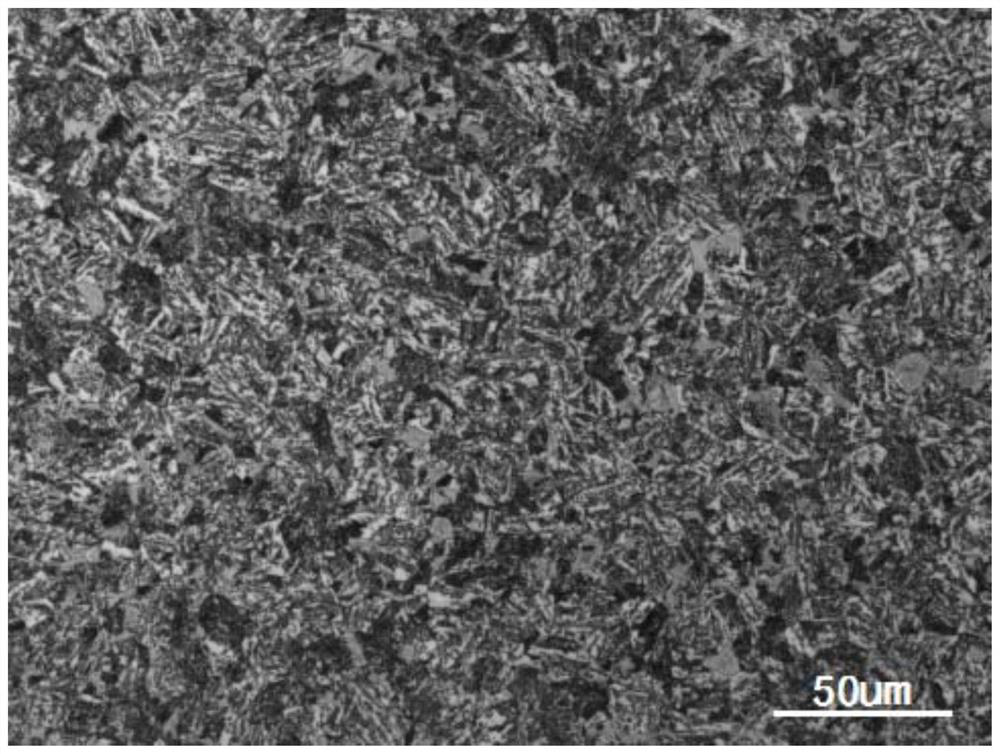

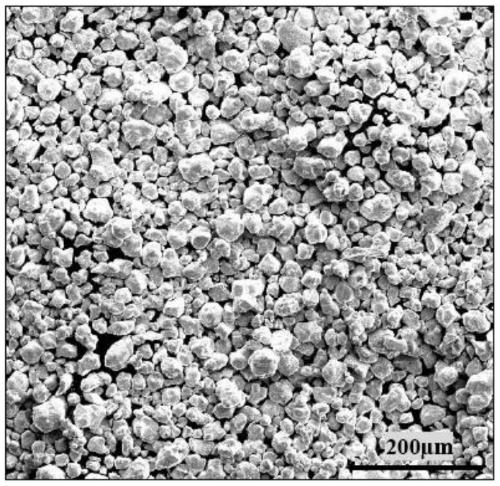

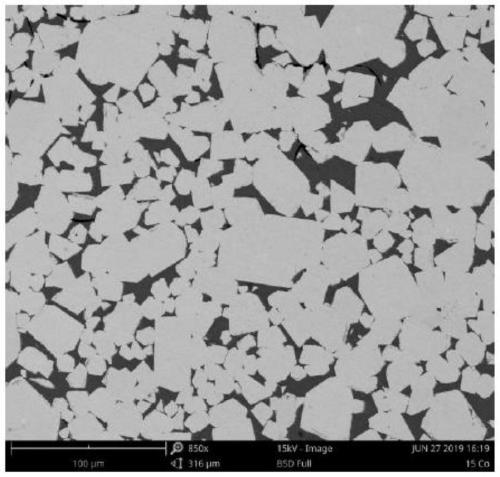

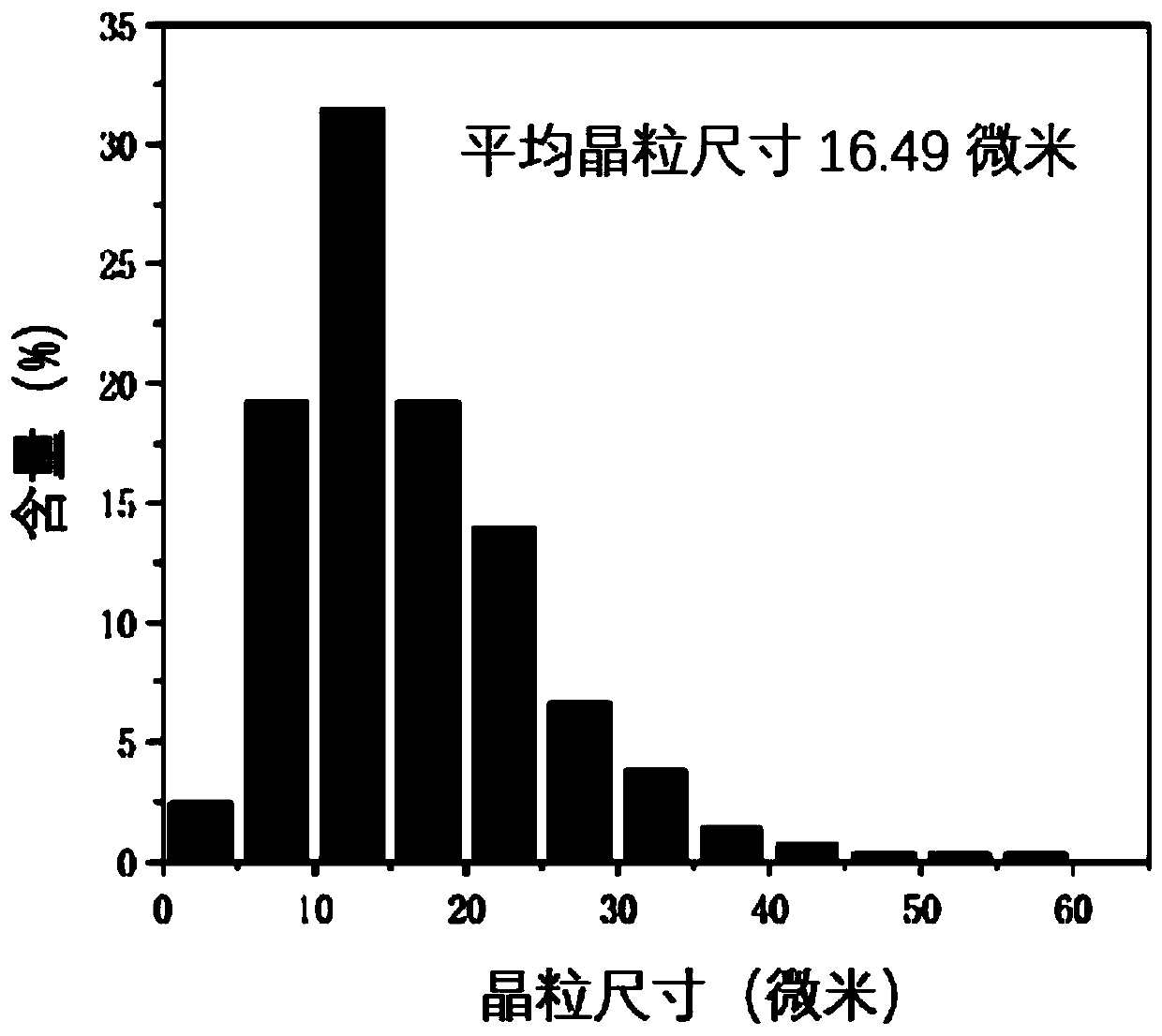

Preparation method of WC-Co hard alloy with average grain size larger than 15 microns

ActiveCN110358961AUniform particle sizeGood uniformityTransportation and packagingMetal-working apparatusCemented carbideCrystallite

