Steel HG785D for tower crane and production method

A technology of tower cranes and production methods, which is applied to the improvement of process efficiency, etc., and can solve the problems of increased thickness of extra-thick steel plates, inability to guarantee the strength and toughness of extra-thick steel plates and uniformity of thickness direction performance, and reduced cooling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

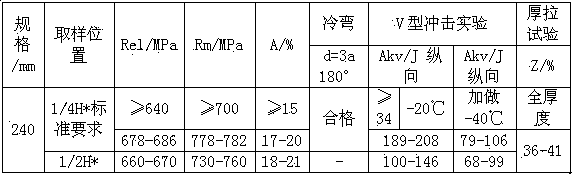

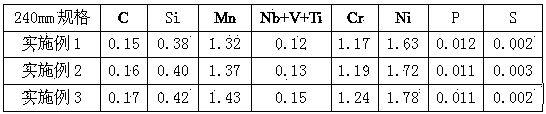

Embodiment 1

[0035] The present embodiment takes the production of 240mm thick HG785D steel as an example, and according to the above-mentioned production method, the main production process parameters of the present embodiment are determined as follows:

[0036] During converter smelting, 10Kg of lime, 8Kg of ferromanganese alloy, and 0.6Kg of ferrosilicon alloy are added to each ton of ladle; LF furnace refining is heated for 9 minutes for the first time and 10 minutes for the second time, and the steel loading temperature is 1600°C; Start pouring afterward; the pouring time for the ingot body is 18 minutes, the pouring time for the cap is 7 minutes, the holding temperature is 450°C, and the wide side of the ingot is extruded for 20 mm in the later stage of solidification; the overall cooling and solidification time for the ingot is 5 hours, and the air gap between the ingot mold and the ingot is controlled to 14 mm; heat treatment In the process, 250Kg / t of industrial salt is added to th...

Embodiment 2

[0038] Present embodiment is on the basis of embodiment 1, and processing parameter is adjusted as follows:

[0039] During converter smelting, 10Kg of lime, 9Kg of ferromanganese alloy, and 0.6Kg of ferrosilicon alloy are added to each ton of ladle; the LF furnace refining is heated for 11 minutes for the first time and 9 minutes for the second time, and the steel loading temperature is 1610°C; After pouring, the pouring time of the steel ingot body is 19 minutes, the pouring time of the cap mouth is 8 minutes, and the cooling and solidification time of the overall steel ingot is 5.5 hours; in the heat treatment process, the quenching temperature is 935 ° C, the holding time is 2.4 min / mm, the tempering temperature is 650 ° C, the holding time 4.4min / mm.

Embodiment 3

[0041] Present embodiment is on the basis of embodiment 1, and processing parameter is adjusted as follows:

[0042] During converter smelting, 10Kg of lime, 10Kg of ferromanganese alloy, and 0.6Kg of ferrosilicon alloy are added to each ton of ladle; the LF furnace refining is heated for 12 minutes for the first time and 8 minutes for the second time, and the steel loading temperature is 1620°C; the pouring temperature is controlled at 1558°C, and the molten steel arrives at the station After pouring, the pouring time of the steel ingot body is 20 minutes, the pouring time of the cap mouth is 9 minutes, and the cooling and solidification time of the overall steel ingot is 6 hours; in the heat treatment process, the quenching temperature is 940 ° C, the holding time is 2.5 min / mm, the tempering temperature is 660 ° C, and the holding time is 4.5 min / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Longitudinal impact work | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com