The invention discloses a preparation method of a WC-Co hard alloy with an average grain size larger than 15 microns, and belongs to the field of block material preparation. The preparation method comprises the steps of taking coarse-particle WC powder as raw material, sieving and grading, stirring and mixing the sieved and graded raw material with a mixed solution formed by PEG and diffusion oilin a certain proportion, and drying and pressing to prepare a WC cold-pressed green body; directly coating the cold-pressed green body with Co powder in different masses, compacting, sintering and cooling in a low-pressure sintering furnace to obtain a WC-Co hard alloy material with WC grain size larger than 15 microns; or sintering the cold-pressed green body to prepare porous carbide; and then coating the porous carbide with the Co powder in different masses and compacting, and sintering at low pressure to prepare the hard alloy material with WC grain size larger than 15 microns and different Co content.

Owner:BEIJING UNIV OF TECH

TC4 titanium alloy submerged-arc welding flux and preparation method and application thereof

InactiveCN114260616AControl mechanical propertiesImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsSlag (welding)Adhesive

The invention discloses a TC4 titanium alloy submerged-arc welding flux and a preparation method and application thereof. The invention belongs to the technical field of welding materials. The invention provides a TC4 titanium alloy submerged-arc welding flux and a preparation method and application thereof. The flux is prepared from an adhesive and powder, wherein the powder is formed by mixing the following components in percentage by mass: 4.5%-5.5% of BaCl2, 1.8%-2.1% of LiF, 4.8%-5.1% of NaF and the balance of CaF2. The method comprises the following steps: step 1, mixing and dry-stirring the raw material powder according to the powder ratio, then adding the adhesive, and continuously stirring to obtain a mixture; and 2, the mixture obtained in the step 1 is subjected to low-temperature drying, high-temperature sintering and sieving after being cooled to the room temperature, and the TC4 titanium alloy submerged-arc welding flux is obtained. The welding flux is matched with a TC4 titanium alloy submerged-arc welding wire for submerged-arc welding. According to the flux, the proportion of all the components of the flux is scientifically adjusted, and the viscosity, the surface tension and the fluidity of slag are optimized. And when the alloy is matched with a TC4 titanium alloy submerged-arc welding wire for submerged-arc welding, the alloy has good welding process performance and mechanical performance.

Owner:HARBIN WELDING INST LTD

Wire rod for deep drawing cold drawn spring steel wire and preparation method thereof

ActiveCN111197140BReduce purityImprove the level ofTemperature control deviceChemical compositionSmelting process

The invention discloses a wire rod for deep drawing and cold drawn spring steel wire and a preparation method thereof. Using a series of measures such as electric furnace, LF furnace, VD furnace, continuous casting process control, etc., through the organic combination of chemical composition optimization design, smelting process control, controlled rolling and controlled cooling process, the steel purity level of deep drawing wire rod It has been greatly improved, the N content is controlled within 70PPm, the central carbon segregation control is ≤1.09, the sorbite rate is ≥85%, and the mechanical performance (same circle) fluctuation of the cleaning rod is within 50Mpa. Overcome the influence of electric furnace smelting residual elements and N content on drawing performance, and realize the synergy between tensile strength and sorbite ratio. Through the optimization process test, some deep drawn products can be produced without VD furnace under certain conditions, reducing the production cost. The deep-drawn cold-drawn spring steel wire rod obtained by this method enables downstream users to reduce the rate of broken wires during cold drawing and the rate of broken wires of the coil spring during use, improve operating efficiency, and obtain excellent fatigue performance .

Owner:SHOUGANG CORPORATION

A kind of production method of carbon black for environment-friendly cable shielding material

ActiveCN112322077BHighly structuredModerate structurePigment physical treatmentProcess engineeringElectrical performance

The invention discloses a method for producing conductive carbon black for an environment-friendly cable shielding material, and mainly relates to the field of carbon black production. Including raw material control, raw material pretreatment, carbon black pyrolysis preparation, carbon black collection, adding binder granulation, carbon black drying and desorption, carbon black refining, volume resistivity test. The beneficial effect of the invention is that the produced carbon black can have good high temperature resistance, good electrical performance at high temperature, superior high temperature extrusion performance, higher purity, and fully meet the use requirements of environment-friendly non-crosslinked cable shielding materials.

Owner:山东联科新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com